ASTM D3982-08

(Specification)Standard Specification for Contact Molded “Fiberglass” (Glass Fiber Reinforced Thermosetting Resin) Ducts

Standard Specification for Contact Molded <span class='unicode'>“</span>Fiberglass<span class='unicode'>”</span> (Glass Fiber Reinforced Thermosetting Resin) Ducts

ABSTRACT

This specification covers the material and design requirements, and fabrication of ducts and hoods made of "fiberglass" (glass fiber reinforced thermosetting resin) consisting of a polyester, vinyl ester, or other qualified resin-matrix systems with fiber reinforcement manufactured by contact molding, intended for use in handling corrosive fumes and process gases. Special attention is given to equipment that operates at specified temperatures with regard to strength and corrosion resistance. This specification does not address the selection of resins and reinforcements for specific chemical environments.

SCOPE

1.1 This specification covers ducts fabricated by contact molding intended for use in handling corrosive fumes and process gases. Special attention is given to equipment that operates at temperatures over 180°F (82.2°C) with regard to strength and corrosion resistance.

1.2 The material of construction shall be “fiberglass” consisting of a polyester, vinyl ester, or other qualified resin-matrix systems with fiber reinforcement in accordance with Specification C 582.

1.3 This specification is not intended to cover selection of resins and reinforcements for specific chemical environments.

1.4 This specification covers ducts up to a design pressure of ±5 psig (34.5 Pa).

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—There is no known ISO equivalent to this standard..

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3982 −08 AnAmerican National Standard

Standard Specification for

Contact Molded “Fiberglass” (Glass Fiber Reinforced

1

Thermosetting Resin) Ducts

This standard is issued under the fixed designation D3982; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope setting Plastic (RTP) Laminates for Corrosion-Resistant

Equipment

1.1 This specification covers ducts fabricated by contact

D883 Terminology Relating to Plastics

molding intended for use in handling corrosive fumes and

D2583 Test Method for Indentation Hardness of Rigid Plas-

process gases. Special attention is given to equipment that

tics by Means of a Barcol Impressor

operates at temperatures over 180°F (82.2°C) with regard to

D2584 Test Method for Ignition Loss of Cured Reinforced

strength and corrosion resistance.

Resins

1.2 The material of construction shall be “fiberglass” con-

F412 Terminology Relating to Plastic Piping Systems

sistingofapolyester,vinylester,orotherqualifiedresin-matrix

F436 Specification for Hardened Steel Washers

systems with fiber reinforcement in accordance with Specifi-

2.2 NFPA Standard:

cation C582.

NFPA 91 Installation of Blower and Exhaust Systems for

3

1.3 This specification is not intended to cover selection of

Duct, Stack and Vapor Removal or Conveying

resins and reinforcements for specific chemical environments.

3. Terminology

1.4 This specification covers ducts up to a design pressure

of 65 psig (34.5 Pa).

3.1 Definitions:

3.1.1 The definitions used in this specification are in accor-

1.5 The values stated in inch-pound units are to be regarded

dancewithdefinitionsinTerminologiesD883andF412,unless

as standard. The values given in parentheses are mathematical

otherwise specified.

conversions to SI units that are provided for information only

3.2 Definitions of Terms Specific to This Standard:

and are not considered standard.

3.2.1 calculated thickness—this description is in accordance

1.6 This standard does not purport to address all of the

with the standard laminate composition tables for Types I and

safety concerns, if any, associated with its use. It is the

II in Specification C582.

responsibility of the user of this standard to establish appro-

3.2.2 contact molding—includes the “hand layup” and the

priate safety and health practices and determine the applica-

“spray up” methods of manufacture.

bility of regulatory limitations prior to use.

NOTE 1—There is no known ISO equivalent to this standard.

