ASTM D6706-01(2007)

(Test Method)Standard Test Method for Measuring Geosynthetic Pullout Resistance in Soil

Standard Test Method for Measuring Geosynthetic Pullout Resistance in Soil

SIGNIFICANCE AND USE

The pullout test method is intended as a performance test to provide the user with a set of design values for the test conditions examined.

5.1.1 The test method is applicable to all geosynthetics and all soils.

5.1.2 This test method produces test data, which can be used in the design of geosynthetic-reinforced retaining walls, slopes, and embankments, or in other applications where resistance of a geosynthetic to pullout under simulated field conditions is important.

5.1.3 The test results may also provide information related to the in-soil stress-strain response of a geosynthetic under confined loading conditions.

The pullout resistance versus normal stress plot obtained from this test is a function of soil gradation, plasticity, as-placed dry unit weight, moisture content, length and surface characteristics of the geosynthetic and other test parameters. Therefore, results are expressed in terms of the actual test conditions. The test measures the net effect of a combination of pullout mechanisms, which may vary depending on type of geosynthetic specimen, embedment length, relative opening size, soil type, displacement rate, normal stress, and other factors.

Information between laboratories on precision is incomplete. In cases of dispute, comparative tests to determine if there is a statistical bias between laboratories may be advisable.

SCOPE

1.1 Resistance of a geosynthetic to pullout from soil is determined using a laboratory pullout box.

1.2 The test method is intended to be a performance test conducted as closely as possible to replicate design or as-built conditions. It can also be used to compare different geosynthetics, soil types, etc., and thereby be used as a research and development test procedure.

1.3 The values stated in SI units are to be regarded as standard. The values stated in parentheses are provided for information only.

This standard may involve hazardous materials, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6706 − 01(Reapproved 2007)

Standard Test Method for

Measuring Geosynthetic Pullout Resistance in Soil

This standard is issued under the fixed designation D6706; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 apertures, n—the open spaces in geogrids which

enable soil interlocking to occur.

1.1 Resistance of a geosynthetic to pullout from soil is

3.1.2 atmosphere for testing geosynthetics, n—air main-

determined using a laboratory pullout box.

tained at a relative humidity of 60 6 10 % and a temperature

1.2 The test method is intended to be a performance test

of 21 6 2°C (70 6 4°F).

conducted as closely as possible to replicate design or as-built

3.1.3 cross-machine direction, n—the direction in the plane

conditions. It can also be used to compare different

of the geosynthetic perpendicular to the direction of manufac-

geosynthetics,soiltypes,etc.,andtherebybeusedasaresearch

ture.

and development test procedure.

3.1.4 failure, n—a defined point at which a material ceases

1.3 The values stated in SI units are to be regarded as

to be functionally capable of its intended use.

standard. The values stated in parentheses are provided for

information only. 3.1.5 geosynthetic, n—a planar product manufactured from

polymeric material used with soil, rock, earth, or other geo-

1.4 This standard may involve hazardous materials, and

technical engineering related material as an integral part of a

equipment. This standard does not purport to address all of the

man-made project, structure, or system. (D4439)

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 3.1.6 junction, n—the point where geogrid ribs are intercon-

priate safety and health practices and determine the applica-

nected in order to provide structure and dimensional stability.

bility of regulatory limitations prior to use.

3.1.7 machine direction, n—the direction in the plane of the

geosynthetic parallel to the direction of manufacture.

2. Referenced Documents

3.1.8 pullout, n—the movement of a geosynthetic over its

2.1 ASTM Standards:

entire embedded length, with initial pullout occurring when the

D123 Terminology Relating to Textiles

back of the specimen moves, and ultimate pullout occurring

D653 Terminology Relating to Soil, Rock, and Contained

when the movement is uniform over the entire embedded

Fluids

length.

D3080 Test Method for Direct Shear Test of Soils Under

3.1.9 pullout force, (kN),n—force required to pull a geo-

Consolidated Drained Conditions

D4354 Practice for Sampling of Geosynthetics for Testing synthetic out of the soil during a pullout test.

