ASTM A500/A500M-10a

(Specification)Standard Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes

Standard Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes

ABSTRACT

This specification covers cold-formed welded and seamless carbon steel round, square, rectangular, or special shape structural tubing for welded, riveted, or bolted construction of bridges and buildings, and for general structural purposes. This tubing shall be produced in both welded and seamless sizes and must have the chemical requirements of carbon, manganese, phosphorus, sulfur, and copper. The steel shall be produced by either open-hearth, basic-oxygen, or electric-furnace melting process. When steels of different grades are sequentially strand cast, the steel producer shall identify the resultant transition material and remove it using an established procedure that positively separates the grades. The tubing shall then be made by a seamless or welding process. Welded tubing shall be made from flat-rolled steel by the electric-resistance-welding process. The longitudinal butt joint of welded tubing shall be welded across its thickness in such a manner that the structural design strength of the tubing section is assured. Tension test and flattening test shall be conducted to the specimens. All tubing shall be inspected at the place of manufacture to ensure conformance to the requirements of this specification and must have a workmanlike finish that is free from defects.

SCOPE

1.1 This specification covers cold-formed welded and seamless carbon steel round, square, rectangular, or special shape structural tubing for welded, riveted, or bolted construction of bridges and buildings, and for general structural purposes.

1.2 This tubing is produced in both welded and seamless sizes with a periphery of 88 in. [2235 mm] or less, and a specified wall thickness of 0.875 in. [22 mm] or less. Grade D requires heat treatment.

Note 1—Products manufactured to this specification may not be suitable for those applications such as dynamically loaded elements in welded structures, etc., where low-temperature notch-toughness properties may be important.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard. The inch-pound units shall apply unless the “M” designation of this specification is specified in the order.

1.4 The text of this specification contains notes and footnotes that provide explanatory material. Such notes and footnotes, excluding those in tables and figures, do not contain any mandatory requirements.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A500/A500M −10a

StandardSpecification for

Cold-Formed Welded and Seamless Carbon Steel Structural

1

Tubing in Rounds and Shapes

This standard is issued under the fixed designationA500/A500M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* A700 Practices for Packaging, Marking, and Loading Meth-

ods for Steel Products for Shipment

1.1 Thisspecificationcoverscold-formedweldedandseam-

A751 Test Methods, Practices, and Terminology for Chemi-

less carbon steel round, square, rectangular, or special shape

cal Analysis of Steel Products

structural tubing for welded, riveted, or bolted construction of

A941 TerminologyRelatingtoSteel,StainlessSteel,Related

bridges and buildings, and for general structural purposes.

Alloys, and Ferroalloys

1.2 This tubing is produced in both welded and seamless

2.2 Military Standards:

sizes with a periphery of 88 in. [2235 mm] or less, and a 3

MIL-STD-129 Marking for Shipment and Storage

specified wall thickness of 0.875 in. [22 mm] or less. Grade D

MIL-STD-163 Steel Mill Products, Preparation for Ship-

requires heat treatment. 3

ment and Storage

NOTE 1—Products manufactured to this specification may not be

2.3 Federal Standards:

3

suitable for those applications such as dynamically loaded elements in

Fed. Std. No. 123 Marking for Shipment

weldedstructures,etc.,wherelow-temperaturenotch-toughnessproperties

Fed.Std.No.183 ContinuousIdentificationMarkingofIron

may be important.

3

and Steel Products

1.3 The values stated in either SI units or inch-pound units

2.4 AIAG Standard:

are to be regarded separately as standard. Within the text, the 4

B-1 Bar Code Symbology Standard

SI units are shown in brackets. The values stated in each

system may not be exact equivalents; therefore, each system

3. Terminology

shall be used independently of the other. Combining values

3.1 Definitions—For definitions of terms used in this

from the two systems may result in non-conformance with the

specification, refer to Terminology A941.

standard. The inch-pound units shall apply unless the “M”

designation of this specification is specified in the order.