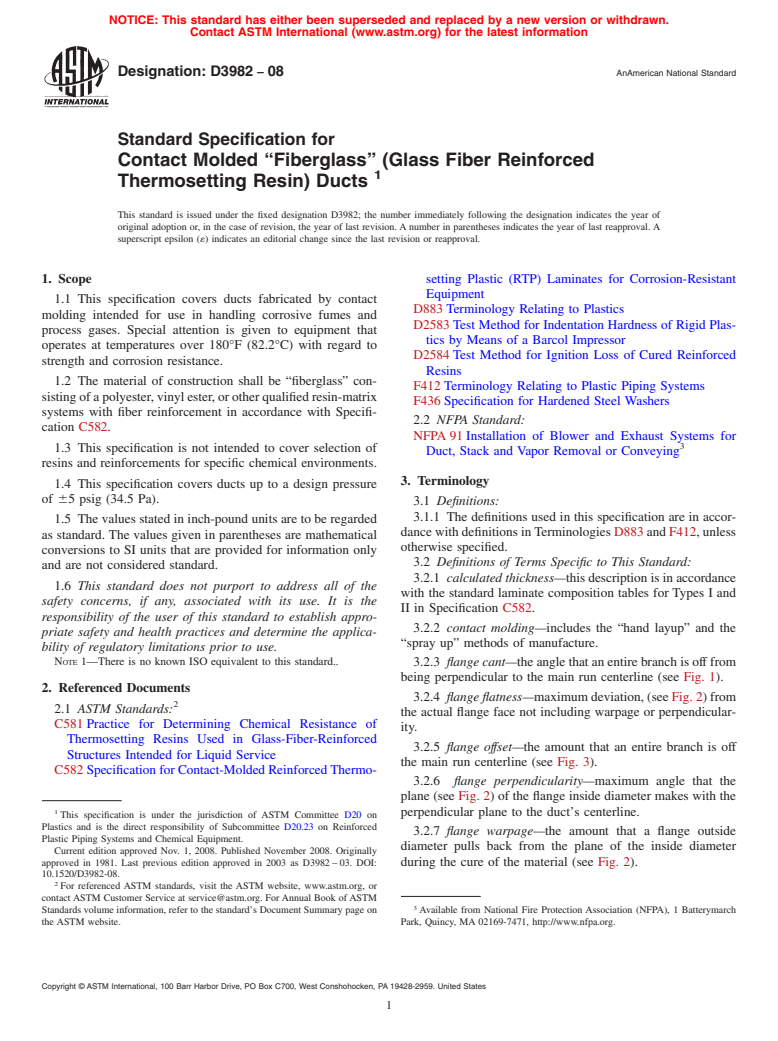

3.2.3 flange cant—the angle that an entire branch is off from

being perpendicular to the main run centerline (see Fig. 1).

