ASTM D2842-12

(Test Method)Standard Test Method for Water Absorption of Rigid Cellular Plastics

Standard Test Method for Water Absorption of Rigid Cellular Plastics

SIGNIFICANCE AND USE

5.1 The purpose of this test method is to provide a means for comparing relative water absorption tendencies between different cellular plastics. It is intended for use in specifications, product evaluation, and quality control. It is applicable to specific end-use design requirements only to the extent that the end-use conditions are similar to the immersion period (normally 96 h) and 5.1-cm [2-in.] head requirements of the test method.Note 2—Studies by ASTM Subcommittee D20.22 show that some cellular plastics, particularly those with open cells or natural interstices, continue to absorb additional significant amounts of water beyond the 96-h immersion period. It was also found that water absorption of some cellular plastics is significantly higher when exposed to a greater pressure head, as might be encountered in certain underwater installations.

5.2 This test method provides a means for measuring absorption as a result of direct contact exposure to free water. Results by this test method cannot be used to compare the resistance of cellular plastics to water vapor transmission and subsequent condensation within the cells. To determine resistance to water vapor transmission, see Test Methods E96.

5.3 Water absorption testing is subject to several important variables, which if not considered, prohibit sufficient agreement among testing laboratories. Development of this test method has taken into account the most serious of the possible sources of error.Note 3—In some methods, an error is encountered due to a rapid absorption of water before an accurate initial weight can be obtained. This test method accounts for that potential error by providing Procedure A for use with materials that behave in this manner. In this procedure the only submerged measurement required is a final weighing taken after the 96-h immersion period.Note 4—The increase in volume that occurs with some foams when immersed is accounted for in Procedure A. This procedure shall be used for m...

SCOPE

1.1 This test method covers the determination of the water absorption of rigid cellular plastics by measuring the change in buoyant force resulting from immersion under a 5.1-cm (2-in.) head of water for the specified immersion period of 96 h.

1.2 This test method describes two procedures that shall be used to measure the change in buoyant force. Procedure A shall be used for materials that either experience rapid water absorption or that show an increase in volume during the exposure period, or both. Materials that do not exhibit either of these characteristics shall be evaluated by Procedure B.

1.3 For specific applications, immersion periods varying from the normal 96-h test requirement shall be agreed upon between the manufacturer and the purchaser.

1.4 The values stated in SI units are to be regarded as the standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2842 − 12

Standard Test Method for

1

Water Absorption of Rigid Cellular Plastics

This standard is issued under the fixed designation D2842; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 2.2 ISO Standard:

ISO2896 Cellular Plastics, Rigid—Determination of Water

1.1 This test method covers the determination of the water

3

Absorption

absorptionofrigidcellularplasticsbymeasuringthechangein

buoyant force resulting from immersion under a 5.1-cm (2-in.)

3. Terminology

head of water for the specified immersion period of 96 h.

3.1 Definitions—There are no terms in this test method that

1.2 This test method describes two procedures that shall be

are new or other than dictionary definitions.

