ASTM D3535-07a(2021)

(Test Method)Standard Test Method for Resistance to Creep Under Static Loading for Structural Wood Laminating Adhesives Used Under Exterior Exposure Conditions

Standard Test Method for Resistance to Creep Under Static Loading for Structural Wood Laminating Adhesives Used Under Exterior Exposure Conditions

SIGNIFICANCE AND USE

5.1 This test method rates the performance of the adhesive in laminated wood as measured by resistance to creep under static load.

5.2 This test method will normally be used in conjunction with Specification D2559.

SCOPE

1.1 This test method covers adhesives suitable for the bonding of wood, including treated wood, into structural laminated wood products for general construction, for marine use, or for other uses where a high-strength general construction, creep-resistant, waterproof adhesive bond is required.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3535 − 07a (Reapproved 2021)

Standard Test Method for

Resistance to Creep Under Static Loading for Structural

Wood Laminating Adhesives Used Under Exterior Exposure

Conditions

This standard is issued under the fixed designation D3535; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D907 Terminology of Adhesives

D2559 Specification for Adhesives for Bonded Structural

1.1 This test method covers adhesives suitable for the

Wood Products for Use Under Exterior Exposure Condi-

bonding of wood, including treated wood, into structural

tions

laminated wood products for general construction, for marine

use, or for other uses where a high-strength general

3. Terminology

construction, creep-resistant, waterproof adhesive bond is re-

quired. 3.1 Definitions:

3.1.1 glulam, n—synonym for structural-glued-laminated

1.2 The values stated in SI units are to be regarded as the

timber.

standard. The values given in parentheses are for information

only.

3.1.2 structural-glued-laminated timber, n—an engineered,

stress-rated product of a timber laminating plant comprising

1.3 This standard does not purport to address all of the

assemblies of specially selected and prepared wood lamina-

safety concerns, if any, associated with its use. It is the

tions securely bonded together with adhesives, with the fol-

responsibility of the user of this standard to establish appro-

lowing characteristics: (1) the grain of all laminations is

priate safety, health, and environmental practices and deter-

approximately parallel longitudinally; and (2) the laminations

mine the applicability of regulatory limitations prior to use.

may be comprised of pieces end-joined to form any length, of

1.4 This international standard was developed in accor-

pieces placed or glued edge-to-edge to make wider ones or of

dance with internationally recognized principles on standard-

pieces bent to curved form during gluing. (Synonym glulam)

ization established in the Decision on Principles for the

ANSI/AITC A190.1 – 2002, American National Standard for

Development of International Standards, Guides and Recom-

Wood Products—Structural Glued Laminated Timber (Edited

mendations issued by the World Trade Organization Technical

to conform with ASTM format).

Barriers to Trade (TBT) Committee.

3.1.3 For other terms used in this test method, refer to

2. Referenced Documents

Terminology D907.

2.1 ASTM Standards:

A125 Specification for Steel Springs, Helical, Heat-Treated

4. Summary of Test Method

4.1 Gluedlaminationsaresubjectedtoaconstantloadunder

This test method is under the jurisdiction of ASTM Committee D14 on

various combinations of temperature and relative humidity.

Adhesives and is the direct responsibility of Subcommittee D14.30 on Wood

Adhesives.

The amount of creep is measured.

Current edition approved April 1, 2021. Published April 2021. Originally

approved in 1976. Last previous edition approved in 2013 as D3535 – 07a (2013).

5. Significance and Use

DOI: 10.1520/D3535-07AR21.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.1 This test method rates the performance of the adhesive

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in laminated wood as measured by resistance to creep under

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. static load.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3535 − 07a (2021)

5.2 This test method will normally be used in conjunction 7.4 Freshly knife plane each lamination before applying the

with Specification D2559. test adhesive. The machining tolerances for each lamination

