ASTM D3354-08

(Test Method)Standard Test Method for Blocking Load of Plastic Film by the Parallel Plate Method

Standard Test Method for Blocking Load of Plastic Film by the Parallel Plate Method

SIGNIFICANCE AND USE

Blocking develops in film processing and storage when layers of smooth film are in intimate contact with nearly complete exclusion of air. Temperature, or pressure, or both, can induce or change the degree of adhesion of the surfaces.

The procedure of this test method closely simulates the operation of separating film in some end-use applications.

SCOPE

1.1 This test method yields quantitative information regarding the degree of blocking (unwanted adhesion) existing between layers of plastic film. It is not intended to measure susceptibility to blocking.

1.2 By this procedure, the film-to-film adhesion, expressed as a blocking load in grams, will cause two layers of film with an area of contact of 100 cm2 to separate. The test method is limited to a maximum load of 200 g.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—This test method is similar to ISO 11502 Method B, but is not technically equivalent.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3354–08

Standard Test Method for

1

Blocking Load of Plastic Film by the Parallel Plate Method

This standard is issued under the fixed designation D3354; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (ϵ) indicates an editorial change since the last revision or reapproval.

1. Scope* 4. Summary of Test Method

1.1 This test method yields quantitative information regard- 4.1 Twopiecesoffilm,whichareincontactwitheachother,

ing the degree of blocking (unwanted adhesion) existing are placed between two 100-mm (4-in.) square blocks. The

between layers of plastic film. It is not intended to measure ends of the films that extend past the blocks are secured to the

susceptibility to blocking. respective upper and lower block. The force required to

1.2 By this procedure, the film-to-film adhesion, expressed overcome the adhesion (blocking force) between the two

as a blocking load in grams, will cause two layers of film with pieces of film or until they reach 1.9 cm of separation is

2

an area of contact of 100 cm to separate. The test method is measured in grams using a constant-rate-of-load or a constant-

limited to a maximum load of 200 g. rate-of separation device.

1.3 The values stated in SI units are to be regarded as

5. Significance and Use

standard. The values given in parentheses are for information

only. 5.1 Blocking develops in film processing and storage when

layers of smooth film are in intimate contact with nearly

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the complete exclusion of air. Temperature, or pressure, or both,

can induce or change the degree of adhesion of the surfaces.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 5.2 The procedure of this test method closely simulates the

operation of separating film in some end-use applications.

bility of regulatory limitations prior to use.

NOTE 1—This test method is similar to ISO 11502 Method B, but is not

6. Apparatus

technically equivalent.

6.1 The parallel block faces shall be square and 100 6 0.1

2. Referenced Documents mm (on each edge with a flat and slightly knurled or sand-

2 blasted finish of root mean square 125). A means must be

2.1 ASTM Standards:

provided to prevent the blocks from sliding when they are in

D618 Practice for Conditioning Plastics for Testing

contact during loading.

