ASTM D2255-96

(Test Method)Standard Test Method for Grading Spun Yarns for Appearance

Standard Test Method for Grading Spun Yarns for Appearance

SCOPE

1.1 This test method covers the grading of singles spun yarns for appearance.

1.2 This test method does not apply to plied yarns.

1.3 This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 2255 – 96

Standard Test Method for

Grading Spun Yarns for Appearance

This standard is issued under the fixed designation D 2255; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Cotton yarn appearance standards were first adopted in 1938 and revised in 1964, with Series III

being revised again in 1975. The 1964 boards had different yarn sizes for the four-grade exhibits on

each board. The 1975 Series III board used the same yarn number for each grade.

The appearance grade of yarn is based on the composite evaluation of several factors, such as

unevenness, fuzziness, and neppiness. The differences in the yarn numbers in the 1964 standards along

with the differences in other factors distort the comparison between grades and makes grading more

difficult.

To overcome this shortcoming, in 1975 the Series III board was revised using the same size yarn

for all four grades. After evaluating the improvements, it was decided to revise all of the series using

a mid-range yarn number for each grade in the series, and narrow the range in the most active series.

This was accomplished by adding a new board, Series VI. A near mid-range yarn number was selected

to represent equal steps between adjacent grades for all the factors considered in yarn appearance

grading. These yarns were produced with current commercial manufacturing equipment and practices.

Finally, to obtain better yarn definition and better reproducibility from set to set, it was decided to

use offset photo printing.

Shortly after these new boards were published in 1979, it became apparent that in the Series II-79

Board the A and B grades were not clearly defined and appeared to be switched. This was corrected

in the 1987 Series II Board.

In 1987 a world wide survey was conducted on how the Yarn Appearance Boards were being used.

From responses it became apparent that the boards are being used for grading yarns other than 100 %

cotton combed or carded yarns. Respondents were using the boards to grade yarn blends, ring spun

yarns, open-end spun yarns and other spinning systems. The boards are used both for process quality

control and customer acceptance.

In view of the above findings, it was decided to revise the method to include grading of all single

spun yarns.

1. Scope 2. Referenced Documents

1.1 This test method covers the grading of singles spun 2.1 ASTM Standards:

yarns for appearance. D 123 Terminology Relating to Textiles

1.2 This test method does not apply to plied yarns. D 2258 Practice for Sampling Yarn for Testing

1.3 This standard does not purport to address the safety

3. Terminology

problems associated with its use. It is the responsibility of the

3.1 Definitions:

user of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limita- 3.1.1 bunch, n—a defect in a yarn characterized by a

2 1

segment not over 6 mm ( ⁄4 in.) in length that shows an abrupt

tions prior to use.

increase in diameter caused by more fibers matted in this

particular place.

3.1.2 cover, n—in yarns, the outside layer of fibers that form

This test method is under the jurisdiction of ASTM Committee D-13 on Textiles

the surface of a yarn.

and is the direct responsibility of Subcommittee D13.58 on Yarn Test Methods,

3.1.3 fuzz, n—untangled fiber ends that protrude from the

General.

surface of a yarn or fabric.

Current edition approved April 10, 1996. Published June 1996. Originally

published as D 2255 – 64. Last previous edition D 2255 – 90.

The requirements for the appearance of cotton yarns are covered in Tolerances

D2645, Roller-Drafted Yarns. 3

Annual Book of ASTM Standards, Vol 07.01.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 2255

TABLE 1 Requirements for Preparations of Specimens

3.1.3.1 Discussion—Fuzz should not be confused with

B

“cover.” Range of Yarn Numbers Wraps

A

Series Count

3.1.4 nep, n—a tightly tangled knot-like mass of unorga-

Single Cot-

Tex per in. per cm

ton Count

nized fibers. (Compare nap, pill.)

3.1.5 slub, n—an abuptly thickened place in a yarn. (Syn. 1 1 to 12 590 to 50 + 8 20 8

2 12+to 24 50to 25+ 18 22 9

lump, piecing, slough-off, slug. Compare cockles.)