used in preparing the test specimen shall be no greater than

6. Apparatus

60.25 mm (0.01 in.) between laminations and 60.20 mm

(0.008 in.) within laminations. Observe the most severe of the

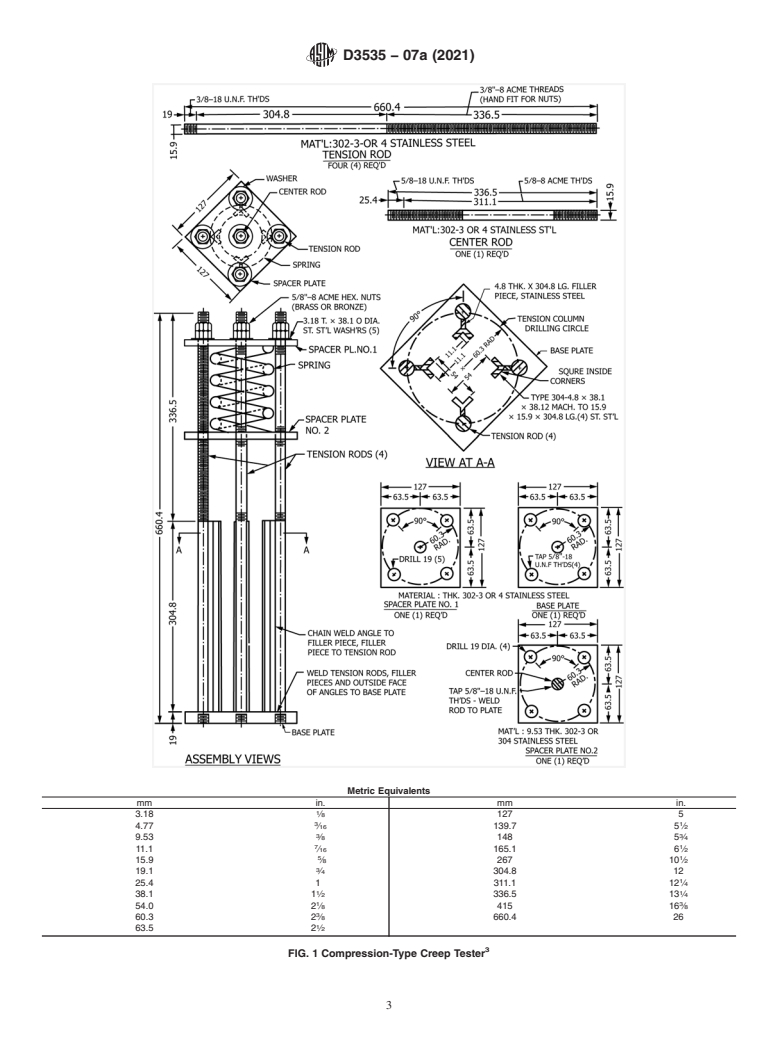

6.1 Compression-Type Creep Tester, as shown in Fig. 1,

above tolerances.

required for testing the specimens under the static load. This

tester consists of:

8. Test Specimens

6.1.1 Base Plate,

6.1.2 Four Tension Rods,

8.1 The laminated wood members shall be prepared from

6.1.3 Spacer Plate, 5 1

boards 15.9 mm ( ⁄8 in.) thick by 63.5 mm (2 ⁄2 in.) wide by

6.1.4 Center Rod,

304.9 mm (12 in.) along the grain for each test condition. Each

6.1.5 Spring,

test lamination shall be made from two outer laminations as

6.1.6 Top Plate, and

above and alternate metal spacers and wood sections for the

6.1.7 Nuts.

inner lamination (Fig. 3). The wood sections shall be sliced

from a third board identical to that above. The wood sections

6.2 Metal Spacers, coated with an effective mold-release

1 5

shall be 28.5 mm (1 ⁄8 in.) along the grain by 15.9 mm ( ⁄8 in.)

agent. Seven are needed for each laminate. Dimensions are

3 5 1

thick by 63.5 mm wide.The laminated wood members shall be

69.8mm(2 ⁄4in.)longby15.9mm( ⁄8in.)wideby6.4mm( ⁄4

prepared by alternately laying seven metal spacers on edge

in.) thick. Spacers made of other materials may also be used

tightly adjacent to eight wood center sections. The wood

provided it does not react with the adhesive and can be

sections should be slightly thicker than the metal spacers to

removed without disturbing the specimen.

obtain adequate pressure on the gluelines. It has been found

6.3 Oven, capable of maintaining 71 6 2°C (160 6 3.6°F)

that running a 13-mm ( ⁄2-in.) piece of tape completely around

and humidity chamber capable of maintaining 26.7 6 2°C (80

the 16 loose pieces holds them together as a unit while gluing.

6 3.6°F) and 90 6 5 % relative humidity.

Glue should be applied to the outer laminations and not the

NOTE 1—Some ovens may not be able to accommodate a full length

center ply. The outer laminations shall then be applied over-

creep tester. Since the test specimen is 276 mm in length, it is permissible

to reduce the “filler pieces” and angles to a length of 267 mm each lapping about 13 mm on each end and the entire assembly

allowing pressure to be exerted directly on the test specimen without the

carefully clamped and the adhesive cured as recommended.

use of filler blocks. Fig. 2 shows an optional creep tester. The changes are

After curing and clamp removal, the metal spacers shall be

to the lengths of the 4-tension rods, center rod, angles and filler pieces.

pushed gently (not impact driven) out. Then each three-ply

Use of this tester requires special care when choosing a spring (see

laminated wood member shall be trimmed along the sides to

footnote 3 in Fig. 1 and 10.1) that will fit the reduced space. All other

measurements will be the same as Fig. 1. leave a width of 50.8 6

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.