ASTM E143-02(2008)

(Test Method)Standard Test Method for Shear Modulus at Room Temperature

Standard Test Method for Shear Modulus at Room Temperature

SIGNIFICANCE AND USE

Shear modulus is a material property useful in calculating compliance of structural materials in torsion provided they follow Hooke's law, that is, the angle of twist is proportional to the applied torque. Examples of the use of shear modulus are in the design of rotating shafts and helical compression springs.

Note 3—For materials that follow nonlinear elastic stress-strain behavior, the value of tangent or chord shear modulus is useful for estimating the change in torsional strain to corresponding stress for a specified stress or stress-range, respectively. Such determinations are, however, outside the scope of this standard. (See for example Ref (1).)

The procedural steps and precision of the apparatus and the test specimens should be appropriate to the shape and the material type, since the method applies to a wide variety of materials and sizes.

Precise determination of shear modulus depends on the numerous variables that may affect such determinations.

These factors include characteristics of the specimen such as residual stress, concentricity, wall thickness in the case of tubes, deviation from nominal value, previous strain history and specimen dimension.

Testing conditions that influence the results include: axial position of the specimen, temperature and temperature variations, and maintenance of the apparatus.

Interpretation of data also influences results.

SCOPE

1.1 This test method covers the determination of shear modulus of structural materials. This test method is limited to materials in which, and to stresses at which, creep is negligible compared to the strain produced immediately upon loading. Elastic properties such as shear modulus, Young's modulus, and Poisson's ratio are not determined routinely and are generally not specified in materials specifications. Precision and bias statements for these test methods are therefore not available.

1.2 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E143 − 02(Reapproved 2008)

Standard Test Method for

1

Shear Modulus at Room Temperature

This standard is issued under the fixed designation E143; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

