ASTM B328-96(2003)e1

(Test Method)Standard Test Method for Density, Oil Content, and Interconnected Porosity of Sintered Metal Structural Parts and Oil-Impregnated Bearings (Withdrawn 2009)

Standard Test Method for Density, Oil Content, and Interconnected Porosity of Sintered Metal Structural Parts and Oil-Impregnated Bearings (Withdrawn 2009)

SIGNIFICANCE AND USE

The volume of an arbitrary P/M shape cannot be accurately measured by standard techniques such as by micrometers or calipers. Since density is mass/volume, a precise method to measure the volume is needed. For nonporous objects, the volume of water displaced by the immersed object is determined by Archimedes principle. For porous P/M parts, a method is required to seal surface connected pores. If the pores are not sealed or the part is not oil impregnated, the part will absorb some of the water and decrease its buoyancy and exhibit an erroneously high density.

Density and oil content values are generally contained in the specifications for oil-impregnated bearings and other self-lubricating P/M parts. Desired lubrication requires sufficient interconnected porosity and satisfactory oil impregnation of the porosity.

For a particular P/M material, the mechanical properties of P/M structural parts are directly related to their density. Density values are therefore generally contained in the specifications for P/M parts.

SCOPE

1.1 This test method covers determination of the density, oil content, and interconnected porosity of sintered bearings and structural parts with or without oil impregnation.

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers determination of the density, oil content, and interconnected porosity of sintered bearings and structural parts with or without oil impregnation.

Formerly under the jurisdiction of Committee B09 on Metal Powders and Metal Powder Products, this test method was withdrawn in April 2009, because the test method has been split into two new standards B962 and B963 respectively.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation:B328–96(Reapproved 2003)

Standard Test Method for

Density, Oil Content, and Interconnected Porosity of

Sintered Metal Structural Parts and Oil-Impregnated

Bearings

This standard is issued under the fixed designation B328; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e NOTE—Section 9 was editorially updated in July 2006.

1. Scope crometers or calipers. Since density is mass/volume, a precise

method to measure the volume is needed. For nonporous

1.1 Thistestmethodcoversdeterminationofthedensity,oil

objects, the volume of water displaced by the immersed object

content, and interconnected porosity of sintered bearings and

is determined byArchimedes principle. For porous P/M parts,

structural parts with or without oil impregnation.

a method is required to seal surface connected pores. If the

1.2 The values stated in SI units are to be regarded as the

pores are not sealed or the part is not oil impregnated, the part

standard. The values in parentheses are for information only.

will absorb some of the water and decrease its buoyancy and

1.3 This standard does not purport to address all of the

exhibit an erroneously high density.

safety concerns, if any, associated with its use. It is the

4.2 Densityandoilcontentvaluesaregenerallycontainedin

responsibility of the user of this standard to establish appro-

the specifications for oil-impregnated bearings and other self-

priate safety and health practices and determine the applica-

lubricating P/M parts. Desired lubrication requires sufficient

bility of regulatory limitations prior to use.

interconnectedporosityandsatisfactoryoilimpregnationofthe

2. Referenced Documents

porosity.

4.3 ForaparticularP/Mmaterial,themechanicalproperties

2.1 ASTM Standards:

of P/M structural parts are directly related to their density.

B243 Terminology of Powder Metallurgy

Density values are therefore generally contained in the speci-

D1217 Test Method for Density and Relative Density

fications for P/M parts.

(Specific Gravity) of Liquids by Bingham Pycnometer

D1298 TestMethodforDensity,RelativeDensity(Specific

5. Apparatus

Gravity), or API Gravity of Crude Petroleum and Liquid

5.1 Analytical Balance, of sufficient capacity and accurate

Petroleum Products by Hydrometer Method

to 0.01% of the test specimen mass.

3. Terminology

5.2 Device for weighing the test piece in air and in liquid

(water); the water is distilled or deionized and preferably

3.1 Definitions of powder metallurgy (P/M) terms can be

degassed.Awettingagent isaddedtothewater,0.05to0.1%

found in Terminology B243. Additional descriptive informa-

by weight, to reduce surface tension effects.

tionisavailableintheRelatedMaterialsectionofVol02.05of

5.3 Soxhlet Extractor, with oil solvent. Extractors may be

the Annual Book of ASTM Standards.

purchased from most laboratory supply companies.

4. Significance and Use

5.4 Apparatus for vacuum impregnation of the test piece

with oil.