D4439 Terminology for Geosynthetics

3.1.10 pullout resistance, (kN/m),n—the pullout force per

width of geosynthetic measured at a specified condition of

3. Terminology

displacement.

3.1 Definitions of Terms Specific to This Standard:

3.1.11 rib, n—the continuous elements of a geogrid which

are either in the machine or cross-machine direction as

This test method is under the jurisdiction of ASTM Committee D35 on

manufactured.

Geosynthetics and is the direct responsibility of Subcommittee D35.01 on Mechani-

cal Properties.

3.1.12 ultimate pullout resistance, (kN/m),n—the maxi-

CurrenteditionapprovedJune1,2007.PublishedJuly2007.Originallyapproved

mum pullout resistance measured during a pullout test.

in 2001. Last previous edition approved in 2001 as D6706–01. DOI: 10.1520/

D6706-01R07.

3.1.13 wire gage, n—a displacement gage consisting of a

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

non extensible wire attached to the geosynthetic and monitored

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

by connection to a dial extensometer, or electronic displace-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. ment transducer.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6706 − 01 (2007)

3.2 For definitions of other terms used in this test method pullout mechanisms, which may vary depending on type of

refer to Terminology D123, D653, and D4439. geosynthetic specimen, embedment length, relative opening

size, soil type, displacement rate, normal stress, and other

4. Summary of Test Method

factors.

4.1 Inthismethod,ageosyntheticisembeddedbetweentwo

5.3 Information between laboratories on precision is incom-

layers of soil, horizontal force is applied to the geosynthetic

plete. In cases of dispute, comparative tests to determine if

and the force required to pull the geosynthetic out of the soil is

there is a statistical bias between laboratories may be advis-

recorded.

able.

4.2 Pullout resistance is obtained by dividing the maximum

6. Apparatus

load by the test specimen width.

6.1 Pullout Box—An open rigid box consisting of two

4.3 The test is performed while subjected to normal com-

smooth parallel sides, a back wall, a horizontal split removable

pressive stresses which are applied to the top soil layer.

door, a bottom plate, and a load transfer sleeve. The door is at

4.4 A plot of maximum pullout resistance versus applied

the front as defined by the direction of applied pullout force.A

normal stress is obtained by conducting a series of such tests.

