ASTM F21-65(1996)

(Test Method)Standard Test Method for Hydrophobic Surface Films by the Atomizer Test

Standard Test Method for Hydrophobic Surface Films by the Atomizer Test

SCOPE

1.1 This test method covers the detection of the presence of hydrophobic (nonwetting) films on surfaces and the presence of hydrophobic organic materials in processing ambients. When properly conducted, the test will enable detection of fractional molecular layers of hydrophobic organic contaminants. On very rough or porous surfaces the sensitivity of the test may be significantly decreased.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 21 – 65 (Reapproved 1996)

Standard Test Method for

Hydrophobic Surface Films by the Atomizer Test

This standard is issued under the fixed designation F 21; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope spread but will tend to remain as fine droplets.

1.1 This test method covers the detection of the presence of

5. Significance and Use

hydrophobic (nonwetting) films on surfaces and the presence

5.1 The atomizer test as described in this test method is

of hydrophobic organic materials in processing ambients.

nondestructive and may be used for control and evaluation of

When properly conducted, the test will enable detection of

processes for the removal of hydrophobic contaminants. The

fractional molecular layers of hydrophobic organic contami-

test may also be used for the detection and control of

nants. On very rough or porous surfaces the sensitivity of the

hydrophobic contaminants in processing ambients. For this

test may be significantly decreased.

application, a surface free of hydrophobic films is exposed to

1.2 The values stated in inch-pound units are to be regarded

the ambient and subsequently tested.

as the standard. The values given in parentheses are for

information only.

6. Interferences

1.3 This standard does not purport to address all of the

6.1 Loss of sensitivity may result from either of the follow-

safety concerns, if any, associated with its use. It is the

ing factors:

responsibility of the user of this standard to establish appro-

6.1.1 The presence of hydrophilic substances on the surface

priate safety and health practices and determine the applica-

to be tested, test equipment, or test materials, or

bility of regulatory limitations prior to use.

6.1.2 An unusually rough or porous surface condition.

2. Referenced Documents

7. Apparatus

2.1 ASTM Standards:

7.1 Spray Gun Atomizer.

D 351 Classification for Natural Muscovite Block Mica and

2 7.2 Low Power Microscope (53 to 503), and light source

Thins Based on Visual Quality

for observation of small piece parts.

3. Terminology

8. Reagents and Materials

3.1 Definitions:

8.1 Acetone, reagent grade.

3.1.1 hydrophilic—having a strong affinity for water; wet-

8.2 Mice Blanks, preferably 1 in. (25 mm) by 2 in. (50 mm)

table.

by 0.015 in. (0.38 mm) or larger, having a minimum ASTM

3.1.2 hydrophobic—having little affinity for water; nonwet-

quality V6 as described in Classification D 351.

table.

8.3 Oleic or Stearic Acid—A 0.005 to 0.05% solution in

acetone.

4. Summary of Test Method

3 8.4 Oxygen—Filtered low-pressure (15 psi min) oxygen or

4.1 The atomizer test is performed by subjecting the dry

other suitable gas that is free of hydrophobic and hydrophilic

surface to be tested to a fine water spray. The interpretation of

substances.