4. Ordering Information

1.4 The text of this specification contains notes and foot-

4.1 Orders for material under this specification shall contain

notes that provide explanatory material. Such notes and

information concerning as many of the following items as are

footnotes, excluding those in tables and figures, do not contain

required to describe the desired material adequately:

any mandatory requirements.

4.1.1 Quantity (feet [metres] or number of lengths),

4.1.2 Name of material (cold-formed tubing),

2. Referenced Documents

4.1.3 Method of manufacture (seamless or welded),

2

2.1 ASTM Standards:

4.1.4 Grade (A, B, C, or D),

A370 Test Methods and Definitions for Mechanical Testing

4.1.5 Size (outside diameter and wall thickness for round

of Steel Products

tubing, and outside dimensions and wall thickness for square

and rectangular tubing),

4.1.6 Copper-containing steel (see Table 1), if applicable,

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

4.1.7 Length (random, multiple, specific; see 11.3),

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

4.1.8 End condition (see 16.3),

A01.09 on Carbon Steel Tubular Products.

4.1.9 Burr removal (see 16.3),

Current edition approved Oct. 1, 2010. Published November 2010. Originally

approved in 1964. Last previous edition approved in 2010 as A500/A500M–10.

DOI: 10.1520/A0500_A0500M-10a.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

4

Standards volume information, refer to the standard’s Document Summary page on Available fromAutomotive IndustryAction Group (AIAG), 26200 Lahser Rd.,

the ASTM website. Suite 200, Southfield, MI 48033, http://www.aiag.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A500/A500M−10a