−2

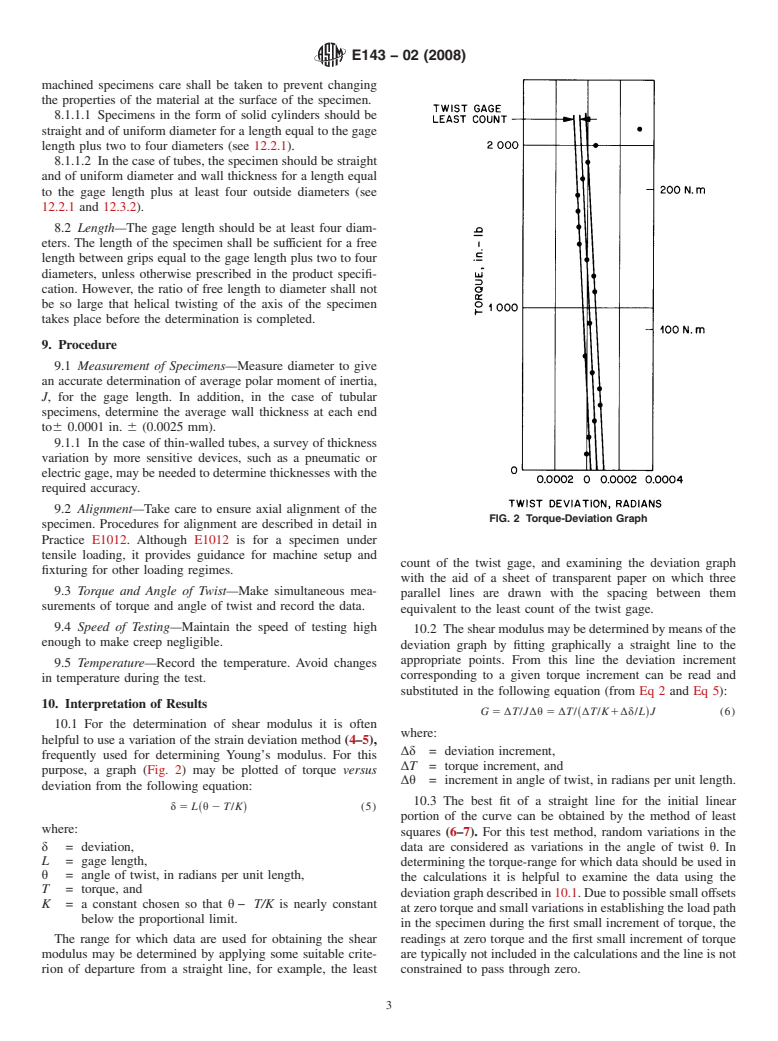

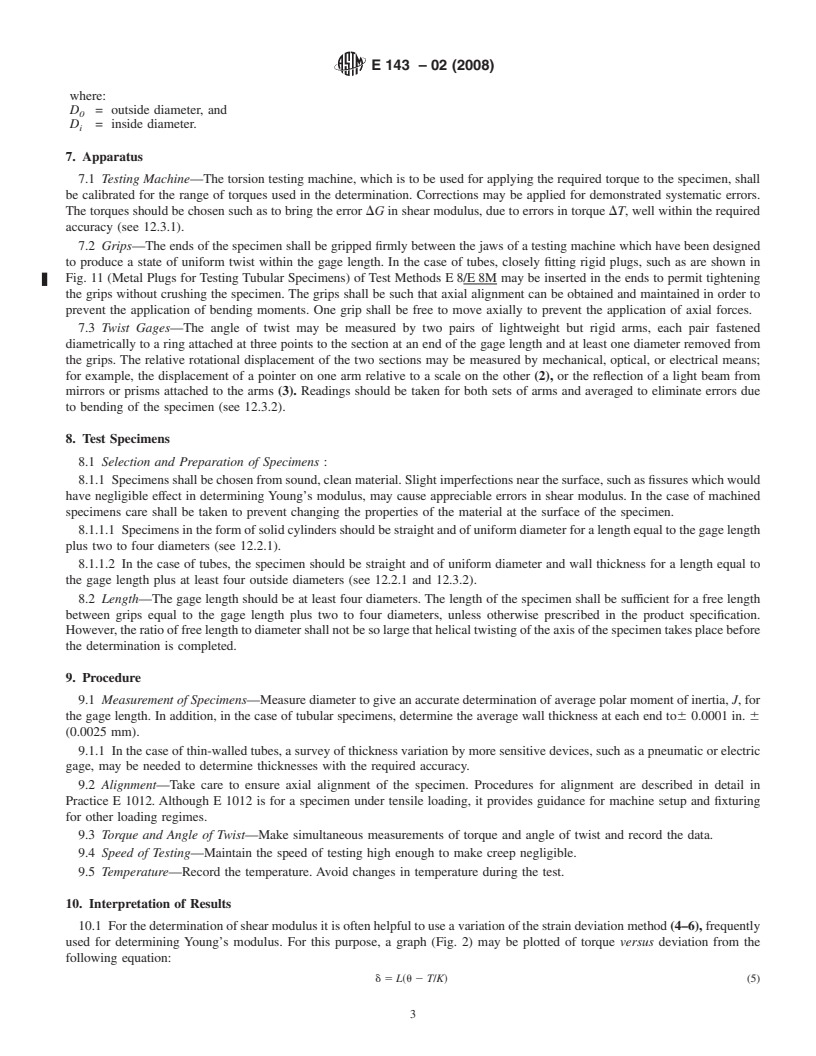

1. Scope 3.1.1 shear modulus [FL ] —the ratio of shear stress to

corresponding shear strain below the proportional limit, also

1.1 This test method covers the determination of shear

called torsional modulus and modulus of rigidity. (See Fig. 1.)

modulus of structural materials. This test method is limited to

materialsinwhich,andtostressesatwhich,creepisnegligible

NOTE 1—The value of shear modulus may depend on the direction in

which it is measured if the material is not isotropic. Wood, many plastics

compared to the strain produced immediately upon loading.

and certain metals are markedly anisotropic. Deviations from isotropy

Elastic properties such as shear modulus, Young’s modulus,

should be suspected if the shear modulus, G, differs from that determined

and Poisson’s ratio are not determined routinely and are

by substituting independently measured values of Young’s modulus, E,

generally not specified in materials specifications. Precision

and Poisson’s ratio, µ in the relation

and bias statements for these test methods are therefore not

E

available.

G 5 (1)

2~11µ!

1.2 Units—The values stated in inch-pound units are to be

NOTE 2—In general, it is advisable, in reporting values of shear

regarded as standard. The values given in parentheses are modulus to state the stress range over which it is measured.

mathematical conversions to SI units that are provided for

3.1.2 torque, [FL]—a moment (of forces) that produces or

information only and are not considered standard.

tends to produce rotation or torsion.

