ASTM E1544-99

(Practice)Standard Practice for Construction of a Stepped Block and Its Use to Estimate Errors Produced by Speed-of-Sound Measurement Systems for Use on Solids

Standard Practice for Construction of a Stepped Block and Its Use to Estimate Errors Produced by Speed-of-Sound Measurement Systems for Use on Solids

SCOPE

1.1 This practice provides a means for evaluating both systematic and random errors for ultrasonic speed-of-sound measurement systems which are used for evaluating material characteristics associated with residual stress and which may also be used for nondestructive measurements of the dynamic elastic moduli of materials. Important features and construction details of a reference block crucial to these error evaluations are described. This practice can be used whenever the precision and bias of sound speed values are in question.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 1544 – 99

Standard Practice for

Construction of a Stepped Block and Its Use to Estimate

Errors Produced by Speed-of-Sound Measurement Systems

for Use on Solids

This standard is issued under the fixed designation E 1544; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope driving pulse as the start marker. Reference techniques that use

two nearly identical sets of experiments, where one is the

1.1 This practice provides a means for evaluating both

reference and the other the unknown and in which the

systematic and random errors for ultrasonic speed-of-sound

difference in time of travel is the output result, cancel out many

measurement systems which are used for evaluating material

of the errors mentioned above (1).

characteristics associated with residual stress and which may

also be used for nondestructive measurements of the dynamic

4. Summary of Practice

elastic moduli of materials. Important features and construction

4.1 The physical quantity, speed of sound of a particular

details of a reference block crucial to these error evaluations

solid, is not a fundamental constant because it depends on

are described. This practice can be used whenever the precision

separate measurements of time and distance. It is a computed

and bias of sound speed values are in question.

value derived from measured values of distance and of time

1.2 This standard does not purport to address all of the

and is based on assumptions about the elastic material through

safety concerns, if any, associated with its use. It is the

which the sound waves travel. Because this quantity is not a

responsibility of the user of this standard to establish appro-

fundamental property (dependent upon many other variables

priate safety and health practices and determine the applica-

besides time and distance) of any material, a reference standard

bility of regulatory limitations prior to use.

having a specific value of speed of sound is virtually impos-

2. Referenced Documents sible to construct. Thus, questions of accuracy have to be

addressed in a different way.

2.1 ASTM Standards:

4.2 The measurement of sound speed depends upon many

E 650 Guide for Mounting Piezoelectric Acoustic Emission

factors. Considerations of the uniformity of both the elastic and

Sensors

the density characteristics of the material, of internal scattering,

E 494 Practice for Measuring Ultrasonic Velocity in Mate-

2 of transducer coupling and loading, of temperature uniformity

rials

and value, of external pressure and stress, and of many other

3. Terminology physical effects that would alter the overall measurement

process must be taken into account. Because the speed of

3.1 Definitions of Terms Specific to This Standard:

sound is affected by so many physical parameters, the only

3.1.1 path length—length of track along which the sound

available test to evaluate the detrimental influence of these

waves actually propagate.

higher order variables is to examine their combined effects on

3.1.2 time of flight—the measured time interval between the

measured speed of sound values as it relates to the definition:

launching of a sonic input pulse at the start of a path and the

time of reception of the pulse at the end of the path of travel. V 5 L/t (1)

3.1.2.1 Discussion—There are many different techniques

4.2.1 This defining equation for the sound speed, V, states a

used to avoid termination errors related to electronic delays and

constant relationship between path length, L, and time of flight,

termination impedance effects and end interference. One com-

t, and is applicable primarily to methods in which the time is

monly accepted procedure is to make the time measurement

measured directly (2).

between successive echoes instead of using the electrical

4.3 Several different methods of measuring speed of sound

exist. A number of these are itemized in Practice E 494.

(McSkimin details many ingenious methods in Ref (1)).

This practice is under the jurisdiction of ASTM Committee E-28 on Mechanical

Regardless of the method used to calculate the sound speed

Testing and is the direct responsibility of Subcommittee E28.13 on Residual Stress

Measurement.

