ASTM F945-12

(Test Method)Standard Test Method for Stress-Corrosion of Titanium Alloys by Aircraft Engine Cleaning Materials

Standard Test Method for Stress-Corrosion of Titanium Alloys by Aircraft Engine Cleaning Materials

SIGNIFICANCE AND USE

3.1 Because of the tendency of prestressed titanium alloy parts to crack if heated while in contact with certain chemical reagents, it is necessary to ensure that cleaning and maintenance materials will not initiate stress corrosion of titanium alloys under controlled conditions. For test specimens, two common titanium alloys are selected, one that is very susceptible (AMS 4916) and one that is not very susceptible (AMS 4911) to stress corrosion cracking.

SCOPE

1.1 This test method establishes a test procedure for determining the propensity of aircraft turbine engine cleaning and maintenance materials for causing stress corrosion cracking of titanium alloy parts.

1.2 The evaluation is conducted on representative titanium alloys by determining the effect of contact with cleaning and maintenance materials on tendency of prestressed titanium alloys to crack when subsequently heated to elevated temperatures.

1.3 Test conditions are based upon manufacturer's maximum recommended operating solution concentration.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see 5.3 and 5.6.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F945 − 12

Standard Test Method for

Stress-Corrosion of Titanium Alloys by Aircraft Engine

1

Cleaning Materials

ThisstandardisissuedunderthefixeddesignationF945;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

INTRODUCTION

Chemical solutions and compounds used for preinspection cleaning or for preservation of titanium

alloy aircraft turbine engine parts shall be subject to qualification requirements of this test method.

1. Scope D841 Specification for Nitration Grade Toluene

D1193 Specification for Reagent Water

1.1 This test method establishes a test procedure for deter-

mining the propensity of aircraft turbine engine cleaning and 2.2 SAE Aerospace Material Specifications:

3

maintenance materials for causing stress corrosion cracking of AMS 4911 Sheet, Strip and Plate-6AL-4V Annealed

titanium alloy parts. AMS 4916 Sheet, Strip, and Plate-8AL 1MO 1V, Duplex

3

Annealed

1.2 The evaluation is conducted on representative titanium

alloys by determining the effect of contact with cleaning and

3. Significance and Use

maintenance materials on tendency of prestressed titanium

alloys to crack when subsequently heated to elevated tempera-

3.1 Because of the tendency of prestressed titanium alloy

tures. parts to crack if heated while in contact with certain chemical

reagents, it is necessary to ensure that cleaning and mainte-

1.3 Test conditions are based upon manufacturer’s maxi-

nance materials will not initiate stress corrosion of titanium

mum recommended operating solution concentration.

alloys under controlled conditions. For test specimens, two

1.4 The values stated in inch-pound units are to be regarded

common titanium alloys are selected, one that is very suscep-

as standard. The values given in parentheses are mathematical

tible (AMS 4916) and one that is not very susceptible (AMS

conversions to SI units that are provided for information only

4911) to stress corrosion cracking.

and are not considered standard.

1.5 This standard does not purport to address all of the

4. Apparatus

safety concerns, if any, associated with its use. It is the

4.1 Measuring Devicecapableoflinearmeasurementwitha

responsibility of the user of this standard to establish appro-

60.01-in. (60.25-mm) tolerance.

