ASTM A829/A829M-06

(Specification)Standard Specification for Alloy Structural Steel Plates

Standard Specification for Alloy Structural Steel Plates

ABSTRACT

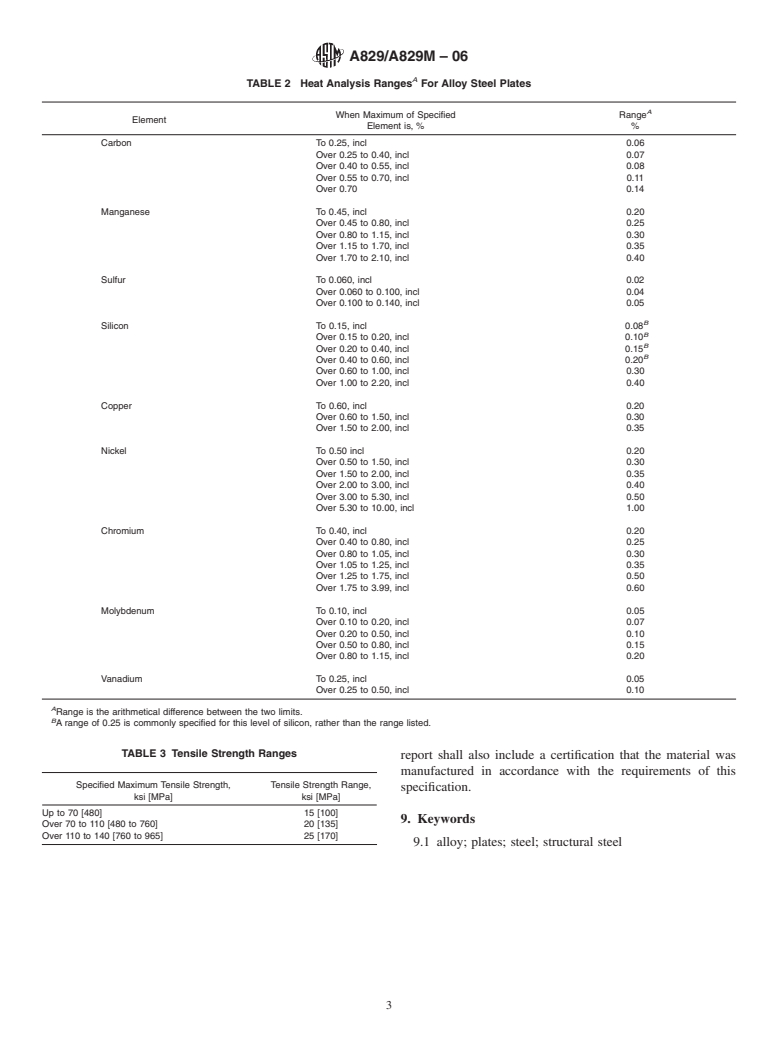

This specification deals with alloy structural steel plates. Plate specimens addressed under this specification are available in four treatment conditions (as rolled or hot rolled; annealed; normalized; and normalized and tempered), three structural forms (rectangular; circular and semi-circular; and sketch, including rings), five edge categories (mill edge; universal mill edge; sheared edge; gas cut edge; and special cut edge), and seven finishes (as rolled or hot rolled; blast cleaned; blast cleaned and oiled; pickled; pickled and oiled; painted with one prime coat; and painted with one prime coat and one finish coat). Steel materials shall be manufactured and furnished in defined procedures unless specified otherwise in the purchase order. Heat analysis shall be performed wherein steel specimens shall conform to required chemical compositions of carbon, manganese, phosphorus, sulfur, silicon, nickel, chromium, molybdenum, vanadium, and copper. Specimens shall also undergo tensile tests and shall conform to required values of tensile strength.

SCOPE

1.1 This specification covers structural quality alloy steel plates.

1.2 The plates are usually specified to chemical composition requirements, but tensile properties may also be specified.

1.2.1 When tensile properties are required, the specific requirements must be compatible with the chemical composition, condition, and plate thickness.

1.3 The plates are available in the following four conditions:

1.3.1 Condition ARAs rolled (hot rolled),

1.3.2 Condition A - Annealed,

1.3.3 Condition NNormalized, and

1.3.4 Condition NT - Normalized and tempered.

1.4 The plates are available in the following three forms:

1.4.1 Form I - Rectangular,

1.4.2 Form II - Circular and semi-circular, and

1.4.3 Form IIISketch, including rings.

1.5 The plates are available in the following five edge categories:

1.5.1 Edge 1 - Mill edge,

1.5.2 Edge 2 - Universal mill edge,

1.5.3 Edge 3 - Sheared edge,

1.5.4 Edge 4 - Gas cut edge, and

1.5.5 Edge 5 - Special cut edge.

1.6 The plates are available in the following seven finishes:

1.6.1 Finish 1 - As rolled (hot rolled),

1.6.2 Finish 2 - Blast cleaned,

1.6.3 Finish 3 - Blast cleaned and oiled,

1.6.4 Finish 4 - Pickled,

1.6.5 Finish 5 - Pickled and oiled,

1.6.6 Finish 6 - Painted, one prime coat, and

1.6.7 Finish 7 - Painted, one prime coat and one finish coat.

1.6.8 The plates are usually specified to have Finish 1.

1.7 Supplementary requirements are provided for additional requirements that may be specified on the order.

1.8 When the steel is to be welded, it is presupposed that a welding procedure suitable for the grade of steel and intended use or service will be utilized. See Appendix X 3 of Specification A 6/A 6M for information on weldability.