−2

1.3 This standard may involve hazardous materials, 3.1.3 torsional stress [FL ]—the shear stress in a body, in

operations, and equipment. This standard does not purport to a plane normal to the axis or rotation, resulting from the

address all of the safety concerns, if any, associated with its application of torque.

use. It is the responsibility of the user of this standard to 3.1.4 angle of twist (torsion test)—the angle of relative

rotation measured in a plane normal to the torsion specimen’s

establish appropriate safety and health practices and deter-

mine the applicability of regulatory limitations prior to use. longitudinal axis over the gage length.

3.1.5 For definitions of other terms used in this test method,

2. Referenced Documents

refer to Terminology E6.

2

2.1 ASTM Standards:

4. Summary of Test Method

E6Terminology Relating to Methods of Mechanical Testing

E8/E8MTest Methods for Tension Testing of Metallic Ma- 4.1 The cylindrical or tubular test specimen is loaded either

terials incrementally or continuously by applying an external torque

E111Test Method for Young’s Modulus, Tangent Modulus, so as to cause a uniform twist within the gage length.

and Chord Modulus 4.1.1 Changes in torque and the corresponding changes in

E1012Practice for Verification of Testing Frame and Speci- angle of twist are determined either incrementally or continu-

men Alignment Under Tensile and Compressive Axial ously. The appropriate slope is then calculated from the shear

Force Application

stress-strain curve, which may be derived under conditions of

either increasing or decreasing torque (increasing from pre-

3. Terminology

torque to maximum torque or decreasing from maximum

3.1 Definitions: torque to pretorque).

5. Significance and Use

1

This test method is under the jurisdiction of ASTM Committee E28 on

Mechanical Testing and is the direct responsibility of Subcommittee E28.04 on 5.1 Shear modulus is a material property useful in calculat-

Uniaxial Testing.

ing compliance of structural materials in torsion provided they

Current edition approved May 1, 2008. Published December 2008. Originally

followHooke’slaw,thatis,theangleoftwistisproportionalto

approved in 1959. Last previous edition approved in 2002 as E143– 02. DOI:

the applied torque. Examples of the use of shear modulus are

10.1520/E0143-02R08.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

inthedesignofrotatingshaftsandhelicalcompressionsprings.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on NOTE 3—For materials that follow nonlinear elastic stress-strain

the ASTM website. behavior, the value of tangent or chord shear modulus is useful for

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Consho

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E143 –01 Designation: E 143 – 02 (Reapproved 2008)

Standard Test Method for

1

Shear Modulus at Room Temperature

This standard is issued under the fixed designation E143; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This test method covers the determination of shear modulus of structural materials.This test method is limited to materials

inwhich,andtostressesatwhich,creepisnegligiblecomparedtothestrainproducedimmediatelyuponloading.Elasticproperties

such as shear modulus, Young’s modulus, and Poisson’s ratio are not determined routinely and are generally not specified in

materials specifications. Precision and bias statements for these test methods are therefore not available.

1.2Values stated in inch-pound units are to be regarded as the standard. SI units are provided for information only.

1.2 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are

mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all

of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate

safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E6 Terminology Relating to Methods of Mechanical Testing

E8/E8M Test Methods offor Tension Testing of Metallic Materials

E 111 Test Method for Young’s Modulus, Tangent Modulus, and Chord Modulus

2

E1012 Practice for Specimen Alignment Under Tensile Loading Practice for Verification of Test Frame and Specimen

Alignment Under Tensile and Compressive Axial Force Application

3. Terminology

3.1 Definitions:

−2

3.1.1 shear modulus [FL ]—theratioofshearstresstocorrespondingshearstrainbelowtheproportionallimitofthematerial

(see —the ratio of shear stress to corresponding shear strain below the proportional limit, also called torsional modulus and

modulus of rigidity. (See Fig. 1). .)

NOTE 1—The value of shear modulus may depend on the direction in which it is measured if the material is not isotropic. Wood, many plastics and

certain metals are markedly anisotropic. Deviations from isotropy should be suspected if the shear modulus, G, differs from that determined by

substituting independently measured values of Young’s modulus, E, and Poisson’s ratio, µ in the relation

E

G 5 (1)

2~1 1 µ!

NOTE 2—In general, it is advisable, in reporting values of shear modulus to state the stress range over which it is measured.

