ASTM D4270-95

(Guide)Standard Guide for Using Existing Practices in Developing and Writing Test Methods

Standard Guide for Using Existing Practices in Developing and Writing Test Methods

SCOPE

1.1 This guide is intended to assist task groups in the preparation of a test method. It can help the task group use existing statistically related ASTM practices more effectively during the development and writing of the test method.

1.2 Some of the essential activities that should occur during the development of a new test method are not in existing or proposed practices under the jurisdiction of ASTM Subcommittee D13.93 on Statistics. This guide includes a brief explanation of how such activities should be carried out.

1.3 This guide is applicable to properties that are evaluated by both parametric and nonparametric methods of estimation. The instructions on properties that are best evaluated by nonparametric methods are less complete than those for properties that are evaluated by parametric methods.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4270 – 95

Standard Guide for

Using Existing Practices in Developing and Writing Test

Methods

This standard is issued under the fixed designation D 4270; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This guide is intended to assist task groups in the

2.2 ASTM Adjuncts:

preparation of a test method. It can help the task group use

TEX-PAC

existing statistically related ASTM practices more effectively

during the development and writing of the test method.

NOTE 1—TEX-PAC is a group of PC programs on floppy disk.

1.2 Some of the essential activities that should occur during

3. Terminology

the development of a new test method are not in existing or

proposed practices under the jurisdiction of ASTM Subcom-

3.1 Definitions:

mittee D13.93 on Statistics. This guide includes a brief

3.1.1 moving range, MR, n—the difference without regard

explanation of how such activities should be carried out.

to sign between two successive observations.

1.3 This guide is applicable to properties that are evaluated

3.1.2 nonparametric, adj—in statistics, a term referring to a

by both parametric and nonparametric methods of estimation.

technique that is not based on assumptions about the nature of

The instructions on properties that are best evaluated by

the underlying frequency distribution. (Compare to paramet-

nonparametric methods are less complete than those for

ric.)

properties that are evaluated by parametric methods.

3.1.3 parametric, adj—in statistics, a term referring to a

technique that assumes the nature of the underlying distribution

2. Referenced Documents

is known. (Compare to nonparametric.)

2.1 ASTM Standards:

3.1.4 practice, n—a definitive procedure for performing one

D 123 Terminology Relating to Textiles

or more specific operations or functions that does not produce

D 2904 Practice for Interlaboratory Testing of a Textile Test

a test result.

Method That Produces Normally Distributed Data

3.1.4.1 Discussion—A practice is not a down-graded test

D 2905 Practice for Statements on Number of Specimens

method. Examples of practices include procedures for conduct-

for Textiles

ing interlaboratory testing programs or other statistical proce-

D 2906 Practice for Statements on Precision and Bias for

dures; for writing statements on sampling or precision and

Textiles

accuracy; and for selection, preparation, application, inspec-

D 3777 Practice for Writing Specifications for Textiles

tion, necessary precautions for use or disposal, installation,

D 4271 Practice for Writing Statements on Sampling in Test

maintenance, and operation of testing equipment.

Methods for Textiles

3.1.5 test method, n—a definitive procedure for the identi-

D 4356 Practice for Establishing Consistent Test Method

fication, measurement, or evaluation of one or more qualities,

Tolerances

characteristics, or properties of a material, product, system, or

D 4467 Practice for Interlaboratory Testing of a Test

service that produces a test result.

Method That Produces Non-Normally Distributed Data

3.1.6 For the definitions of other terms that appear in this

D 4853 Guide for Reducing Test Variability

standard, refer to Terminology D 123 and Terminology E 456.