1.9 The values stated in either inch-pound units or SI units are to be regarded as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A829/A829M – 06

Standard Specification for

1

Alloy Structural Steel Plates

This standard is issued under the fixed designationA829/A829M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* use or service will be utilized. See Appendix X 3 of Specifi-

cation A6/A6M for information on weldability.

1.1 This specification covers structural quality alloy steel

1.9 The values stated in either inch-pound units or SI units

plates.

are to be regarded as standard. Within the text, the SI units are

1.2 Theplatesareusuallyspecifiedtochemicalcomposition

shown in brackets. The values stated in each system are not

requirements, but tensile properties may also be specified.

exact equivalents; therefore, each system must be used inde-

1.2.1 When tensile properties are required, the specific

pendentlyoftheother.Combiningvaluesfromthetwosystems

requirements must be compatible with the chemical composi-

may result in nonconformance with the specification.

tion, condition, and plate thickness.

1.3 Theplatesareavailableinthefollowingfourconditions:

2. Referenced Documents

1.3.1 Condition AR—As rolled (hot rolled),

2

2.1 ASTM Standards:

1.3.2 Condition A—Annealed,

A6/A6M SpecificationforGeneralRequirementsforRolled

1.3.3 Condition N—Normalized, and

Structural Steel Bars, Plates, Shapes, and Sheet Piling

1.3.4 Condition NT—Normalized and tempered.

1.4 The plates are available in the following three forms:

3. Ordering Information

1.4.1 Form I—Rectangular,

3.1 Orders for plates under this specification should include

1.4.2 Form II—Circular and semi-circular, and

the following information:

1.4.3 Form III—Sketch, including rings.

3.1.1 ASTM designation and year of issue.

1.5 The plates are available in the following five edge

3.1.2 Grade (see 5.1) or chemical composition (see 5.2).

categories:

3.1.3 Tensile properties, if required (see Section 6).

1.5.1 Edge 1—Mill edge,

3.1.4 Coarse austenitic grain size, if required (see 4.1).

1.5.2 Edge 2—Universal mill edge,

3.1.5 Condition (see 1.3).

1.5.3 Edge 3—Sheared edge,

3.1.6 Form (see 1.4).

1.5.4 Edge 4—Gas cut edge, and

3.1.7 Edge, if other than Edge 3 or 4 (see 4.3).

1.5.5 Edge 5—Special cut edge.

3.1.8 Finish (see 1.6).

1.6 The plates are available in the following seven finishes:

3.1.9 Dimensions of plate.

1.6.1 Finish 1—As rolled (hot rolled),

3.1.10 Limitations on repair by welding, if any (see 4.5.2).

1.6.2 Finish 2—Blast cleaned,

3.1.11 Supplementary Requirements, if any, including all

1.6.3 Finish 3—Blast cleaned and oiled,

the additional information called for in the Supplementary

1.6.4 Finish 4—Pickled,

Requirements.

1.6.5 Finish 5—Pickled and oiled,

1.6.6 Finish 6—Painted, one prime coat, and

4. Materials and Manufacture

1.6.7 Finish7—Painted, one prime coat and one finish coat.

4.1 The steel shall be made to fine grain practice, unless

1.6.8 The plates are usually specified to have Finish 1.

coarse austenitic grain size is specified in the purchase order.

1.7 Supplementary requirements are provided for additional

4.2 The plates shall be furnished in the condition specified

requirements that may be specified on the order.

in the purchase order.

1.8 When the steel is to be welded, it is presupposed that a

4.2.1 Plates specified to be furnished in a heat-treated

welding procedure suitable for the grade of steel and intended

condition shall be heated to a suitable temperature at or above

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel, and RelatedAlloys and is the direct responsibility of Subcommittee

2

A01.02 on Structural Steel for Bridges, Buildings, Rolling Stock, and Ships. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Sept. 1, 2006. Published September 2006. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1984. Last previous edition approved in 2004 as A829/A829M – 04. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/A0829_A0829M-06. the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A829/A829M – 06

the upper critical temperature, but not exceeding 1700°F 5.2 The chemical composition for heat analysis may be

[925°C], held a sufficient length of time to attain essentially specified in accord

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.