ASTM D2047-04

(Test Method)Standard Test Method for Static Coefficient of Friction of Polish-Coated Flooring Surfaces as Measured by the James Machine

Standard Test Method for Static Coefficient of Friction of Polish-Coated Flooring Surfaces as Measured by the James Machine

SIGNIFICANCE AND USE

Test Method D 2047 establishes a compliance criterion relating static coefficient of friction measurements of flooring surfaces with human locomotion safety. The compliance criterion is based on extensive experiential data from residential, commercial, industrial and institutional walkway surfaces since 1942.

Polishes and other floor maintenance coatings having a static coefficient of friction of not less than 0.5, as measured by this test method, have been recognized as providing nonhazardous walkways.

Note 1—The value of 0.5 meets the requirements for compliance with Rule 5 on “The use of terms slip retardant, slip resistant, or terms of similar import,” of the Proposed Trade Practice Rules for the Floor Wax and Floor Polish Industry as issued by the Federal Trade Commission on March 17, 1953.

The 0.5 static coefficient of friction compliance criterion of this test method is only appropriate for polish-coated surfaces tested in accordance with this machine and test method. The use of this compliance criterion with other test methods, other test instruments, and other surfaces is improper, because they are not a part of the body of experiential data upon which the conformance criterion is based.

Note 2—The conformance criteria of this test method may be valid for other surfaces and surface coatings tested by this test method, but this has not been substantiated by correlation with experiential data.

SCOPE

1.1 This laboratory test method covers the use of the James Machine for the measurement of the static coefficient of friction of polish-coated flooring surfaces with respect to human locomotion safety. Further, this test method also establishes a compliance criterion to meet the requirement for a nonhazardous polished walkway surface. The test method is not intended for use on "wet" surfaces or on surfaces wherein the texture, projections, profile or clearance between the sculptured pattern of the surface does not permit adequate contact between the machine foot and the test surface.

1.2 This test method is the only method appropriate for testing polishes for specification compliance with the floor polish static coefficient of friction criterion.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2047–04

Standard Test Method for

Static Coefficient of Friction of Polish-Coated Flooring

1

Surfaces as Measured by the James Machine

This standard is issued under the fixed designation D2047; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D2825 Terminology Relating to Polishes and Related Ma-

