ASTM D6420-99

(Test Method)Standard Test Method for Determination of Gaseous Organic Compounds by Direct Interface Gas Chromatography-Mass Spectrometry

Standard Test Method for Determination of Gaseous Organic Compounds by Direct Interface Gas Chromatography-Mass Spectrometry

SCOPE

1.1 This test method employs a direct interface gas chromatograph/mass spectrometer (GCMS) to identify and quantify the 36 volatile organic compounds (or sub-set of these compounds). The individual Chemical Abstract Service (CAS) numbers are listed after each compound.

1.2 The test method incorporates a performance-based approach, which validates each GCMS analysis by placing boundaries on the instrument response to gaseous internal standards and their specific mass spectral relative abundance. Using this approach, the test method may be extended to analyze other compounds.

1.3 The test method provides on-site analysis of extracted, unconditioned, and unsaturated (as the instrument) gas samples from stationary sources. Gas streams with high moisture content may require conditioning to prevent moisture condensation within the instrument. For these samples, quality assurance (QA) requirements are provided in the test method to validate the analysis of polar, water-soluble compounds.

1.4 The instrument range should be sufficient to measure the listed volatile organic compounds from 150 ppb(v) to 100 ppm(v), using a full scan operation (between 45 and 300 atomic mass units). The range may be extended to higher or lower concentrations using either of the following procedures:

1.4.1 The initial three-point calibration concentrations and the continuing calibration checks are adjusted to match the stack concentrations, or

1.4.2 The three-point calibration is extended to include additional concentrations to cover the measurement range.

1.5 The minimum quantification level is 50% of the lowest calibration concentration. Responses below this level are considered to be estimated concentration, unless a calibration standard check is conducted at a lower concentration to demonstrate linearity. The sensitivity of the GCMS measurement system for the individual target analytes depends upon:

1.5.1 The specific instrument response for each target analyte and the number of mass spectral quantification ions available.

1.5.2 The amount of instrument noise, and

1.5.3 The percent moisture content of the sample gas.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Additional safety precautions are described in Section 9.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 6420 – 99

Standard Test Method for

Determination of Gaseous Organic Compounds by Direct

Interface Gas Chromatography-Mass Spectrometry

This standard is issued under the fixed designation D 6420; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope atomic mass units). The range may be extended to higher or

lower concentrations using either of the following procedures:

1.1 This test method employs a direct interface gas

1.4.1 The initial three-point calibration concentrations and

chromatograph/mass spectrometer (GCMS) to identify and

the continuing calibration checks are adjusted to match the

quantify the 36 volatile organic compounds (or sub-set of these

stack concentrations, or

compounds) listed as follows. The individual Chemical Ab-

1.4.2 The three-point calibration is extended to include

stract Service (CAS) numbers are listed after each compound.

additional concentrations to cover the measurement range.

Benzene-71432 Methylene chloride-75092

1.5 The minimum quantification level is 50 % of the lowest

Bromodichloromethane-75274 1,1,2,2-Tetrachloroethane-79349

Carbon disulfide-75150 1,1,1-Trichloroethane-71556

calibration concentration. Responses below this level are

Chloroform-67663 1,1,2-Trichloroethane-79005

considered to be estimated concentrations, unless a calibration

Methyl iso-Butyl ketone-108101 p-Xylene-106423

standard check is conducted at a lower concentration to

Styrene-100425 Bromomethane-74839

Tetrachloroethylene-127184 Carbon tetrachloride-56235

demonstrate linearity. The sensitivity of the GCMS measure-

Toluene-108883 Chlorobenzene-108907

ment system for the individual target analytes depends upon:

Bromoform-75252 c-1,3-Dichloropropene-10061015

1.5.1 The specific instrument response for each target ana-

Vinyl acetate-108054 1,2-Dichloroethane-156592

Vinyl chloride-75014 1,1-Dichloroethene-75354

lyte and the number of mass spectral quantification ions

Chloromethane-74873 t-1,2-Dichloroethene-156605

available.

cis-1,2-Dichloroethene-156592 Methyl ethyl ketone-78933

Dibromochloromethane-124481 2-Hexanone-591786 1.5.2 The amount of instrument noise, and

1,1-Dichloroethane-107062 t-1,3-Dichloropropene-542756

1.5.3 The percent moisture content of the sample gas.

1,2-Dichloropropane-78875 Trichloroethene-79016

1.6 This standard does not purport to address all of the

Ethylbenzene-100414 m-Xylene-108383

Ethyl chloride-75003 o-Xylene-95476 safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

1.2 The test method incorporates a performance-based ap-

priate safety and health practices and determine the applica-

proach, which validates each GCMS analysis by placing

bility of regulatory limitations prior to use. Additional safety

boundaries on the instrument response to gaseous internal

precautions are described in Section 9.

standards and their specific mass spectral relative abundance.

