ASTM F1948-99a

(Specification)Standard Specification for Metallic Mechanical Fittings for Use on Outside Diameter Controlled Thermoplastic Gas Distribution Pipe and Tubing

Standard Specification for Metallic Mechanical Fittings for Use on Outside Diameter Controlled Thermoplastic Gas Distribution Pipe and Tubing

SCOPE

1.1 This specification describes requirements and test methods for the qualification of metallic mechanical fittings for use with outside diameter controlled thermoplastic gas distribution pipe and tubing as specified in Specification D 2513.

1.2 The test methods described in this specification are not intended to be routine quality control tests.

1.3 This specification covers the types of mechanical fittings described in 3.2.1.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for informational purposes only.

1.5 The following safety hazards caveat pertains only to the test method portion, Section 7, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.6 The text of this standard references notes and footnotes, which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of this specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1948 – 99a

Standard Specification for

Metallic Mechanical Fittings for Use on Outside Diameter

Controlled Thermoplastic Gas Distribution Pipe and Tubing

This standard is issued under the fixed designation F 1948; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ASME Standard:

ASME B 31.8 Gas Transmission and Distribution Piping

1.1 This specification covers requirements and test methods

Systems

for the qualification of metallic mechanical fittings for use with

2.3 Federal Specification:

outside diameter controlled thermoplastic gas distribution pipe

OPS Part 192 Title 49, Code of Federal Regulations

and tubing as specified in Specification D 2513.

2.4 Other Document:

1.2 The test methods described are not intended to be

PPI TR-4 Recommended Hydrostatic Strengths and Design

routine quality control tests.

Stresses for Thermoplastic Pipe and Fitting Compounds

1.3 This specification covers the types of mechanical fittings

described in 3.3.

3. Terminology

1.4 The values stated in inch-pound units are to be regarded

3.1 Definitions are in accordance with Definitions F 412

as standard. The values given in parentheses are mathematical

unless otherwise specified. Abbreviations are in accordance

conversions to SI units which are provided for information

with Abbreviations D 1600 unless otherwise specified.

only and not considered standard.

3.1.1 The gas industry terminology used in this specification

1.5 The following safety hazards caveat pertains only to the

is in accordance with ASME/ANSI B31.8 or United States

test method portion, Section 7, of this specification. This

CFR 49 Part 192 unless otherwise indicated.

standard may involve hazardous material, operations and

3.1.2 The term “pipe” used herein refers to both pipe and

equipment. This standard does not purport to address all of the

tubing unless specifically stated otherwise. The term “fitting”

safety concerns, if any, associated with its use. It is the

refers to a mechanical connecting device as described in 3.2.5

responsibility of the user of this standard to establish appro-

and 3.2.7.

priate safety and health practices and determine the applica-

3.2 Definitions:

bility of regulatory limitations prior to use.

3.2.1 Category 1 mechanical fitting, n—fitting for assem-

1.6 The text of this standard references notes and footnotes

bling pipe, which includes a compression zone(s) to provide

which provide explanatory material. These notes and footnotes

for pressure integrity, leak tightness, and resistance to end

(excluding those in tables and figures), shall not be considered

loads sufficient to cause no less than 25 % elongation of the

as requirements of the standard.

piping, as described in this standard.

2. Referenced Documents 3.2.2 Category 2 mechanical fitting, n—fitting for assem-

bling pipe, which includes a compression zone(s) to provide

2.1 ASTM Standards:

for pressure integrity and leak tightness; Category 2 fittings do

D 638 Test Method for Tensile Property of Plastics

not provide for resistance to end loads.

D 1598 Test Methods for Time-To-Failure of Plastic Pipe

3.2.3 Category 3 mechanical fitting, n—fitting for assem-

Under Constant Internal Pressure

2 bling pipe, which includes a compression zone(s) for pressure

D 1600 Abbreviations of Terms Relating to Plastics

integrity, leak tightness, and resistance to end loads; the

D 2513 Specification for Thermoplastic Gas Pressure Pipe,

3 nominal size of the fitting shall be 4 and larger in diameter.

Tubing and Fittings

3.2.3.1 Discussion—Resistance to end loads shall be equal

D 2837 Method for Obtaining Hydrostatic Design Basis for

3 to or greater than the maximum thermal stress that would be

Thermoplastic Pipe Materials

produced by a temperature change of 100°F (55°C) (for

F 412 Definitions of Terms Relating to Plastic Piping Sys-

tems

F 1588 Test Method for Constant Tensile Load Test

Available from the American Society of Mechanical Engineers, Three Park

Ave., New York, NY, 10016-5990.

