ASTM C225-85(1999)

(Test Method)Standard Test Methods for Resistance of Glass Containers to Chemical Attack

Standard Test Methods for Resistance of Glass Containers to Chemical Attack

SCOPE

1.1 These test methods cover the evaluation of the resistance of glass containers to chemical attack. Three test methods are presented, as follows:

1.1.1 Test Method B-A covers autoclave tests at 121°C on bottles partially filled with dilute acid as the attacking medium.

1.1.2 Test Method B-W covers autoclave tests at 121°C on bottles partially filled with distilled water as the attacking medium.

1.1.3 Test Method P-W covers autoclave tests at 121°C on powdered samples with pure water as the attacking medium.

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 225 – 85 (Reapproved 1999)

Standard Test Methods for

Resistance of Glass Containers to Chemical Attack

This standard is issued under the fixed designation C 225; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope E 691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 These test methods cover the evaluation of the resis-

tance of glass containers to chemical attack. Three test methods

3. Significance and Use

are presented, as follows:

3.1 The solubility of glass in contact with food, beverages,

1.1.1 Test Method B-A covers autoclave tests at 121°C on

or pharmaceutical products is an important consideration for

bottles partially filled with dilute acid as the attacking medium.

the safe packaging and storage of such materials. Autoclave

1.1.2 Test Method B-W covers autoclave tests at 121°C on

conditions are specified since sterilization is often employed

bottles partially filled with distilled water as the attacking

for the packaging of the product. It also represents one of the

medium.

most extreme conditions, particularly of temperature, that

1.1.3 Test Method P-W covers autoclave tests at 121°C on

containers will ordinarily experience. Any of the three test

powdered samples with pure water as the attacking medium.

methods described may be used to establish specifications for

1.2 The values stated in SI units are to be regarded as the

conformity to standard values, either as specified by a cus-

standard. The values in parentheses are for information only.

tomer, an agency, or “The United States Pharmacopeia:”

1.3 This standard does not purport to address all of the

3.1.1 Test Method B-A is intended particularly for testing

safety concerns, if any, associated with its use. It is the

glass containers primarily destined for containment of products

responsibility of the user of this standard to establish appro-

with a pH under 5.

priate safety and health practices and determine the applica-

3.1.2 Test Method B-W is intended particularly for testing

bility of regulatory limitations prior to use.

glass containers to be used for products with a pH of 5.0 or

2. Referenced Documents over.

3.1.3 Test Method P-W is a hydrolytic autoclave test prima-

2.1 ASTM Standards:

rily intended for evaluating samples from untreated glass

A 569/A 569M Specification for Steel, Carbon (0.15 Maxi-

containers. It is often useful for testing the resistance of

mum Percent), Hot-Rolled Sheet and Strip Commercial

2 containers of too small capacity to permit measurements of

Quality

solubility on the unbroken article by the B-W test method.

D 1125 Test Methods for Electrical Conductivity and Re-

3 Yielding the water resistance of the bulk glass, it can also be

sistivity of Water

used in conjunction with the B-W test method to distinguish

D 1193 Specification for Reagent Water

whether the internal surface of a container has been treated to

E 11 Specification for Wire-Cloth Sieves for Testing Pur-

improve its durability.

poses

3.2 All three test methods are suitable for specification

acceptance.

These test methods are under the jurisdiction of ASTM Committee C-14 on

4. Purity of Reagents

Glass and Glass Products and are the direct responsibility of Subcommittee C14.03

on Chemical Properties.

4.1 Reagent grade chemicals shall be used in all tests.

Current edition approved July 26, 1985. Published September 1985. Originally

e1

Unless otherwise indicated, it is intended that all reagents shall

published as C 225 – 49 T. Last previous edition C 225 – 85 (1994) .

Annual Book of ASTM Standards, Vol 01.03.

conform to the specifications of the Committee on Analytical

Annual Book of ASTM Standards, Vol 11.01.

Reagents of the American Chemical Society, where such

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C 225 – 85 (1999)

specifications are available. Other grades may be used, pro- to the first persistent pink color. Adjust the standard NaOH

vided it is first ascertained that the reagent is of sufficiently solution to 0.020N strength.

high purity to permit its use without lessening the accuracy of 6.4.1 Calculate the normality N of the NaOH solution as

the determination. follows:

4.2 Unless otherwise indicated, references to water shall be

N 5 0.9798/mL of NaOH (1)

understood to mean distilled water or other water meeting the

requirements for one of the types of reagent water covered by

6.5 High-Purity Water—This water shall be free of heavy

Specification D 1193.

metals, particularly copper, as shown by a dithizone test and

have a conductivity (consult Test Methods D 1125) not exceed-

TEST METHOD B-A—RESISTANCE OF BOTTLES

ing 0.15 μS/cm.

