ASTM B871-01(2013)

(Test Method)Standard Test Method for Tear Testing of Aluminum Alloy Products (Withdrawn 2017)

Standard Test Method for Tear Testing of Aluminum Alloy Products (Withdrawn 2017)

SIGNIFICANCE AND USE

5.1 The significance of the tear test is similar to that of the notch-tensile test, and its primary usefulness is as an indicator of toughness or as a ranking test as described in Test Method E338 and Practice B646.

5.1.1 This test method provides a comparative measure of resistance of aluminum alloys and products to unstable fracture originating from the presence of crack-like stress concentrators. This test method is not intended to provide an absolute measure of resistance to crack propagation that might be used in the design of a structure.

5.2 Values of the energies required to initiate and propagate cracks in tear specimens are determined by measuring or integrating the appropriate areas under the test curve developed during the test.

5.3 The unit propagation energy (UPE) is the primary result of the tear test. This value provides a measure of the combination of strength and ductility that permits a material to resist crack growth under either elastic or plastic stresses. The UPE value normally will exhibit greater scatter than conventional tensile or yield strength values. In order to establish a reasonable estimate of average properties, it is recommended that replicate specimens be tested for each metal condition being evaluated. The UPE value has significance as a relative index of fracture toughness.

5.4 The ratio of the tear strength to the tensile yield strength is a measure of notch toughness comparable to the notch-yield ratio from notch-tensile tests carried out in accordance with Test Method E338. It is of value in relative ranking of materials with regard to their toughness.2,3

5.5 The numerical results of the test are dependent upon the specimen size and geometry, although specimen thicknesses over the range of 0.063 in. (1.6 mm) to 0.100 in. (2.5 mm) have not shown a significant effect on tear strength (TS) and unit propagation energy (UPE).6 These values may exhibit a dependency to thickness when the specimen thickness is outside ...

SCOPE

1.1 This test method covers the static tear test of aluminum alloy products using specimens that are 0.040 in. (1 mm) to 0.250 in. (6.35 mm) thick.

1.2 This test method is applicable to aluminum alloy products having a minimum thickness of 0.040 in. (1 mm).

1.3 This test method provides a measure of both notch toughness and resistance to crack propagation with the primary use as a screening or merit rank test.

1.4 The reliability of the tear test has been established in various research programs by reasonably good correlations between data from the tear tests and fracture toughness tests.2,3Note 1—Direct measurement of fracture toughness may be made in accordance with Practices B645, B646 and Test Method E399.

1.5 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers the static tear test of aluminum alloy products using specimens that are 0.040 in. (1 mm) to 0.250 in. (6.35 mm) thick.

Formerly under the jurisdiction of Committee B07 on Light Metals and Alloys, this test method was withdrawn in November 2017. This standard is being withdrawn without replacement due to its limited use by industry.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B871 − 01 (Reapproved 2013)

Standard Test Method for

Tear Testing of Aluminum Alloy Products

This standard is issued under the fixed designation B871; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope B646 Practice for Fracture Toughness Testing of Aluminum

Alloys

1.1 This test method covers the static tear test of aluminum

E4 Practices for Force Verification of Testing Machines

alloy products using specimens that are 0.040 in. (1 mm) to

E83 Practice for Verification and Classification of Exten-

0.250 in. (6.35 mm) thick.

someter Systems

1.2 This test method is applicable to aluminum alloy prod-

E338 Test Method of Sharp-Notch Tension Testing of High-

ucts having a minimum thickness of 0.040 in. (1 mm). 5

Strength Sheet Materials (Withdrawn 2010)

E399 Test Method for Linear-Elastic Plane-Strain Fracture

1.3 This test method provides a measure of both notch

toughness and resistance to crack propagation with the primary Toughness K of Metallic Materials

Ic

use as a screening or merit rank test.