3.1.2 torque, [FL]— a moment (of forces) that produces or tends to produce rotation or torsion.

−2

3.1.3 torsional stress [FL ]—theshearstressinabody,inaplanenormaltotheaxisorrotation,resultingfromtheapplication

of torque.

3.1.4 angle of twist (torsion test)— the angle of relative rotation measured in a plane normal to the torsion specimen’s

longitudinal axis over the gage length.

3.1.5 For definitions of other terms used in this test method, refer to Terminology E6.

1

ThistestmethodisunderthejurisdictionofASTMCommitteeE28onMechanicalTestingandisthedirectresponsibilityofSubcommitteeE28.03onElasticProperties.

Current edition approved Oct. 10, 2001. Published November 2001. Originally published as E143–59T. Last previous edition E143– 87(1998).

1

This test method is under the jurisdiction ofASTM Committee E28 on MechanicalTesting and is the direct responsibility of Subcommittee E28.04 on UniaxialTesting.

Current edition approved May 1, 2008. Published December 2008. Originally approved in 1959. Last previous edition approved in 2002 as E143– 02.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

, Vol 03.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E 143 – 02 (2008)

FIG. 1 Shear Stress-Strain Diagram Showing a Straig

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E143 –02 Designation: E 143 – 02 (Reapproved 2008)

Standard Test Method for

1

Shear Modulus at Room Temperature

This standard is issued under the fixed designation E143; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This test method covers the determination of shear modulus of structural materials.This test method is limited to materials

inwhich,andtostressesatwhich,creepisnegligiblecomparedtothestrainproducedimmediatelyuponloading.Elasticproperties

such as shear modulus, Young’s modulus, and Poisson’s ratio are not determined routinely and are generally not specified in

materials specifications. Precision and bias statements for these test methods are therefore not available.

1.2Values stated in inch-pound units are to be regarded as the standard. SI units are provided for information only.

1.2 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are

mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all

of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate

safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E6 Terminology Relating to Methods of Mechanical Testing

E8/E8M Test Methods offor Tension Testing of Metallic Materials

E 111 Test Method for Young’s Modulus, Tangent Modulus, and Chord Modulus

2

E1012 Practice for Specimen Alignment Under Tensile Loading Practice for Verification of Test Frame and Specimen

Alignment Under Tensile and Compressive Axial Force Application

3. Terminology

3.1 Definitions:

−2

3.1.1 shear modulus [FL ] —the ratio of shear stress to corresponding shear strain below the proportional limit, also called

torsional modulus and modulus of rigidity. (See Fig. 1.)

NOTE 1—The value of shear modulus may depend on the direction in which it is measured if the material is not isotropic. Wood, many plastics and

certain metals are markedly anisotropic. Deviations from isotropy should be suspected if the shear modulus, G, differs from that determined by

substituting independently measured values of Young’s modulus, E, and Poisson’s ratio, µ in the relation

E

G 5 (1)

2 1 1 µ

~ !

NOTE 2—In general, it is advisable, in reporting values of shear modulus to state the stress range over which it is measured.

3.1.2 torque, [FL]— a moment (of forces) that produces or tends to produce rotation or torsion.

−2

3.1.3 torsional stress [FL ]—theshearstressinabody,inaplanenormaltotheaxisorrotation,resultingfromtheapplication

of torque.

3.1.4 angle of twist (torsion test)— the angle of relative rotation measured in a plane normal to the torsion specimen’s

longitudinal axis over the gage length.

3.1.5 For definitions of other terms used in this test method, refer to Terminology E6.

4. Summary of Test Method

4.1 The cylindrical or tubular test specimen is loaded either incrementally or continuously by applying an external torque so

1

This test method is under the jurisdiction ofASTM Committee E28 on MechanicalTesting and is the direct responsibility of Subcommittee E28.04 on UniaxialTesting.

Current edition approved Nov. 10, 2002. Published January 2003. Originally approved in 1959. Last previous edition approved in 2001 as E143– 01.

Current edition approved May 1, 2008. Published December 2008. Originally approved in 1959. Last previous edition approved in 2002 as E143– 02.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

, Vol 03.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E 143 – 02 (2008)

FIG. 1 Shear Stress-Strain Diagram Showing a Straight Line, Corresponding to the Shear Modulus, BetweenR , a Pretorque Stress,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.