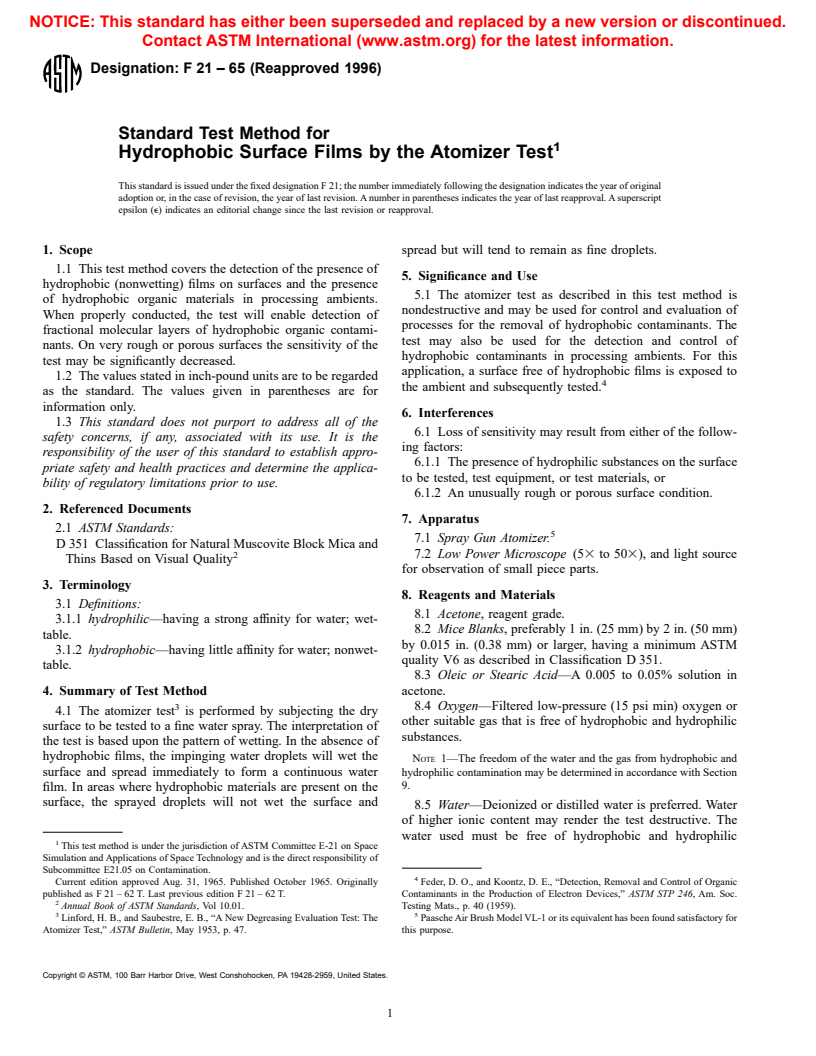

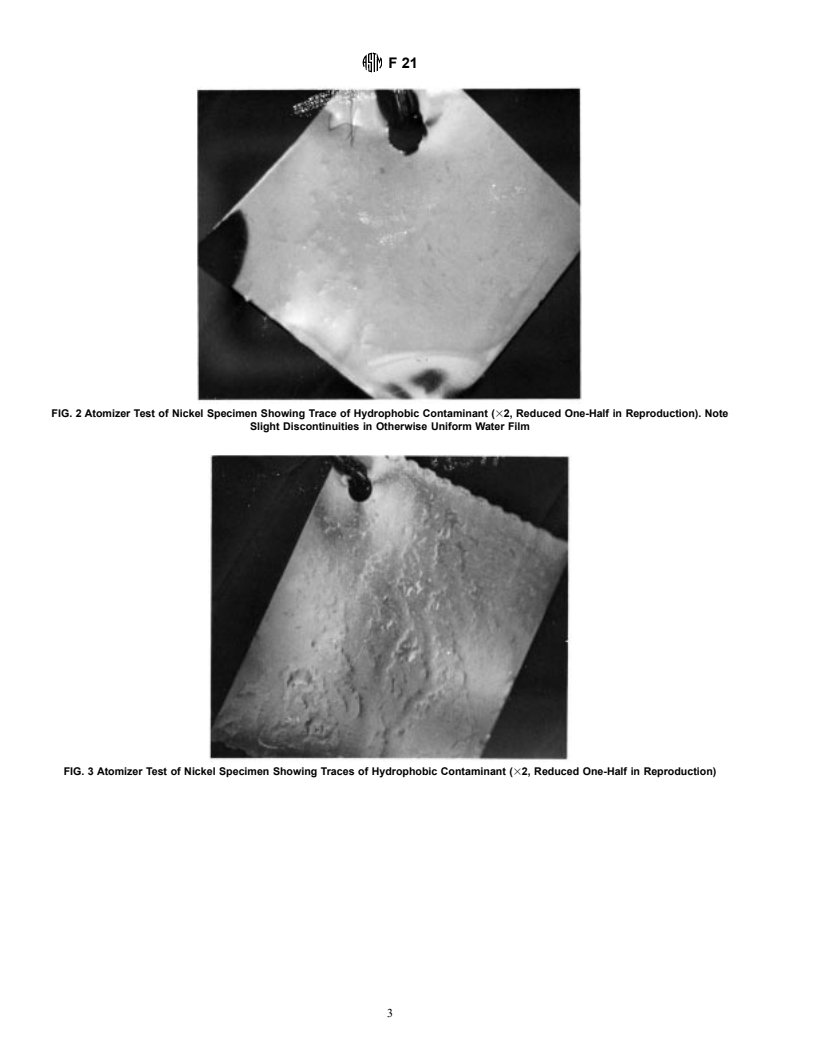

the test is based upon the pattern of wetting. In the absence of

hydrophobic films, the impinging water droplets will wet the

NOTE 1—The freedom of the water and the gas from hydrophobic and

surface and spread immediately to form a continuous water hydrophilic contamination may be determined in accordance with Section

9.

film. In areas where hydrophobic materials are present on the

surface, the sprayed droplets will not wet the surface and

8.5 Water—Deionized or distilled water is preferred. Water

of higher ionic content may render the test destructive. The

water used must be free of hydrophobic and hydrophilic

This test method is under the jurisdiction of ASTM Committee E-21 on Space

Simulation and Applications of Space Technology and is the direct responsibility of

Subcommittee E21.05 on Contamination.

Current edition approved Aug. 31, 1965. Published October 1965. Originally Feder, D. O., and Koontz, D. E., “Detection, Removal and Control of Organic

published as F 21 – 62 T. Last previous edition F 21 – 62 T. Contaminants in the Production of Electron Devices,” ASTM STP 246, Am. Soc.

Annual Book of ASTM Standards, Vol 10.01. Testing Mats., p. 40 (1959).

3 5

Linford, H. B., and Saubestre, E. B., “A New Degreasing Evaluation Test: The Paasche Air Brush Model VL-1 or its equivalent has been found s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.