usedtomeasurethechangeinbuoyantforce.ProcedureAshall

4. Summary of Test Method

be used for materials that either experience rapid water

absorption or that show an increase in volume during the

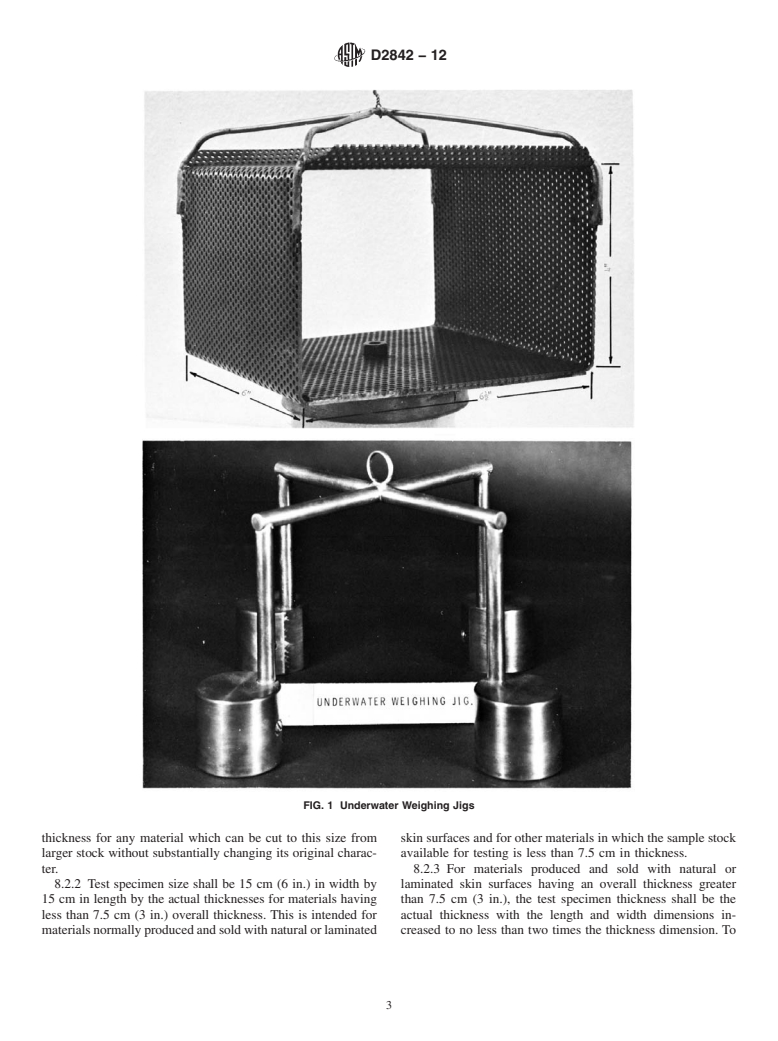

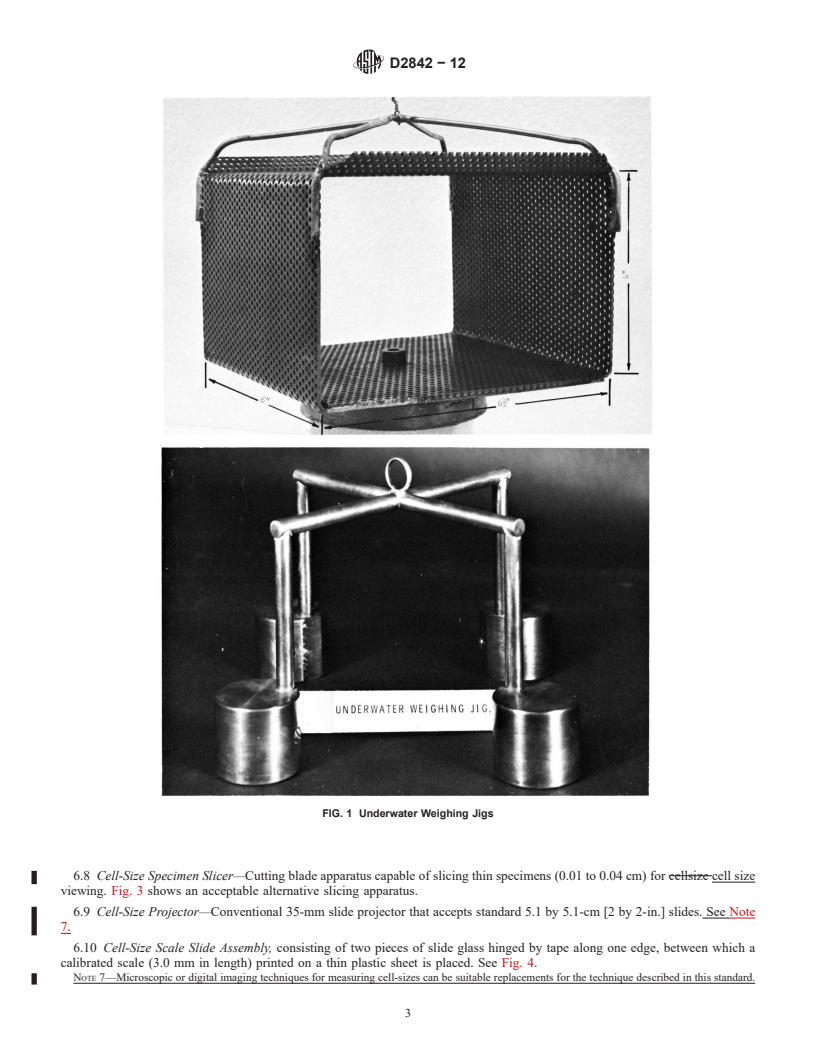

4.1 The buoyant force of an object less dense than water is

exposureperiod,orboth.Materialsthatdonotexhibiteitherof

equal to the weight of water it displaces when submerged, less

these characteristics shall be evaluated by Procedure B.

the dry weight of the object. Water absorbed into the object

lowers the buoyant force by increasing the weight of the

1.3 For specific applications, immersion periods varying

sample. By knowing the volume and initial dry weight of the

from the normal 96-h test requirement shall be agreed upon

sample,theinitialbuoyantforcecanbecalculatedortheinitial

between the manufacturer and the purchaser.

buoyant force can be determined by direct measurement. The

1.4 The values stated in SI units are to be regarded as the

final buoyant force at the end of the immersion period is

standard.

measured with an underwater weighing assembly. The differ-

encebetweentheinitialandfinalbuoyantforceistheweightof

1.5 This standard does not purport to address all of the

the water absorbed per unit of specimen volume.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Significance and Use

priate safety and health practices and determine the applica-

5.1 Thepurposeofthistestmethodistoprovideameansfor

bility of regulatory limitations prior to use.

comparing relative water absorption tendencies between dif-

NOTE 1—This test method is equivalent to ISO2896.

ferent cellular plastics. It is intended for use in specifications,

product evaluation, and quality control. It is applicable to

2. Referenced Documents

specificend-usedesignrequirementsonlytotheextentthatthe

2

2.1 ASTM Standards: end-use conditions are similar to the immersion period (nor-

E96Test Methods for Water Vapor Transmission of Materi- mally 96 h) and 5.1-cm (2-in.) head requirements of the test

als method.