Current edition approved October 10, 1999. Published December 1999. Origi-

nally published as E 1544 – 93. Last previous edition E 1544 – 94. The boldface numbers in parentheses refer to a list of references at the end of

Annual Book of ASTM Standards, Vol 03.03. the text.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 1544

from two measurements, the intent is to determine this con- 4.6 Any gage block used for the purpose of checking the

stant, V, that represents the transport of the elastic potential process of sound speed measurement must have uniform elastic

function and related parameters through the solid body. and density characteristics throughout the gage block; thus, it

4.4 This definition is based on the assumption that the must be homogeneous and isotropic. Only then can it be

medium that transmits the elastic waves is both homogeneous assumed that the speed of sound is uniform and not dependent

and isotropic. In such a case, a constant, V, is the applicable on location and wave direction within the gage block. A

property throughout the whole volume and in all directions of method for assuring the high uniformity of the block is

the solid body. To the degree that this assumption holds, (Eq 1) detailed.

and any other analytical description associated with other

5. Significance and Use

methods should yield a linear relationship between time of

5.1 The use of sound speed values to determine changes in

flight (or other parameters) and path length traversed. (Another

the elastic constants due to applied or residual stress requires

form of this comparison would be for the computed sound

that such measurements be of high precision and low bias. For

speed to be a constant for different paths of different lengths.)

that reason, special evaluation tests to determine a representa-

Errors from this linear prediction are associated with errors in

tive precision and bias for the specific technique, method, and

the measurement of time of flight (or the other parameters) and

equipment setup used are given.

path length. Deviation of the measured values of sound speed

5.2 Speed of sound is a measure that depends on the

beyond the estimated errors in the time measurement and the

accurate measurements of length of path of travel and transit

length measurement are connected with the systematic and

time or other related parameters such as frequency, etc. Both

random errors associated with all other unwanted variables of

measurements are subject to certain interpretations and as-

non-ideal material, non-ideal measuring technique, and lack of

sumptions and are highly dependent on laboratory expertise.

control on the many variables of indirect influence. An ex-

This practice provides a means of checking overall technique.

ample of a second order dependence is a nonlinear relationship

5.3 This practice shall be used when it is necessary to assess

between time and distance due to diffraction effects associated

the systematic and random errors associated with a particular

with a finite transducer aperture.

