ASTM F2625-10(2016)

(Test Method)Standard Test Method for Measurement of Enthalpy of Fusion, Percent Crystallinity, and Melting Point of Ultra-High-Molecular Weight Polyethylene by Means of Differential Scanning Calorimetry

Standard Test Method for Measurement of Enthalpy of Fusion, Percent Crystallinity, and Melting Point of Ultra-High-Molecular Weight Polyethylene by Means of Differential Scanning Calorimetry

SIGNIFICANCE AND USE

5.1 The crystallinity of UHMWPE will influence its mechanical properties, such as creep and stiffness. The reported crystallinity will depend on the integration range used to determine the heat of fusion, and the theoretical heat of fusion of 100 % crystalline polyethylene used to calculate the percent crystallinity in an unknown specimen. Differential scanning calorimetry is an effective means of accurately measuring both heat of fusion and melting temperature.

5.2 This test method is useful for both process control and research.

SCOPE

1.1 This test method discusses the measurement of the heat of fusion and the melting point of ultra-high-molecular weight polyethylene (UHMWPE), and the subsequent calculation of the percentage of crystallinity.

1.2 This test method can be used for UHMWPE in powder form, consolidated form, finished product, or a used product. It can also be used for irradiated or chemically-crosslinked UHMWPE.

1.3 This test method does not suggest a desired range of crystallinity or melting points for specific applications.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2625 − 10 (Reapproved 2016)

Standard Test Method for

Measurement of Enthalpy of Fusion, Percent Crystallinity,

and Melting Point of Ultra-High-Molecular Weight

Polyethylene by Means of Differential Scanning Calorimetry

This standard is issued under the fixed designation F2625; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ential Scanning Calorimetry

E691 Practice for Conducting an Interlaboratory Study to

1.1 This test method discusses the measurement of the heat

Determine the Precision of a Test Method

of fusion and the melting point of ultra-high-molecular weight

E793 Test Method for Enthalpies of Fusion and Crystalliza-

polyethylene (UHMWPE), and the subsequent calculation of

tion by Differential Scanning Calorimetry

the percentage of crystallinity.

E967 Test Method for Temperature Calibration of Differen-

1.2 This test method can be used for UHMWPE in powder

tial Scanning Calorimeters and Differential Thermal Ana-

form, consolidated form, finished product, or a used product. It

lyzers

can also be used for irradiated or chemically-crosslinked

E968 Practice for Heat Flow Calibration of Differential

UHMWPE.

Scanning Calorimeters

1.3 This test method does not suggest a desired range of E1953 Practice for Description of Thermal Analysis and

Rheology Apparatus

crystallinity or melting points for specific applications.

1.4 The values stated in SI units are to be regarded as

3. Terminology

standard. No other units of measurement are included in this

3.1 Symbols:

standard.

3.1.1 ΔH , n—theoretical heat of fusion of 100 % crystalline

f

1.5 This standard does not purport to address all of the

material (J/g).

safety concerns, if any, associated with its use. It is the

3.1.2 ΔH , n—mass normalized heat of fusion of the test

s

responsibility of the user of this standard to establish appro-

sample (J/g).

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

3.1.3 T , n—melting temperature at the peak of the melting

p

1.6 This international standard was developed in accor- endotherm (°C).

dance with internationally recognized principles on standard-

3.1.4 T , n—onset temperature of the melting endotherm

o

ization established in the Decision on Principles for the

(°C).

Development of International Standards, Guides and Recom-

3.1.5 %X, n—percentage of crystallinity of material.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

4. Summary of Test Method

4.1 This test method consists of placing a known mass of

2. Referenced Documents

2 UHMWPE in a sample pan and heating the sample pan at a

2.1 ASTM Standards:

controlled temperature while measuring the heat flow to the

D3418 Test Method for Transition Temperatures and Enthal-

sample pan and an empty reference pan. The area under the

pies of Fusion and Crystallization of Polymers by Differ-

melting endotherm, indicative of the enthalpy of melting, is

normalized with the sample mass. This value is then normal-

ized with the theoretical enthalpy of melting of 100 % crystal-

This test method is under the jurisdiction of ASTM Committee F04 on Medical

and Surgical Materials and Devices and is the direct responsibility of Subcommittee

line polyethylene to determine the percentage of crystallinity in

F04.15 on Material Test Methods.

the test sample.