3. Terminology

1.4 The reliability of the tear test has been established in

3.1 Definitions of Terms Specific to This Standard:

various research programs by reasonably good correlations

2,3 3.1.1 initiation energy, IE (FL)—the amount of energy

between data from the tear tests and fracture toughness tests.

required to initiate a crack in a tear specimen. Initiation energy

NOTE 1—Direct measurement of fracture toughness may be made in

is determined by integrating the area under the force-

accordance with Practices B645, B646 and Test Method E399.

displacement curve from the beginning of the test to the point

1.5 The values stated in inch-pound units are to be regarded

of maximum force.

as the standard. The values given in parentheses are for

3.1.2 propagation energy, PE (FL)—the amount of energy

information only.

required to propagate a crack in a tear specimen. Propagation

1.6 This standard does not purport to address all of the

energy is determined by integrating the area under the force-

safety concerns, if any, associated with its use. It is the

displacement curve from the point of maximum force to the

responsibility of the user of this standard to establish appro-

point of complete fracture.

priate safety and health practices and determine the applica-

3.1.3 tear resistance—a general term describing the resis-

bility of regulatory limitations prior to use.

tance of a material to crack propagation under static loading,

either in an elastic or plastic stress field.

2. Referenced Documents

−2

3.1.4 tear strength, TS (FL )—the maximum nominal di-

2.1 ASTM Standards:

rect and bending stress that the tear specimen is capable of

B557 Test Methods for Tension Testing Wrought and Cast

sustaining.

Aluminum- and Magnesium-Alloy Products

3.1.5 tear strength to tensile yield strength ratio (TYR)—the

B645 Practice for Linear-Elastic Plane–Strain Fracture

ratio of the tear strength to tensile yield strength of the material

Toughness Testing of Aluminum Alloys

determined in accordance with Test Methods B557.

−1

3.1.6 unit propagation energy, UPE (FL )—the amount of

This test method is under the jurisdiction of ASTM Committee B07 on Light

energy required to propagate a crack across a tear specimen

Metals and Alloys and is the direct responsibility of Subcommittee B07.05 on

divided by the original net area of the specimen.

Testing.

Current edition approved May 1, 2013. Published August 2013. Originally

4. Summary of Test Method

approved in 1996. Last previous edition approved in 2007 as B871–01 (2007). DOI:

10.1520/B0871-01R13.

4.1 The tear test involves a single edge notched specimen

Kaufman, J. G., and Holt, Marshall, “Fracture Characteristics of Aluminum

that is statically loaded through pin loading holes. The force

Alloys,” Alcoa Research Laboratories Technical Paper No. 18.

and displacement required to fracture the specimen are re-

Kaufman, J. G., and Knoll,A. H., “Kahn-TypeTearTests and CrackToughness

of Aluminum Sheet,” Metals Research and Standards, April 1964, pp. 151–155.

corded for analysis.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B871 − 01 (2013)

4.2 Tear test specimens should be fractured using any data and fracture toughness test data of aluminum alloys and

mechanical test machine capable of quasi-static loading at a products, as determined in accordance with Practices B645,

crosshead speed of 0.05 in./min (1.3 mm/min) or less. B646 andTest Method E399. Limited data suggest that the test

may be sensitive to crosshead rates above 0.5 in./min.

5. Significance and Use

5.1 The significance of the tear test is similar to that of the 6. Apparatus

notch-tensile test, and its primary usefulness is as an indicator

6.1 The test shall be conducted with a tension testing

of toughness or as a ranking test as described in Test Method

machine conforming to the requirements of Practices E4.

E338 and Practice B646.