D883 Terminology Relating to Plastics

4

6.2 Constant-Rate-of-Load Device :

E691 Practice for Conducting an Interlaboratory Study to

2 2

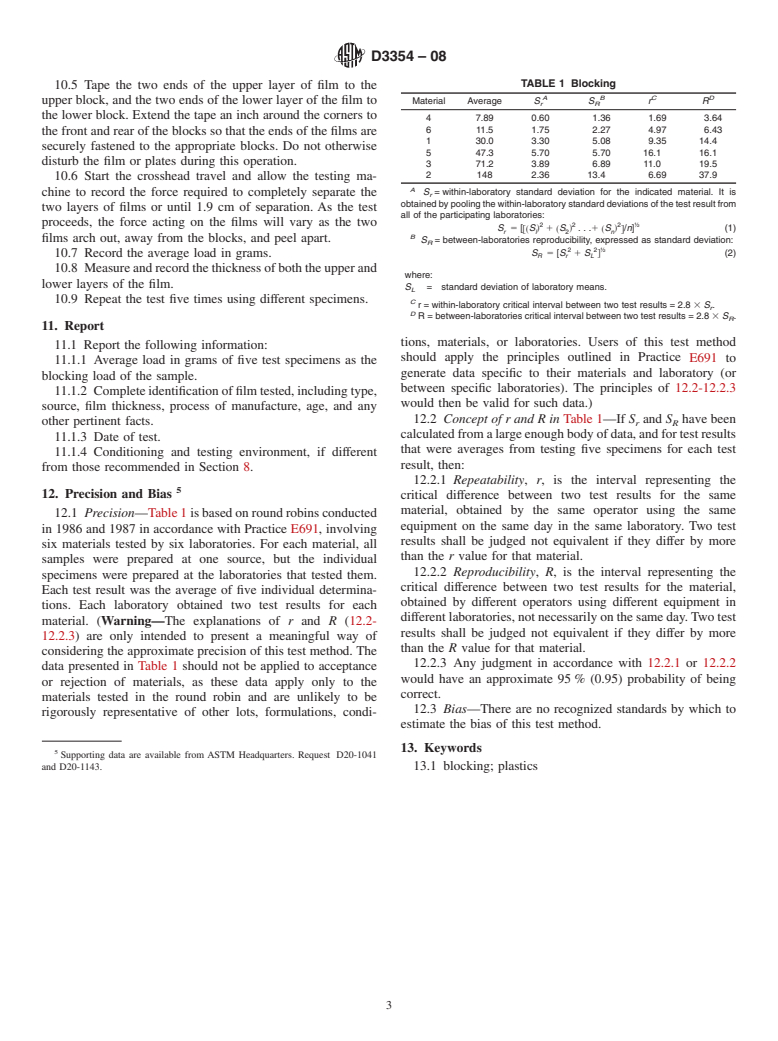

6.2.1 An instrument with 100-cm (4-in. ) blocks which

Determine the Precision of a Test Method

electronicallytimesaloadingrateof90gramsperminute(61)

2.2 ISO Standard:

3 (see Fig. 1). The force required to separate the blocks is

ISO 11502 Determination of Blocking Resistance

displayed electronically.

3. Terminology

NOTE 2—Onsomeconstant-rate-ofloaddevices,theweightisaddedby

3.1 Definitions: For definitions of terms used in this test

moving a weight axially along the beam with a precision-drive system.

This may be accomplished using a stepper motor with a digital stepping

method, refer to Terminology D883.

drive with 60 cycles as its reference control. The load rate must be 90

grams per minute.

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

6.3 Constant-Rate-of-Separation Testing Device—A testing

and is the direct responsibility of Subcommittee D20.19 on Film and Sheeting.

machine of the constant-rate-of crosshead-movement type and

Current edition approved Nov. 1, 2008. Published November 2008. Originally

approved in 1974. Last previous edition approved in 2004 as D3354 - 04. DOI: comprising essentially the following:

10.1520/D3354-08.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM The sole source of supply of the electro mechanical apparatus known to the

Standards volume information, refer to the standard’s Document Summary page on committee at this time is Kayeness, Inc., East Main St., Honeybrook, PA 19344. If

the ASTM website. you are aware of alternative suppliers, please provide this information to ASTM

3

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St., International Headquarters. Your comments will receive careful consideration at a

1

4th Floor, New York, NY 10036, http://www.ansi.org. meeting of the responsible technical committee, which you may attend.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, W

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D3354–04 Designation: D 3354 – 08

Standard Test Method for

1

Blocking Load of Plastic Film by the Parallel Plate Method

This standard is issued under the fixed designation D 3354; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method yields quantitative information regarding the degree of blocking (unwanted adhesion) existing between

layers of plastic film. It is not intended to measure susceptibility to blocking.

1.2 By this procedure, the film-to-film adhesion, expressed as a blocking load in grams, will cause two layers of film with an

2

area of contact of 100 cm to separate. The test method is limited to a maximum load of 200 g.

1.3 The values stated in SI units are to be regarded as standard. The values given in bracketsparentheses are for information

only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

NOTE 1—This test method is similar to ISO 11502 Method B, but is not technically equivalent.

2. Referenced Documents

2

2.1 ASTM Standards:

D 618 Practice for Conditioning Plastics for Testing

D 883 Terminology Relating to Plastics

E 691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

2.2 ISO Standard:

3

ISO 11502 Determination of Blocking Resistance

3. Terminology

3.1 Definitions: For definitions of terms used in this test method, refer to Terminology D 883.

4. Summary of Test Method

4.1 Two pieces of film, which are in contact with each other, are placed between two 100-mm [4-in.](4-in.) square blocks. The

ends of the films that extend past the blocks are secured to the respective upper and lower block. The force required to overcome

the adhesion (blocking force) between the two pieces of film or until they reach 1.9 cm of separation is measured in grams using

a constant-rate-of-load or a constant-rate-of separation device.

5. Significance and Use

5.1 Blocking develops in film processing and storage when layers of smooth film are in intimate contact with nearly complete

exclusion of air. Temperature, or pressure, or both, can induce or change the degree of adhesion of the surfaces.

5.2 The procedure of this test method closely simulates the operation of separating film in some end-use applications.

6. Apparatus

6.1 The parallel block faces shall be square and 100 6 0.1 mm (on each edge with a flat and slightly knurled or sand-blasted

finish of root mean square 125). A means must be provided to prevent the blocks from sliding when they are in contact during

loading.

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.19 on Film and Sheeting .

Current edition approved Sept.Nov. 1, 2004.2008. Published May 2006.November 2008. Originally approved in 1974. Last previous edition approved in 19962004 as

D3354-96.D 3354 - 04.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3354–08

4

6.2 Constant-Rate-of-Load Device :

2

2 (4-in.

6.2.1 An instrument with 100-cm [4-in. ]) blocks which electronically times a loading rate of 90 grams per minute (61)

(see Fig. 1). The force required to separate the blocks is displayed electronically.

NOTE 2—On some constant-rate-of load devices, the weight is added by moving a weight axially along the beam with a precision-drive system. This

may be accomplished using a stepper motor with a digital stepping drive with 60 cycles as its reference control. The load rate must be 90 grams per

minute.

6.3 Constant-Rate-of-Separation Testing Device—A testing machine of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.