ASTM D6337-98(2013)

(Practice)Standard Practice for Physical Characterization of Woven Paint Applicator Fabrics

Standard Practice for Physical Characterization of Woven Paint Applicator Fabrics

SIGNIFICANCE AND USE

4.1 It is important to recognize that all woven paint applicator fabrics are pile fabrics and can be a combination of several different yarns, in a range of densities, chemical compositions, and pile heights, which may influence painting performance.

SCOPE

1.1 This practice covers the dimensions, terminology, and characteristics generally considered of importance to those dealing with woven paint applicator fabrics and describes methods for determining these parameters. This practice is not meant to be a definitive analytical method to deformulate woven fabrics.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6337 − 98 (Reapproved 2013)

Standard Practice for

Physical Characterization of Woven Paint Applicator

1

Fabrics

This standard is issued under the fixed designation D6337; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 Definitions of Terms Specific to This Standard:

3.2.1 backcoating, n—a resin coating that is usually applied

1.1 This practice covers the dimensions, terminology, and

to the back of a fabric and heat cured to enhance its stability.

characteristics generally considered of importance to those

dealing with woven paint applicator fabrics and describes

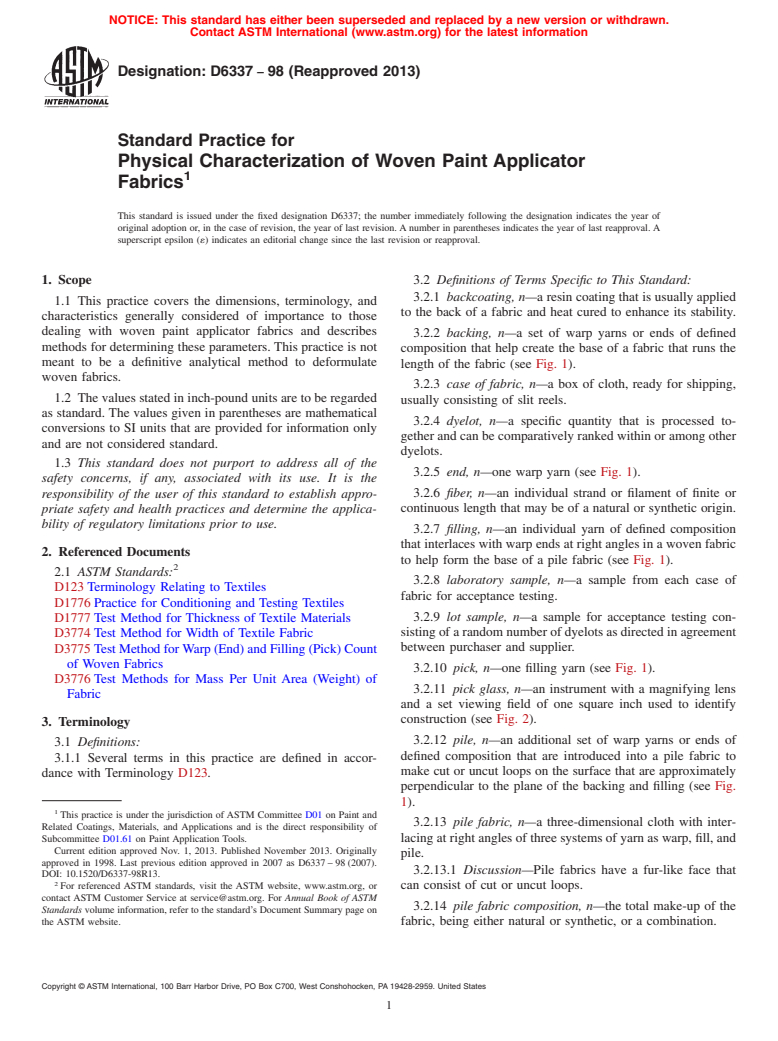

3.2.2 backing, n—a set of warp yarns or ends of defined

methods for determining these parameters. This practice is not

composition that help create the base of a fabric that runs the

meant to be a definitive analytical method to deformulate

length of the fabric (see Fig. 1).

woven fabrics.

3.2.3 case of fabric, n—a box of cloth, ready for shipping,

1.2 The values stated in inch-pound units are to be regarded

usually consisting of slit reels.

as standard. The values given in parentheses are mathematical

3.2.4 dyelot, n—a specific quantity that is processed to-

conversions to SI units that are provided for information only

gether and can be comparatively ranked within or among other

and are not considered standard.

dyelots.

1.3 This standard does not purport to address all of the

3.2.5 end, n—one warp yarn (see Fig. 1).

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 3.2.6 fiber, n—an individual strand or filament of finite or

continuous length that may be of a natural or synthetic origin.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

3.2.7 filling, n—an individual yarn of defined composition

that interlaces with warp ends at right angles in a woven fabric

2. Referenced Documents

to help form the base of a pile fabric (see Fig. 1).