TO ATTACK BY DILUTE ACID

6.5.1 The source water shall be distilled, then passed

through a deionizer cartridge packed with a mixed bed of

5. Apparatus

nuclear-grade resin, then through a cellulose ester membrane

5.1 Autoclave or Steam Sterilizer, capable of withstanding a

having openings not exceeding 0.45 μm. Pass the purified

pressure of 165 kPa (24 psi) and, preferably, equipped with a

water through an in-line conductivity cell to verify its purity.

constant-pressure regulator or other means for maintaining the

After flushing discharge lines, suitable water should be dis-

temperature at 121 6 0.5°C (250 6 0.9°F). This temperature

pensed directly into the test vessels.

shall be checked by means of a suitably calibrated instrument.

The autoclave shall be capable of accommodating at least six NOTE 1—Copper tubing should not be used in the discharge lines.

TFE-fluorocarbon or pure tin are suitable.

and preferably twelve of the largest containers to be tested. It

NOTE 2—Reference should be made to Specification D 1193. Type I

shall be equipped with a rack for supporting the samples, a

reagent water as defined therein complies with the present 6.5. In the

thermometer, a pressure gage, and a vent cock.

interest of practicality and demonstrated sufficiency, 6.5 allows the

following deviations from Type I reagent water specifications.

6. Reagents and Materials

(1) Source water is unspecified whereas Type I specifies source water

6.1 Acetone, USP grade. having a maximum conductivity of 20 μS/cm at 25°C.

(2) The final step is filtration through a membrane having openings not

6.2 Methyl Red Indicator Solution—Dissolve 24 mg of the

exceeding 0.45 μm. Type I directs filtration through a 0.2-μm membrane.

sodium salt of methyl red in 100 mL of water. If necessary,

(3) The conductivity immediately before dispensing is required not to

neutralize the indicator solution with 0.020N sodium hydroxide

exceed 0.15 μS/cm at 25°C whereas Type I is limited to 0.06 μS/cm at

(NaOH) solution so that the titer of five drops of the indicator

25°C.

solution in 100 mL of the special distilled water does not

The distillation step is essential to minimize or avoid cultivation of

exceed 0.02 mL of 0.020N NaOH solution. In titrations using

microorganisms in the ion-exchange bed and consequent clogging of the

the methyl red indicator solution, the end point shall be taken membrane filter. When preceded by distillation, the ion-exchange bed

should have a long life, but as the conductivity begins to rise toward the

at a pH of 5.6.

limit it should be replaced by a new bed.

6.3 Phenolphthalein Indicator Solution—Dissolve 0.5 g of

Distillation from phosphoric acid with a conductivity of the product

phenolphthalein in 60 mL of ethyl alcohol (95 %) and dilute

between 0.5 and 1.0 μS/cm was specified as water for extraction in Test

with water to 100 mL.

Methods C 225. Water prepared as described herein gave results averaging

6.4 Sodium Hydroxide Solution, Standard (0.020N)—

about 8 % higher than water prepared by distillation from phosphoric acid

Dissolve 100 g of NaOH in 100 mL of water in a 150-mL test

when Test Method B-W was applied to soda-lime and borosilicate glass

tube. Avoid wetting the top of the test tube. Stopper the tube bottles in seven laboratories. The trend to slightly greater extraction may

be associated with the higher average purity of this water. The limit on

loosely with a stopper covered with tinfoil and allow to stand

conductivity of 0.15 μS/cm for water prepared by this means was set

in a vertical position until the supernatant liquid is clear.

because water of less conductivity is readily obtained and when 0.15

Withdraw some of the clear solution in a measuring pipet and

μS/cm is exceeded, the conductivity rises rapidly on further use of the

deliver 1.3 mL into a paraffin-lined bottle containing 1 L of

system.

