ASTM D4674-89(1997)

(Test Method)Standard Test Method for Accelerated Testing for Color Stability of Plastics Exposed to Indoor Fluorescent Lighting and Window-Filtered Daylight

Standard Test Method for Accelerated Testing for Color Stability of Plastics Exposed to Indoor Fluorescent Lighting and Window-Filtered Daylight

SCOPE

1.1 This test method covers an accelerated procedure intended to determine the resistance to color change of plastics in typical office environments, where overhead fluorescent light and window-filtered daylight are used for illumination, and where temperature and humidity conditions are in accordance with American Society of Heating, Refrigerating, and Airconditioning Engineers (ASHRAE) recommendations for workers' comfort.

1.2 This standard does not purport to address all of the safety concerns, is any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 6.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4674 – 89 (Reapproved 1997) An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Accelerated Testing for Color Stability of Plastics Exposed

to Indoor Fluorescent Lighting and Window-Filtered

Daylight

This standard is issued under the fixed designation D 4674; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope separately as the product of UV irradiance at the start of the test

2 2

and exposure time, in Watt-hours/m (W–h/m ).

1.1 This test method covers an accelerated procedure in-

3.1.1 The contribution of sunlamp irradiation to the total

tended to determine the resistance to color change of plastics in

UV actinic exposure is maintained constant by adjusting the

typical office environments, where overhead fluorescent light

on/off cycle time of the sunlamps.

and window-filtered daylight are used for illumination, and

3.1.2 The average nominal sunlamp UV actinic exposure is

where temperature and humidity conditions are in accordance

set at 12 % of the value for the VHO lamps.

with American Society of Heating, Refrigerating, and Aircon-

ditioning Engineers (ASHRAE) recommendations for work-

NOTE 1—Although office machines see some UV exposure due to

ers’ comfort. sunlight, most originates from fluorescent lighting. The 12 % is an

estimate of a representative office environment.

1.2 This standard does not purport to address all of the

safety concerns, is any, associated with its use. It is the

3.2 Color change is determined periodically throughout the

responsibility of the user of this standard to establish appro-

course of the exposure by comparison of the exposed to the

priate safety and health practices and determine the applica-

masked or unexposed specimens, using either visual or instru-

bility of regulatory limitations prior to use. Specific precau-

mental procedures.

tionary statements are given in Section 6.

3.3 The final color change should be evaluated in less than

24 h after the test is completed, preferably in less than 1 h, to

2. Referenced Documents

eliminate possible misleading consequences of postactinic

2.1 Specification for ASTM Standards:

reaction. (Color change initiated by accelerated exposure may

D 1729 Practice for Visual Evaluation of Color Differences

continue after removal of specimens from exposure to radia-

of Opaque Materials

tion.)

D 2244 Method for Calculation of Color Differences from

4. Significance and Use

Instrumentally Measured Color Coordinates

2.2 Other Document:

4.1 This test method is intended to produce the color

American Society of Heating, Refrigerating, and Aircondi-

changes that may occur in plastics upon exposure to irradiation

tioning Engineers, Applications Handbook 1981, Section

from typical office lighting by simulating these office condi-

1 on Comfort, Chapter 3.9

tions.

4.1.1 It is recognized that the rate of photodegradation of

3. Summary of Test Method

plastics will vary significantly due to factors such as processing

3.1 This test method provides for the exposure of specimens

conditions, initial color, pigment loading, the presence/type of

to the radiant energy from an array of eleven very-high output

flame retardants and other additives, etc. Consequently, corre-

(VHO) cool, white fluorescent lamps and, simultaneously, to

lation of accelerated test results with actual end-use perfor-

intermittent energy from two soda-lime glass-filtered fluores-

mance must be determined individually for each resin system.

cent UV sunlamps. The extent of UV irradiation (nominal UV

4.1.2 Variations in exposure time, temperature and humidity

actinic exposure or UVAE) from both sources is determined

may also affect results.

