ASTM D5617-04(2010)

(Test Method)Standard Test Method for Multi-Axial Tension Test for Geosynthetics

Standard Test Method for Multi-Axial Tension Test for Geosynthetics

SIGNIFICANCE AND USE

Installed geosynthetics are subjected to forces from more than one direction including forces perpendicular to the surfaces of the geosynthetic. Out of plane deformation of a geosynthetic may be useful in evaluating materials for caps where subsidence of the subsoil may be problematic.

Failure mechanisms on this test may be different compared to other relatively small scale index tests and may be beneficial for design purposes.

In applications where local subsidence is expected, this test can be considered a performance test.

Note 1—Although, this test specifies a vessel size of 600 mm, larger diameter vessels will better approximate field performance. However, the user is cautioned that different size vessels may yield different results and hence may not be comparable.

5.4 For applications where geosynthetics cannot be deformed in the fashion this test method prescribes, this test method should be considered an index test.

Due to the time involved to perform this test method, it is not considered practical as a quality control test.

SCOPE

1.1 This test method covers the measurement of the out-of-plane response of geosynthetics to a force that is applied perpendicular to the initial plane of the sample.

1.2 When the geosynthetic deforms to a prescribed geometric shape (arc of a sphere or ellipsoid) formulations are provided to convert the test data to biaxial tensile stress-strain values. These formulations cannot be used for other geometric shapes. With other geometric shapes, comparative data on deformation versus pressure is obtained.

1.3 This test method is more commonly used to test geomembranes. Permeable materials may also be tested in conjunction with an impermeable material.

1.4 This test method requires a large diameter pressure vessel (600 mm). Information obtained from this test method may be more appropriate for design purposes than many small scale index tests such as Test Method D6693 or Test Method D7003.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5617 − 04(Reapproved 2010)

Standard Test Method for

Multi-Axial Tension Test for Geosynthetics

This standard is issued under the fixed designation D5617; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Polypropylene Geomembranes

D7003Test Method for Strip Tensile Properties of Rein-

1.1 This test method covers the measurement of the out-of-

forced Geomembranes

plane response of geosynthetics to a force that is applied

perpendicular to the initial plane of the sample.

3. Terminology

1.2 When the geosynthetic deforms to a prescribed geomet-

3.1 Definitions:

ric shape (arc of a sphere or ellipsoid) formulations are

3.1.1 geosynthetic, n—planar product manufactured from

provided to convert the test data to biaxial tensile stress-strain

polymeric material used with soil, rock, earth, or other geo-

values. These formulations cannot be used for other geometric

technical engineering related material as an integral part of a

shapes. With other geometric shapes, comparative data on

man-made project, structure, or system.

deformation versus pressure is obtained.

3.1.2 multi-axial tension, n—stress in more than one direc-

1.3 This test method is more commonly used to test

tion.

geomembranes. Permeable materials may also be tested in

3.1.3 Fordefinitionsofothertermsusedinthistestmethod,

conjunction with an impermeable material.

refer to Terminology D4439.

1.4 This test method requires a large diameter pressure

vessel (600 mm). Information obtained from this test method

4. Summary of Test Method

may be more appropriate for design purposes than many small

4.1 Apre-cut geosynthetic sample is secured at the edges of

scale index tests such as Test Method D6693 or Test Method

a large diameter (600 mm) pressure vessel. Pressure is applied

D7003.

to the sample to cause out-of-plane deformation and failure.

1.5 The values stated in SI units are to be regarded as

This deformation with pressure information can then be

standard. No other units of measurement are included in this

analyzed to evaluate various materials.

standard.

5. Significance and Use

1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5.1 Installed geosynthetics are subjected to forces from

responsibility of the user of this standard to establish appro-

more than one direction including forces perpendicular to the

priate safety and health practices and determine the applica-

surfaces of the geosynthetic. Out of plane deformation of a

bility of regulatory limitations prior to use.

geosynthetic may be useful in evaluating materials for caps

where subsidence of the subsoil may be problematic.

2. Referenced Documents

5.2 Failure mechanisms on this test may be different com-

2.1 ASTM Standards:

pared to other relatively small scale index tests and may be

D4439Terminology for Geosynthetics

beneficial for design purposes.

D6693Test Method for Determining Tensile Properties of

5.3 In applications where local subsidence is expected, this

Nonreinforced Polyethylene and Nonreinforced Flexible

test can be considered a performance test.

NOTE 1—Although, this test specifies a vessel size of 600 mm, larger

1 diameter vessels will better approximate field performance. However, the

This test method is under the jurisdiction of ASTM Committee D35 on

user is cautioned that different size vessels may yield different results and

GeosyntheticsandisthedirectresponsibilityofSubcommitteeD35.10onGeomem-

hence may not be comparable.

branes.

Current edition approved March 1, 2010. Published April 2010. Originally

5.4 For applications where geosynthetics cannot be de-

approved in 1994. Last previous edition approved in 2004 as D5617–04. DOI:

formed in the fashion this test method prescribes, this test

10.1520/D5617-04R10.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or method should be considered an index test.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.5 Due to the time involved to perform this test method, it

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. is not considered practical as a quality control test.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5617 − 04 (2010)

plastic sheet has to overlay the permeable material to maintain

the pressure in the vessel during the test.