4.1 The volume of an arbitrary P/M shape cannot be

5.5 Beaker and Wires, of various sizes. A wire basket may

accurately measured by standard techniques such as by mi-

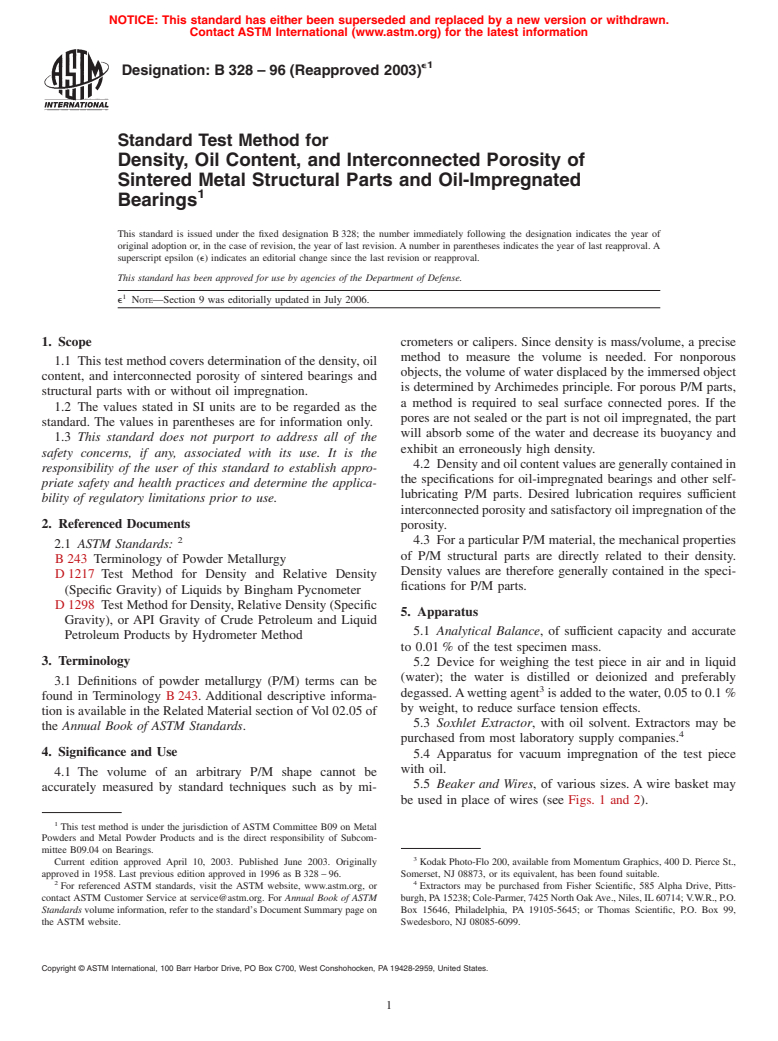

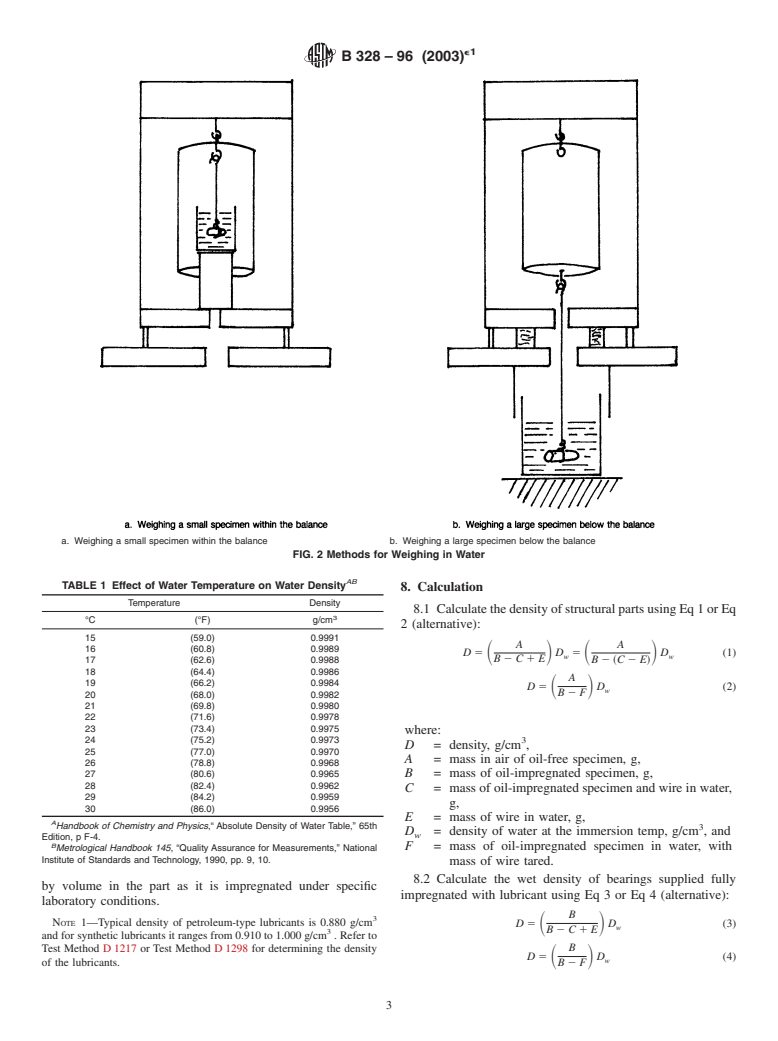

be used in place of wires (see Figs. 1 and 2).