speed of sound measurement in a solid medium. It can be used

4.5 In order to check a particular sound speed measuring

to check both equipment performance and measurement tech-

system or particular applied technique, or both, a stepped gage

nique for these errors. It can also be used to study inherent

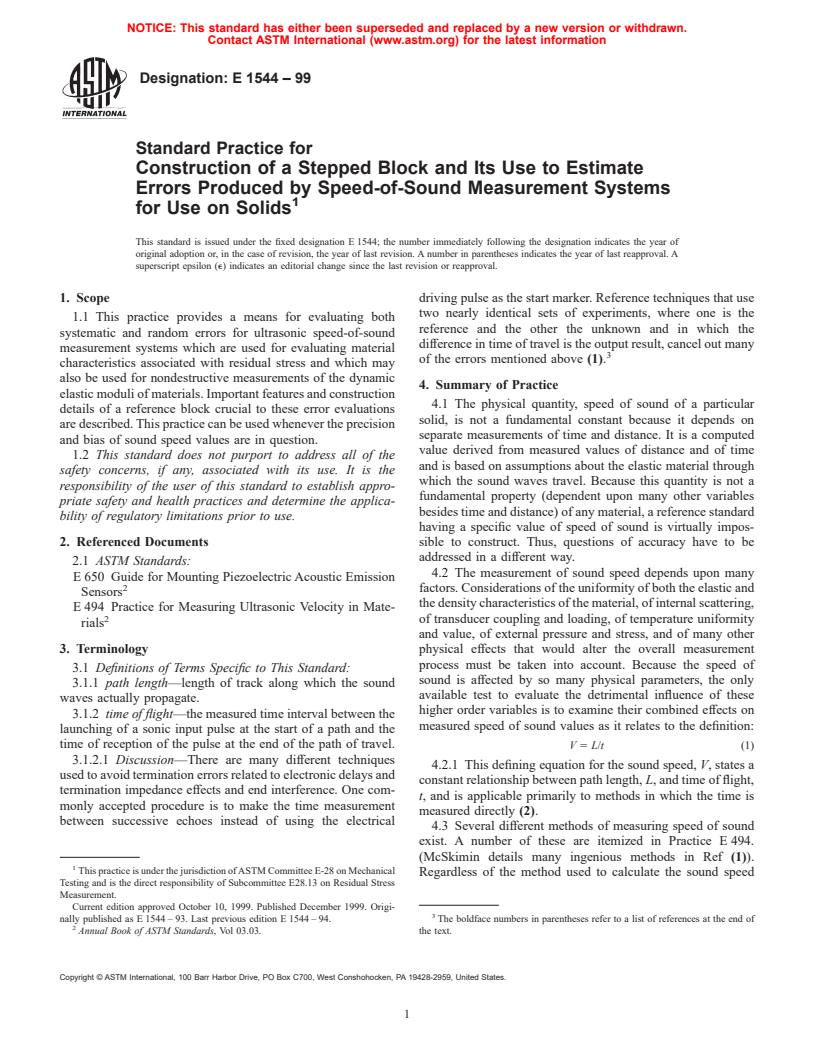

block, similar to Fig. 1, of very uniform material properties can

errors in a particular method. It can also be used to assess

be constructed to check the performance of a measurement

proposed corrections to sound speed measurements such as the

system by examining differences from the predicted linear

phase corrections of Papadakis (3, 4).

relationship of Eq 1. Demonstrating that the calculated speed

5.4 The resultant precision and bias determined by the use

of sound, V, is constant for the different path lengths as

of the described block represents a more ideal situation than the

determined in such a gage block experiment is a necessary

same measurement performed in practice, in the field. Thus,

condition for the confirmation of system performance to have

the error for the specific field measurement may be larger than

a lack of bias. The described gage block has six path lengths,

indicated by this test. This test represents the best error

although a reference gage block for this purpose need not be

condition for a given technique and practice.

limited to such a geometry. (Another geometry that is easier to

manufacture is a rectangular parallelepiped with three dis-

6. Procedure

tinctly different dimensions (2). Polyhedra of parallel opposite

6.1 Speed of Sound Test Block Construction:

sides would also be appropriate.)

6.1.1 Construct a glass block of the general shape and size

of Fig. 1 of optical quality glass having at least a medium

valued stress-optic coefficient (5). A stress-optic coefficient in

the range of 20 to 40 nm/cm/MPa is desirable and the sample

should be well annealed for a low internal stress state. Adhere

to the glass manufacturer’s annealing schedule. The dimen-

sions of such a reference glass block can be chosen to

approximate the dimensions and time of flight simulating the

situation for which this assurance test is being done.

NOTE 1—The test block constructed and tested has nominal dimensions

of L1 = 63.5 mm, L2 = 66.7 mm, L3 = 69.9 mm, L4 = 73 mm, L5 = 88.9

mm, and L6 = 101.6 mm. The step or facet on which the transducer is

mounted should, of course, be at least as large as the aperture of the

transducer.

6.1.2 The glass of this block shall be free of internal stresses

and variations of optical index throughout its volume. Deter-

mine these two important features by examining the glass

NOTE 1—Sound speed reference block manufactured of optical quality

blank from which the block is to be cut between crossed

glass of high uniformity. The multiple sound propagation paths are marked

polarizers before the cutting and polishing processes begin.

L1 through L6.

FIG. 1 Sound Speed Reference Block, Optical Glass Also, apply this test intermittently during both the grinding and

E 1544

polishing processes, and on the completed block. Any signifi- 6.2.4 Correct each sound speed value for thermal expansion

cant change in optical index or any significant internal stress and thermal changes in the elasticity associated with tempera-

patterns will show up immediately as a nonuniformity in the ture variation occurring between measurements of the different

visual optical field. (A good quality optical glass that is well path lengths of the set and then plot against the measured path

length.

annealed and is uniform in temperature during observation will

show no shadow or dark regions when viewed between crossed 6.2.5 If poor precision or significant bias is suspected,

measure and plot several values for each path length. This

polaroids and the viewing regions will be perfectly uniform.

Any region of shadow is an indication of optical birefringence process will help establish a precision value for this particular

arrangement and path length. In general, make at least five

associated with variations of uniformity of various physical

separate measurements of speed of sound for each path length

parameters such as density, internal stress, and temperature.)

to ascertain consistency of the process. From this set of

Shadowed regions represent positions where the relative retar-

measurements a standard deviation can be computed and error

dation differs by at least one-fifth of a wavelength of the

bounds assigned for each length.

illumination used. Such a visual indication should be grounds

6.2.6 The results for all path lengths can then be examined

for rejection of the material blank.

for the variation of the measured sound speed values from a

6.1.3 Grind and polish all surfaces to better than 0.5 μm of

single constant value. (The average value might be satisfactory

being flat and each surface shall be cut so as to be parallel to

for this purpose.)

the opposite surface.