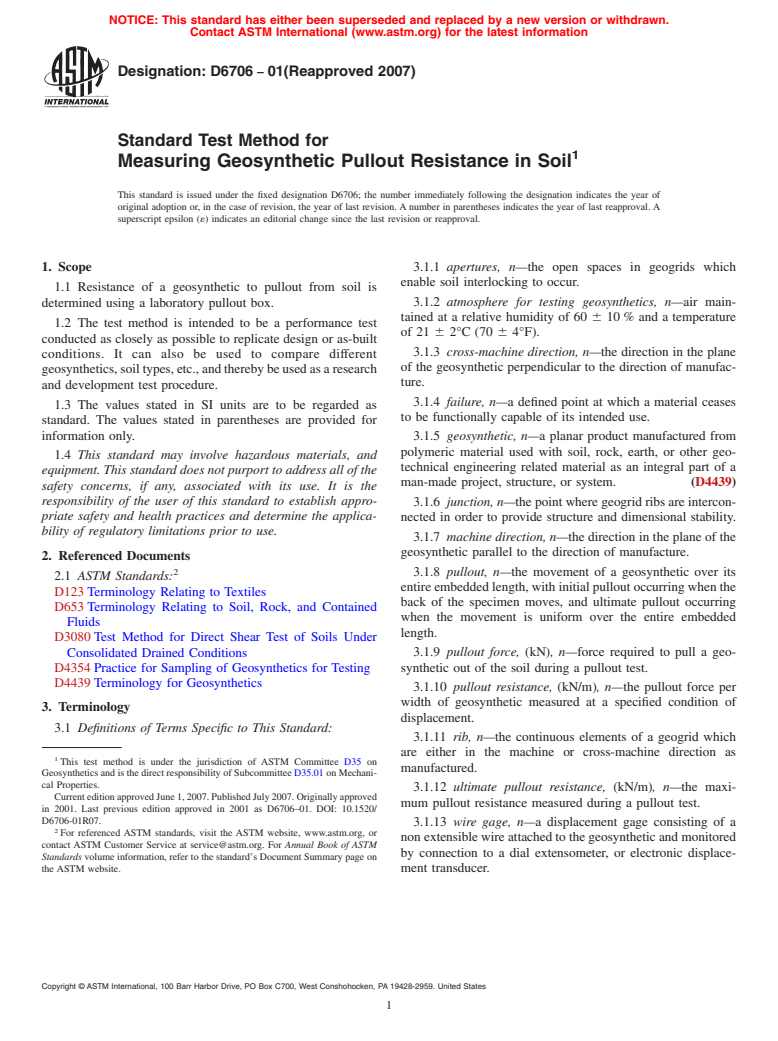

typical box is shown in Fig. 1.

6.1.1 The box should be square or rectangular with mini-

5. Significance and Use

mum dimensions 610 mm (24 in.) long by 460 mm (18 in.)

5.1 The pullout test method is intended as a performance

wide by 305 mm (12 in.) deep, if sidewall friction is mini-

test to provide the user with a set of design values for the test

mized, otherwise the minimum width should be 760 mm (30

conditions examined.

in.). The dimensions should be increased, if necessary, so that

5.1.1 The test method is applicable to all geosynthetics and

minimum width is the greater of 20 times the D85 of the soil

all soils.

or 6 times the maximum soil particle size, and the minimum

5.1.2 Thistestmethodproducestestdata,whichcanbeused

length greater than 5 times the maximum geosynthetic aperture

inthedesignofgeosynthetic-reinforcedretainingwalls,slopes,

size. The box shall allow for a minimum depth of 150 mm (6

and embankments, or in other applications where resistance of

in.) above and below the geosynthetic. The depth of the soil in

a geosynthetic to pullout under simulated field conditions is

theboxaboveorbelowthegeosyntheticshallbeaminimumof

important.

6 times the D85 of the soil or 3 times the maximum particle

5.1.3 The test results may also provide information related

size of the soil, whichever is greater.The box must allow for at

to the in-soil stress-strain response of a geosynthetic under

least 610 mm (24 in.) embedment length beyond the load

confined loading conditions.

transfer sleeve and a minimum specimen length to width ratio

of 2.0. It should be understood that when testing large aperture

5.2 Thepulloutresistanceversusnormalstressplotobtained

geosynthetics the actual pullout box may have to be larger than

from this test is a function of soil gradation, plasticity,

the stated minimum dimensions.

as-placed dry unit weight, moisture content, length and surface

characteristics of the geosynthetic and other test parameters.

NOTE 1—To remove side wall friction as much as possible a high

Therefore, results are expressed in terms of the actual test

density polyethylene (HDPE) geomembrane should be bonded to the

conditions.The test measures the net effect of a combination of inside surfaces of the pullout box.The sidewalls may also be covered with

FIG. 1 Experimental Set-Up for Geosynthetic Pullout Testing

D6706 − 01 (2007)