This test method is under the jurisdiction of ASTM Committee B09 on Metal

Powders and Metal Powder Products and is the direct responsibility of Subcom-

mittee B09.04 on Bearings.

Current edition approved April 10, 2003. Published June 2003. Originally Kodak Photo-Flo 200, available from Momentum Graphics, 400 D. Pierce St.,

approved in 1958. Last previous edition approved in 1996 as B328–96. Somerset, NJ 08873, or its equivalent, has been found suitable.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Extractors may be purchased from Fisher Scientific, 585 Alpha Drive, Pitts-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM burgh,PA15238;Cole-Parmer,7425NorthOakAve.,Niles,IL60714;V.W.R.,P.O.

Standards volume information, refer to the standard’s Document Summary page on Box 15646, Philadelphia, PA 19105-5645; or Thomas Scientific, P.O. Box 99,

the ASTM website. Swedesboro, NJ 08085-6099.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

B328–96 (2003)

eitherofthefollowingtwomethodsmaybeusedtoimpregnate

the test specimen. The vacuum method is preferred.

7.3.1 At room temperature, using a suitable evacuating

method, reduce the pressure over the immersed specimen to

not more than 7 kPa (2 in. mercury) pressure for 30 min.Then

permitthepressuretoincreasetoatmosphericpressureandthe

specimen to remain immersed in oil 20 to 65 cSt (100 to 300

SSU) 38°C (100°F) at room temperature and pressure for 10

min.

7.3.2 Immerse the specimen in oil, viscosity of 20 to 65 cSt

(100 to 300 SSU) at 38°C (100°F), hold at a temperature of

a. Twisted wire arrangement b. Basket support arrangement

82°C 6 5°C (180°F 6 10°F) for at least 4 h, and then cool to

FIG. 1 Methods for Holding Test Specimen When Weighing in

Water

room temperature by immersion in oil at room temperature.

7.4 To weigh the specimen in water, select a fine wire for

supporting the specimen. Suspend the wire from the beam

5.6 Thermometer—Capable of reading temperature in the

hook, while the specimen is immersed in a beaker of distilled

range of 10 to 38°C (50 to 100°F) to an accuracy of 0.5°C

water.Supportthebeakerofwateroverthepanofthebalance,

(1°F).

using a suitable bridge. The container of water may also be

5.7 Lubricant, of 20 to 65 cSt (100 to 300 SSU) at 38°C

supported below the balance for weighing specimens if the

(100°F).

balance has a lower beam hook for this purpose. See Fig. 2b.

Useawettingagent(intheamountof0.05to0.1%byweight)

6. Test Specimen

to reduce the effects of surface tension. The recommended

diameter of wire (copper or stainless steel) to be used for

6.1 The specimen mass shall be a minimum of 1.0 g.

various weight range is as follows:

Several specimens may be used to reach the minimum mass.

less than 50 g−0.12 mm (0.005 in.)

50 to less than 200 g−0.25 mm (0.010 in.)

7. Procedure

200 to less than 600 g−0.40 mm (0.015 in.)

7.1 Using an analytical balance, obtain the mass of the as

600 g and greater−0.50 mm (0.020 in.)

received oil-containing specimen (Mass J), the oil-free speci-

In place of attaching the specimen on a wire, the use of a

men (MassA), and the fully impregnated specimen (Mass B).

wire basket suspended in water may be used as an alternate

These,andallsubsequentweighing,shouldbeto0.01%ofthe

method (see Fig. 1b).

mass of the part, for example:

7.5 Twistthewirearoundthespecimenandsuspenditfrom

Specimen Mass, g Balance Sensitivity, g

thebeamhooksothatthespecimeniscompletelyimmersedin

less than 10 0.0001

the water. The water should cover the specimen by at least 6

10 to less than 100 0.001

mm (0.25 in.) and the wire twist should be completely

100 to less than 1000 0.01

1000 to less than 10 000 0.1

submerged. Immersion should be to the same point each time.

Take care to ensure that no air bubbles adhere to the specimen

7.2 To determine MassA, remove any oil from the samples

or to the wire. If a wire basket is used as an alternate method,

by extracting it in a Soxhlet apparatus of suitable size using

completely immerse the wire basket in the water.

toluol or petroleum ether as a solvent. After extracting for

7.6 Weigh the specimen and wire in water. This is Mass C.

approximately 1 h, r

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.