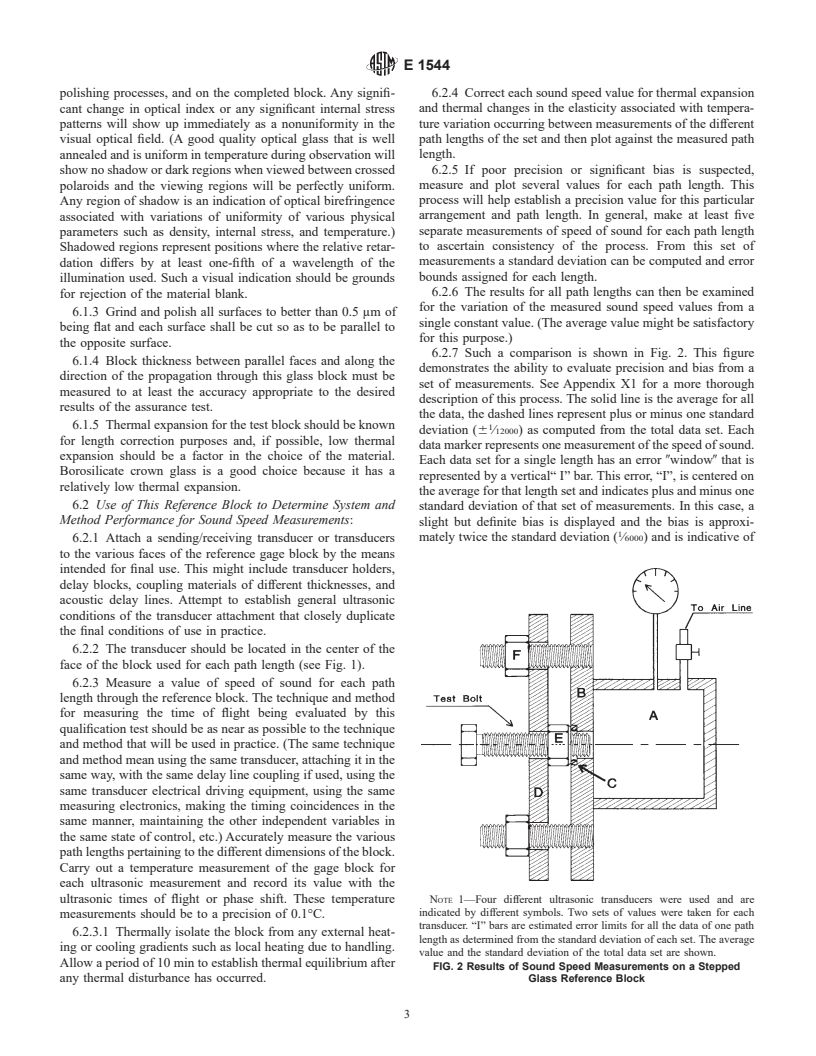

6.2.7 Such a comparison is shown in Fig. 2. This figure

6.1.4 Block thickness between parallel faces and along the

demonstrates the ability to evaluate precision and bias from a

direction of the propagation through this glass block must be

set of measurements. See Appendix X1 for a more thorough

measured to at least the accuracy appropriate to the desired

description of this process. The solid line is the average for all

results of the assurance test.

the data, the dashed lines represent plus or minus one standard

6.1.5 Thermal expansion for the test block should be known

deviation (6 ⁄12000) as computed from the total data set. Each

for length correction purposes and, if possible, low thermal

data marker represents one measurement of the speed of sound.

expansion should be a factor in the choice of the material.

Each data set for a single length has an error 9window9 that is

Borosilicate crown glass is a good choice because it has a

represented by a vertical“ I” bar. This error, “I”, is centered on

relatively low thermal expansion.

the average for that length set and indicates plus and minus one

6.2 Use of This Reference Block to Determine System and

standard deviation of that set of measurements. In this case, a

Method Performance for Sound Speed Measurements:

slight but definite bias is displayed and the bias is approxi-

mately twice the standard deviation ( ⁄6000) and is indicative of

6.2.1 Attach a sending/receiving transducer or transducers

to the various faces of the reference gage block by the means

intended for final use. This might include transducer holders,

delay blocks, coupling materials of different thicknesses, and

acoustic delay lines. Attempt to establish general ultrasonic

conditions of the transducer attachment that closely duplicate

the final conditions of use in practice.

6.2.2 The transducer should be located in the center of the

face of the block used for each path length (see Fig. 1).

6.2.3 Measure a value of speed of sound for each path

length through the reference block. The technique and method

for measuring the time of flight being evaluated by this

qualification test should be as near as possible to the technique

and method that will be used in practice. (The same techniq

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.