5. Apparatus

This test method is under the jurisdiction of ASTM Committee D–20 on

5.1 The test chamber shall be constructed of UV reflective

Plastics and is the direct responsibility of Subcommittee D20.50 on Permanence

aluminum with a clear, chromate conversion coating. An

Properties.

Current edition approved June 30, 1989. Published August 1989. Originally

arched reflector with a radius of 330 mm serves as the chamber

e1

published as D 4674 – 87. Last previous edition D 4674 – 87 .

Annual Book of ASTM Standards, Vol 14.02.

Annual Book of ASTM Standards, Vol 06.01.

4 5

Available from the American Society of Heating, Refrigerating, and Aircondi- Apparatus available from Atlas Electric Devices Co., 4114 Ravenswood Ave.,

tioning Engineers 1791 Tullie Circle Northeast, Atlanta, GA, 30329. Chicago, IL 60613 has been found satisfactory.

D 4674

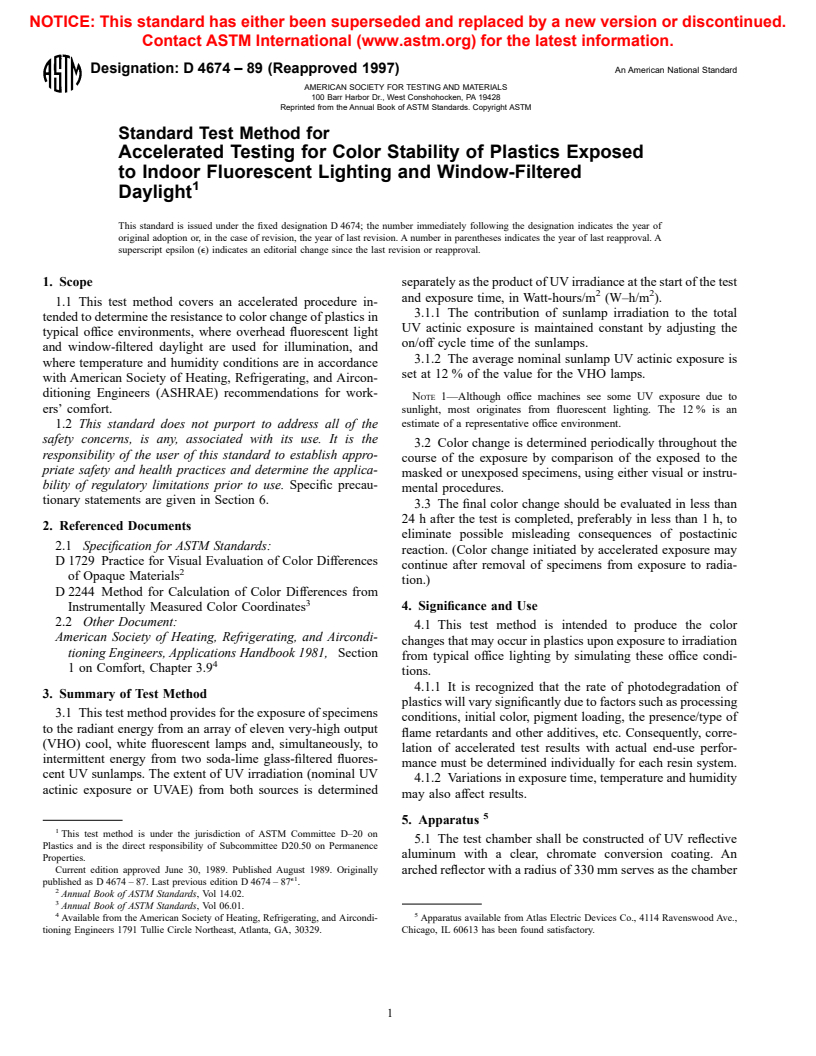

NOTE 1—Inside view showing curved reflecting roof (tunnel) and fluorescent lamps. The two 40-W fluorescent sunlamps are on the upper portion of

the reflecting tunnel directly above the soda-lime glass filters placed in the apertures in the tunnel. The eleven VHO fluorescent lamps are mounted on

the underside of the tunnel. The sensor for the high-temperature thermostatic switch is below the center fluorescent lamp and at the right edge of the

specimen drawer.