3 24+to 36 25to 16+ 30 26 10

3.1.6 thick place, n—a yarn defect characterized by a

4 36+to 50 16to 12+ 42 32 13

5 50+to 75 12to 8+ 60 38 15

diameter greater than that of the adjoining segments and

6 75 + to 135 8 to 4 + 100 48 19

extending for 6 mm ( ⁄4 in.).

A

Actual single yarn count used on boards.

3.1.6.1 Discussion—The thick place is normally caused by

B

The specified number of wraps is subject to a tolerance of 6 10 %.

a greater number of fibers per yarn cross section than usual.

3.1.7 thin place, n—a yarn defect characterized by a seg-

6. Significance and Use

ment that is at least 25 % smaller in diameter than the average

diameter of the yarn. 6.1 This method is considered satisfactory for acceptance

3.1.7.1 Discussion—A thin place may be of any length. grading of commercial shipments because it has been used

extensively in the trade for this purpose.

3.1.8 yarn appearance, n—the visual effect obtained by

viewing a sample of yarn wound with a designated traverse on 6.1.1 In case of dispute, the statistical bias, if any, between

the laboratory of the purchaser and the laboratory of the

a black board of designated size.

supplier should be determined with each comparison being

3.1.9 For definitions of other textile terms used in this

based on testing randomized specimens from one sample of

method, refer to Terminology D 123.

material.

4. Description of Yarn Grades 6.2 The appearance of a woven or knitted fabric depends to

a large extent on the smoothness, cleanliness, and general

4.1 Grade A Yarn—Grade A yarn may have no large neps

appearance of the yarns from which the fabric is manufactured.

which are over three times the normal diameter of the yarn and

Instruments are available for the measurement of unevenness

very few small ones. Grade A yarn must have good uniformity

and for counting neps and other imperfections in yarn, but the

from inch to inch, and good cover without excessive fuzziness.

values obtained from such tests are not easily integrated into an

No foreign matter may be present in Grade A yarn.

over-all expression for actual fabric appearance. Yarn appear-

4.2 Grade B Yarn—Grade B Yarn may have no large neps,

ance grading affords additional information which the manu-

but may have a few small ones. Grade B yarn may have no

facturer of woven or knitted goods may, through experience,

more than three small pieces of foreign matter per board or

correlate with the appearance to be expected in fabrics made

specimen providing they do not form slubs. Grade B yarn may

from the yarns.

be slightly more irregular and may have slightly more fuzz than

a Grade A yarn.