Current edition approved April 1, 2016. Published May 2016. Originally

approved in 2007. Last previous edition approved in 2010 as F2625 – 10. DOI:

5. Significance and Use

10.1520/F2625-10R16.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.1 The crystallinity of UHMWPE will influence its me-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

chanical properties, such as creep and stiffness. The reported

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. crystallinity will depend on the integration range used to

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

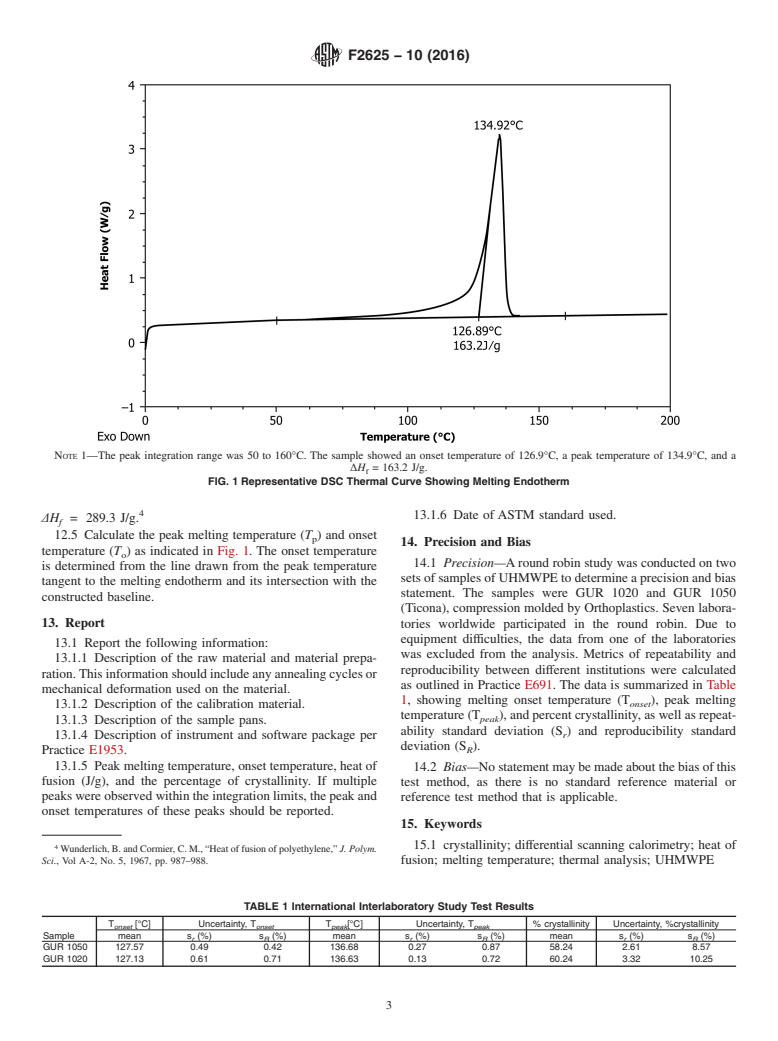

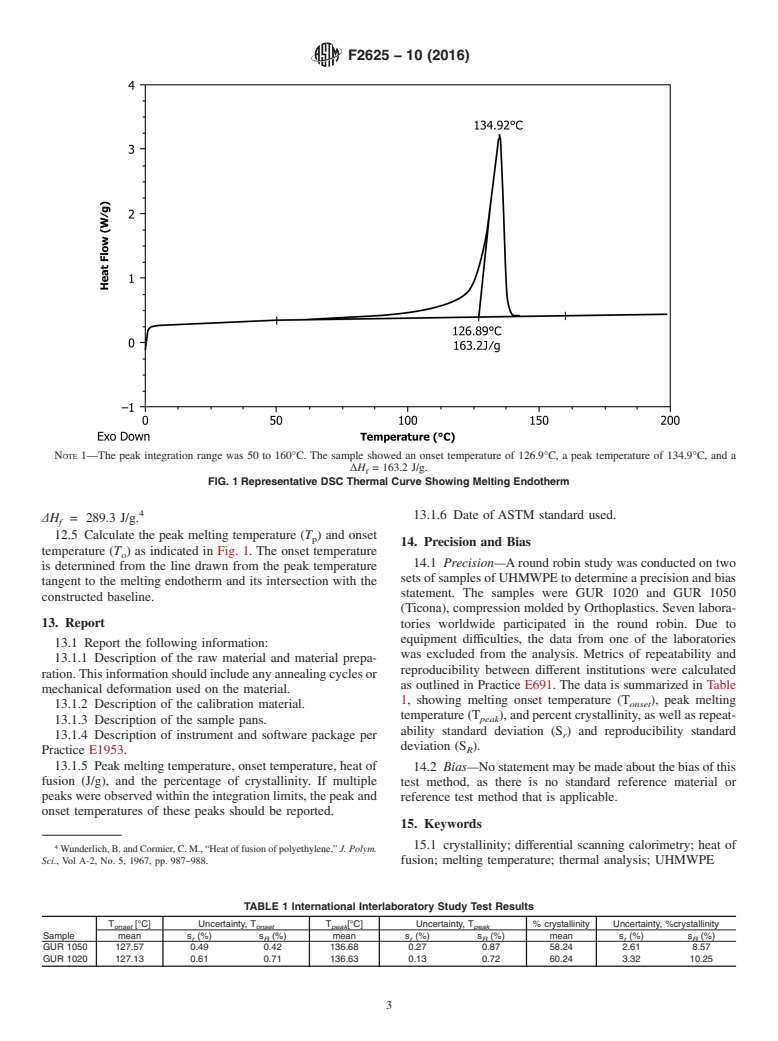

F2625 − 10 (2016)

determine the heat of fusion, and the theoretical heat of fusion 10. Calibration and Standardization

of 100 % crystalline polyethylene used to calculate the percent

10.1 Calibrate the temperature and heat flow signals of the

crystallinity in an unknown specimen. Differential scanning

DSC according to Test Method E967 and Practice E968,

calorimetry is an effective means of accurately measuring both

respectively. Typically, pure indium is used as a reference

heat of fusion and melting temperature.

material. Both onset of the melting endotherm of the reference

5.2 This test method is useful for both process control and

standard and the heat of fusion shall be reported and compared

research.

with published values (T = 156.6°C, Δ H = 28.57 J/g). The

o f

DSC calibration should be verified on at least a monthly basis.

6. Interferences

NOTE 3—The value of the ΔH will vary with the lot of the indium by

f

6.1 As machining processes can affect the crystalline struc-

as much as 3 %. Users should refer to the certificate of analysis for the ΔH

f

ture of UHMWPE, care should be taken to obtain a represen- of their specific lot of indium.

tative sample away from the surface of a component if bulk

11. Procedure

measurements are desired.

6.2 The integration range used to measure the area of the

11.1 Weigh an UHMWPE specimen on an analytical bal-

melting endotherm will affect the measured value, as can

ance to a resolution of 0.01 mg. The specimen weight should

heating rate. Therefore, the same ranges and test conditions

be between 5 and 10 mg. The replicate specimens should all be

must be used to ensure comparative results between laborato-

within 62 mg of each other.

ries.