priate safety and health practices and determine the applica-

4

4.2 Press Forming Apparatus with 0.56-in. (14-mm) diam-

bility of regulatory limitations prior to use. For specific

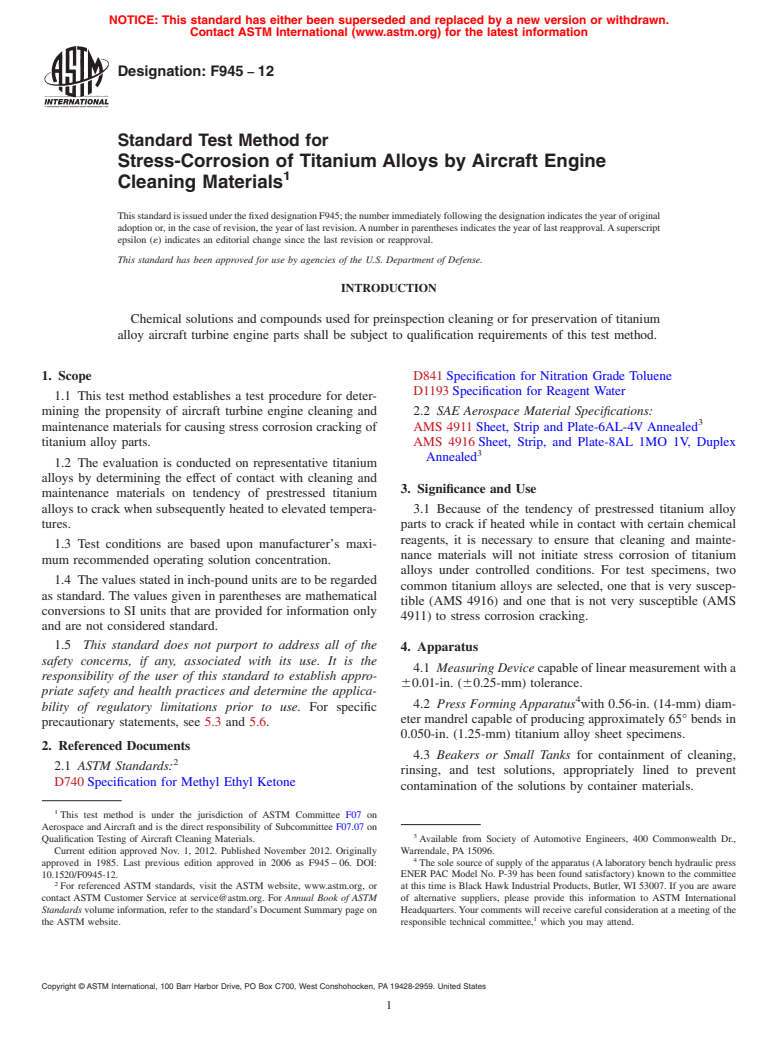

eter mandrel capable of producing approximately 65° bends in

precautionary statements, see 5.3 and 5.6.

0.050-in. (1.25-mm) titanium alloy sheet specimens.

2. Referenced Documents

4.3 Beakers or Small Tanks for containment of cleaning,

2

2.1 ASTM Standards:

rinsing, and test solutions, appropriately lined to prevent

D740 Specification for Methyl Ethyl Ketone

contamination of the solutions by container materials.

1

This test method is under the jurisdiction of ASTM Committee F07 on

Aerospace and Aircraft and is the direct responsibility of Subcommittee F07.07 on

3

Qualification Testing of Aircraft Cleaning Materials. Available from Society of Automotive Engineers, 400 Commonwealth Dr.,

Current edition approved Nov. 1, 2012. Published November 2012. Originally Warrendale, PA 15096.

4

approved in 1985. Last previous edition approved in 2006 as F945 – 06. DOI: The sole source of supply of the apparatus (Alaboratory bench hydraulic press

10.1520/F0945-12. ENER PAC Model No. P-39 has been found satisfactory) known to the committee

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or at this time is Black Hawk Industrial Products, Butler, WI 53007. If you are aware

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM of alternative suppliers, please provide this information to ASTM International

Standards volume information, refer to the standard’s Document Summary page on Headquarters.Your comments will receive careful consideration at a meeting of the

1

the ASTM website. responsible technical committee, which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F945 − 12