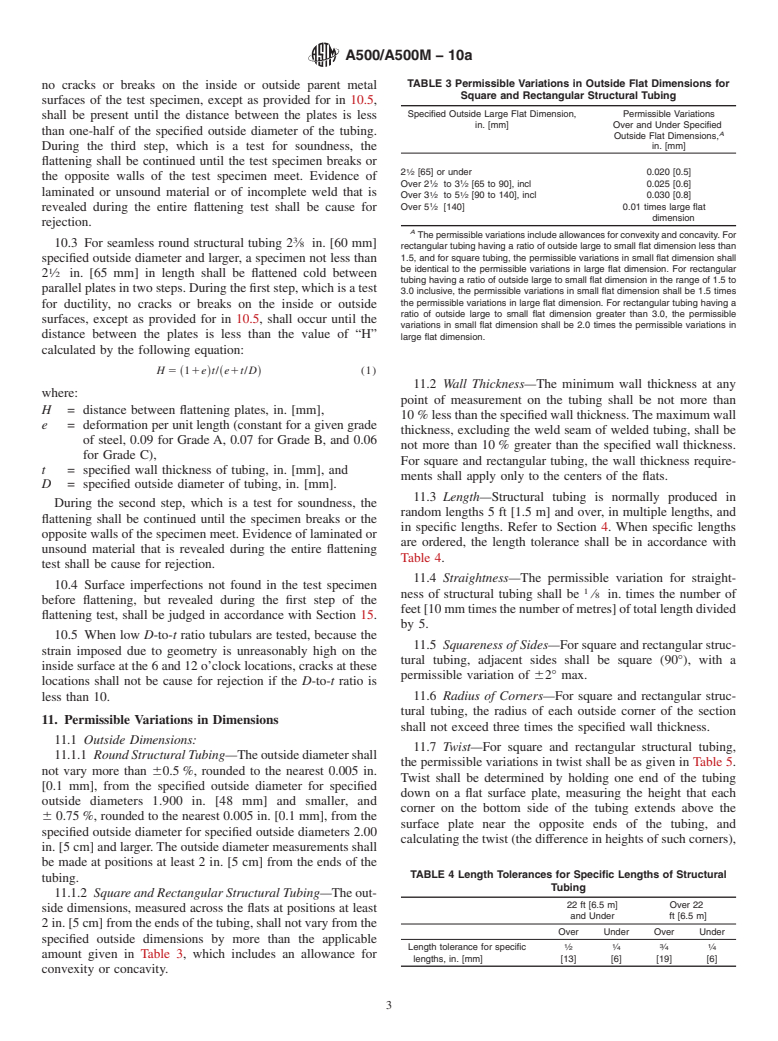

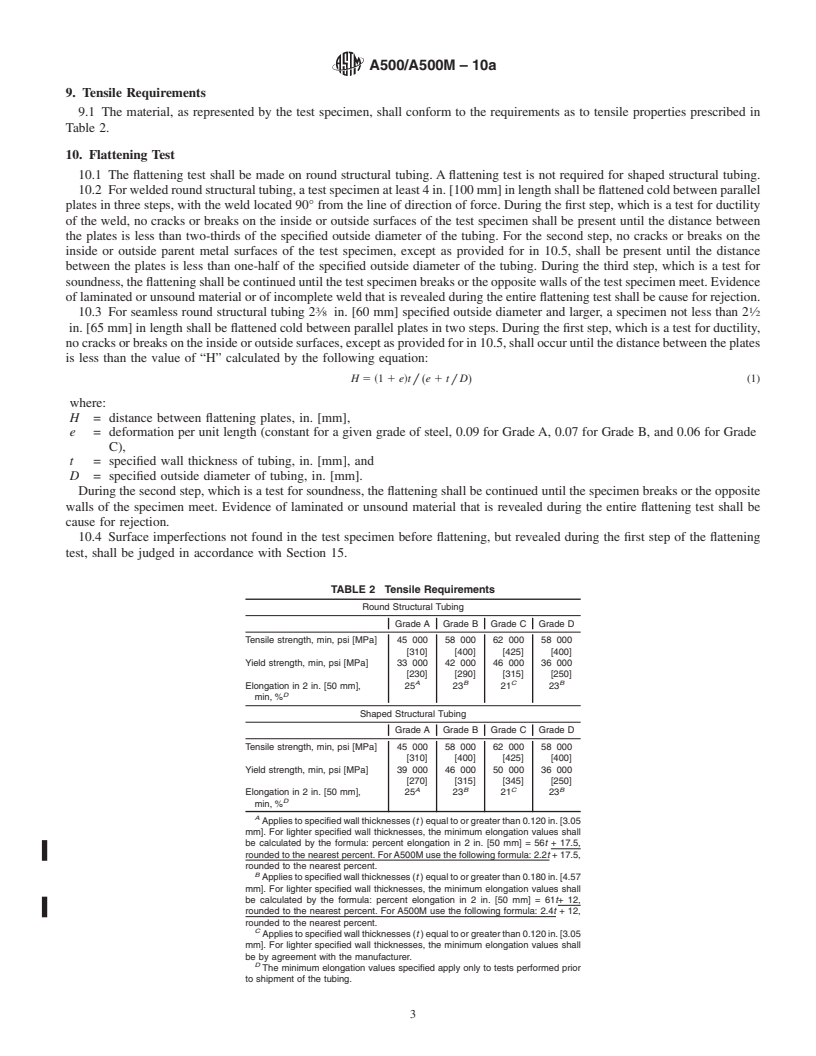

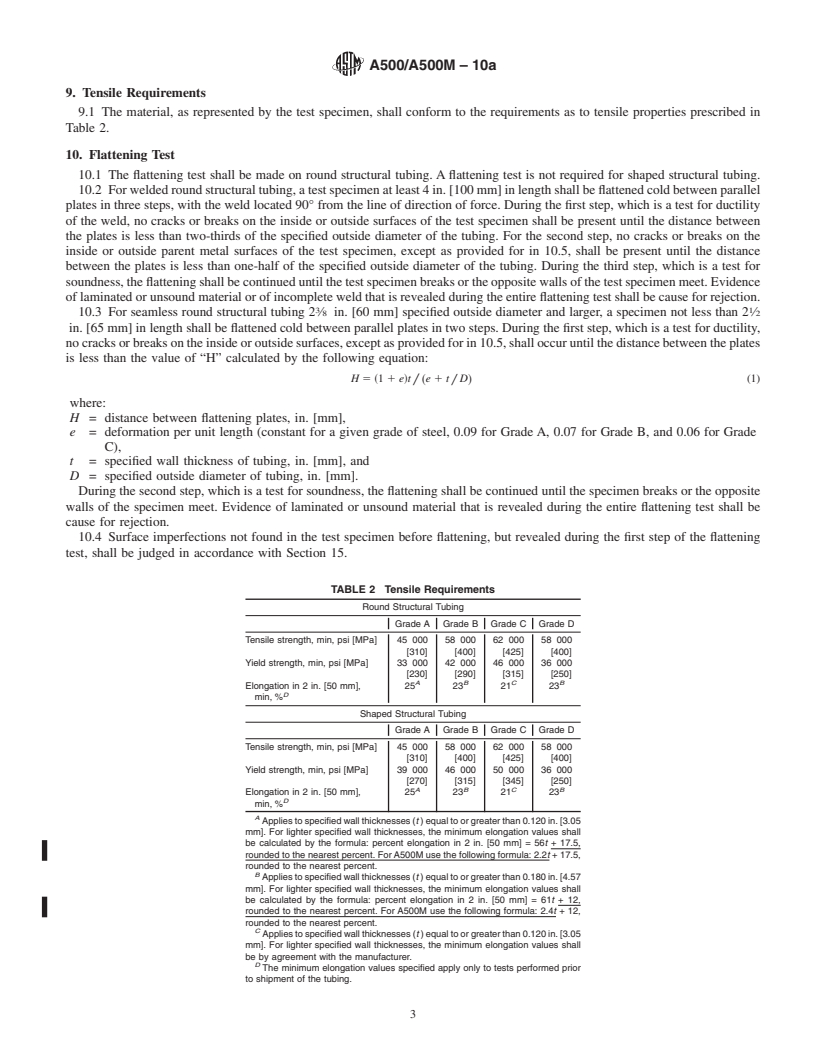

TABLE 1 Chemical Requirements

stock from each lot of a corresponding quantity of flat-rolled

Composition, % stock.Methodsandpracticesrelatingtochemicalanalysisshall

Grades A, B, and Grade C be in accordance with Test Methods, Practices, an

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A500/A500M–10 Designation: A500/A500M – 10a

Standard Specification for

Cold-Formed Welded and Seamless Carbon Steel Structural

1

Tubing in Rounds and Shapes

This standard is issued under the fixed designationA500/A500M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This specification covers cold-formed welded and seamless carbon steel round, square, rectangular, or special shape

structural tubing for welded, riveted, or bolted construction of bridges and buildings, and for general structural purposes.

1.2 This tubing is produced in both welded and seamless sizes with a periphery of 88 in. [2235 mm] or less, and a specified

wall thickness of 0.875 in. [22 mm] or less. Grade D requires heat treatment.

NOTE 1—Products manufactured to this specification may not be suitable for those applications such as dynamically loaded elements in welded

structures, etc., where low-temperature notch-toughness properties may be important.

1.3 ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Withinthetext,theSIunits

are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used

