ASTM E1898-97

(Test Method)Standard Test Method for Determination of Silver in Copper Concentrates by Flame Atomic Absorption Spectrometry

Standard Test Method for Determination of Silver in Copper Concentrates by Flame Atomic Absorption Spectrometry

SCOPE

1.1 This test method covers the determination of silver in the range of 50 g/g to 1000 g/g by acid dissolution of the silver and measurement by atomic absorption spectrophotometry. Copper concentrates are internationally traded within the following concentration ranges:ElementUnit Concentration RangeAluminum%0.05to 2.50Antimony%0.0001to 4.50Arsenic%0.01to 0.50Barium%0.003to 0.10Bismuth%0.001to 0.16Cadmium%0.0005to 0.04Calcium%0.05to 4.00Carbon %0.10to 0.90Chlorine%0.001to 0.006Chromium%0.0001to 0.10Cobalt%0.0005to 0.20Copper%10.0to 44.0Fluorine%0.001to 0.10Gold g/g1.40to100.0Iron %12.0to30.0Lead %0.01to1.40Magnesium%0.02to 2.00Manganese%0.009to 0.10Mercuryg/g0.05to 50.0Molybdenum% 0.002to 0.25Nickel%0.0001to 0.08Silicon%0.40to 20.0Silverg/g18.0to 8000Sulfur%10.0to 36.0Tin %0.004to0.012Zinc %0.005to4.30

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to its use./p>

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1898 – 97

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Determination of Silver in Copper Concentrates by Flame

1

Absorption Spectrometry

This standard is issued under the fixed designation E 1898; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

2

1. Scope Determine Conformance With Specifications

E 50 Practices for Apparatus, Reagents and Safety Precau-

1.1 This test method covers the determination of silver in

2

tions for Chemical Analysis of Metals

the range of 50 μg/g to 1000 μg/g by acid dissolution of the

3

E 663 Practice for Flame Atomic Absorption Analysis

silver and measurement by atomic absorption spectrophotom-

E 882 Guide for Accountability and Quality Control in the

etry. Copper concentrates are internationally traded within the

3

Chemical Analysis of Metals

following concentration ranges:

E 1024 Guide for Chemical Analysis of Metals and Metal

Element Unit Concentration Range

Bearing Ores by Flame Atomic Absorption Spectropho-

Aluminum % 0.05 to 2.50

3

Antimony % 0.0001 to 4.50

tometry

Arsenic % 0.01 to 0.50

E 1601 Practice for Conducting an Interlaboratory Study to

Barium % 0.003 to 0.10

2

Evaluate the Performance of an Analytical Method

Bismuth % 0.001 to 0.16

Cadmium % 0.0005 to 0.04

E 1763 Guide for Interpretation and Use of Results from

Calcium % 0.05 to 4.00

2

Interlaboratory Testing of Chemical Analysis Methods

Carbon % 0.10 to 0.90

Chlorine % 0.001 to 0.006

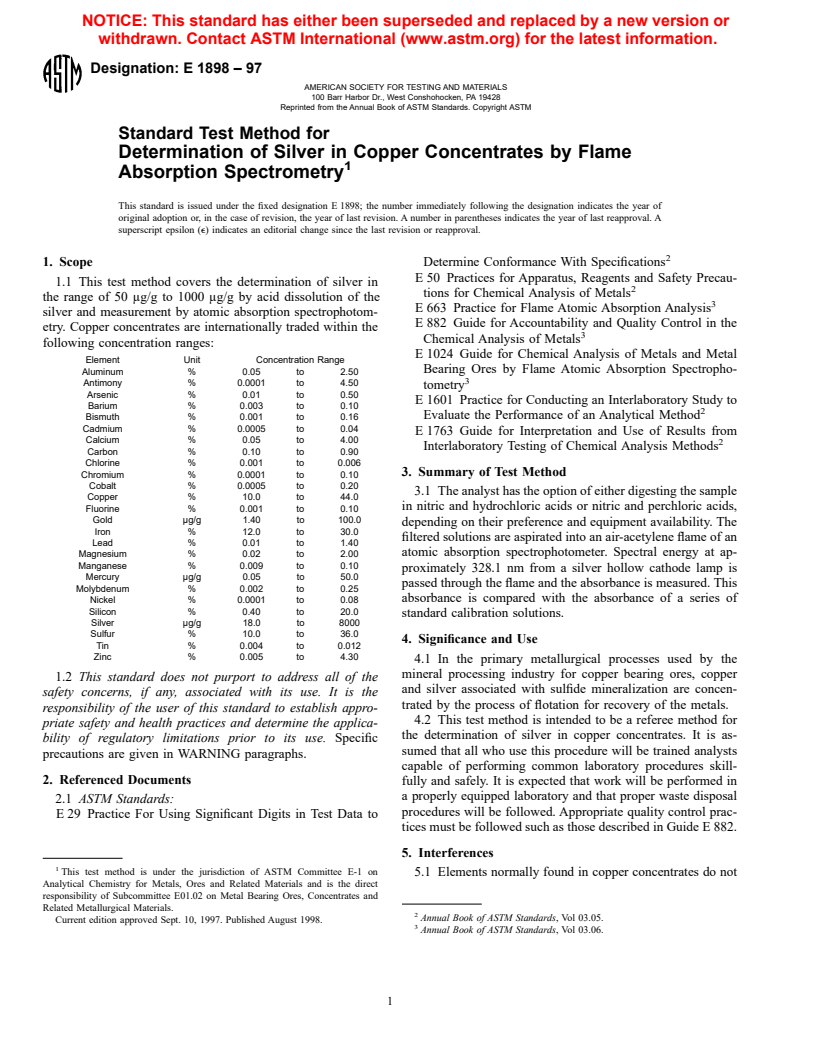

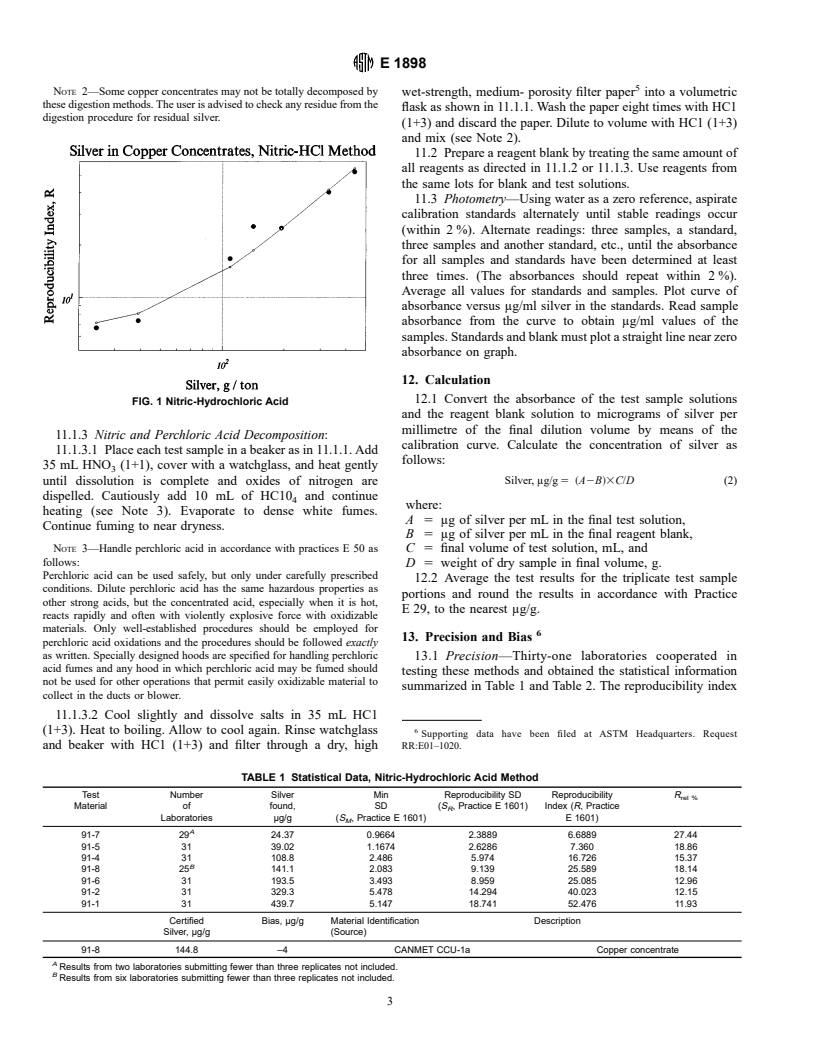

3. Summary of Test Method

Chromium % 0.0001 to 0.10

Cobalt % 0.0005 to 0.20

3.1 The analyst has the option of either digesting the sample

Copper % 10.0 to 44.0

in nitric and hydrochloric acids or nitric and perchloric acids,

Fluorine % 0.001 to 0.10

Gold μg/g 1.40 to 100.0

depending on their preference and equipment availability. The

Iron % 12.0 to 30.0

filtered solutions are aspirated into an air-acetylene flame of an

Lead % 0.01 to 1.40

atomic absorption spectrophotometer. Spectral energy at ap-

Magnesium % 0.02 to 2.00

Manganese % 0.009 to 0.10

proximately 328.1 nm from a silver hollow cathode lamp is

Mercury μg/g 0.05 to 50.0

passed through the flame and the absorbance is measured. This

Molybdenum % 0.002 to 0.25

absorbance is compared with the absorbance of a series of

Nickel % 0.0001 to 0.08

Silicon % 0.40 to 20.0

standard calibration solutions.

Silver μg/g 18.0 to 8000

Sulfur % 10.0 to 36.0

4. Significance and Use

Tin % 0.004 to 0.012

Zinc % 0.005 to 4.30

4.1 In the primary metallurgical processes used by the

mineral processing industry for copper bearing ores, copper

1.2 This standard does not purport to address all of the

and silver associated with sulfide mineralization are concen-