2. Referenced Documents

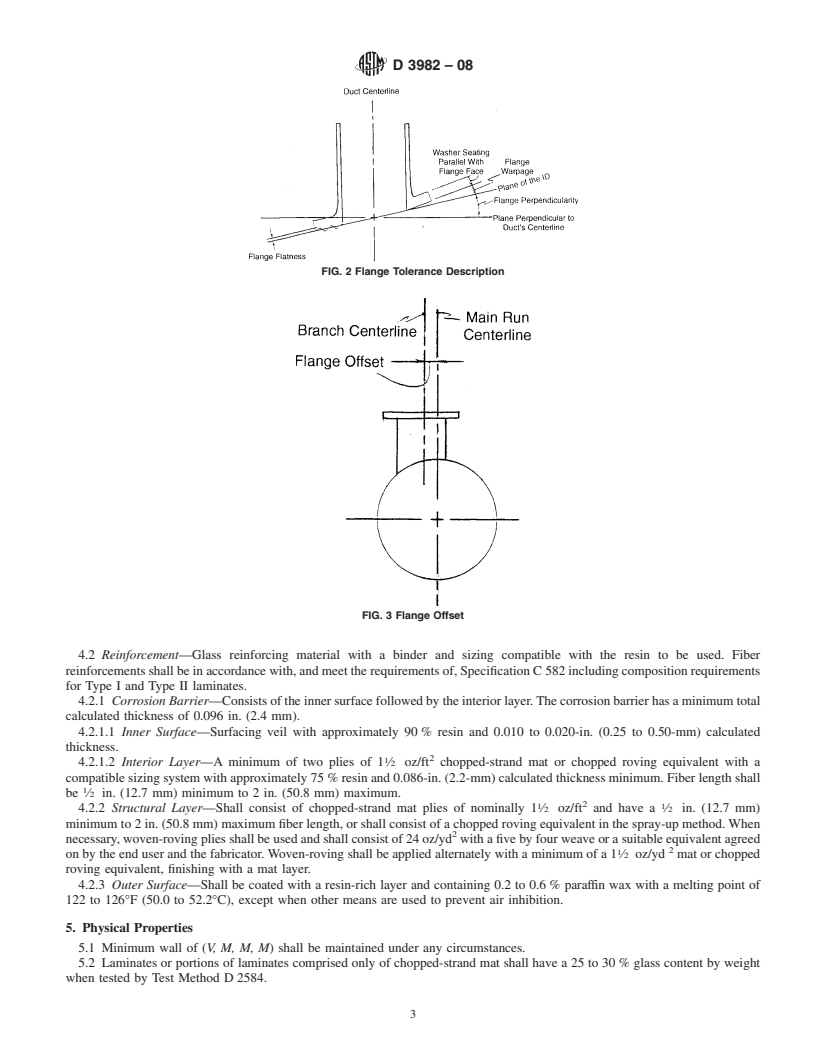

3.2.4 flange flatness—maximumdeviation,(seeFig.2)from

2

2.1 ASTM Standards:

the actual flange face not including warpage or perpendicular-

C581 Practice for Determining Chemical Resistance of

ity.

Thermosetting Resins Used in Glass-Fiber-Reinforced

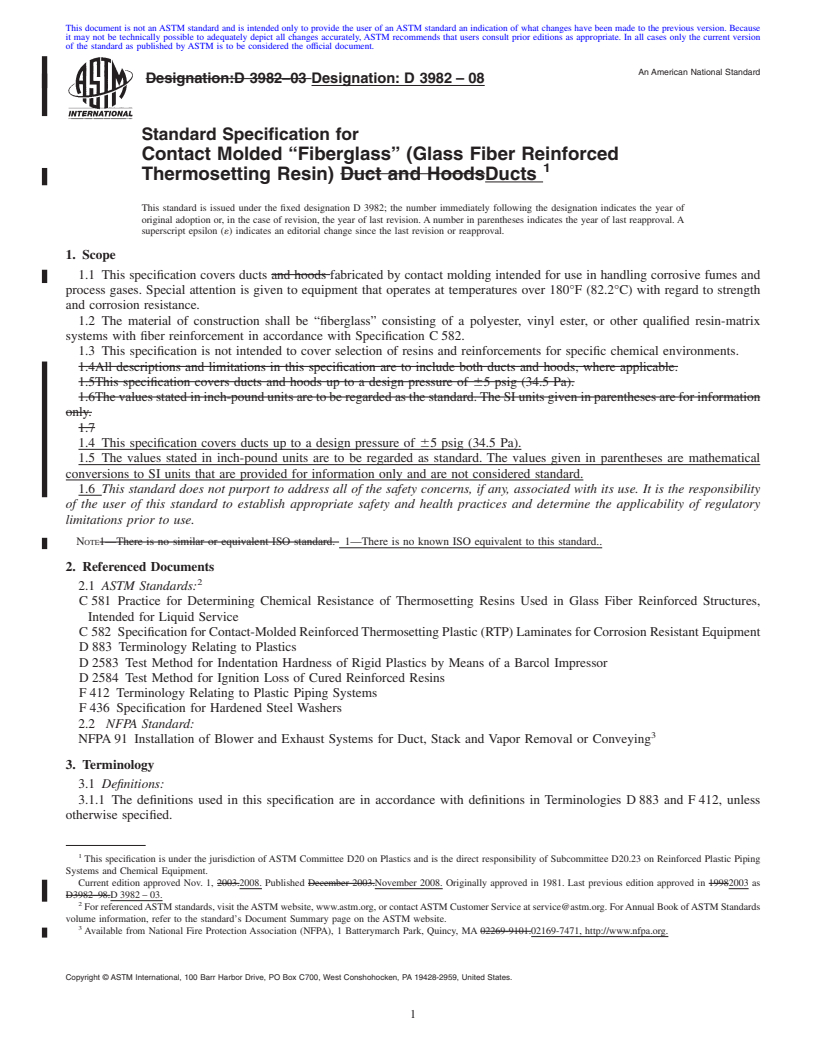

3.2.5 flange offset—the amount that an entire branch is off

Structures Intended for Liquid Service

the main run centerline (see Fig. 3).

C582 Specification for Contact-Molded ReinforcedThermo-

3.2.6 flange perpendicularity—maximum angle that the

plane (see Fig. 2) of the flange inside diameter makes with the

1

perpendicular plane to the duct’s centerline.