independently of the other. Combining values from the two systems may result in non-conformance with the standard. The

inch-pound units shall apply unless the “M” designation of this specification is specified in the order.

1.4 The text of this specification contains notes and footnotes that provide explanatory material. Such notes and footnotes,

excluding those in tables and figures, do not contain any mandatory requirements.

2. Referenced Documents

2

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A700 Practices for Packaging, Marking, and Loading Methods for Steel Products for Shipment

A751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

A941 Terminology Relating to Steel, Stainless Steel, Related Alloys, and Ferroalloys

2.2 Military Standards:

3

MIL-STD-129 Marking for Shipment and Storage

3

MIL-STD-163 Steel Mill Products, Preparation for Shipment and Storage

2.3 Federal Standards:

3

Fed. Std. No. 123 Marking for Shipment

3

Fed. Std. No. 183 Continuous Identification Marking of Iron and Steel Products

2.4 AIAG Standard:

4

B-1 Bar Code Symbology Standard

3. Terminology

3.1 Definitions—For definitions of terms used in this specification, refer to Terminology A941.

4. Ordering Information

4.1 Orders for material under this specification shall contain information concerning as many of the following items as are

required to describe the desired material adequately:

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel and RelatedAlloys and is the direct responsibility of SubcommitteeA01.09

on Carbon Steel Tubular Products.

