ASTM F432-04

(Specification)Standard Specification for Roof and Rock Bolts and Accessories

Standard Specification for Roof and Rock Bolts and Accessories

ABSTRACT

This specification covers the chemical, mechanical, and dimensional requirements for roof and rock bolts and accessories. Addressed in this specification are double-end threaded and slotted steel bars; fully grouted bolts and threaded bars; mechanical anchorage devices used for point anchorage applications; roof truss systems; partially grouted deformed bolts; formable anchorage devices; and other frictional anchorage devices. All of these products represent various designs used for ground support systems. Threads on bolts or threaded bars may be cold rolled or machine cut on the hot-rolled bars. Bearing and header plates may be strengthened by cold forming or may be hardened by quenching in a liquid medium from above the austenitizing temperature and tempering. Hardened steel washers shall be through hardened by quenching in a liquid medium from above the austenitizing temperature and tempering. Test shall be performed in accordance with the following test methods: tensile strength; elongation; test for bearing and header plates; test for notched bendable bolts; and tests of roof truss components.

SCOPE

1.1 This specification covers the chemical, mechanical, and dimensional requirements for roof and rock bolts and accessories. Addressed in this specification are double-end threaded and slotted steel bars; fully grouted bolts and threaded bars; mechanical anchorage devices used for point anchorage applications; roof truss systems; partially grouted deformed bolts; formable anchorage devices; and other frictional anchorage devices. All of these products represent various designs used for ground support systems. This specification can be revised to address new technologies.

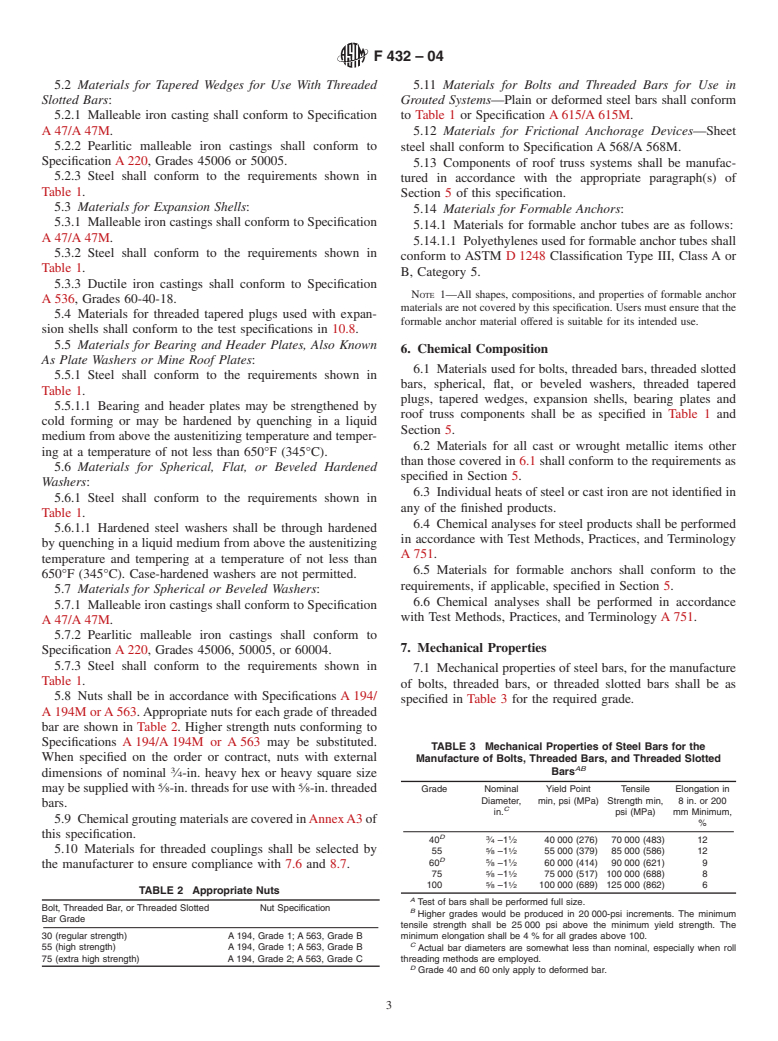

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This hazard statement applies only to Section 10, Test Methods of this specification. This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 432 – 04