FIG. 1 Inside View Showing Curved Reflecting Roof (Tunnel) and Fluorescent Lamps

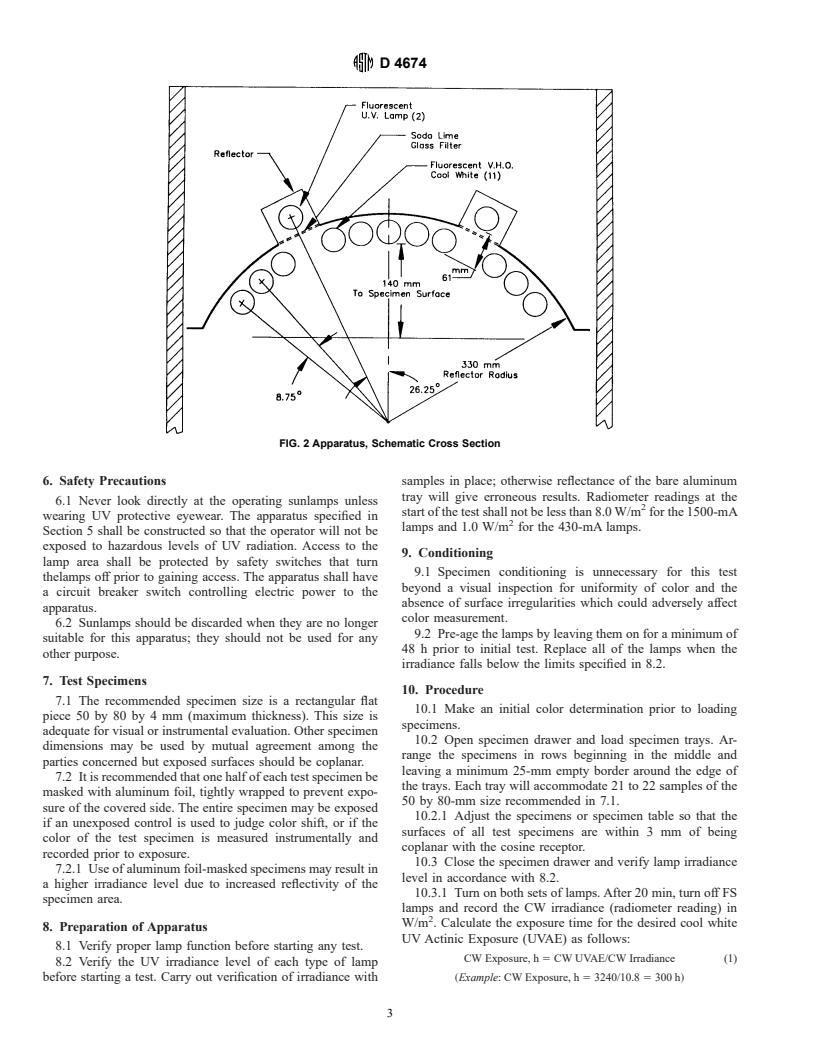

roof. The reflector also contains two apertures that hold modate two specimen trays, each having an area of approxi-

soda-lime glass panels which filter the sunlamps. The vertical

mately 0.13 m (630 by 210 mm) separated by a median

distance from the exposed surface of the specimen to the lamp containing a center port for the cosine receptor (light sensor) of

surface shall be 140 6 3 mm at the midpoint of the arch. See

the radiometer.

Figs. 1 and 2.

5.3 To assure uniform test conditions, it is important that all

5.1.1 Eleven 1500-mA cool white VHO fluorescent lamps

lamps shall be in accordance with 5.1.1 and 5.1.2. All 1500-mA

(CW) shall be mounted in three groups on the inner surface of

lamps shall be cool white. Both 430-mA lamps shall be

the reflector. The angular spacing between lamps in each group

fluorescent F40T12UVB sunlamps.

shall be 8°, 45 min. See Figs. 1 and 2.