This specification is under the jurisdiction of ASTM Committee F-17 on Plastic Available from the Office of Pipeline Safety, Research and Special Programs

Piping Systems, and is the direct responsibility of Subcommittee F17.60 on Gas. Administration, U.S. Department of Transportation, 400 Seventh Street, S.W.,

Current edition approved April 10, 1999. Published July 1999. Washington, DC, 20006-1301.

2 6

Annual Book of ASTM Standards, Vol 08.01. Available from the Plastics Pipe Institute, 1801 K Street N.W., Suite 600K,

Annual Book of ASTM Standards, Vol 08.04. Washington, DC, 20006-1301.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 1948

solutions used to thaw frozen lines.

formula, see Annex A1).

3.2.4 joint, n—the location at which two or more pieces of

5. Dimensions

pipe, or a pipe and a fitting, are connected (an installed

5.1 The dimensions and tolerances shall be determined by

coupling has two joints).

the manufacturer.

3.2.5 joint, mechanical, n—a connection between piping

components employing physical force to develop a seal or

6. Qualification Requirements

produce alignment.

6.1 General—Unless otherwise specified, each nominal size

3.2.6 maximum allowable operating pressure, MAOP,

of fitting shall be tested. Testing the fitting with the thickest

n—of the fuel gas piping system, in psig, as determined in

wall pipe for which the fitting is designed qualifies that type of

accordance with US DOT CFR, Title 49, Part 192.121, and as

fitting for use with pipe of lesser wall thickness.

represented in the following:

6.1.1 Mechanical joint qualification shall be performed on

MAOP5P52 3 S/~R–1!xf (1)

assembled joints using the fitting manufacturer’s joining pro-

cedure. All mechanical fittings offered by the manufacturer

where:

shall be capable of meeting the requirements of this standard

S 5 the pipe material’s HDB as published in PPI TR 4,

when connecting thermoplastic piping materials complying

R 5 the pipe’s dimension ratio determined by dividing the

with Specification D 2513. It is not the intent of this standard

pipe’s specified nominal outside diameter by the pipe’s

to require the testing of all fitting configurations (that is, tee,

specified nominal wall thickness, and

ells, etc.) but each joint design in each size.

f 5 design (derating) factor for thermoplastic fuel gas

6.1.2 All mechanical fittings described in 3.3 shall have an

piping as set by the authority having jurisdiction. In the

internal pipe reinforcing tubular stiffener that extends at least

United States, the design factor is cited in CFR, Title

under the seal and gripping device (where used).

49, Part 192.121.

6.2 Performance Requirements:

3.2.7 mechanical fitting, n—fitting for making a mechanical

6.2.1 Tensile Strength—The pipe joint shall accommodate

joint to provide for pressure integrity, leak tightness, and,

the tensile loads, when tested in accordance with 7.2.

depending on category, as defined in this standard, resistance to

6.2.1.1 Category 1—The joint shall provide resistance to a

end loads.

force on the pipe joint equal to or greater than that which will

3.3 Types of Mechanical Fittings:

cause no less than 25 % elongation of the pipe, or which causes

3.3.1 clamped insert fitting, n—mechanical fitting used to

the pipe to fail outside the joint area when tested in accordance

make a mechanical joint that utilizes external clamps, or other

with 7.2.

mechanical devices, to form a pressure seal between the

6.2.1.2 Category 2—Joint design that only provides a seal.

reinforcing tubular stiffener and the surface of the pipe.

A mechanical joint designed for this category excludes any

3.3.2 compression fitting, n—mechanical fitting used to

provisions in the design of the joint to resist axial pullout

make a mechanical joint by compressing either externally,

forces; therefore, tensile tests are not required.

internally, or radially to form a pressure seal between the fitting

6.2.1.3 Category 3—Joint of nominal pipe size 4 and larger

and the surface of the pipe.

in diameter shall provide resistance to a force on the pipe joint

3.3.3 compression gasket fitting, n—mechanical fitting used

equal to or greater than the maximum thermal stress that would

to make a mechanical joint that utilizes a compression nut,

be produced by a temperature change of 100°F (55°C) (for

tightening ring, bolts, or any other device to compress gasket-

formula, see Annex A1).

ing onto the surface of the pipe to form a pressure seal.

3.3.4 stab-type fitting, n—mechanical fitting used to make a

NOTE 3—Category 3 has a manufacturer’s rated pipe end restraint less

mechanical joint in which a seal is achieved by radial com-

than the value required to yield the pipe as outlined in 6.2.1.1 (Category

pression of a gasket between the outside diameter (OD) of the 1).

pipe and the inside diameter (ID) of the fitting.

