ASTM A901-12

(Specification)Standard Specification for Amorphous Magnetic Core Alloys, Semi-Processed Types

Standard Specification for Amorphous Magnetic Core Alloys, Semi-Processed Types

ABSTRACT

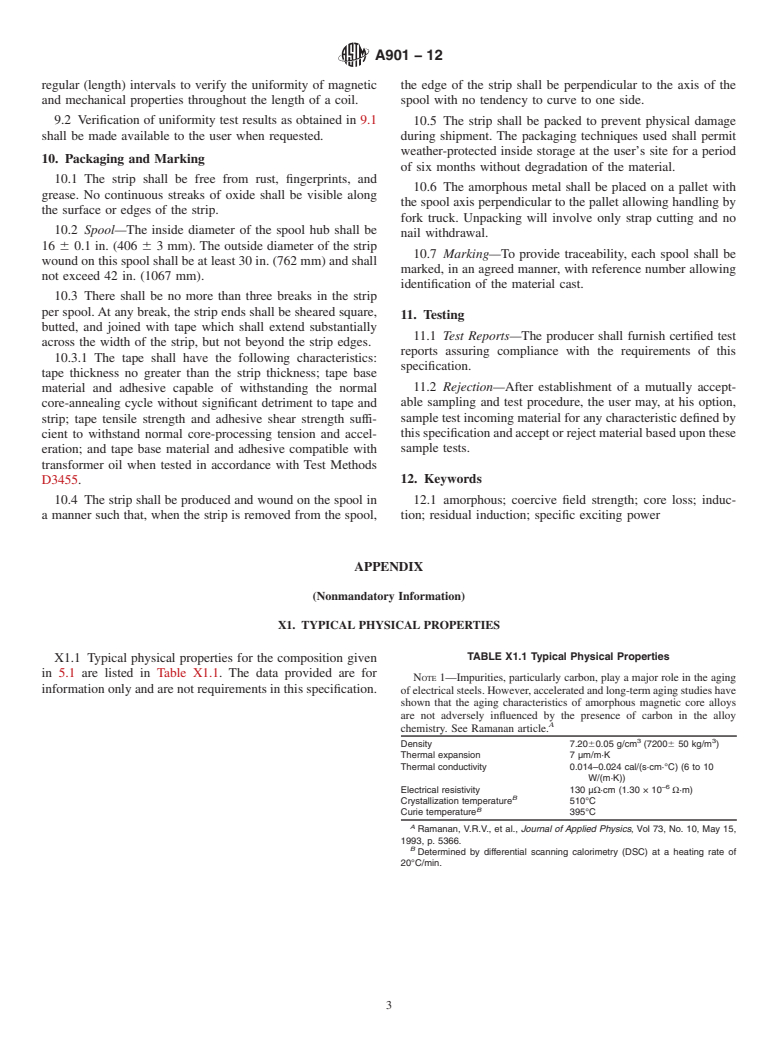

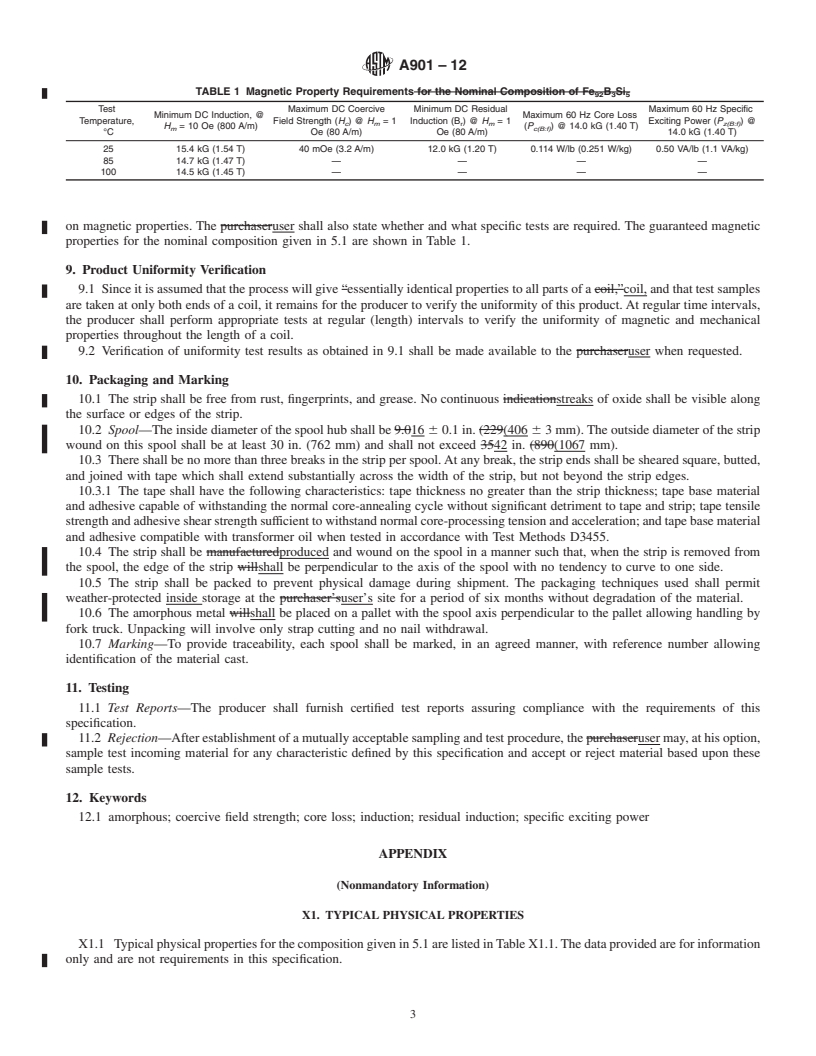

This specification covers the general requirements to which flat-cast, amorphous, semi-processed, iron-base magnetic core alloys must conform. These alloys shall be produced by a rapid-quenching, direct-casting process, resulting in metals with noncrystalline structure. The metallic alloys shall be made to meet specified maximum core-loss values and shall be intended primarily for commercial power frequency applications in magnetic devices. Desirable core-loss and permeability characteristics shall be developed by further heat treatment in a magnetic field. Amorphous magnetic core alloys shall be composed principally of iron with small amounts of alloying elements such as boron and silicon. Other chemical elements shall be in residual amounts or can be added to improve fabrication or the physical or magnetic properties. The material shall conform to the required physical and mechanical properties such as density, ductility, thermal expansion, thermal conductivity, volume resistivity, lamination factor, surface, edge, and pinholes. The alloy shall also conform to the magnetic property requirements such as DC induction, DC coercive field strength, DC residual induction, core loss, and specific exciting power.

SCOPE

1.1 This specification covers the general requirements to which flat-cast, amorphous, semi-processed, iron-base magnetic core alloys must conform.

1.2 These alloys are produced by a rapid-quenching, direct-casting process, resulting in metals with noncrystalline (amorphous) structure. The metallic alloys are made to meet specified maximum core-loss values and are intended primarily for commercial power frequency (50- and 60-Hz) applications in magnetic devices. Desirable core-loss and permeability characteristics are developed by further heat treatment in a magnetic field by the user. The heat treatment typically consists of heating the material to a temperature of 320 to 420°C in a dry, inert atmosphere for 5 to 10 min, although soak times of up to 2 h may be used for large transformer cores. A magnetic field may be required during annealing as designated by the producer. Exact optimum annealing conditions depend on the processing of the material and the size and shape of the device.

1.3 Some of these alloys are sensitive to mechanical stress. Care must be exercised in minimizing any stresses on the material in its final application, otherwise, its magnetic properties will be significantly impaired.

1.4 This specification is developed to aid in the purchase of transformer grade amorphous strip. It provides the chemical, physical, and magnetic parameters and procedures for quality control tests.

