ASTM D6335-98

(Test Method)Standard Test Method for Determination of High Temperature Deposits by Thermo-Oxidation Engine Oil Simulation Test

Standard Test Method for Determination of High Temperature Deposits by Thermo-Oxidation Engine Oil Simulation Test

SCOPE

1.1 This test method covers the procedure to determine the amount of deposits formed by automotive engine oils utilizing the thermo-oxidation engine oil simulation test (TEOST). An interlaboratory study has determined it to be applicable over the range from 10 to 65 mg total deposits.

Note 1-Operational experience with the test method has shown the test method to be applicable to engine oils having deposits over the range from 2 to 180 mg total deposits.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact

ASTM International (www.astm.org) for the latest information.

Designation: D 6335 – 98 An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Determination of High Temperature Deposits by Thermo-

1

Oxidation Engine Oil Simulation Test

This standard is issued under the fixed designation D 6335; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2.1.6 pump—the gear pump that controls the flow rate of

sample through the depositor rod casing.

1.1 This test method covers the procedure to determine the

2.1.7 pump inlet tube—the tube connecting the reactor

amount of deposits formed by automotive engine oils utilizing

2 3

chamber to the pump.

the thermo-oxidation engine oil simulation test (TEOST ). An

4

2.1.8 pump outlet tube—the tube connecting the pump to

interlaboratory study has determined it to be applicable over

the depositor rod casing.

the range from 10 to 65 mg total deposits.

2.1.9 reactor chamber—the reservoir that contains the bulk

NOTE 1—Operational experience with the test method has shown the

of the sample throughout the test. It has a drain valve for

test method to be applicable to engine oils having deposits over the range

removing sample at the end of the test and an inlet valve for

from 2 to 180 mg total deposits.

adding gases to the sample. The chamber contains a magnetic

1.2 The values stated in SI units are to be regarded as the

stir bar well in the bottom in which a stir bar is placed to mix

standard.

the reactor contents.