terials

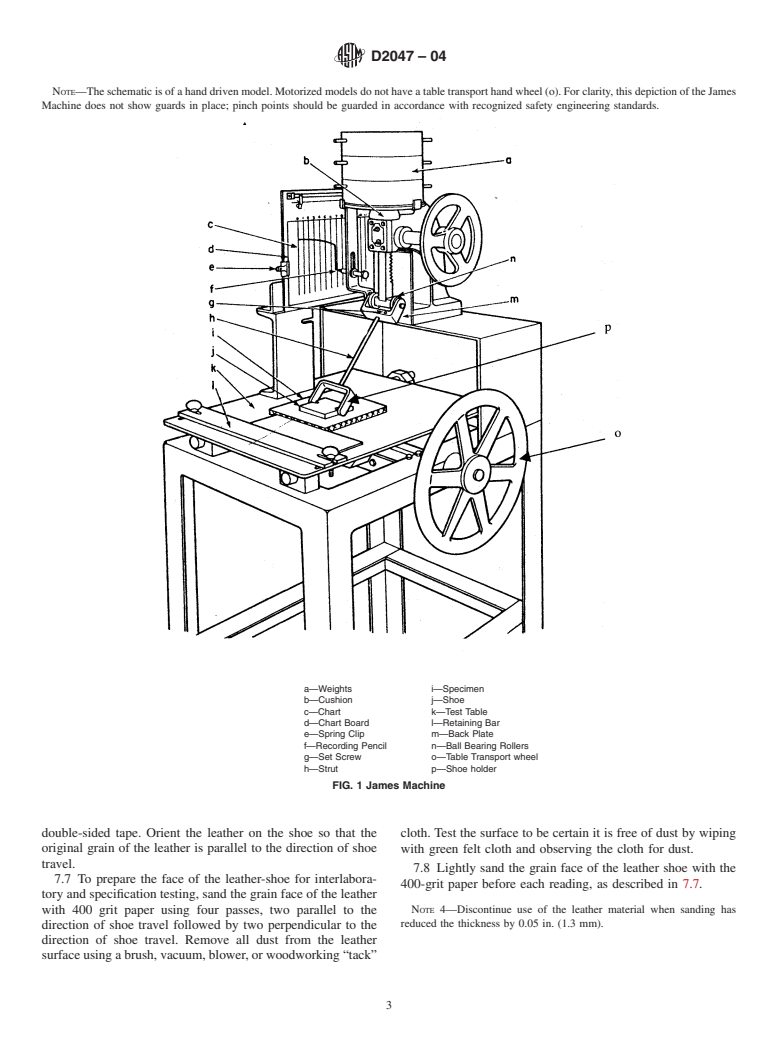

1.1 This laboratory test method covers the use of the James

D4103 Practice for Preparation of Substrate Surfaces for

Machine for the measurement of the static coefficient of

Coefficient of Friction Testing

friction of polish-coated flooring surfaces with respect to

D6205 Practice for Calibration of the James Static Coeffi-

human locomotion safety. Further, this test method also estab-

cient of Friction Machine

lishes a compliance criterion to meet the requirement for a

E29 Practice for Using Significant Digits in Test Data to

nonhazardous polished walkway surface. The test method is

Determine Conformance with Specifications

not intended for use on “wet” surfaces or on surfaces wherein

E456 Terminology Relating to Quality and Statistics

the texture, projections, profile or clearance between the

3

F489 Test Method for Using a James Machine

sculptured pattern of the surface does not permit adequate

2.2 Federal Specification:

contact between the machine foot and the test surface.

KK-L-165C Leather, Cattlehide, Vegetable Tanned and

1.2 This test method is the only method appropriate for

4

Chrome Retanned, Impregnated, and Soles. Type 1–Fac-

testing polishes for specification compliance with the floor

tory (for Shoe Making), Class 6–Strips

polish static coefficient of friction criterion.

1.3 This standard does not purport to address all of the

3. Terminology

safety problems, if any, associated with its use. It is the

3.1 Definitions—See also Teminologies D1436 and D2825.

responsibility of the user of this standard to establish appro-

3.1.1 friction, n—the resistance to relative motion devel-

priate safety and health practices and determine the applica-

oped between two solid contacting bodies at, and parallel to,

bility of regulatory limitations prior to use.

the sliding plane.

2. Referenced Documents 3.1.2 coeffıcient of friction, n—the ratio of the horizontal

2 (shear) component of force required to overcome friction, to

2.1 ASTM Standards:

the vertical (normal) component of force applied.

C1028 Test Method for Determining the Static Coefficient

3.1.3 static coeffıcient of friction, n—the ratio of the hori-

of Friction of CeramicTile and Other Like Surfaces by the

zontal component of force applied to a body that just over-

Horizontal Dynamometer Pull-Meter Method

comes the friction or resistance to sliding, to the vertical

D1436 Test Methods for Application of Emulsion Floor

component of force applied.

Polishes to Substrates for Testing Purposes

3.1.4 dynamic coeffıcient of friction, n—the ratio of the

D1630 Test Method for Rubber Property—Abrasion Resis-

horizontal component of force required to cause a body to

tance (Footwear Abrader)

continue to slide at a constant velocity, to the vertical compo-

nent of force applied.

3.1.5 slip resistance, n—thefrictionalforceopposingmove-

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD21onPolishes

ment of an object across its surface, usually with reference to

and is the direct responsibility of Subcommittee D21.06 on Slip Resistance.

the sole or heel of a shoe on a floor. A surface having a static

Current edition approved March 1, 2004. Published July 2004. Originally

approved in 1964 as D2047–64T. Last previous edition approved in 1999 as

D2047 – 99. DOI: 10.1520/D2047-04.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Withdrawn. The last approved version of this historical standard is referenced

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM on www.astm.org.

4

Standards volume information, refer to the standard’s Document Summary page on AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

the ASTM website. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D2047–04

coefficient of friction of 0.5 or greater as measured by this test 5.3 Substrate—For interlaboratory and specification testing,

7 8 9

method is considered to have adequate slip resistance. That is, OVCT ,woodpanels ,orstandardceramictiles shallbeused.

it will provide the required traction for preventing or markedly

5.3.1 If substrate

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.