E691Practice for Conducting an Interlaboratory Study to

NOTE 2—Studies by ASTM Subcommittee D20.22 show that some

Determine the Precision of a Test Method

cellular plastics, particularly those with open cells or natural interstices,

continue to absorb additional significant amounts of water beyond the

96-h immersion period. It was also found that water absorption of some

cellular plastics is significantly higher when exposed to a greater pressure

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

head, as might be encountered in certain underwater installations.

and is the direct responsibility of Subcommittee D20.22 on Cellular Materials -

5.2 This test method provides a means for measuring

Plastics and Elastomers.

Current edition approved Oct. 1, 2012. Published November 2012. Originally

absorption as a result of direct contact exposure to free water.

approved in 1969. Last previous edition approved in 2006 as D2842-06. DOI:

Results by this test method cannot be used to compare the

10.1520/D2842-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2842 − 12

resistance of cellular plastics to water vapor transmission and attachingt

...

Designation: D2842 − 06 D2842 − 12

Standard Test Method for

1

Water Absorption of Rigid Cellular Plastics

This standard is issued under the fixed designation D2842; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This test method covers the determination of the water absorption of rigid cellular plastics by measuring the change in

buoyant force resulting from immersion under a 5.1-cm (2-in.) head of water for the specified immersion period of 96 h.

1.2 This test method describes two procedures that shall be used to measure the change in buoyant force. Procedure A shall be

used for materials that either experience rapid water absorption or that show an increase in volume during the exposure period,

or both. Materials that do not exhibit either of these characteristics shall be evaluated by Procedure B.

1.3 For specific applications, immersion periods varying from the normal 96-h test requirement shall be agreed upon between

the manufacturer and the purchaser.

1.4 The values stated in SI units are to be regarded as the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

NOTE 1—This test method is equivalent to ISO 2896.

NOTE 1—This test method is equivalent to ISO 2896.

2. Referenced Documents

2

2.1 ASTM Standards:

E96/E96ME96 Test Methods for Water Vapor Transmission of Materials

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

2.2 ISO Standard:

3

ISO 2896 Cellular Plastics, Rigid—Determination of Water Absorption

3. Terminology

3.1 Definitions—There are no terms in this test method that are new or other than dictionary definitions.

3.1 Definitions—There are no terms in this test method that are new or other than dictionary definitions.

4. Summary of Test Method

4.1 The buoyant force of an object less dense than water is equal to the weight of water it displaces when submerged, less the

dry weight of the object. Water absorbed into the object lowers the buoyant force by increasing the weight of the sample. By

knowing the volume and initial dry weight of the sample, the initial buoyant force can be calculated or the initial buoyant force

can be determined by direct measurement. The final buoyant force at the end of the immersion period is measured with an

underwater weighing assembly. The difference between the initial and final buoyant force is the weight of the water absorbed per

unit of specimen volume.

5. Significance and Use

5.1 The purpose of this test method is to provide a means for comparing relative water absorption tendencies between different

cellular plastics. It is intended for use in specifications, product evaluation, and quality control. It is applicable to specific end-use

design requirements only to the extent that the end-use conditions are similar to the immersion period (normally 96 h) and 5.1-cm

[2-in.] head requirements of the test method.

NOTE 2—Studies by ASTM Subcommittee D20.22 show that some cellular plastics, particularly those with open cells or natural interstices, continue

to absorb additional significant amounts of water beyond the 96-h immersion period. It was also found that water absorption of some cellular plastics

is significantly higher when exposed to a greater pressure head, as might be encountered in certain underwater installations.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2842 − 12

5.2 This test method provides a means for measuring absorption as a result of direct contact exposure to free water. Results by

this test method cannot be used to compare the resistance of cellular plastics to water vapor transmission and subsequent

condensation within the cells. To determine resistance to water vapor transmission, see Test Methods E96/E96ME96.

5.3 Water absorption testing is subject to several important variables, which if not considered, prohibit sufficient agreement

among testing laboratories. Development of this test method has taken into account the most serious of the possible sources of

error.

NOTE 3—In some methods, an error is encountered due to a rapid absorption of water before an accurate initial weight can be obtained. This test method

accounts for that potential error by providing Procedure A for use with materials that behave in this manne

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.