ASTM C12-07

(Practice)Standard Practice for Installing Vitrified Clay Pipe Lines

Standard Practice for Installing Vitrified Clay Pipe Lines

ABSTRACT

This practice covers the proper methods of installing vitified clay pipe lines in order to fully utilize the structural properties of such pipe. The external loads on installed vitrified clay pipe are of two general types: (I) dead loads and (2) live loads. For pipes installed in trenches at a given depth, the dead load increases as the trench width, measured at the top of the pipe, increases. Live loads that act at the ground surface are partially transmitted to the pipe. Live loads may be produced by wheel loading, construction equipment or by compactive effort. Classes of bedding and encasements for pipe in trenches are defined as Class D wherein the pipe shall be placed on a firm and unyielding trench bottom with bell holes provided, Class C wherein the pipe shall be bedded in clean coarse-grained gravels and sands, Class B wherein the pipe shall be bedded in suitable material and Class A. Trenches shall be excavated to a width that will provide adequate working space, but not more than the maximum design width. Trench walls shall not be undercut. Bell holes shall be excavated to prevent point loading of the bells or couplings of laid pipe, and to establish full-length support of the pipe barrel. Final backfill need not be compacted to develop field supporting strength of the pipe. Final backfill may require compaction to prevent settlement of the ground surface.

SCOPE

1.1 This practice covers the proper methods of installing vitrified clay pipe lines in order to fully utilize the structural properties of such pipe.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 12 – 07

Standard Practice for

1

Installing Vitrified Clay Pipe Lines

ThisstandardisissuedunderthefixeddesignationC 12;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope DESIGN CONSIDERATIONS

1.1 This practice covers the proper methods of installing

4. Supporting Strength

vitrified clay pipe lines in order to fully utilize the structural

4.1 The field supporting strength of vitrified clay pipe is

properties of such pipe.

materially affected by the methods of installation. The field

1.2 The values stated in inch-pound units are to be regarded

supporting strength of a pipe is defined as its capacity to

as the standard. The values given in parentheses are for

support dead and live loads under actual field conditions. It is

information only.

dependent upon two factors: (1) the inherent strength of the

1.3 This standard does not purport to address all of the

pipe and (2) the bedding of the pipe.

safety concerns, if any, associated with its use. It is the

4.2 The minimum bearing strength requirement in accor-

responsibility of the user of this standard to establish appro-

dance with Specification C 700, as determined by the 3-edge-

priate safety and health practices and determine the applica-

bearing test of Test Methods C 301, is a measure of the

bility of regulatory limitations prior to use.

inherent strength of the pipe.

2. Referenced Documents 4.3 The tests used to measure bearing strength determine

2

relative pipe strengths but do not represent actual field condi-

2.1 ASTM Standards:

tions. Therefore, an adjustment called a load factor is intro-

C 301 Test Methods for Vitrified Clay Pipe

duced to convert minimum bearing strength to field supporting

C 425 Specification for Compression Joints for Vitrified

strength. The magnitude of the load factor depends on how the

Clay Pipe and Fittings

pipe is bedded. The relationship is:

C 700 Specification for Vitrified Clay Pipe, Extra Strength,

Standard Strength, and Perforated Field supporting strength 5 minimum bearing strength 3 load factor

C 828 Test Method for Low-Pressure Air Test of Vitrified

4.4 Afactor of safety greater than 1.0 and less than or equal

Clay Pipe Lines

to 1.5 shall be applied to the field supporting strength to

C 896 Terminology Relating to Clay Products

calculate a safe supporting strength. The relationship is:

C 1091 Test Method for Hydrostatic Infiltration Testing of

Field supporting strength

Vitrified Clay Pipe Lines

Safe supporting strength 5

Factor of safety

D 2487 Practice for Classification of Soils for Engineering

Purposes (Unified Soil Classification System)

5. External Loads

5.1 The external loads on installed vitrified clay pipe are of

3. Terminology

two general types: (1) dead loads and (2) live loads.

3.1 General—Terminology C 896 can be used for clarifica-

5.2 For pipes installed in trenches at a given depth, the dead

tion of terminology in this specification.

load increases as the trench width, measured at the top of the

pipe,increases.Consequently,thetrenchwidthatthetopofthe

pipeshallbekeptasnarrowaspossible.Pipefailuremayresult

1

This practice is under the jurisdiction of ASTM Committee C04 on Vitrified

if the design trench width is exceeded. If the trench width

Clay Pipe and is the direct responsibility of Subcommittee C04.20 on Methods of

exceeds the design width, a higher class of bedding, stronger

Test and Specifications.

pipe, or both, must be investigated.

Current edition approved April 1, 2007. Published April 2007. Originally

approved in 1915. Last previous edition approved in 2006 as C 12 – 06.

5.3 Live loads that act at the ground surface are partially

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

transmitted to the pipe. Live loads may be produced by wheel

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

loading, construction equipment or by compactive effort.