6.2.1.4 Joint restraint capabilities less than as defined in

6.2.2.1 and 6.2.2.3 shall constitute failure of the test.

4. Material

6.2.2 Temperature Cycling Test—The mechanical joint shall

4.1 The physical properties of each material used to produce

provide a pressure seal after 10 cycles of the temperature

the fitting shall be available from the fitting manufacturer upon

cycling test when tested in accordance with 7.3.

request.

6.2.3 Constant Tensile Load Test—The joint shall not fail by

4.2 Specifications outlining the physical and chemical prop-

leakage or pullout when loaded to an axial tensile stress of

erties of all fitting materials shall be available from the fitting

1320 psi (9101 kPa) and tested in accordance with 7.4.

manufacturer upon request.

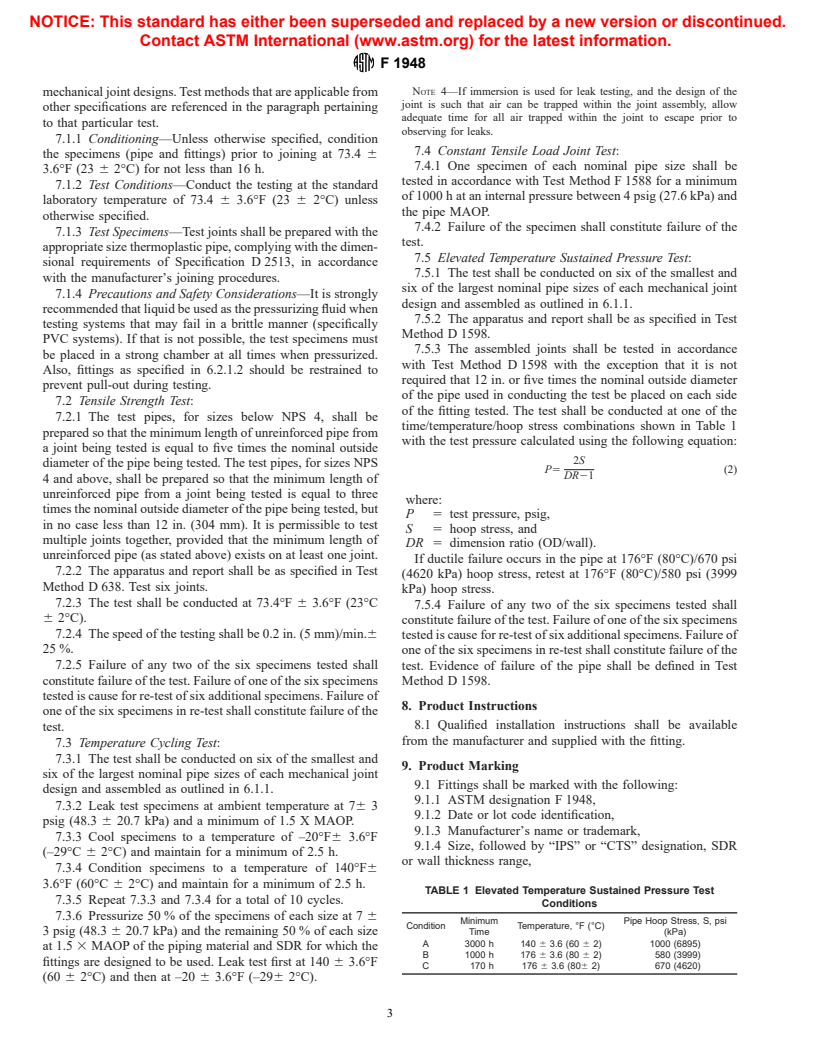

6.3 Elevated Temperature Sustained Pressure—The fitting,

NOTE 1—Materials in long-term contact with natural gas of line quality

joint or pipe in the area affected by the fitting shall not fail as

and LP gas vapor should be demonstrated to not adversely effect the

defined in Test Method D 1598, when tested in accordance

performance of the fitting.

with 7.5. The fitting or joint meets this requirement when tested

NOTE 2—Materials should have a demonstrated resistance to environ-

in accordance with any one of the three conditions (A, B, or C)

mental stress cracking when exposed, under stress, to chemical com-

listed in 7.5.

pounds encountered in or external to gas piping systems, and a demon-

strated resistance to bacteriological decomposition. Such compounds

7. Test Methods

include, but are not limited to, ice thawing chemicals, fertilizers, insecti-

cides, herbicides, leak detection fluids, acids, bases and antifreeze 7.1 General—The test methods in this specification cover

------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.