6.2 The device for transmitting force to the specimen shall

5.1.1 This test method provides a comparative measure of

be such that force axis coincides with the root of the edge

resistanceofaluminumalloysandproductstounstablefracture

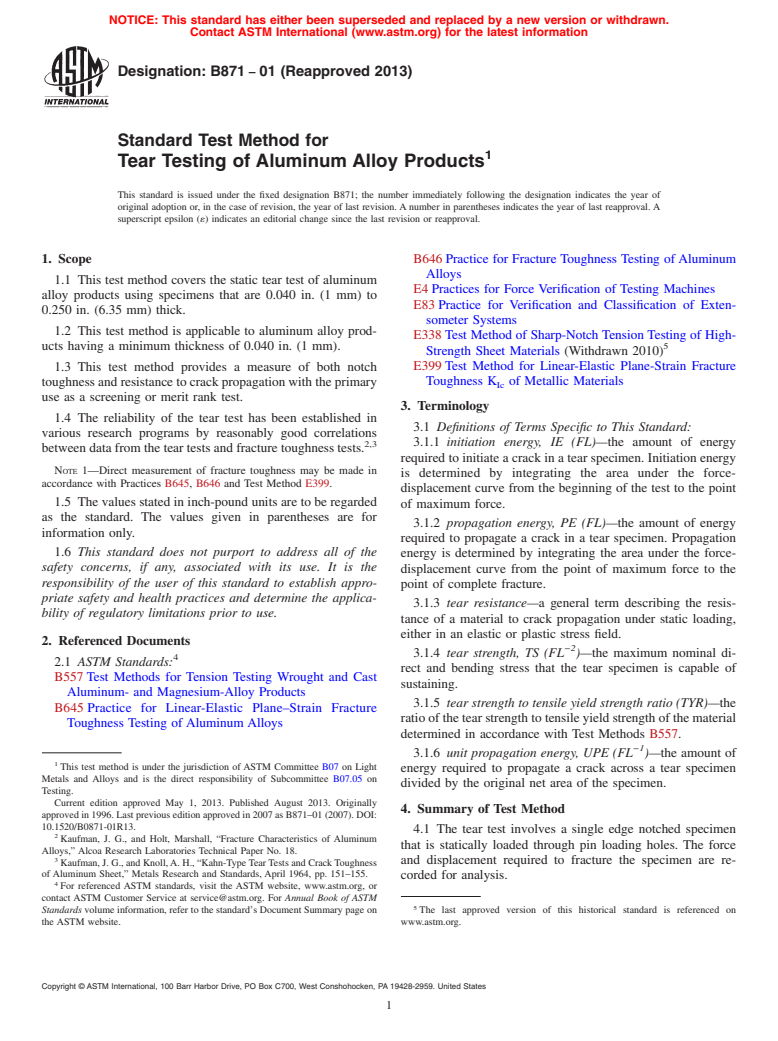

notch. A satisfactory arrangement for force application incor-

originating from the presence of crack-like stress concentra-

porates clevises having hardened pins that pass through the

tors. This test method is not intended to provide an absolute

holes in the specimen. The diameter of the hardened pins is

measure of resistance to crack propagation that might be used

slightly smaller than that of the holes. Spacing washers of the

in the design of a structure.

necessary thickness shall be used to center the specimen in the

5.2 Values of the energies required to initiate and propagate

clevises. A typical arrangement is shown in Fig. 1.

cracks in tear specimens are determined by measuring or

6.3 Displacement at the notch tip is measured by displace-

integratingtheappropriateareasunderthetestcurvedeveloped

ment gages or similar devices that are mounted on the

during the test.

specimenortheclevisatapointcorrespondingtotheforceaxis

5.3 The unit propagation energy (UPE) is the primary result

of the specimen. The devices shall be calibrated in accordance

of the tear test. This value provides a measure of the combi-

with Practice E83. For ductile materials, it is recommended

nation of strength and ductility that permits a material to resist

that the displacement gages have a travel capability of at least

crack growth under either elastic or plastic stresses. The UPE

0.5 in.

value normally will exhibit greater scatter than conventional

6.4 The use of crosshead displacement is not recommended

tensile or yield strength values. In order to establish a reason-

because of the fact that all deformation in the test fixtures and

able estimate of average properties, it is recommended that

specimen clevis is then included in the displacement measure-

replicate specimens be tested for each metal condition being

ment and contributes to the apparent initiation and propagation

evaluated. The UPE value has significance as a relative index

energies measured. If crosshead displacement is used, the data

of fracture toughness.

cannot be compared directly with data measured in accordance

5.4 The ratio of the tear strength to the tensile yield strength

is a measure of notch toughness comparable to the notch-yield

ratio from notch-tensile tests carried out in accordance with

TestMethodE338.Itisofvalueinrelativerankingofmaterials

2,3

with regard to their toughness.

5.5 The numerical results of the test are dependent upon the

specimen size and geometry, although specimen thicknesses

overtherangeof0.063in.(1.6mm)to0.100in.(2.5mm)have

not shown a significant effect on tear strength (TS) and unit

propagation energy (UPE). These values may exhibit a depen-

dency to thickness when the specimen thickness is outside of

this stated range and care shall be taken when using this data.

5.6 The tear test can serve the following purposes:

5.6.1 In the research and development of materials, to study

the effects of variables of composition, processing, heat

treatment, etc.

5.6.2 In service evaluation, to compare the relative crack

propagation resistance of a number of aluminum alloys or

products that are otherwise equally suitable for an application.

5.6.3 For specifications of material acceptance and manu-

facturing quality control when there is a sound basis for

establishing a minimum acceptable tear test property, that is,

UPE.