a layer of silk fabric, which has been shown to eliminate adhesion and has

anticipated.Arecommended normal stress-loading device is an

a very low friction value. Alternatively, a lubricant can be spread on the

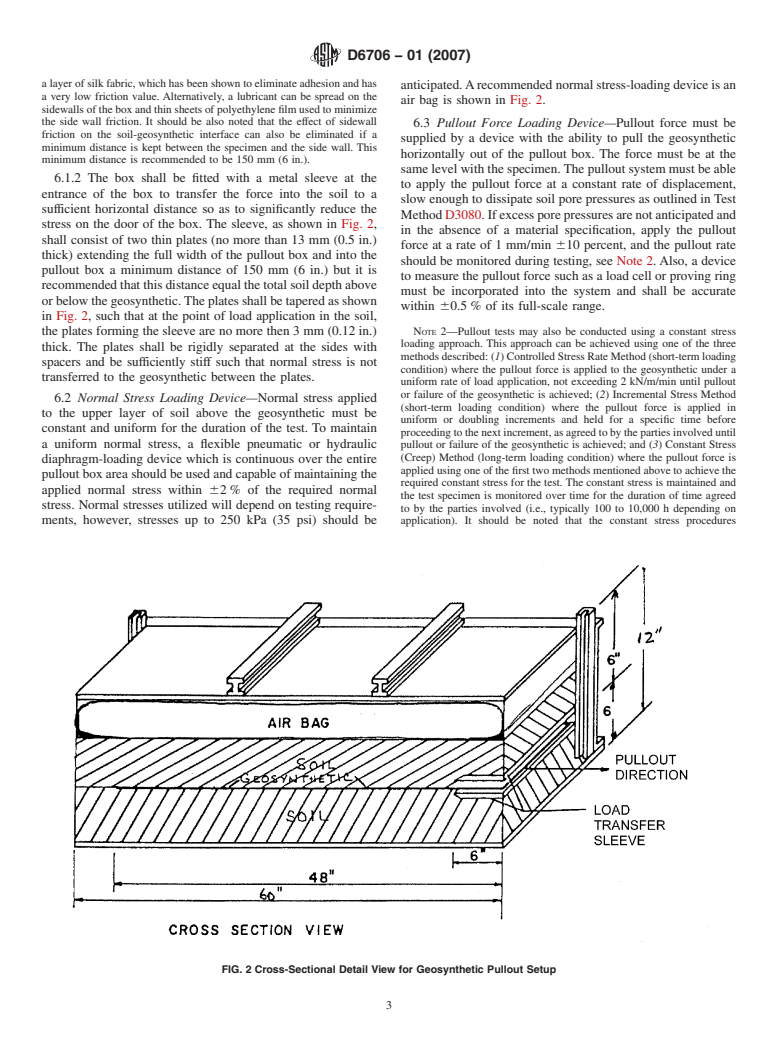

air bag is shown in Fig. 2.

sidewalls of the box and thin sheets of polyethylene film used to minimize

the side wall friction. It should be also noted that the effect of sidewall

6.3 Pullout Force Loading Device—Pullout force must be

friction on the soil-geosynthetic interface can also be eliminated if a

supplied by a device with the ability to pull the geosynthetic

minimum distance is kept between the specimen and the side wall. This

horizontally out of the pullout box. The force must be at the

minimum distance is recommended to be 150 mm (6 in.).

same level with the specimen.The pullout system must be able

6.1.2 The box shall be fitted with a metal sleeve at the

to apply the pullout force at a constant rate of displacement,

entrance of the box to transfer the force into the soil to a

slow enough to dissipate soil pore pressures as outlined in Test

sufficient horizontal distance so as to significantly reduce the

MethodD3080.Ifexcessporepressuresarenotanticipatedand

stress on the door of the box. The sleeve, as shown in Fig. 2,

in the absence of a material specification, apply the pullout

shall consist of two thin plates (no more than 13 mm (0.5 in.)

force at a rate of 1 mm/min 610 percent, and the pullout rate

thick) extending the full width of the pullout box and into the

should be monitored during testing, see Note 2.Also, a device

pullout box a minimum distance of 150 mm (6 in.) but it is

to measure the pullout force such as a load cell or proving ring

recommendedthatthisdistanceequalthetotalsoildepthabove

must be incorporated into the system and shall be accurate

orbelowthegeosynthetic.Theplatesshallbetaperedasshown

within 60.5 % of its full-scale range.