This specification is under the jurisdiction of ASTM Committee D20 on

Plastics and is the direct responsibility of Subcommittee D20.23 on Reinforced

3.2.7 flange warpage—the amount that a flange outside

Plastic Piping Systems and Chemical Equipment.

diameter pulls back from the plane of the inside diameter

Current edition approved Nov. 1, 2008. Published November 2008. Originally

approved in 1981. Last previous edition approved in 2003 as D3982 – 03. DOI: during the cure of the material (see Fig. 2).

10.1520/D3982-08.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contactASTM Customer Service at service@astm.org. ForAnnual Book ofASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from National Fire Protection Association (NFPA), 1 Batterymarch

the ASTM website. Park, Quincy, MA 02169-7471, http://www.nfpa.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3982−08

FIG. 1 Flange Cant

FIG. 3Flange Offset

conditions. Where service conditions have not been evaluated

a suitable resin may be selected by agreement between the

manufacturer and the end user.

4.1.1 The resin may contain fillers or pigments in accor-

dance with Specification C582.

4.1.2 Athixotropic agent may be added up to 5 % by

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:D 3982–03 Designation: D 3982 – 08

Standard Specification for

Contact Molded “Fiberglass” (Glass Fiber Reinforced

1

Thermosetting Resin) Duct and HoodsDucts

This standard is issued under the fixed designation D 3982; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers ducts and hoods fabricated by contact molding intended for use in handling corrosive fumes and

process gases. Special attention is given to equipment that operates at temperatures over 180°F (82.2°C) with regard to strength

and corrosion resistance.

1.2 The material of construction shall be “fiberglass” consisting of a polyester, vinyl ester, or other qualified resin-matrix

systems with fiber reinforcement in accordance with Specification C 582.

1.3 This specification is not intended to cover selection of resins and reinforcements for specific chemical environments.

1.4All descriptions and limitations in this specification are to include both ducts and hoods, where applicable.

1.5This specification covers ducts and hoods up to a design pressure of 65 psig (34.5 Pa).

1.6The values stated in inch-pound units are to be regarded as the standard.The SI units given in parentheses are for information

only.

1.7

1.4 This specification covers ducts up to a design pressure of 65 psig (34.5 Pa).

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

NOTE1—There is no similar or equivalent ISO standard. 1—There is no known ISO equivalent to this standard.

2. Referenced Documents

2

2.1 ASTM Standards:

C 581 Practice for Determining Chemical Resistance of Thermosetting Resins Used in Glass Fiber Reinforced Structures,

Intended for Liquid Service

C 582 SpecificationforContact-MoldedReinforcedThermosettingPlastic(RTP)LaminatesforCorrosionResistantEquipment

D 883 Terminology Relating to Plastics

D 2583 Test Method for Indentation Hardness of Rigid Plastics by Means of a Barcol Impressor

D 2584 Test Method for Ignition Loss of Cured Reinforced Resins

F 412 Terminology Relating to Plastic Piping Systems

F 436 Specification for Hardened Steel Washers

2.2 NFPA Standard:

3

NFPA 91 Installation of Blower and Exhaust Systems for Duct, Stack and Vapor Removal or Conveying

3. Terminology

3.1 Definitions:

3.1.1 The definitions used in this specification are in accordance with definitions in Terminologies D 883 and F 412, unless

otherwise specified.

1

This specification is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.23 on Reinforced Plastic Piping

Systems and Chemical Equipment.

Current edition approved Nov. 1, 2003.2008. Published December 2003.November 2008. Originally approved in 1981. Last previous edition approved in 19982003 as

D3982–98.D 3982 – 03.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from National Fire Protection Association (NFPA), 1 Batterymarch Park, Quincy, MA 02269-9101.02169-7471, http://www.nfpa.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 3982 – 08

3.2 Definitions of Terms Specific to This Standard:

3.2.1 calculated thickness—this description is in accordance with the standard laminate composition tables for Types I and II

in Specification C 582.

3.2.2 contact molding—includes the “hand layup” and the “spray up” methods of manufacture.

3.2.3 flange cant—the angle that an entire branch is off from being perpendicular to the main run centerline (see Fig. 1).

3.2.4 flange flatness—maximum deviation, (see Fig. 2) from the actual flange face not including warpage or perpendicularity.

3.2.5 fl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.