D 4854 Guide for Estimating the Magnitude of Variability

4. Summary of Guide

from Expected Sources in Sampling Plans

D 4855 Practice for Comparing Test Methods

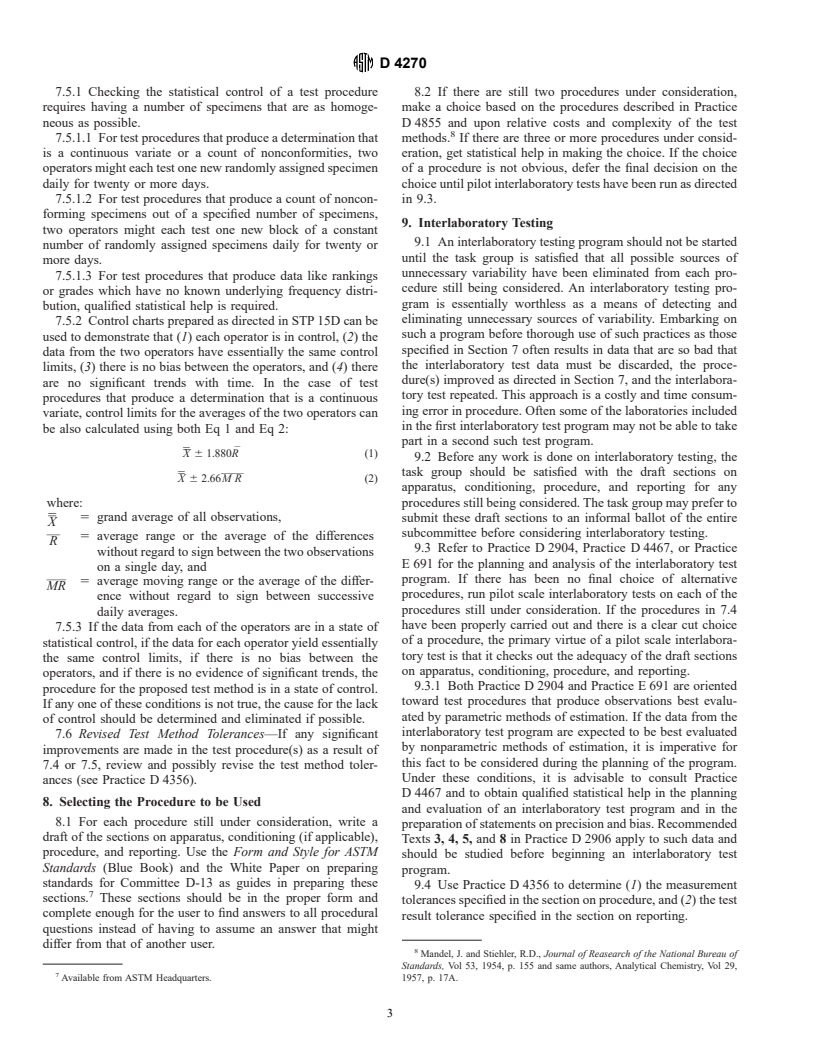

4.1 The guide is summarized in Fig. 1, which shows the

E 456 Terminology Relating to Quality and Statistics

steps in test method development, the sections of this guide

which apply, and other references that may be used as aids in

a specific step in the development of the test method. As Fig.

This guide is under the jurisdiction of ASTM Committee D-13 on Textiles and

1 points out, the references should show to which of the

is the direct responsibility of Subcommittee D13.93 on Statistics.

previous steps the development should revert when the results

Current edition approved May 15, 1995. Published July 1995. Originally

published as D 4270 – 83. Last previous edition D 4270 – 90.

Annual Book of ASTM Standards, Vol 07.01.

3 5

Annual Book of ASTM Standards, Vol 07.02. PC programs on floppy disk are available through ASTM. For a 3 ⁄2 in. disk

Annual Book of ASTM Standards, Vol 14.02. request PCN: 12-429040; for a 5 ⁄4 in. disk request PCN: 12-429041-18.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 4270

When the results of a step are less than completely satisfactory, the reference

that is being used by them, or someone has decided that a

practice(s) should show to which of the previous steps the development of the test

specific procedure is a reasonable one to use even though it has

method should revert.

not been used in industry. Existing procedures may be modified

Step in

by the task group in the light of a consensus of viewpoints.