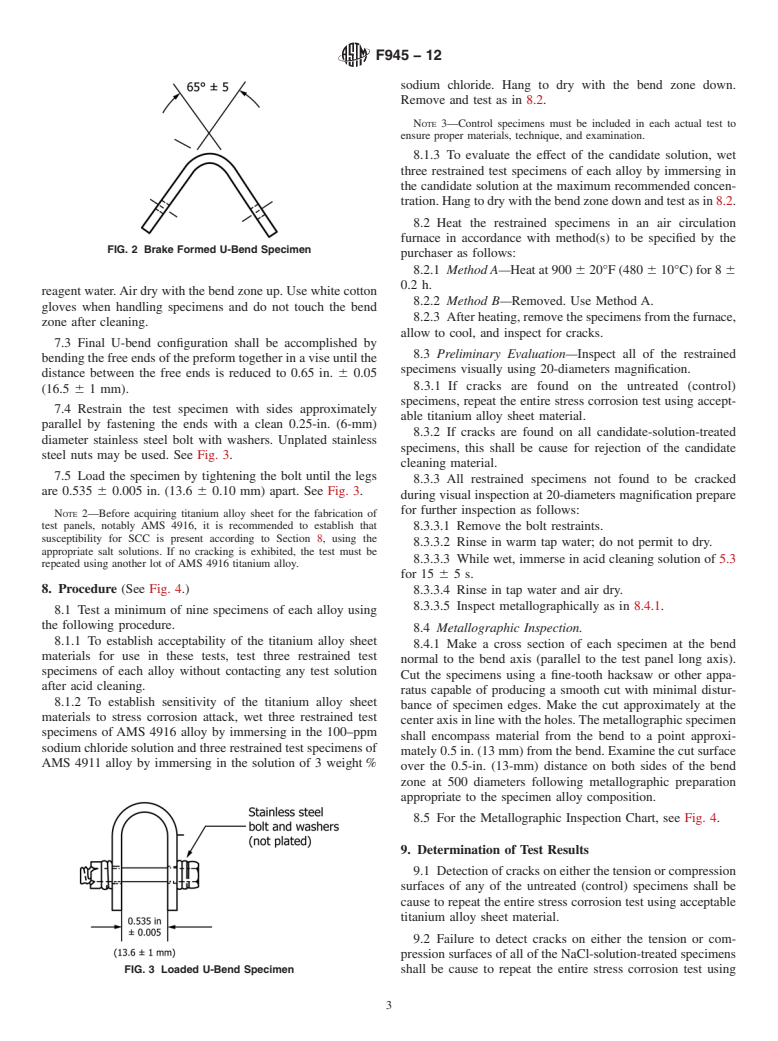

4.4 Vise, capable of precise manipulation at jaw opening of 5.3 Cleaning Solution, mix 35 volume % nitric acid (42°

0.65 in. (16.5 mm). A standard sheet metal worker’s vise with Be') (Warning —See Annex A1.2) and 3 volume % hydro–

a 3-in. jaw has been found satisfactory. fluoric acid (70 %) (Warning—SeeAnnex A1.3) with reagent

wat

...

Designation: F945 − 06 F945 − 12

Standard Test Method for

Stress-Corrosion of Titanium Alloys by Aircraft Engine

1

Cleaning Materials

This standard is issued under the fixed designation F945; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

INTRODUCTION

Chemical solutions and compounds used for preinspection cleaning or for preservation of titanium

alloy aircraft turbine engine parts shall be subject to qualification requirements of this test method.

1. Scope

1.1 This test method establishes a test procedure for determining the propensity of aircraft turbine engine cleaning and

maintenance materials for causing stress corrosion cracking of titanium alloy parts.

1.2 The evaluation is conducted on representative titanium alloys by determining the effect of contact with cleaning and

maintenance materials on tendency of prestressed titanium alloys to crack when subsequently heated to elevated temperatures.

1.3 Test conditions are based upon manufacturer’s maximum recommended operating solution concentration.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific precautionary statements, see 5.3 and 5.6.

2. Referenced Documents

2

2.1 ASTM Standards:

D740 Specification for Methyl Ethyl Ketone

D841 Specification for Nitration Grade Toluene

D1193 Specification for Reagent Water

2.2 SAE Aerospace Material Specifications:

3

AMS 4911 Sheet, Strip and Plate-6AL-4V Annealed

3

AMS 4916 Sheet, Strip, and Plate-8AL 1MO 1V, Duplex Annealed

3. Significance and Use

3.1 Because of the tendency of prestressed titanium alloy parts to crack if heated while in contact with certain chemical reagents,

it is necessary to ensure that cleaning and maintenance materials will not initiate stress corrosion of titanium alloys under

controlled conditions. For test specimens, two common titanium alloys are selected, one that is very susceptible (AMS 4916) and

one that is not very susceptible (AMS 4911) to stress corrosion cracking.