5.4 The apparatus shall be used only in an environment

5.1.2 A 430-mA fluorescent sunlamp (FS) shall be mounted

which meets ASHRAE recommendations of 20 to 25.5°C

directly above each of the two apertures at a position 26° 15

ambient temperature and 40 to 50 % relative humidity.

min from the vertical plane intersecting the longitudinal axis of

5.4.1 The lamps and ballasts shall be forced-air cooled to

the test chamber. Each lamp must be mounted behind a

maintain the air temperature in the test chamber between 30

soda-lime glass filter (2.4 6 0.2 mm thick). (See Fig. 1, lamps

and 40°C.

12 and 13).

5.4.2 The apparatus shall be equipped with a thermostatic

5.2 The specimen table shall have the same reflecting

sensor that will cause the lamps to be turned off should the

surface as the lamp reflector. It shall have a vertical adjustment

upper temperature limit in the specimen area be exceeded.

to control specimen-to-lamp distance. The table shall accom-

5.5 The apparatus shall be equipped with timing devices and

time meters to control on-time for the 1500-mA lamps, to

A 1500-mA lamp is a cool white (CW) fluorescent lamp with a tubular bulb

control on/off cycling for the 430-mA lamps, and to record

approximately 38 mm in diameter and 1220 mm in length, rated at 110 W and

total time of operation for each type of lamp.

designated F48T12 CW/VHO, or its equivalent. F48T12CW/VHO Fluorescent Cool

5.6 The apparatus shall include a properly calibrated radi-

White Lamps, available from North American Philips Lighting Corp., Bloomfield,

NJ 07003, have been found satisfactory.

ometer to measure irradiance in the exposure chamber. The

A 430-mA lamp is a fluorescent sunlamp (FS) of similar dimension to the cool

light detector shall be located centrally in the exposure table; it

white lamp described in Footnote 5, rated at 40 W and designated as F40T12UVB,

shall have a bandpass from 250 to 400 nm and be a cosine

or its equivalent. F40T12UVB Fluorescent UV Sunlamps are also available from

North American Philips Lighting Corp. response receptor.

D 4674

FIG. 2 Apparatus, Schematic Cross Section

6. Safety Precautions samples in place; otherwise reflectance of the bare aluminum

tray will give erroneous results. Radiometer readings at the

6.1 Never look directly at the operating sunlamps unless

start of the test shall not be less than 8.0 W/m for the 1500-mA

wearing UV protective eyewear. The apparatus specified in

lamps and 1.0 W/m for the 430-mA lamps.

Section 5 shall be constructed so that the operator will not be

exposed to hazardous levels of UV radiation. Access to the

9. Conditioning

lamp area shall be protected by safety switches that turn

9.1 Specimen conditioning is unnecessary for this test

thelamps off prior to gaining access. The apparatus shall have

beyond a visual inspection for uniformity of color and the

a circuit breaker switch controlling electric power to the

absence of surface irregularities which could adversely affect

apparatus.

color measurement.

6.2 Sunlamps should be discarded when they are no longer

9.2 Pre-age the lamps by leaving them on for a minimum of

suitable for this apparatus; they should not be used for any

48 h prior to initial test. Replace all of the lamps when the

other purpose.

irradiance falls below the limits specified in 8.2.

7. Test Specimens

10. Procedure

7.1 The recommended specimen size is a rectangular flat

10.1 Make an initial color determination prior to loading

piece 50 by 80 by 4 mm (maximum thickness). This size is

specimens.

adequate for visual or instrumental evaluation. Other specimen

10.2 Open specimen drawer and load specimen trays. Ar-

dimensions may be used by mutual agreement among the

range the specimens in rows beginning in the middle and

parties concerned but exposed surfaces should be coplanar.

leaving a minimum 25-mm empty border around the edge of

7.2 It is recommended that one half of each test specimen be

the trays. Each tray will accommodate 21 to 22 samples of the

masked with aluminum foil, tightly wrapped to prevent expo-

50 by 80-mm size recommended in 7.1.

sure of the covered side. The entire specimen may be exposed

10.2.1 Adjust the specimens or specimen table so that the

if an unexposed control is used to judge color shift, or if the

surfaces of all test specimens are within 3 mm of being

color of the test specimen is measured instrumentally and

coplanar with the cosine receptor.

recorded prior to exposure.