1.5 The values stated in customary (cgs-emu and inch-pound) units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units which are provided for information only and are not considered standard.

Note 1—For more information on procedures associated with this specification, refer to the following: Practices A34/A34M, A664, A700, and B490; Test Methods A370 and A773/A773M.

1.6 This standard does not purport to address the safety concerns associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A901 −12

Standard Specification for

1

Amorphous Magnetic Core Alloys, Semi-Processed Types

This standard is issued under the fixed designation A901; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

NOTE 1—For more information on procedures associated with this

1. Scope

specification, refer to the following: Practices A34/A34M, A664, A700,

1.1 This specification covers the general requirements to

and B490; Test Methods A370 and A773/A773M.

which flat-cast, amorphous, semi-processed, iron-base mag-

1.6 This standard does not purport to address the safety

netic core alloys must conform.

concerns associated with its use. It is the responsibility of the

1.2 These alloys are produced by a rapid-quenching, direct-

user of this standard to establish appropriate safety and health

casting process, resulting in metals with noncrystalline (amor-

practices and determine the applicability of regulatory limita-

phous) structure. The metallic alloys are made to meet speci-

tions prior to use.

fied maximum core-loss values and are intended primarily for

commercial power frequency (50- and 60-Hz) applications in

2. Referenced Documents

magnetic devices. Desirable core-loss and permeability char-

3

2.1 ASTM Standards:

acteristics are developed by further heat treatment in a mag-

2

netic field by the user. The heat treatment typically consists of A34/A34M Practice for Sampling and Procurement Testing

of Magnetic Materials

heating the material to a temperature of 320 to 420°C in a dry,

inert atmosphere for 5 to 10 min, although soak times of up to A340 Terminology of Symbols and Definitions Relating to

2 h may be used for large transformer cores. A magnetic field Magnetic Testing

may be required during annealing as designated by the pro- A370 Test Methods and Definitions for Mechanical Testing

ducer. Exact optimum annealing conditions depend on the of Steel Products

processing of the material and the size and shape of the device.

A664 Practice for Identification of Standard Electrical Steel

Grades in ASTM Specifications

1.3 Some of these alloys are sensitive to mechanical stress.

A700 Practices for Packaging, Marking, and Loading Meth-

Care must be exercised in minimizing any stresses on the

ods for Steel Products for Shipment

material in its final application, otherwise, its magnetic prop-

A712 Test Method for Electrical Resistivity of Soft Mag-

erties will be significantly impaired.

netic Alloys

1.4 This specification is developed to aid in the purchase of

A773/A773M Test Method for dc Magnetic Properties of

transformer grade amorphous strip. It provides the chemical,

Materials Using Ring and Permeameter Procedures with

physical, and magnetic parameters and procedures for quality

dc Electronic Hysteresigraphs

control tests.

A900/A900M Test Method for Lamination Factor of Amor-

1.5 The values stated in customary (cgs-emu and inch-

phous Magnetic Strip

pound) units are to be regarded as standard. The values given

B490 Practice for Micrometer Bend Test for Ductility of

in parentheses are mathematical conversions to SI units which

Electrodeposits

are provided for information only and are not considered

C693 Test Method for Density of Glass by Buoyancy

standard.

D3455 Test Methods for Compatibility of Construction Ma-

terial with Electrical Insulating Oil of Petroleum Origin

1

This specification is under the jurisdiction of ASTM Committee A06 on

3. Terminology

Magnetic Properties and is the direct responsibility of Subcommittee A06.02 on

Material Specifications.

3.1 The terms and symbols used in this specification are

Current edition approved Feb. 15, 2012. Published March 2012. Originally

defined in Terminology A340.

approved in 1990. Last previous edition approved in 2008 as A901–03(2008). DOI:

10.1520/A0901-12.