1.3 This standard does not purport to address all of the

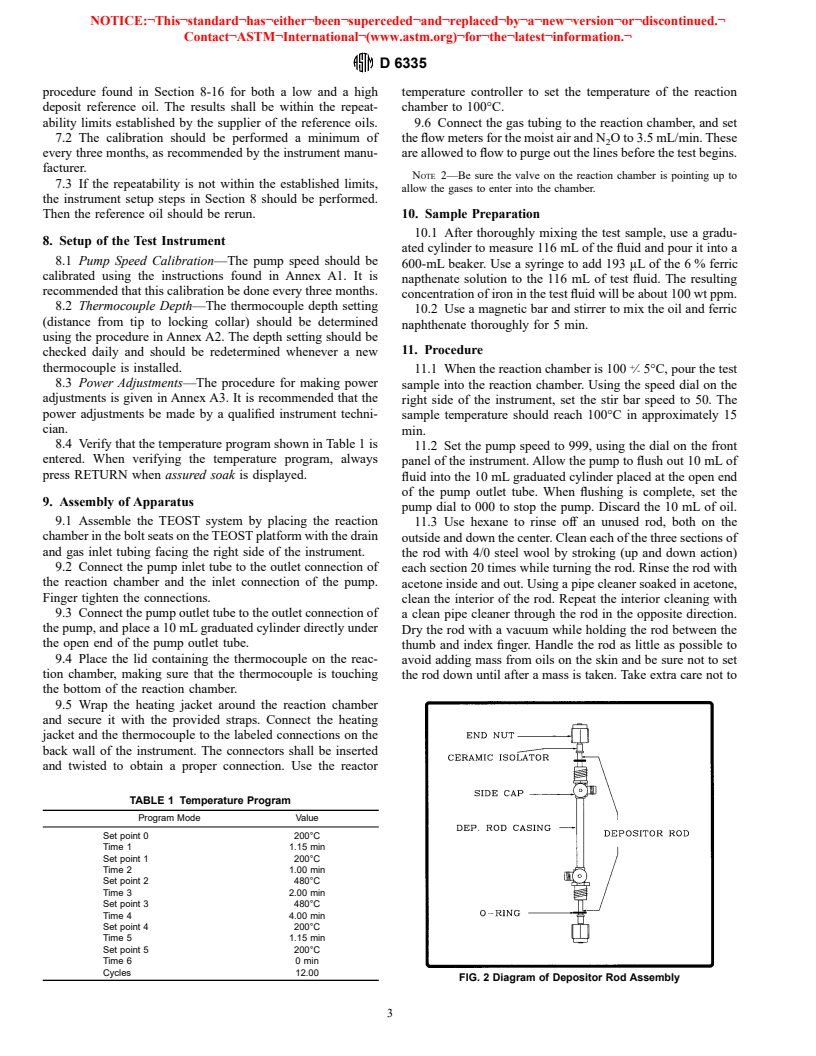

2.1.10 rod o-rings—the o-rings that seal the outside of the

safety concerns, if any, associated with its use. It is the

rod and the depositor rod casing to prevent sample leaks.

responsibility of the user of this standard to establish appro-

2.1.11 side nut—the fitting creates a seal to prevent sample

priate safety and health practices and determine the applica-

leaking from the front holes of the depositor rod casing.

bility of regulatory limitations prior to use.

2.1.12 thermocouple lock collar—a fitting that tightens on

the thermocouple to ensure the thermocouple is at the correct

2. Terminology

depth when placed inside the rod.

2.1 Definitions of Terms Specific to This Standard:

2.1.13 rod deposits—the mass in mg of the deposits col-

2.1.1 ceramic isolator—the fitting that compresses the

lected on the depositor rod.

o-ring into the depositor rod casing and isolates the depositor

2.1.14 filter deposits—the mass in mg of the deposits

rod casing from the voltage applied to the depositor rod.

collected on the filter cartridge.

2.1.2 depositor rod—the steel rod on which the deposits are

2.1.15 total deposits—the rod deposits plus the filter depos-

collected. It is resistively heated through a temperature cycle

its.

during the test.

2.1.3 depositor rod casing—the sleeve that surrounds the 3. Summary of Test Method

depositor rod and allows the flow of specimen around the

3.1 A sample of the engine oil at a temperature of 100°C

outside of the rod.

that contains ferric napthenate and is in contact with nitrous

2.1.4 drain tube—the tube connecting the outlet of the

oxide and moist air is pumped at a set flow rate past a tared

depositor rod casing to the reaction chamber.

depositor rod. The rod is resistively heated through twelve, 9.5

2.1.5 end cap—the fitting to tighten the ceramic isolators

min temperature cycles that go from 200 to 480°C. When the

down onto the o-rings at the ends of the depositor rod casing.

twelve cycle program is complete, the depositor rod rinsed of

oil residue and dried and the gross rod mass obtained. The

sample is flushed from the system and filtered through a tared

1

This guide is under the jurisdiction of ASTM Committee D-2 on Petroleum

filter. The mass of deposits on the rod plus the mass of deposits

Products and Lubricants and is the direct responsibility of Subcommittee D02.09.0G

on the filter is the total deposit mass.

on Response of Base Oil to Oxidation Inhibitors.

Current edition approved Nov. 10, 1998. Published March 1999.

2

4. Significance and Use

TEOST is a trademark of the Tannas Co. (Reg. 2001396).

3

The Development of Thermo-Oxidation Engine Oil Simulation Test (TEDST),

4.1 The test method is designed to predict the high tempera-

Society of Automotive Engineers (SAE No. 932837), 400 Commonwealth Dr.,

ture deposit forming tendencies of an engine oil. This test

Warrendale, PA 15096-0001.

4

Supporting data are available from ASTM Headquarters. Request RR:

D02–1391.

1

--------------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.