11.2 Place the specimen into an aluminum DSC sample pan,

6.3 The sample must not be too tall, as temperature gradi-

cover with an aluminum lid, and crimp to seal the sample. If

ents can then be generated in the sample, leading to erroneous

the DSC software allows compensation for the pan weight,

results. It is suggested that the sample height should be less

record the weight.

than 2 mm.

11.3 Inspect the bottom of the sample pan to ensure that it

is flat. If it is not flat, prepare another sample.

7. Apparatus

11.4 Place the sample pan into the DSC chamber, along with

7.1 Differential scanning calorimeter (DSC), as described in

an empty reference pan.

Test Method D3418 and Practice E1953.

11.5 Equilibrate the sample at ambient temperature for at

7.2 Aluminum DSC sample pans, crimpable. Pans with

least 3 min.

venting holes are optional. The same type of pan must be used

for the sample and reference pan.

11.6 Heat the sample from ambi

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2625 − 10 (Reapproved 2016)

Standard Test Method for

Measurement of Enthalpy of Fusion, Percent Crystallinity,

and Melting Point of Ultra-High-Molecular Weight

Polyethylene by Means of Differential Scanning Calorimetry

This standard is issued under the fixed designation F2625; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ential Scanning Calorimetry

E691 Practice for Conducting an Interlaboratory Study to

1.1 This test method discusses the measurement of the heat

Determine the Precision of a Test Method

of fusion and the melting point of ultra-high-molecular weight

E793 Test Method for Enthalpies of Fusion and Crystalliza-

polyethylene (UHMWPE), and the subsequent calculation of

tion by Differential Scanning Calorimetry

the percentage of crystallinity.

E967 Test Method for Temperature Calibration of Differen-

1.2 This test method can be used for UHMWPE in powder

tial Scanning Calorimeters and Differential Thermal Ana-

form, consolidated form, finished product, or a used product. It

lyzers

can also be used for irradiated or chemically-crosslinked

E968 Practice for Heat Flow Calibration of Differential

UHMWPE.

Scanning Calorimeters

E1953 Practice for Description of Thermal Analysis and

1.3 This test method does not suggest a desired range of

crystallinity or melting points for specific applications. Rheology Apparatus

1.4 The values stated in SI units are to be regarded as

3. Terminology

standard. No other units of measurement are included in this

3.1 Symbols:

standard.

3.1.1 ΔH , n—theoretical heat of fusion of 100 % crystalline

f

1.5 This standard does not purport to address all of the

material (J/g).

safety concerns, if any, associated with its use. It is the

3.1.2 ΔH , n—mass normalized heat of fusion of the test

responsibility of the user of this standard to establish appro- s

sample (J/g).

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. 3.1.3 T , n—melting temperature at the peak of the melting

p

1.6 This international standard was developed in accor-

endotherm (°C).

dance with internationally recognized principles on standard-

3.1.4 T , n—onset temperature of the melting endotherm

o

ization established in the Decision on Principles for the

(°C).

Development of International Standards, Guides and Recom-

3.1.5 %X, n—percentage of crystallinity of material.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

4. Summary of Test Method

4.1 This test method consists of placing a known mass of

2. Referenced Documents

UHMWPE in a sample pan and heating the sample pan at a

2.1 ASTM Standards:

controlled temperature while measuring the heat flow to the

D3418 Test Method for Transition Temperatures and Enthal-

sample pan and an empty reference pan. The area under the

pies of Fusion and Crystallization of Polymers by Differ-

melting endotherm, indicative of the enthalpy of melting, is

normalized with the sample mass. This value is then normal-

ized with the theoretical enthalpy of melting of 100 % crystal-

This test method is under the jurisdiction of ASTM Committee F04 on Medical

and Surgical Materials and Devices and is the direct responsibility of Subcommittee

line polyethylene to determine the percentage of crystallinity in

F04.15 on Material Test Methods.

the test sample.