2

2.1 ASTM Standards:

3.2.8 laboratory sample, n—a sample from each case of

D123 Terminology Relating to Textiles

fabric for acceptance testing.

D1776 Practice for Conditioning and Testing Textiles

3.2.9 lot sample, n—a sample for acceptance testing con-

D1777 Test Method for Thickness of Textile Materials

sisting of a random number of dyelots as directed in agreement

D3774 Test Method for Width of Textile Fabric

between purchaser and supplier.

D3775 Test Method forWarp (End) and Filling (Pick) Count

of Woven Fabrics

3.2.10 pick, n—one filling yarn (see Fig. 1).

D3776 Test Methods for Mass Per Unit Area (Weight) of

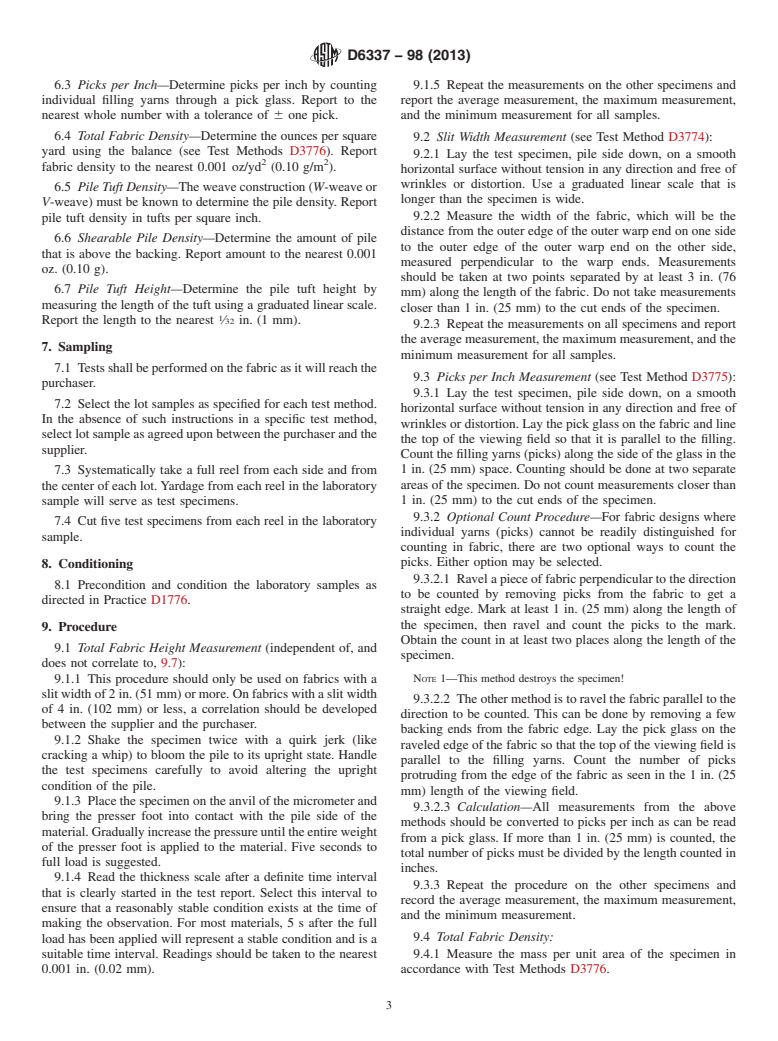

3.2.11 pick glass, n—an instrument with a magnifying lens

Fabric

and a set viewing field of one square inch used to identify

construction (see Fig. 2).

3. Terminology

3.2.12 pile, n—an additional set of warp yarns or ends of

3.1 Definitions:

defined composition that are introduced into a pile fabric to

3.1.1 Several terms in this practice are defined in accor-

make cut or uncut loops on the surface that are approximately

dance with Terminology D123.

perpendicular to the plane of the backing and filling (see Fig.

1).

1

This practice is under the jurisdiction of ASTM Committee D01 on Paint and

3.2.13 pile fabric, n—a three-dimensional cloth with inter-

Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.61 on Paint Application Tools. lacing at right angles of three systems of yarn as warp, fill, and

Current edition approved Nov. 1, 2013. Published November 2013. Originally

pile.

approved in 1998. Last previous edition approved in 2007 as D6337 – 98 (2007).

3.2.13.1 Discussion—Pile fabrics have a fur-like face that

DOI: 10.1520/D6337-98R13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or can consist of cut or uncut loops.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.2.14 pile fabric composition, n—the total make-up of the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. fabric, being either natural or synthetic, or a combination.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6337 − 98 (2013)

3.2.21 test specimen, n—a specimen cut from a reel of

fabric.

3.2.21.1 Discussion—Each specimen shall be 6 in. (152.4

mm) in length, with one side of each specimen parallel to the

warp ends.

3.2.22 total fabric density, n—fabric weight in ounces per

square yard of finished fabric.

3.2.23 tuft, n—

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.