carbon dioxide (CO )-free water. Stopper the bottle with a

6.6 Sulfuric Acid, Standard (0.020N) containing approxi-

two-hole stopper carrying a glass siphon tube (for delivering

mately 0.58 mL of concentrated sulfuric acid (H SO ,spgr

2 4

the solution to a buret) and a soda-lime or soda-asbestos guard

1.84) in 1 L of solution. Prepare 0.1N H SO containing 3.0

2 4

tube. Standardize the 0.020N NaOH solution against the

National Institute of Standards and Technology Standard

Sample No. 84h of acid potassium phthalate. Transfer 0.2000 g

Feigl, Fritz, “Spot Tests in Inorganic Analysis,” D. Van Nostrand Co., Inc.,

of the phthalate to a 250-mL Erlenmeyer flask and dissolve in

Princeton, NJ, 1958, p. 90; H. J. Wichman, “Isolation and Determination of Traces

about 75 mL of CO -free water. Add five drops of phenol-

of Metals,” Industrial and Engineering Chemistry, Vol 11, No. 2, 1939, pp. 67–72.

A nuclear-grade resin mixture of the strong acid cation exchanger in the

phthalein indicator solution and titrate with the NaOH solution

hydrogen form and the strong base anion exchanger in the hydroxide form with a

one-to-one cation to anion equivalence ratio, such as that available from the

Millipore Corp., 80 Ashby Rd., Bedford, MA 01730; Barnstead Co., 225 Rivermoor

Reagent Chemicals, American Chemical Society Specifications, American St., Boston, MA 02131; Illinois Water Treatment Co., 854 Cedar St., Rockford, IL

Chemical Society, Washington, DC. For suggestions on the testing of reagents not 61105; or Vaponics, Inc., 200 Cordage Park, Plymouth, MA 02360, has been found

listed by the American Chemical Society, see Analar Standards for Laboratory satisfactory for this purpose.

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia An in-line filter such as those made by the Millipore Corp., Gelman Instrument

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, Co., 600 S. Wagner Rd., Ann Arbor, MI 48106; and Schleicher and Schuell, Inc.,

MD. 540 Washington St., Keene, NH 10003 has been found satisfactory for this purpose.

C 225 – 85 (1999)

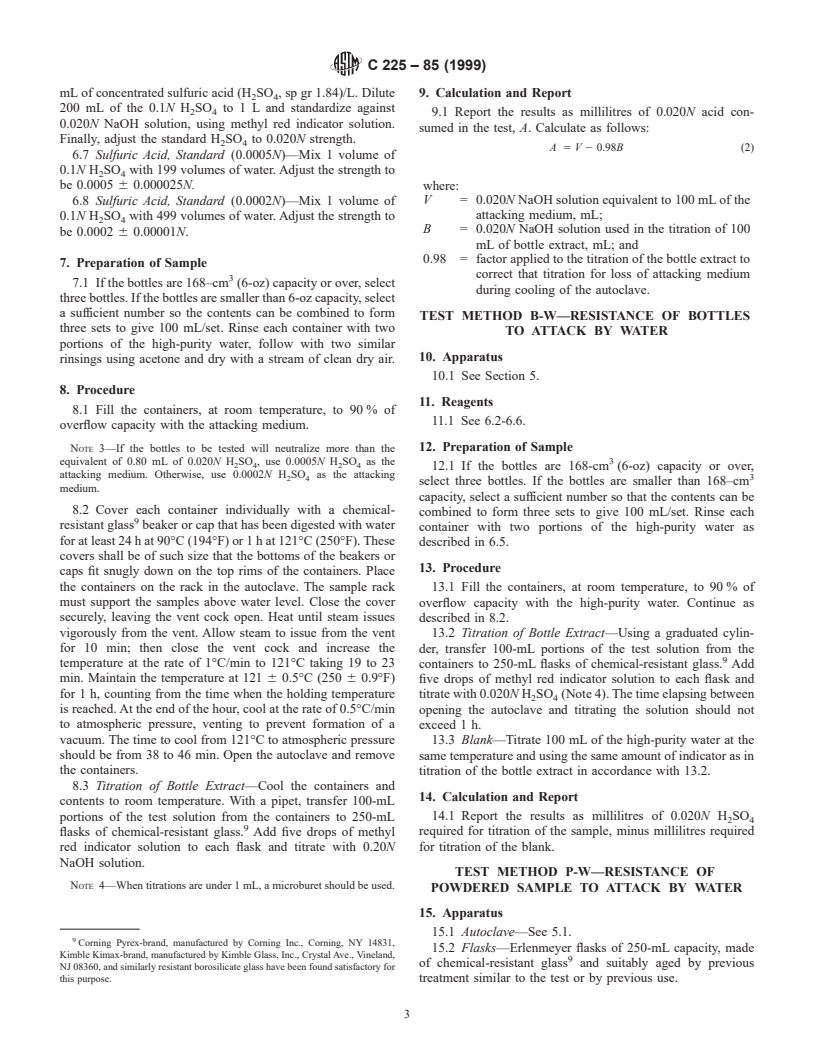

mL of concentrated sulfuric acid (H SO , sp gr 1.84)/L. Dilute 9. Calculation and Report