Using this approach, the test method may be extended to

2. Referenced Documents

analyze other compounds.

2.1 ASTM Standards:

1.3 The test method provides on-site analysis of extracted,

D 1356 Terminology Relating to Sampling and Analysis of

unconditioned, and unsaturated (at the instrument) gas samples

Atmospheres

from stationary sources. Gas streams with high moisture

D 3195 Practice for Rotameter Calibration

content may require conditioning to prevent moisture conden-

2.2 EPA Test Methods:

sation within the instrument. For these samples, quality assur-

Method 1–Sample and Velocity Traverses for Stationary

ance (QA) requirements are provided in the test method to

Sources

validate the analysis of polar, water-soluble compounds.

Method 2–Determination of Stack Gas Velocity and Volu-

1.4 Theinstrumentrangeshouldbesufficienttomeasurethe

metric Flow Rate (Type S Pitot Tube)

listed volatile organic compounds from 150 ppb(v) to 100

Method 3–Gas Analysis for Carbon Dioxide, Oxygen, Ex-

ppm(v), using a full scan operation (between 45 and 300

cess Air, and Dry Molecular Weight

1 2

This test method is under the jurisdiction of ASTM Committee D-22 on Annual Book of ASTM Standards, Vol 11.03.

Sampling and Analysis of Atmospheres and is the direct responsibility of Subcom- Code of Federal Regulations 40 CFR Part 60, Appendix A, available from

mittee D22.03 on Ambient Atmospheres and Source Emissions. Superintendent of Documents, U.S. Government Printing Office, Washington, DC

Current edition approved May 10, 1999. Published July 1999. 20402.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 6420

Method 4–Determination of Moisture Content in Stack 5.2 Multiplying the mass concentration by the effluent

Gases volumetric flow rate (see 2.2) yields mass emission rates.

Method 624–Purgables 5.3 This field test method employs the typical laboratory

GCMS techniques and QA/QC procedures.

3. Terminology 5.4 This field test method provides data with accuracy and

precision similar to most laboratory GCMS instrumentation.

3.1 See Terminology D 1356 for definition of terms used in

this test method.

NOTE 1—Supporting data are available from ASTM Headquarters

3.2 Definitions of Terms Specific to This Standard:

Request RR:_______.

3.2.1 blank analysis, n—injecting zero air or nitrogen into

6. Interferences

the GCMS to determine background levels of the target

analytes.

6.1 Analytical Interferences—Analytical interferences oc-

3.2.2 CCC, n—continuing calibration check—injecting

cur when chromatographic peak(s) and quantification ion(s)

calibration gas standards into the GCMS to verify the calibra-

overlap to such an extent that quantification of specific target

tion status.

compounds is prohibited. The nature of the GCMS technique

3.2.2.1 Discussion—The continuing calibration check is

virtually eliminates these types of analytical interferences.

performed before each testing day, before resuming sampling

However, compounds having very simple mass spectra (that is,

afterinstrumentshutdownormalfunction,andbeforeresuming

only one or two mass fragments) may be difficult to identify

sampling after 12 h of continuous instrument operation.

positively.

3.2.3 quantification ion, n—a specific ion in the analytes

6.2 Sampling System Interferences—Sampling system inter-

mass spectrum that is used for quantification.

ferences occur when target analytes are not transported to the

3.2.4 system calibration, n—calibration obtained by inject-

instrumentation or when compounds damage the measurement

ing the calibration standard(s) through the entire sampling

system components. Water, reactive particulate matter, adsorp-

system.

tive sites within the sampling system components, and reactive

3.2.5 system zero, n—zero obtained by injecting dry nitro-

gases are examples of such potential sampling system interfer-

gen or zero gas through the entire sampling system to deter-

ences. Specific provisions and performance criteria are in-

mine the system background levels of the target analytes.

cluded in this test method to detect and prevent the presence of

sampling system interferences.