5.7 The reliability of the tear test has been well established

2,3

bydevelopingreasonablygoodcorrelations betweenteartest

Kaufman, J. G., and Reedy, J. F., “Description and Procedure for Making

Kahn-TypeTearTests,”Alcoa Research Laboratory Report 9-M 681, Feb. 10, 1966. FIG. 1 Tear Test Specimen Clevis Arrangement

B871 − 01 (2013)

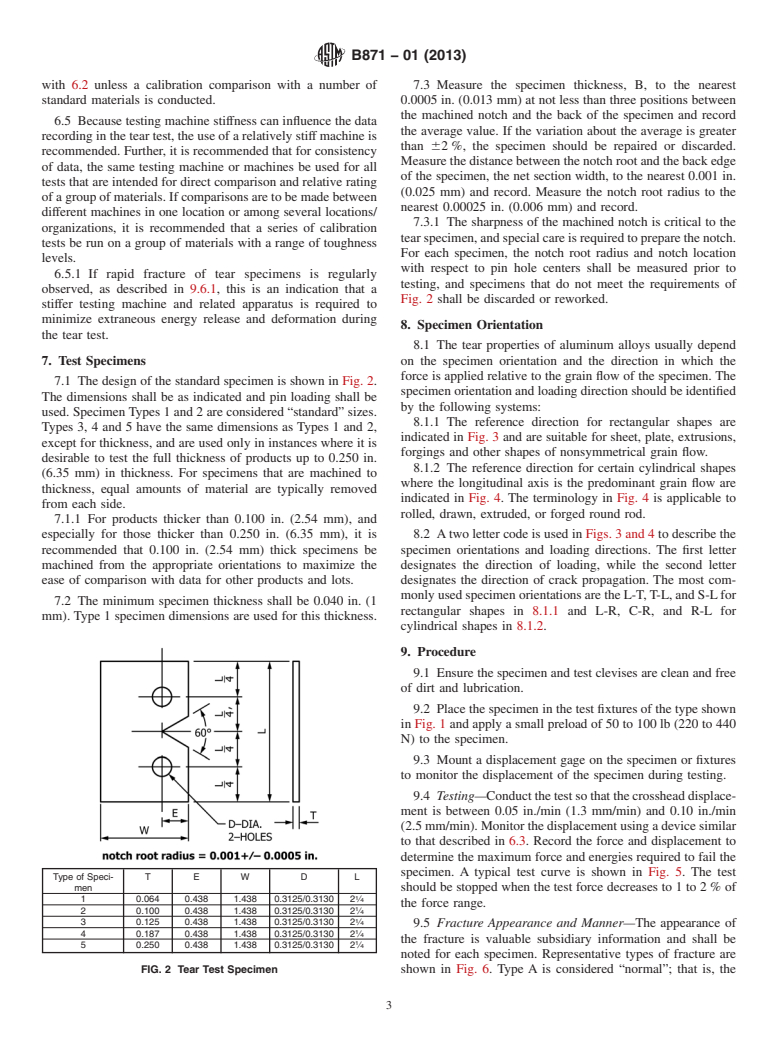

with 6.2 unless a calibration comparison with a number of 7.3 Measure the specimen thickness, B, to the nearest

standard materials is conducted. 0.0005 in. (0.013 mm) at not less than three positions between

the machined notch and the back of the specimen and record

6.5 Because testing machine stiffness can influence the data

the average value. If the variation about the average is greater

recording in the tear test, the use of a relatively stiff machine is

than 62 %, the specimen should be repaired or discarded.

recommended. Further, it is recommended that for consistency

Measure the distance between the notch root and the back edge

of data, the same testing machine or machines be used for all

of the specimen, the net section width, to the nearest 0.001 in.

tests that are intended for direct comparison and relative rating

(0.025 mm) and record. Measure the notch root radius to the

of a group of materials. If comparisons are to be made between

nearest 0.00025 in. (0.006 mm) and record.

different machines in one location or among several locations/

7.3.1 The sharpness of the machined notch is critical to the

organizations, it is recommended that a series of calibration

tearspecimen,andspecialcareisrequiredtopreparethenotch.

tests be run on a group of materials with a range of toughness

For each specimen, the notch root radius and notch location

levels.

with respect to pin hole centers shall be measured prior to

6.5.1 If rapid fract

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.