2

The process of heat treatment in a magnetic field is covered by a patent held by

General Electric Co. Interested parties are invited to submit information regarding

3

the identification of acceptable alternatives to this patented item to the Committee For referenced ASTM standards, visit the ASTM website, www.astm.org, or

on Standards, ASTM International Headquarters. Your comments will receive contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

careful consideration at a meeting of the responsible technical committee, which Standards volume information, refer to the standard’s Document Summary page on

you may attend. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ---------

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A901–03 (Reapproved 2008) Designation: A901 – 12

Standard Specification for

1

Amorphous Magnetic Core Alloys, Semi-Processed Types

This standard is issued under the fixed designation A901; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the general requirements to which flat-cast, amorphous, semi-processed, iron-base magnetic core

alloys must conform.

1.2 Thesealloysareproducedbyarapid-quenching,direct-castingprocess,resultinginmetalswithnoncrystalline(amorphous)

structure. The metallic alloys are made to meet specified maximum core-loss values and are intended primarily for commercial

power frequency (50- and 60-Hz) applications in magnetic devices. Desirable core-loss and permeability characteristics are

2

developed by further heat treatment in a magnetic field by the purchaser.user. The heat treatment typically consists of heating the

materialtoatemperatureof320to420°Cinadry,inertatmospherefor5to10min,althoughsoaktimesofupto2hmaybeused

for large transformer cores. A magnetic field may be required during annealing as designated by the producer. Exact optimum

annealing conditions depend on the processing of the material and the size and shape of the device.

1.3 Some of these alloys are sensitive to mechanical stress. Care must be exercised in minimizing any stresses on the material

in its final application, otherwise, its magnetic properties will be impaired significantly. significantly impaired.

1.4 This specification is developed to aid in the purchase of transformer grade amorphous strip. It provides the chemical,

physical, and magnetic parameters and procedures for quality control tests.

1.5 The values stated in customary (cgs-emu and inch-pound) units are to be regarded as standard. The values given in

parentheses are mathematical conversions to SI units which are provided for information only and are not considered standard.

NOTE 1—For more information on procedures associated with this specification, refer to the following: PracticesA34/A34M,A664,A700, and B490;

Test Methods A370 and A773/A773M.

1.6 This standard does not purport to address the safety concerns associated with its use. It is the responsibility of the user of

this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior

to use.

2. Referenced Documents

3

2.1 ASTM Standards:

A34/A34M Practice for Sampling and Procurement Testing of Magnetic Materials

A340 Terminology of Symbols and Definitions Relating to Magnetic Testing

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A664 Practice for Identification of Standard Electrical Steel Grades in ASTM Specifications

A700 Practices for Packaging, Marking, and Loading Methods for Steel Products for Shipment

A712 Test Method for Electrical Resistivity of Soft Magnetic Alloys

A773/A773M TestMethodfordcMagneticPropertiesofMaterialsUsingRingandPermeameterProcedureswithdcElectronic

Hysteresigraphs

A900/A900M Test Method for Lamination Factor of Amorphous Magnetic Strip

B490 Practice for Micrometer Bend Test for Ductility of Electrodeposits

C693 Test Method for Density of Glass by Buoyancy

1

This specification is under the jurisdiction of ASTM Committee A06 on Magnetic Properties and is the direct responsibility of Subcommittee A06.02 on Material

Specifications.

Current edition approved Nov. 1, 2008. Published December 2008. Originally approved in 1990. Last previous edition approved in 2003 as A901–03. DOI:

10.1520/A0901-03R08.

Current edition approved Feb. 15, 2012. Published March 2012. Originally approved in 1990. Last previous edition approved in 2008 as A901–03(2008). DOI:

10.1520/A0901-12.

2

The process of heat treatment in a magnetic field is covered by a patent held by General Electric Co. Interested parties are invited to submit information regarding the

identification of acceptable alternatives to this patented item to the Committee on Standards, ASTM International Headquarters. Your comments will receive careful

consideration at a meeting of the responsible technical committee, which you may attend.

3

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.