Current edition approved AprilOct. 1, 2010. Published MayNovember 2010. Originally approved in 1964. Last previous edition approved in 20092010 as

A500/A500M–109. DOI: 10.1520/A0500_A0500M-10a.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700 Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

4

Available from Automotive Industry Action Group (AIAG), 26200 Lahser Rd., Suite 200, Southfield, MI 48033, http://www.aiag.org.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A500/A500M – 10a

4.1.1 Quantity (feet [metres] or number of lengths),

4.1.2 Name of material (cold-formed tubing),

4.1.3 Method of manufacture (seamless or welded),

4.1.4 Grade (A, B, C, or D),

4.1.5 Size (outside diameter and wall thickness for round tubing, and outside dimensions and wall thickness for square and

rectangular tubing),

4.1.6 Copper-containing steel (see Table 1), if applicable,

4.1.7 Length (random, multiple

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A500/A500M–10 Designation: A500/A500M – 10a

Standard Specification for

Cold-Formed Welded and Seamless Carbon Steel Structural

1

Tubing in Rounds and Shapes

This standard is issued under the fixed designationA500/A500M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This specification covers cold-formed welded and seamless carbon steel round, square, rectangular, or special shape

structural tubing for welded, riveted, or bolted construction of bridges and buildings, and for general structural purposes.

1.2 This tubing is produced in both welded and seamless sizes with a periphery of 88 in. [2235 mm] or less, and a specified

wall thickness of 0.875 in. [22 mm] or less. Grade D requires heat treatment.

NOTE 1—Products manufactured to this specification may not be suitable for those applications such as dynamically loaded elements in welded

structures, etc., where low-temperature notch-toughness properties may be important.

1.3 ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Withinthetext,theSIunits

are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used

independently of the other. Combining values from the two systems may result in non-conformance with the standard. The

inch-pound units shall apply unless the “M” designation of this specification is specified in the order.

1.4 The text of this specification contains notes and footnotes that provide explanatory material. Such notes and footnotes,

excluding those in tables and figures, do not contain any mandatory requirements.

2. Referenced Documents

2

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A700 Practices for Packaging, Marking, and Loading Methods for Steel Products for Shipment

A751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

A941 Terminology Relating to Steel, Stainless Steel, Related Alloys, and Ferroalloys

2.2 Military Standards:

3

MIL-STD-129 Marking for Shipment and Storage

3

MIL-STD-163 Steel Mill Products, Preparation for Shipment and Storage

2.3 Federal Standards:

3

Fed. Std. No. 123 Marking for Shipment

3

Fed. Std. No. 183 Continuous Identification Marking of Iron and Steel Products

2.4 AIAG Standard:

4

B-1 Bar Code Symbology Standard

3. Terminology

3.1 Definitions—For definitions of terms used in this specification, refer to Terminology A941.

4. Ordering Information

4.1 Orders for material under this specification shall contain information concerning as many of the following items as are

required to describe the desired material adequately:

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel and RelatedAlloys and is the direct responsibility of SubcommitteeA01.09

on Carbon Steel Tubular Products.

Current edition approved AprilOct. 1, 2010. Published MayNovember 2010. Originally approved in 1964. Last previous edition approved in 20092010 as

A500/A500M–109. DOI: 10.1520/A0500_A0500M-10a.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700 Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

4

Available from Automotive Industry Action Group (AIAG), 26200 Lahser Rd., Suite 200, Southfield, MI 48033, http://www.aiag.org.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A500/A500M – 10a

4.1.1 Quantity (feet [metres] or number of lengths),

4.1.2 Name of material (cold-formed tubing),

4.1.3 Method of manufacture (seamless or welded),

4.1.4 Grade (A, B, C, or D),

4.1.5 Size (outside diameter and wall thickness for round tubing, and outside dimensions and wall thickness for square and

rectangular tubing),

4.1.6 Copper-containing steel (see Table 1), if applicable,

4.1.7 Length (random, multiple

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.