Current edition approved April 1, 2016. Published May 2016. Originally

approved in 2007. Last previous edition approved in 2010 as F2625 – 10. DOI:

5. Significance and Use

10.1520/F2625-10R16.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.1 The crystallinity of UHMWPE will influence its me-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

chanical properties, such as creep and stiffness. The reported

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. crystallinity will depend on the integration range used to

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2625 − 10 (2016)

determine the heat of fusion, and the theoretical heat of fusion 10. Calibration and Standardization

of 100 % crystalline polyethylene used to calculate the percent

10.1 Calibrate the temperature and heat flow signals of the

crystallinity in an unknown specimen. Differential scanning

DSC according to Test Method E967 and Practice E968,

calorimetry is an effective means of accurately measuring both

respectively. Typically, pure indium is used as a reference

heat of fusion and melting temperature.

material. Both onset of the melting endotherm of the reference

5.2 This test method is useful for both process control and

standard and the heat of fusion shall be reported and compared

research.

with published values (T = 156.6°C, Δ H = 28.57 J/g). The

o f

DSC calibration should be verified on at least a monthly basis.

6. Interferences

NOTE 3—The value of the ΔH will vary with the lot of the indium by

f

6.1 As machining processes can affect the crystalline struc-

as much as 3 %. Users should refer to the certificate of analysis for the ΔH

f

ture of UHMWPE, care should be taken to obtain a represen- of their specific lot of indium.

tative sample away from the surface of a component if bulk

measurements are desired. 11. Procedure

6.2 The integration range used to measure the area of the

11.1 Weigh an UHMWPE specimen on an analytical bal-

melting endotherm will affect the measured value, as can

ance to a resolution of 0.01 mg. The specimen weight should

heating rate. Therefore, the same ranges and test conditions

be between 5 and 10 mg. The replicate specimens should all be

must be used to ensure comparative results between laborato-

within 62 mg of each other.

ries.

11.2 Place the specimen into an aluminum DSC sample pan,

6.3 The sample must not be too tall, as temperature gradi-

cover with an aluminum lid, and crimp to seal the sample. If

ents can then be generated in the sample, leading to erroneous

the DSC software allows compensation for the pan weight,

results. It is suggested that the sample height should be less

record the weight.

than 2 mm.

11.3 Inspect the bottom of the sample pan to ensure that it

is flat. If it is not flat, prepare another sample.

7. Apparatus

11.4 Place the sample pan into the DSC chamber, along with

7.1 Differential scanning calorimeter (DSC), as described in

an empty reference pan.

Test Method D3418 and Practice E1953.

11.5 Equilibrate the sample at ambient temperature for at

7.2 Aluminum DSC sample pans, crimpable. Pans with

least 3 min.

venting holes are optional. The same type of pan must be used

for the sample and reference pan.

11.6 Heat the sample from ambient to 200°C at 10°C/min.

An additional cooling cycle and heating run can be

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2625 − 10 F2625 − 10 (Reapproved 2016)

Standard Test Method for

Measurement of Enthalpy of Fusion, Percent Crystallinity,

and Melting Point of Ultra-High-Molecular Weight

Polyethylene by Means of Differential Scanning Calorimetry

This standard is issued under the fixed designation F2625; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method discusses the measurement of the heat of fusion and the melting point of ultra-high-molecular weight

polyethylene (UHMWPE), and the subsequent calculation of the percentage of crystallinity.

1.2 This test method can be used for UHMWPE in powder form, consolidated form, finished product, or a used product. It can

also be used for irradiated or chemically-crosslinked UHMWPE.

1.3 This test method does not suggest a desired range of crystallinity or melting points for specific applications.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D3418 Test Method for Transition Temperatures and Enthalpies of Fusion and Crystallization of Polymers by Differential

Scanning Calorimetry

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E793 Test Method for Enthalpies of Fusion and Crystallization by Differential Scanning Calorimetry

E967 Test Method for Temperature Calibration of Differential Scanning Calorimeters and Differential Thermal Analyzers

E968 Practice for Heat Flow Calibration of Differential Scanning Calorimeters

E1953 Practice for Description of Thermal Analysis and Rheology Apparatus

3. Terminology

3.1 Symbols:

3.1.1 ΔH , n—theoretical heat of fusion of 100 % crystalline material (J/g).

f

3.1.2 ΔH , n—mass normalized heat of fusion of the test sample (J/g).

s

3.1.3 T , n—melting temperature at the peak of the melting endotherm (°C).

p

3.1.4 T , n—onset temperature of the melting endotherm (°C).

o

3.1.5 %X, n—percentage of crystallinity of material.