10.3 Close the specimen drawer and verify lamp irradiance

7.2.1 Use of aluminum foil-masked specimens may result in

level in accordance with 8.2.

a higher irradiance level due to increased reflectivity of the

10.3.1 Turn on both sets of lamps. After 20 min, turn off FS

specimen area.

lamps and record the CW irradiance (radiometer reading) in

W/m . Calculate the exposure time for the desired cool white

8. Preparation of Apparatus

UV Actinic Exposure (UVAE) as follows:

8.1 Verify proper lamp function before starting any test.

CW Exposure, h 5 CW UVAE/CW Irradiance (1)

8.2 Verify the UV irradiance level of each type of lamp

before starting a test. Carry out verification of irradiance with ~Example: CW Exposure, h 5 3240/10.8 5 300 h!

D 4674

at intermediate points of the test cycle, complete color mea-

where:

surements as rapidly as possible. Following each color mea-

3240 W-h/m 5 example of an often-agreed-upon expo-

surement, return test specimens to the appropriate locations

sure, and

10.8 5 radiometer reading. and resume exposure until the test is completed.

10.6.2 If immediate evaluation of the final, post-exposure

10.3.2 Turn off the CW lamps and turn on the FS lamps.

color change is not possible, refrigerate test specimens at − 15

Record the radiometer reading (W/m ). Calculate the total FS

to − 20°C to minimize possible effects of post-actinic reaction.

lamp on-time as follows:

In any case, make measurement within 5 days of test comple-

FS On2time, h 5 12 % CW UVAE/FS Irradiance (2)

tion.

~Example:FSOn2time, h 5 ~0.12!~3240!/2.0 5 194 h!

10.6.3 Terminology for describing the observed color

change shall be established by mutual agreement among the

where:

parties concerned.

2.0 5 radiometer reading for the FS lamps.

10.6.4 Instrumental evaluation of color difference in CIE

10.4 Calculate the off-time interval/cycle for the FS lamps

L*a*b (CIE LAB) units in accordance with Method D 2244

by subtracting the FS on-time from the CW exposure time and

shall be the preferred method for describing the color change

dividing by the FS on-time.

between an unexposed control specimen and the exposed

300 2 194 106

Example: 5 0.546 off2time h/cycle (3) specimen or between the masked and unmasked areas of an

S D

194 194

exposed specimen, unless agreed upon by the parties involved.

10.4.1 Program the FS lamp cycling timer to a 1-h time-on

NOTE 3—The preferred method uses reflectance measurement with

interval/cycle.

integrating-sphere geometry, specular component included, and integra-

10.4.2 Program the FS lamp timer to the off-time interval/

tion for CIE standard illuminant C and the 1931 (2°) standard observer;

cycle calculated in 10.4.

the UV component of the instrument source should be excluded. It should

10.4.3 Replace the CW lamps if the total on-time for the FS

also be noted that significant differences in color measurements can occur,

exceeds the CW exposure time.

particularly in dark colors, when using different types of instruments.

10.4.4 Do not add additional specimens once the test has

11. Report

begun.

10.5 Start the test at a time which will assure prompt color 11.1 The report shall include the following:

measurement when the test is completed. 11.1.1 Material identification and source (if known).

10.5.1 The CW lamps should be on continuously throughout 11.1.2 Exposure apparatus type.

the entire exposure except for brief periods in which the 11.1.3 Initial and final CW UV irradiance, W/m .

samples are removed for color measurement in accordance 11.1.4 Initial and final FS UV irradiance, W/m .

with 10.6. Verify that the FS lamps maintain a reproducible 11.1.5 Total exposure time, h.

cycle of1hon followed by the calculated time off. 11.1.6 Total FS on-time, h.

10.5.2 Having determined and verified the test duration and 11.1.7 FS off-time interval.

FS cycle intervals, do not make adjustments in test/cycle time 11.1.8

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.