in Fig. 2, such that at the point of load application in the soil,

the plates forming the sleeve are no more then 3 mm (0.12 in.) NOTE 2—Pullout tests may also be conducted using a constant stress

loading approach. This approach can be achieved using one of the three

thick. The plates shall be rigidly separated at the sides with

methodsdescribed:(1)ControlledStressRateMethod(short-termloading

spacers and be sufficiently stiff such that normal stress is not

condition) where the pullout force is applied to the geosynthetic under a

transferred to the geosynthetic between the plates.

uniform rate of load application, not exceeding 2 kN/m/min until pullout

or failure of the geosynthetic is achieved; (2) Incremental Stress Method

6.2 Normal Stress Loading Device—Normal stress applied

(short-term loading condition) where the pullout force is applied in

to the upper layer of soil above the geosynthetic must be

uniform or doubling increments and held for a specific time before

constant and uniform for the duration of the test. To maintain

proceedingtothenextincrement,asagreedtobythepartiesinvolveduntil

a uniform normal stress, a flexible pneumatic or hydraulic pullout or failure of the geosynthetic is achieved; and (3) Constant Stress

(Creep) Method (long-term loading condition) where the pullout force is

diaphragm-loading device which is continuous over the entire

applied using one of the first two methods mentioned above to achieve the

pullout box area should be used and capable of maintaining the

required constant stress for the test. The constant stress is maintained and

applied normal stress within 62 % of the required normal

the test specimen is monitored over time for the duration of time agreed

stress. Normal stresses utilized will depend on testing require-

to by the parties involved (i.e., typically 100 to 10,000 h depending on

ments, however, stresses up to 250 kPa (35 psi) should be application). It should be noted that the constant stress procedures

FIG. 2 Cross-Sectional Detail View for Geosynthetic Pullout Setup

D6706 − 01 (2007)

described above, have not been widely researched and comparisons with NOTE 3—A suggested device is shown in Fig. 4 and includes a simple

the constant strain method have not been determined. clamp consisting of two, 100 mm (4 in.) wide metal angle pieces with a

series of bolts and nuts holding the material between them. One possible

6.4 Displacement Indicators—Horizontal displacement of

modification is the addition of a metal rod behind the back flange which

the geosynthetic is measured at the entrance of the pullout box

allowsloopingofthematerialaroundtherodandbackintotheclamp.The

and at several locations on the embedded portion of the

use of epoxy bonding within the clamp is generally recommended when

accurate measurement of the geosynthetic displacements within the soil

specimen. Measurements outside the door at the pullout box

are required.

entrance are made by a dial extensometer or electronic dis-

6.6 Soil Preparation Equipment—Use equipment as neces-

placement transducers (e.g. liner variable differential trans-

formers (LVDT’s) can be used) mounted to the box frame to sary for the placement of soils at desired conditions. This may

include compaction devices such as vibratory or “jumping-

read against a plate attached to the specimen near the door.

6.4.1 Determine the displacement of the geosynthetic at a jack” type compaction, or hand compaction hammers. Soil

container or hopper, leveling tools and soil placement/removal

minimum of three equally spaced distances from the clamping

plates. Displacement measurements within the box may em- tools may be required.

ploy any of several methods, which place sensors or gauge

6.7 Miscellaneous Equipment—Measurement and trimming

connectors directly on the geosynthetic and monitor their

equipment as necessary for geosynthetic preparation, a timing

change in location remotely. One such device utilizes wire

device and soil property testing equipment if desired.

gages,whichareprotectedfromnormalstressbyasurrounding

tube, which runs from a location mounted on the specimen to

7. Geosynthetic Sampling

the outside of the box where displacements are measured by a

7.1 Lot Sample—Divide the product into lots and for any lot

dial indicator or electronic displacement transducer. A typical

to be tested, take the lot samples as directed in Practice D4354,

instrumentation setup is shown in Fig. 3.

see Note 4.

6.4.2 All dial gauges or electronic measurement devices

must be accurate to 6 0.10 mm. Locations of the devices must

NOTE 4—Lots of geosynthetics are usually designated by the producer

be accurately determined and recorded. Minimum extension during manufacture. While this test method does not attempt to establish

a frequency of testing for determination of design oriented data, the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.