4. Summary of Test Method

4.1 This test method consists of placing a known mass of UHMWPE in a sample pan and heating the sample pan at a controlled

temperature while measuring the heat flow to the sample pan and an empty reference pan. The area under the melting endotherm,

This test method is under the jurisdiction of ASTM Committee F04 on Medical and Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.15 on Material Test Methods.

Current edition approved Dec. 1, 2010April 1, 2016. Published December 2010May 2016. Originally approved in 2007. Last previous edition approved in 20072010 as

F2625 – 07.F2625 – 10. DOI: 10.1520/F2625-10.10.1520/F2625-10R16.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2625 − 10 (2016)

indicative of the enthalpy of melting, is normalized with the sample mass. This value is then normalized with the theoretical

enthalpy of melting of 100 % crystalline polyethylene to determine the percentage of crystallinity in the test sample.

5. Significance and Use

5.1 The crystallinity of UHMWPE will influence its mechanical properties, such as creep and stiffness. The reported

crystallinity will depend on the integration range used to determine the heat of fusion, and the theoretical heat of fusion of 100 %

crystalline polyethylene used to calculate the percent crystallinity in an unknown specimen. Differential scanning calorimetry is

an effective means of accurately measuring both heat of fusion and melting temperature.

5.2 This test method is useful for both process control and research.

6. Interferences

6.1 As machining processes can affect the crystalline structure of UHMWPE, care should be taken to obtain a representative

sample away from the surface of a component if bulk measurements are desired.

6.2 The integration range used to measure the area of the melting endotherm will affect the measured value, as can heating rate.

Therefore, the same ranges and test conditions must be used to ensure comparative results between laboratories.

6.3 The sample must not be too tall, as temperature gradients can then be generated in the sample, leading to erroneous results.

It is suggested that the sample height should be less than 2 mm.

7. Apparatus

7.1 Differential scanning calorimeter (DSC), as described in Test Method D3418 and Practice E1953.

7.2 Aluminum DSC sample pans, crimpable. Pans with venting holes are optional. The same type of pan must be used for the

sample and reference pan.

7.3 Analytical balance, accurate to 60.01 mg.

NOTE 1—According to Test Method E793, the repeatability standard deviation for the enthalpy of fusion of a polyolefin is 1.2 % when using a balance

resolution of 0.01 mg.

8. Sampling, Test Specimens, and Test Units

8.1 The UHMWPE test specimen can be in the form of powder, flake, film, or pellet.

8.2 If a specimen is to be cut from a larger piece of polyethylene, it is recommended that a clean, sharp razor blade or other

equivalent tool is used to cut a slice. The specimen must not be cut with a tool that generates enough heat to melt the UHMWPE.

A core borer or punch can also be used to cut a sample from a film of UHMWPE.

8.3 The specimen should be fairly flat to ensure good thermal contact with the sample pan.

8.4 It is recommended that a minimum of three specimens per test location are tested.

NOTE 2—“Test location” is defined as the location on the sample where the DSC analysis is performed.

9. Preparation of Apparatus

9.1 The DSC test chamber should be purged with dry nitrogen, argon, or helium at a controlled flow rate during all tests. The

same rate and gas should be used for all calibrations and tests. A purge rate of 10 to 50 ml/min is recommended.

10. Calibration and Standardization

10.1 Calibrate the temperature and heat flow signals of the DSC according to Test Method E967 and Practice E968, respectively.

Typically, pure indium is used as a reference material

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.