Standards volume information, refer to the standard’s Document Summary page on

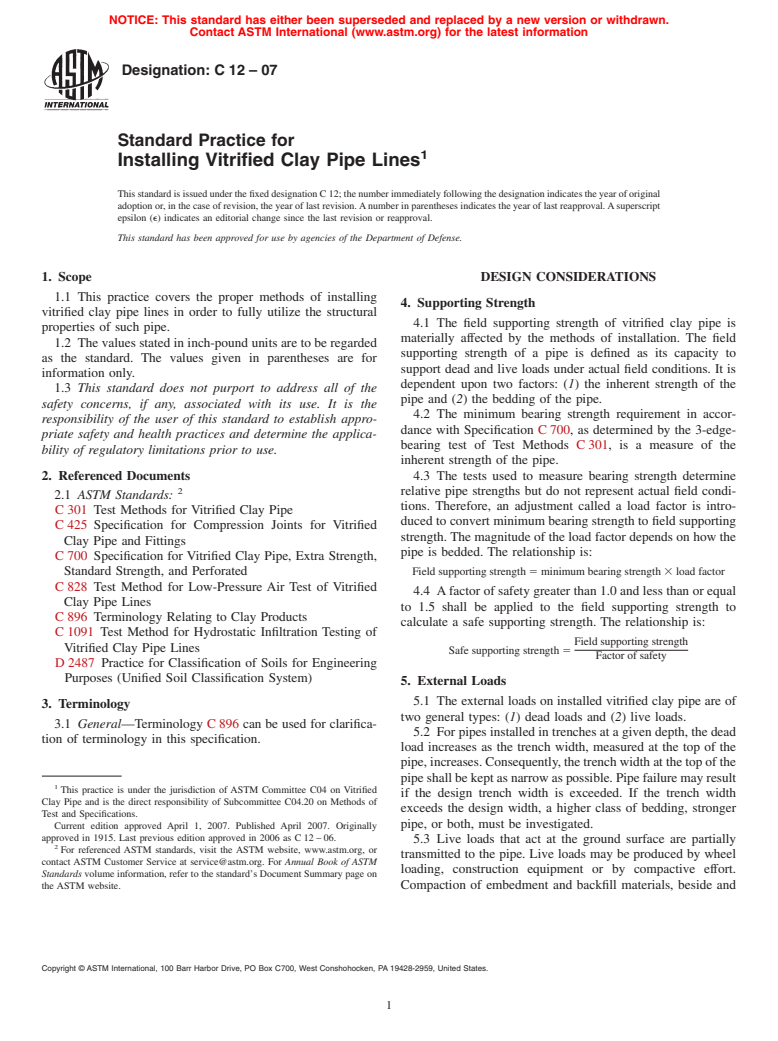

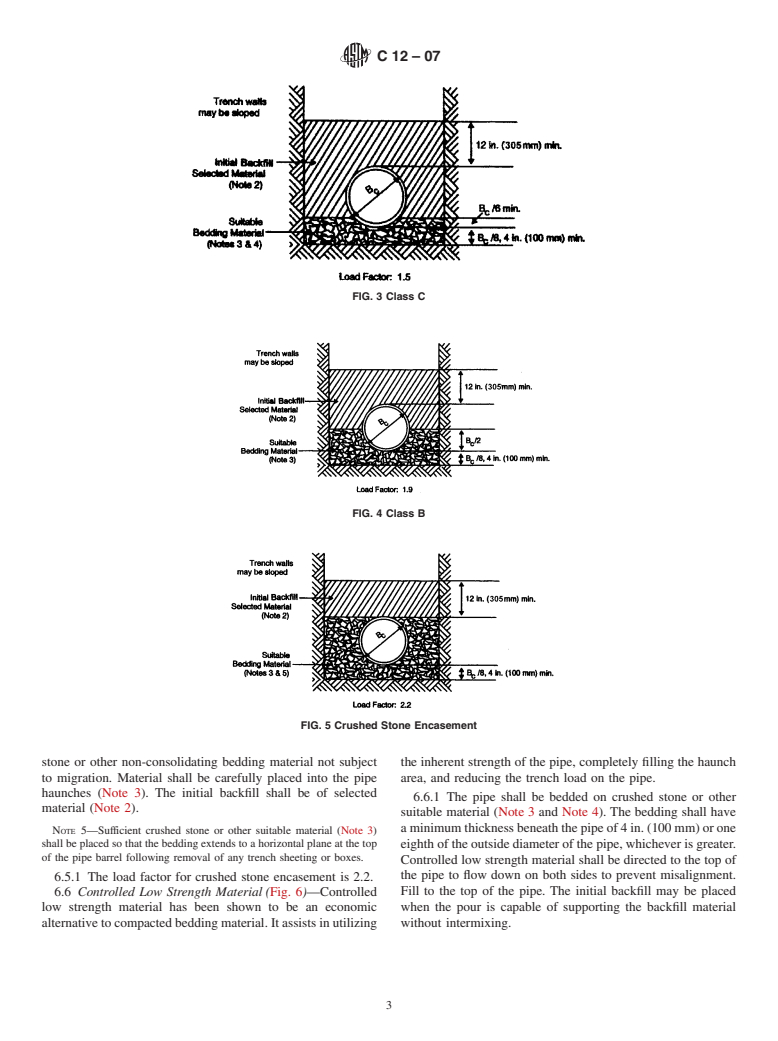

the ASTM website. Compaction of embedment and backfill materials, beside and

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C12–07

Construction, Water Pollution Control Federation Manual of Practice No.

FD-5, American Society of Civil Engineers—Manuals and Report on

3

Engineering Practice—No. 60.

6. Bedding and Encasement

6.1 Classes of bedding and encasements for pipe in trenches

are defined herein. The load factors indicated are for c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.