7.3.1 When testing permeable materials, the impermeable

material shall be more elastic than the permeable material

(unless the combination of the two materials is the desired test

variable). This is required so that the permeable material fails

first.

7.3.2 Testresultsonpermeablematerialswillbeaffectedby

the impermeable material used in the test.

7.4 Test three replicate specimens on each sample unless

otherwise noted.

8. Procedure

8.1 Cut the test specimen to the requirements of the test

vesseltoensureagoodseal.Placespecimenacrosstheopening

of the vessel. Be sure the specimen is not sagging.

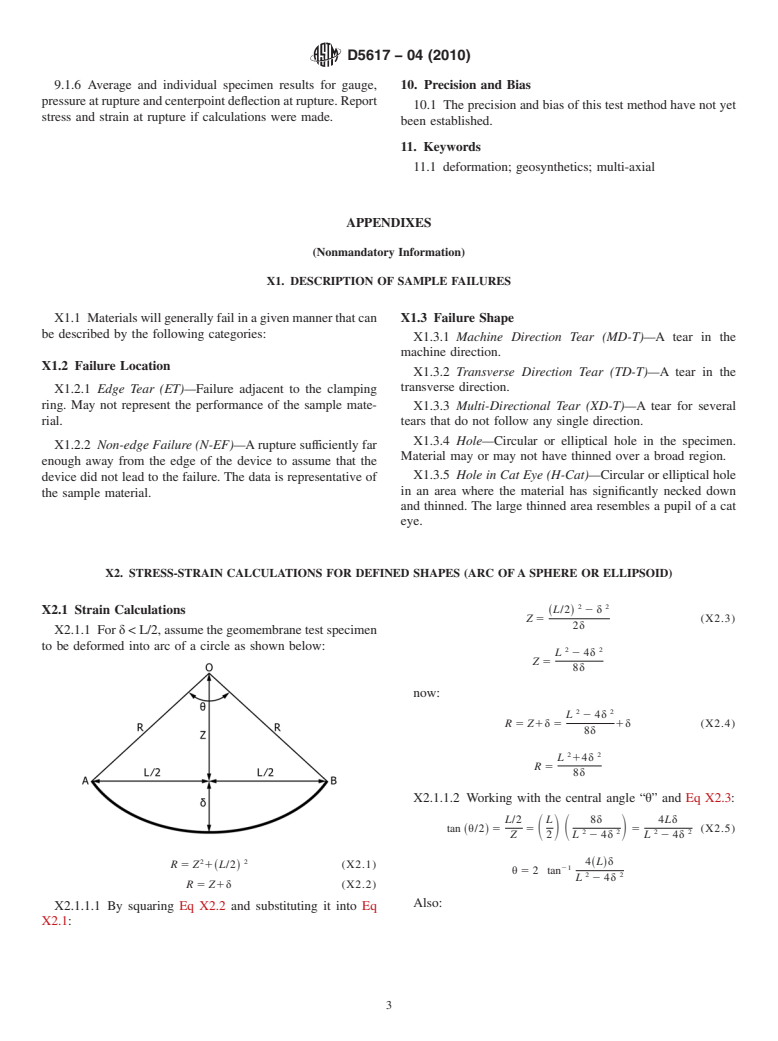

FIG. 1 Multi-Axial Burst Apparatus

8.2 Be sure the specimen remains flat while the edge of the

specimen is being securely clamped into place.

8.3 Either air or water can be used to pressurize the vessel.

6. Apparatus

If a water system is used, introduce water into the vessel until

6.1 Fig.1showsanexampleofthetestapparatusthatcanbe

it is completely filled.

used in the performance of this test method. The apparatus

8.4 Add water or air into the system so as to control the rate

requires a pressure vessel rated to a minimum of 690 kPa. The

3 ofcenterpointdeflectionat20mm/mininacontinuousfashion.

vessel diameter should be 600 mm. Other size vessels may be

8.4.1 Stepwise increments of center point deflection are not

used but it is up to the user to establish correlation to the

allowed.

standard size vessel.

8.5 Record the amount of centerpoint deflection and pres-

6.2 If the vessel has a deflection chamber it should not

sure at least every 10 s.

inhibit the geosynthetic from freely deflecting during the test.

The deflection chamber shall be vented.

8.6 Continue with the test by maintaining a constant rate of

6.2.1 Some materials will expand laterally beyond the centerpoint deflection at the specified rate until the specimen

diameterofthepressurevesselandmaycontactthesidesofthe

has ruptured (as noted by a sudden loss in pressure) or until

deflection chamber. In these cases, the test is no longer valid some predetermined end point has been reached.

andadifferentdevicemustbeused.Deviceswithoutdeflection

NOTE 2—The user is cautioned that the sudden release of pressure at

chambers have worked well in these situations.

rupture could potentially be dangerous and cause either personal injury or

damage to the surroundings.

6.3 The vessel will have a system to measure pressure

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.