4. Summary of Test Method

4.1 Analysis—Volatile Organic Hazardous Air Pollutants 7. Apparatus

(VOHAP) are analyzed using gas chromatography (GC) to

7.1 Analytical Instrumentation:

separate the individual compounds and mass spectrometry

7.1.1 Gas Chromatograph/Mass Spectrometer (GCMS), ca-

(MS) to identify the compounds. The MS scans a defined mass

pable of separating the analyte mixture and detecting com-

range (usually from 45 to 300 atomic mass units (amu) for

pounds in the 45 to 300 atomic mass unit (amu) range.

combustion sources) to identify the specific fragments for each

7.1.2 Personal Computer, with compatible GCMS software

molecule. The target analytes are identified positively by: (1)

for control of the GCMS and for data quantification.

comparing eluting analyte GC peak retention times in the total

7.2 Sampling System:

ion chromatograph (TIC) to those contained in a three-point

7.2.1 Sampling Probe, glass, stainless steel, or other appro-

calibration, and (2) examining the mass spectral pattern of the

priate material of sufficient length and physical integrity to

eluted peaks. Internal standards are used to correct for

sustainheating,preventadsorptionofanalytes,andtoreachthe

hardware-related errors such as different injection volumes,

gas sampling point.

operational temperature fluctuations, and electron multiplier

7.2.2 Calibration Assembly, typically fabricated by user, to

drift.

introduce calibration standards into the sampling system at the

4.2 Sampling—Samples are extracted from the stack or duct

probe outlet, upstream of the primary particulate filter, at the

at a constant rate, filtered, conditioned (if required), and

same pressure and temperature as that of the effluent samples,

transported to the GCMS for analysis. Calibration gases are

with provisions for monitoring the sample pressure and tem-

introduced at the extractive probe outlet, upstream of the

perature during continuing calibrations and effluent sampling.

primaryparticulatefilter.Allsampleextractioncomponentsare

7.2.3 Particulate Filters, rated at 0.3 µm, placed immedi-

maintained at temperatures that prevent moisture condensation

ately after the heated probe and after the sample condenser

within the measurement system components.

system.

7.2.4 Pump, leak-free, with heated head, capable of main-

5. Significance and Use

taining an adequate sample flow rate (at least 1.5 L/min).

5.1 This field test method determines the mass concentra-

7.2.5 Sampling Line, of suitable internal diameter, heated to

tion of VOHAPs (or any subset) listed in Section 1.

prevent sample condensation, made of stainless steel, tetrafluo-

rocarbon polymer, or other material that minimizes adsorption

of analytes, of minimal length.

7.2.6 Sample Condenser System,arefrigerationunitcapable

Code of Federal Regulations 40 CFR Part 136, Appendix A, available from

of reducing and removing the moisture of the sample gas to a

Superintendent of Documents, U.S. Government Printing Office, Washington, DC

20402. level acceptable for sample injection.

D 6420

7.2.7 Sample Flow Rotameters, capable of withstanding certified by the manufacturer to be accurate to 5 % or better,

sample gas conditions, calibrated according to Practice used for the initial and continuing calibrations.

D 3195.

NOTE 2—The analytical accuracy of the calibration standards must be

7.2.8 Sample Transfer Line, to transport sample from

known. The analytical accuracy for gas mixtures may be concentration

sample interface to GCMS, heated to prevent sample conden-

dependent.

sation and fabricated of stainless steel, tetrafluorocarbon poly-

8.2 Internal Standards, manufacturer-certified mixtures for

mer, or other material to minimize adsorption of analytes, of

co-injection with sample gas.

minimal length.