safety concerns, if any, associated with its use. It is the

trated by the process of flotation for recovery of the metals.

responsibility of the user of this standard to establish appro-

4.2 This test method is intended to be a referee method for

priate safety and health practices and determine the applica-

the determination of silver in copper concentrates. It is as-

bility of regulatory limitations prior to its use. Specific

sumed that all who use this procedure will be trained analysts

precautions are given in WARNING paragraphs.

capable of performing common laboratory procedures skill-

2. Referenced Documents

fully and safely. It is expected that work will be performed in

a properly equipped laboratory and that proper waste disposal

2.1 ASTM Standards:

procedures will be followed. Appropriate quality control prac-

E 29 Practice For Using Significant Digits in Test Data to

tices must be followed such as those described in Guide E 882.

5. Interferences

1

This test method is under the jurisdiction of ASTM Committee E-1 on

5.1 Elements normally found in copper concentrates do not

Analytical Chemistry for Metals, Ores and Related Materials and is the direct

responsibility of Subcommittee E01.02 on Metal Bearing Ores, Concentrates and

Related Metallurgical Materials.

2

Annual Book of ASTM Standards, Vol 03.05.

Current edition approved Sept. 10, 1997. Published August 1998.

3

Annual Book of ASTM Standards, Vol 03.06.

1

---------------------- Page: 1 ----------------------

E 1898

interfere. Use of instrumental background correction is re- 10.2.1 With the silver hollow cathode lamp in position,

quired to compensate for non specific absorption interferences energized and stabilized, adjust the wavelength to maximize

in the flame. the energy response of the 328.1 nm line.

10.2.2 Light the burner, allo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.