Standard Specification for

1

Roof and Rock Bolts and Accessories

This standard is issued under the fixed designation F432; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* A568/A568M Specification for Steel, Sheet, Carbon, and

High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled,

1.1 This specification covers the chemical, mechanical, and

General Requirements for

dimensional requirements for roof and rock bolts and accesso-

A 615/A 615M Specification for Deformed and Plain

ries. Addressed in this specification are double-end threaded

Billet-Steel Bars for Concrete Reinforcement

and slotted steel bars; fully grouted bolts and threaded bars;

A 751 Test Methods, Practices, and Terminology for

mechanical anchorage devices used for point anchorage appli-

Chemical Analysis of Steel Products

cations; roof truss systems; partially grouted deformed bolts;

D1248 Specification for Polyethylene Plastics Extrusion

formable anchorage devices; and other frictional anchorage

Materials for Wire Cable

devices. All of these products represent various designs used

F436 Specification for Hardened Steel Washers

for ground support systems. This specification can be revised

F606 Test Methods for Determining the Mechanical Prop-

to address new technologies.

erties of Externally and Internally Threaded Fasteners,

1.2 Thevaluesstatedininch-poundunitsaretoberegarded

Washers, and Rivets

as the standard. The values given in parentheses are for

3

2.2 ASME Standards:

information only.

B1.1 Unified Screw Threads

1.3 This hazard statement applies only to Section 10, Test

B1.3M Screw Thread Gaging Systems for Dimensional

Methods of this specification. This standard does not purport

Acceptability—Inch and Metric Screw Threads

to address the safety concerns, if any, associated with its use.

B18.2.2 Square and Hex Nuts

It is the responsibility of the user of this standard to establish

appropriate safety and health practices and determine the

3. Terminology

applicability of regulatory limitations prior to use.

3.1 Definitions:

2. Referenced Documents 3.1.1 bearing plates, plate washers, mine roof plates—

2

plates that serve to distribute the load from the exposed end of

2.1 ASTM Standards:

the bolt or threaded bar to the rock face or intermediate

A29/A29M SpecificationforSteelBars,CarbonandAlloy,

member.

Hot-Wrought, General Requirements for

3.1.1.1 header plates—large rectangular bearing plates,

A47/A47M Specification for Ferritic Malleable Iron Cast-

usually 6 in. (152 mm) wide by 16 to 18 in. (406.4 to 457.2

ings

mm) long, or any other shape with an equivalent area, used in

A194/A194M Specification for Carbon and Alloy Steel

substitutionforwoodenheaderblocksforwiderdistributionof

Nuts for Bolts for High-Pressure or High-Temperature

the bolt load than is possible with standard bearing plates.

Service, or Both

3.1.2 bendable bolts—bolts furnished with an altered sec-

A220 Specification for Pearlitic Malleable Iron

tionatsomelocation,tobespecifiedbythecustomer,atwhich

A370 TestMethodsandDefinitionsforMechanicalTesting

the bar will bend.

of Steel Products

3.1.2.1 Discussion—Bending is necessary to permit instal-

A536 Specification for Ductile Iron Castings

lationofbarslongerthanthemineopeningheight.Thisaltered

A563 Specification for Carbon and Alloy Steel Nuts

sectionmaybeproducedbyhotorcoldforging,orbyshearing,

sawing, trimming, machining, grinding, or a combination of

these processes.

1

This specification is under the jurisdiction of ASTM Committee F16 on

3.1.3 beveledwashers—washerswhosefacesareatanangle

Fasteners and is the direct responsibility of Subcommittee F16.02 on Steel Bolts,

permitting a headed bolt or threaded bar to be installed at a

Nuts, Rivets, and Washers.

Current edition approved Aug. 1, 2004. Published August 2004. Originally slight angle to the rock face and yet maintained the face of the

approved in 1975. Last previous edition approved in 2001 as F432–95(2001).

bolt head perpendicular to the bolt axis.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from American Society of Mechanical Engineers (ASME), ASME

the ASTM website. International Headquarters, Three Park Ave., New York, NY 10016-5990.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 -------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.