Development Section(s) Other References

7.2 Applicability of Potential Methods—The first job of the

Determining Need 6 none

task group is to consider each of the potential methods and

Sources of Methods 7.1 none

determine if the method really measures the property of interest

Applicability of Potential Methods 7.2 none

Initial Test Method Tolerances 7.3 Practice D 4356

or whether it measures some related property instead. A

Reducing Variability 7.4 Practice D 4853

specific procedure can usually be investigated within a single

Statistical Control 7.5 none

laboratory. In the light of these findings, a judgment should be

Revised Test Method Tolerances 7.6 Practice D 4356

Initial Draft(s) 8.1 Blue Book made whether each of the potential methods is worthy of

D13.91 White Paper

further work. In addition, if the method is supposed to predict

Selecting Procedure to Use 8.2 Practice D 4855

performance in a later stage in the life of a material or product,

Interlaboratory Testing 9 Practice D 2904

Practice D 4467

the task group needs to verify that the method will really do so.

Practice E 691

At this point, the task group should eliminate any potential test

Terminology 10.2 Terminology D 123

procedure that does not meet these requirements. If all of the

Terminology E 456

Uses and Significance 10.3 Practice D 2906

potential procedures are eliminated, the task group should

Sampling 10.4 Practice D 2905

make every reasonable attempt to discover or invent a proce-

Practice D 3777

dure that does meet these requirements. Failure to do so will

Practice D 4271

Guide D 4854

mean that the selected test method will not be as good as the

Precision and Bias 10.5 Practice D 2906

users have a right to expect.

Blue Book

7.3 Initial Test Method Tolerances—Practice D 4356 dis-

Review of Draft 11.1 none

Ballots 12.1 ASTM Regulations

cusses the fact that the tolerances specified for each of the

FIG. 1 Suggested Steps in Test Method Development measurements of some characteristic of a test specimen deter-

mine the exactness with which a test result can realistically be

reported. For example, a procedure for determining mass per

of a specific step are less than satisfactory.

unit area of a fabric specimen should require that the length and

width of the specimen be measured to within some tolerance

5. Significance and Use

and the mass to within another tolerance. If these tolerances are

5.1 There are enough existing practices related to the

broad, it will not be realistic to require reporting the mass per

development of test methods or the preparation of one or more

unit area quite exactly. Before starting work on the one or more

sections of new test methods so that even the experienced

potential procedures that are still under consideration, the task

author may not use them as effectively as possible. This guide

group should select consistent test method tolerances.

shows the person(s) preparing a new test method where and

7.4 Reducing Variability—It is quite likely that the results

when the existing practices can best be used.

for each of the potential test methods include variability that

5.2 Using this standard as a guide, a task group should be

might be eliminated or reduced by changes in the procedure.

able to prepare a draft of a new test in less time and with less

Guide D 4853 discusses how to locate the sources of such

effort than if this guide were not used. In addition, a well-

unnecessary variability and how to eliminate them by (1) using

prepared draft of a new test method is less likely to receive

ruggedness tests, (2) evaluating and using components of

negative votes.

variance, (3) averaging results from more than one specimen,

(4) compositing samples prior to testing, and (5) using physical

6. Determining Need for a Method

standards to reduce time related changes in the method or

6.1 There is no simple answer to the question: “Is a new test

equipment. A brief description of ruggedness testing and a set

method needed?” Generally, a new test method is needed if (1)

of references are given in Practice D 2904. The task group

no ASTM test method exists to identify, measure, or evaluate

should contact a person with statistical experience for help with

one or more significant qualities, characteristics, or properties

the methods of eliminating unnecessary variability listed

of a material, product, system, or service and (2) need for such

above.

a method exists on an industry-wide basis. The responsible

7.5 Statistical Control—Useful testing procedures should

subcommittee needs to be convinced that a true need exists and

be in a state of statistical control; that is, the long-term

be agreed upon the exact nature of the quality, characteristic, or

variability should be no greater than is predicted from the

property of interest to be evaluated. It is essential that a test

short-term variability. Guidance is given in 7.4 for detecting

method measure a quality, characteristic, or property that will

and eliminating assignable causes of increased long-term

predict the usefulness of a material, product, system, or service

variability. The existence of a state of statistical control can be

when it is put to its intended use.

demonstrated by control charts prepared as directed in STP

15D.

7. Evaluating Potential Methods

7.1 Sources of Potential Methods—Potential procedures for

a proposed new test method usually come from two sources:

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.