4. Apparatus

4.1 Measuring Device capable of linear measurement with a 60.01-in. (60.25-mm) tolerance.

4

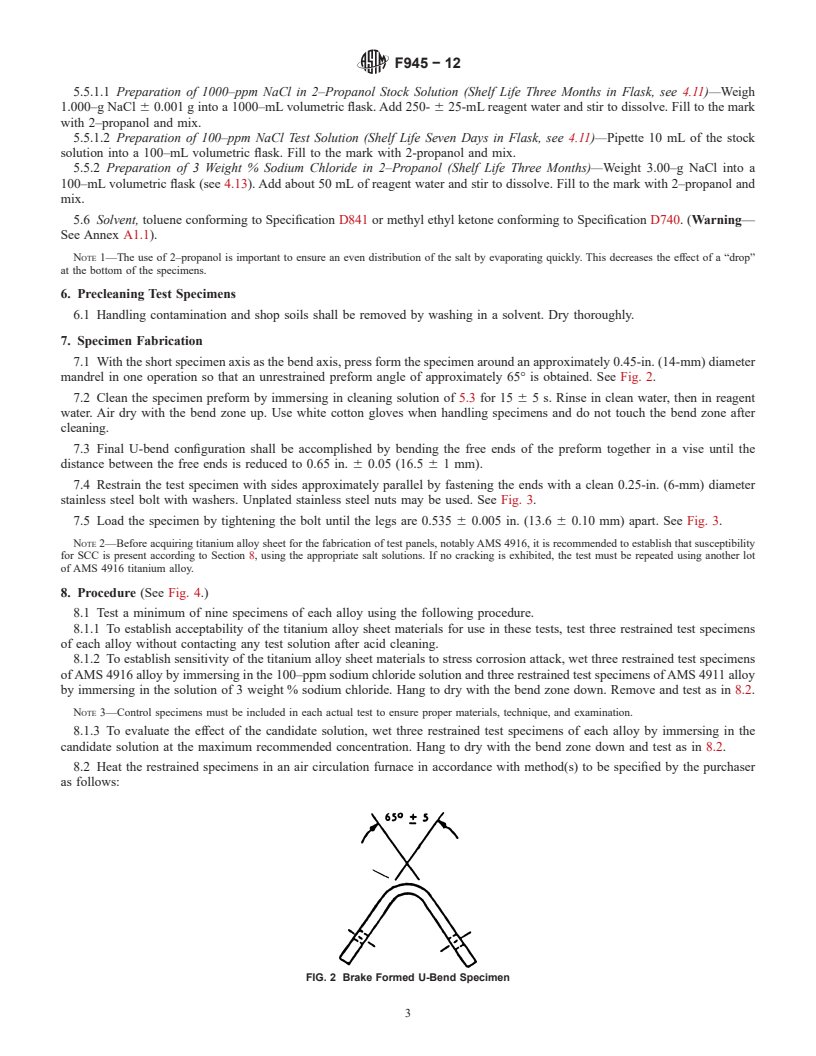

4.2 Press Forming Apparatus with 0.56-in. (14-mm) diameter mandrel capable of producing approximately 65° bends in

0.050-in. (1.25-mm) titanium alloy sheet specimens.

4.3 Beakers or Small Tanks for containment of cleaning, rinsing, and test solutions, appropriately lined to prevent contamination

of the solutions by container materials.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F945 − 12

4.4 Vise, capable of precise manipulation at jaw opening of 0.65 in. (16.5 mm). A standard sheet metal worker’s vise with a 3-in.

jaw has been found satisfactory.

4.5 Air Circulation Furnace capable of operating at 900°F (480°C) with control to 620°F (10°C).

4.6 Magnifier capable of 20-diameters magnification.

4.7 Microscope capable of 500-diameters magnification.

4.8 Bolt, stainless steel, 0.25-in. (6-mm) diameter with stainless steel washers and nut.

4.9 Test Specimens, AMS 4911 and AMS 4916 Titanium Alloys—with specimens prepared from the same sheet stock for each

alloy and cut parallel to the rolling direction to the dimensions of Fig. 1. The specimen edges shall not be deburred or otherwise

relieved before testing.

4.10 Cotton Gloves, white.

4.11 Volumetric Flask of Low Sodium Glass with Ground Glass Stopper, 1000 and 100 mL.

4.12 Volumetric Pipette, 10 mL.

4.13 Volumetric Flask with Ground Glass Stopper, 100 mL.

5. Reagents and Materials

5.1 Purity of Reagent—Reagent grade chemicals shall be used in all cases. Unless otherwise indicated, it is intended that all

reagents shall conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society, where

5

such specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high

purity to permit its use without lessening the accuracy of analysis.

5.2 Purity of Water—Unless otherwise indicated, references to water shall be understood to mean reagent water conforming to

Specification D1193 Type IV.

5.3 Cleaning Solution, mix 35 volume % nitric acid (42° Be`) (Warning —See Annex A1.2)

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.