8.3 High Purity (HP) Nitrogen or Zero Air, for purging

7.3 Auxiliary Equipment:

sample lines and sampling system components, dilutions, and

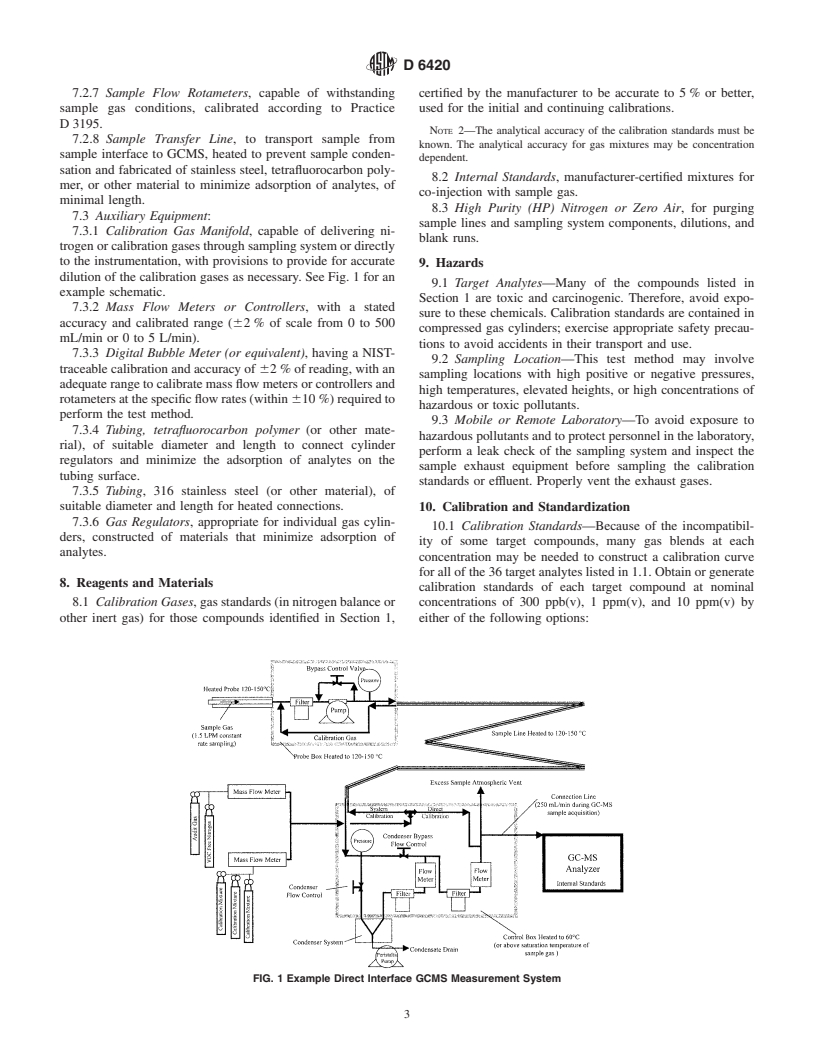

7.3.1 Calibration Gas Manifold, capable of delivering ni-

blank runs.

trogen or calibration gases through sampling system or directly

to the instrumentation, with provisions to provide for accurate

9. Hazards

dilution of the calibration gases as necessary. See Fig. 1 for an

9.1 Target Analytes—Many of the compounds listed in

example schematic.

Section 1 are toxic and carcinogenic. Therefore, avoid expo-

7.3.2 Mass Flow Meters or Controllers, with a stated

sure to these chemicals. Calibration standards are contained in

accuracy and calibrated range (62 % of scale from 0 to 500

compressed gas cylinders; exercise appropriate safety precau-

mL/min or 0 to 5 L/min).

tions to avoid accidents in their transport and use.

7.3.3 Digital Bubble Meter (or equivalent), having a NIST-

9.2 Sampling Location—This test method may involve

traceable calibration and accuracy of 62 % of reading, with an

sampling locations with high positive or negative pressures,

adequate range to calibrate mass flow meters or controllers and

high temperatures, elevated heights, or high concentrations of

rotametersatthespecificflowrates(within 610 %)requiredto

hazardous or toxic pollutants.

perform the test method.

9.3 Mobile or Remote Laboratory—To avoid exposure to

7.3.4 Tubing, tetrafluorocarbon polymer (or other mate-

hazardous pollutants and to protect personnel in the laboratory,

rial), of suitable diameter and length to connect cylinder

perform a leak check of the sampling system and inspect the

regulators and minimize the adsorption of analytes on the

sample exhaust equipment before sampling the calibration

tubing surface.

standards or effluent. Properly vent the exhaust gases.

7.3.5 Tubing, 316 stainless steel (or other material), of

suitable diameter and length for heated connections. 10. Calibration and Standardization

7.3.6 Gas Regulators, appropriate for individual gas cylin-

10.1 Calibration Standards—Because of the incompatibil-

ders, constructed of materials that minimize adsorption of

ity of some target compounds, many gas blends at each

analytes.

concentration may be needed to construct a calibration curve

for all of the 36 target analytes listed in 1.1. Obtain or generate

8. Reagents and Materials

calibration standards of each target compound at nominal

8.1 Calibration Gases, gas standards (in nitrogen balance or concentrations of 300 ppb(v), 1 ppm(v), and 10 ppm(v) by

other inert gas) for those compounds identified in Section 1, either of the following options:

FIG. 1 Example Direct Interface GCMS Measurement System

D 6420

TABLE 2 Relative Ion Abundance Criteria for

10.1.1 Option 1—Obtain calibration gas standards for the

Bromofluorobenzene

target compounds at the three specified nominal concentra-

Mass Fragment Ion Abundance Criteria

tions.

50 15-40 %

10.1.2 Option 2—Obtain 10 ppm(v) calibration standards

75 30-60 %

for the target analytes. Then successively dilute the 10 ppm(v)

95 Base peak

standard with ultra-pure nitrogen using mass flow meters.

96 5-9 % of mass 95

Dilute the 10 ppm(v) standard to 1 ppm(v) and then the 1 173 <2 % of mass 174

174 >50 % of mass 95

ppm(v) to 300 ppb(v). If Option 2 is used, analyze the

175 5-9 % of mass 174

calibration check (see Table 5) compounds directly as a QA

176 >95 % but <101 % of mass 174

177 5-9 % of mass 174

audit of the dilution technique. The audit result using the

calibrated GCMS must be within 620 % for the cal

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.