7. Apparatus

4.3 Grade C Yarn—Grade C yarn may have more neps, and

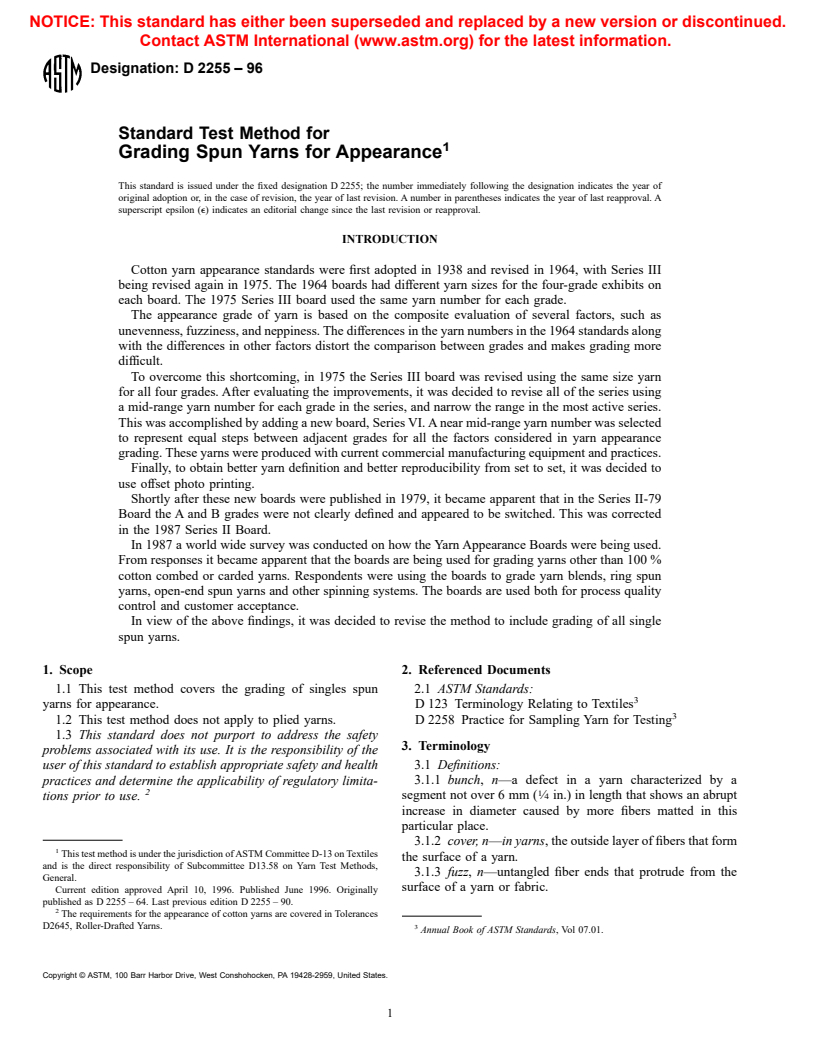

7.1 Spun Yarn Appearance Standards —A series of photo-

larger ones as well as more fuzziness and a greater amount of

graphic standards representing Grades A, B, C, and D in six

foreign matter than Grade B yarn. The contrast between the

ranges of yarn numbers. Grade A is the highest and the others

thick and thin places and the normal diameter of the yarn may

are progressively lower. The range of yarn numbers to be

be greater than in Grade B yarn resulting in an over-all rougher

graded by each series is listed in Table 1. The standards are

appearance.

illustrated in Fig. 1.

4.4 Grade D Yarn—Grade D yarn may have some slubs that

7.2 Yarn Grading Cabinet —A cabinet with storage space

are more than three times the average diameter of the yarn.

for the appearance standards, a shelf or rack on which one

Grade D yarn may have more neps, neps of a larger size, more

panel of standards and the specimen to be graded can be

thick and thin places, more fuzz and more foreign matter than

displayed, and lights mounted on brackets to illuminate the

Grade C yarn. When slubs or large neps are present, Grade D

specimen and standards at the proper angle. A picture of the

yarn may have fewer neps than Grade C yarn. Grade D yarn

yarn appearance grading cabinet being used by a grader is

may have an over-all rougher appearance than Grade C yarn.

shown in Fig. 2.

4.5 Yarn Below Grade D—Yarn below Grade D may have

7.2.1 The lights on the cabinet shall consist of two units

more defects and an overall rougher appearance than Grade D

focused on the standard when in the grading position from a

yarn.

location about 300 mm (12 in.) in front with one unit slightly

NOTE 1—The permitted number of defects for any grade should always

above and one unit slightly below the standards. Each unit shall

be determined by comparison with the official “ASTM Spun Yarn

be equipped with two 150-W daylight incandescent bulbs

Appearance Standards” photographs.

5. Summary of Test Method

Available from the ASTM Headquarters. Request adjunct No. as follows:

ADJD225501 (Series 1-79) ADJD225504 (Series 4-79)

5.1 Yarn specimens, wound on black boards, are compared

ADJD225502 (Series 2-79) ADJD225505 (Series 5-79)

with photographs of specimens representing the appearance

ADJD225503 (Series 3-79) ADJD225506 (Series 6-79)

grades. The grade is based on fuzziness, neppiness, uneven-

Prints of detailed drawings of a suitable cabinet are available fr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.