2 4

200 mL of the 0.1N H SO to 1 L and standardize against

2 4

9.1 Report the results as millilitres of 0.020N acid con-

0.020N NaOH solution, using methyl red indicator solution.

sumed in the test, A. Calculate as follows:

Finally, adjust the standard H SO to 0.020N strength.

2 4

A 5 V 2 0.98B (2)

6.7 Sulfuric Acid, Standard (0.0005N)—Mix 1 volume of

0.1N H SO with 199 volumes of water. Adjust the strength to

2 4

be 0.0005 6 0.000025N.

where:

V = 0.020N NaOH solution equivalent to 100 mL of the

6.8 Sulfuric Acid, Standard (0.0002N)—Mix 1 volume of

attacking medium, mL;

0.1N H SO with 499 volumes of water. Adjust the strength to

2 4

B = 0.020N NaOH solution used in the titration of 100

be 0.0002 6 0.00001N.

mL of bottle extract, mL; and

0.98 = factor applied to the titration of the bottle extract to

7. Preparation of Sample

correct that titration for loss of attacking medium

7.1 If the bottles are 168–cm (6-oz) capacity or over, select

during cooling of the autoclave.

three bottles. If the bottles are smaller than 6-oz capacity, select

a sufficient number so the contents can be combined to form

TEST METHOD B-W—RESISTANCE OF BOTTLES

three sets to give 100 mL/set. Rinse each container with two

TO ATTACK BY WATER

portions of the high-purity water, follow with two similar

10. Apparatus

rinsings using acetone and dry with a stream of clean dry air.

10.1 See Section 5.

8. Procedure

11. Reagents

8.1 Fill the containers, at room temperature, to 90 % of

11.1 See 6.2-6.6.

overflow capacity with the attacking medium.

12. Preparation of Sample

NOTE 3—If the bottles to be tested will neutralize more than the

equivalent of 0.80 mL of 0.020N H SO , use 0.0005N H SO as the 3

2 4 2 4

12.1 If the bottles are 168-cm (6-oz) capacity or over,

attacking medium. Otherwise, use 0.0002N H SO as the attacking

2 4

select three bottles. If the bottles are smaller than 168–cm

medium.

capacity, select a sufficient number so that the contents can be

8.2 Cover each container individually with a chemical-

combined to form three sets to give 100 mL/set. Rinse each

resistant glass beaker or cap that has been digested with water

container with two portions of the high-purity water as

for at least 24 h at 90°C (194°F) or1hat 121°C (250°F). These

described in 6.5.

covers shall be of such size that the bottoms of the beakers or

13. Procedure

caps fit snugly down on the top rims of the containers. Place

the containers on the rack in the autoclave. The sample rack

13.1 Fill the containers, at room temperature, to 90 % of

must support the samples above water level. Close the cover

overflow capacity with the high-purity water. Continue as

securely, leaving the vent cock open. Heat until steam issues

described in 8.2.

vigorously from the vent. Allow steam to issue from the vent 13.2 Titration of Bottle Extract—Using a graduated cylin-

for 10 min; then close the vent cock and increase the

der, transfer 100-mL portions of the test solution from the

temperature at the rate of 1°C/min to 121°C taking 19 to 23 containers to 250-mL flasks of chemical-resistant glass. Add

min. Maintain the temperature at 121 6 0.5°C (250 6 0.9°F)

five drops of methyl red indicator solution to each flask and

for 1 h, counting from the time when the holding temperature titrate with 0.020N H SO (Note 4). The time elapsing between

2 4

is reached. At the end of the hour, cool at the rate of 0.5°C/min

opening the autoclave and titrating the solution should not

to atmospheric pressure, venting to prevent formation of a exceed 1 h.

vacuum. The time to cool from 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.