ASTM A804/A804M-04

(Test Method)Standard Test Methods for Alternating-Current Magnetic Properties of Materials at Power Frequencies Using Sheet-Type Test Specimens

Standard Test Methods for Alternating-Current Magnetic Properties of Materials at Power Frequencies Using Sheet-Type Test Specimens

SCOPE

1.1 These test methods cover the determination of specific core loss and peak permeability of single layers of sheet-type specimens tested with normal excitation at a frequency of 50 or 60 Hz.

Note 1—These test methods have been applied only at the commercial power frequencies, 50 and 60 Hz, but with proper instrumentation and application of the principles of testing and calibration embodied in the test methods, they are believed to be adaptable to testing at frequencies ranging from 25 to 400 Hz.

1.2 These test methods use calibration procedures that provide correlation with the 25-cm [250-mm] Epstein test.

1.3 The range of test magnetic flux densities is governed by the properties of the test specimen and by the available instruments and other equipment components. Normally, nonoriented electrical steels can be tested over a range from 8 to 16 kG [0.8 to 1.6 T] for core loss. For oriented electrical steels, the normal range extends to 18 kG [1.8 T]. Maximum magnetic flux densities in peak permeability testing are limited principally by heating of the magnetizing winding and tests are limited normally to a maximum ac magnetic field strength of about 150 Oe [12 000 A/m].

1.4 These test methods cover two alternative procedures as follows:Test Method 1—Sections 6-12

Test Method 2—Sections 13-19

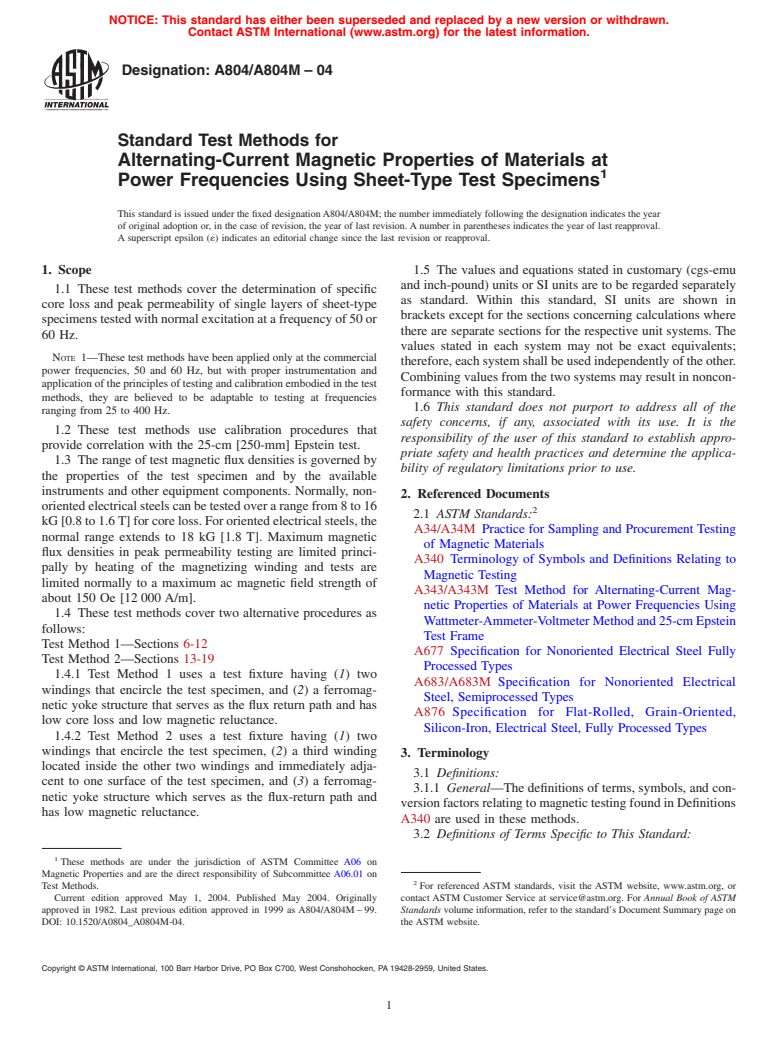

1.4.1 Test Method 1 uses a test fixture having (1) two windings that encircle the test specimen, and (2) a ferromagnetic yoke structure that serves as the flux return path and has low core loss and low magnetic reluctance.

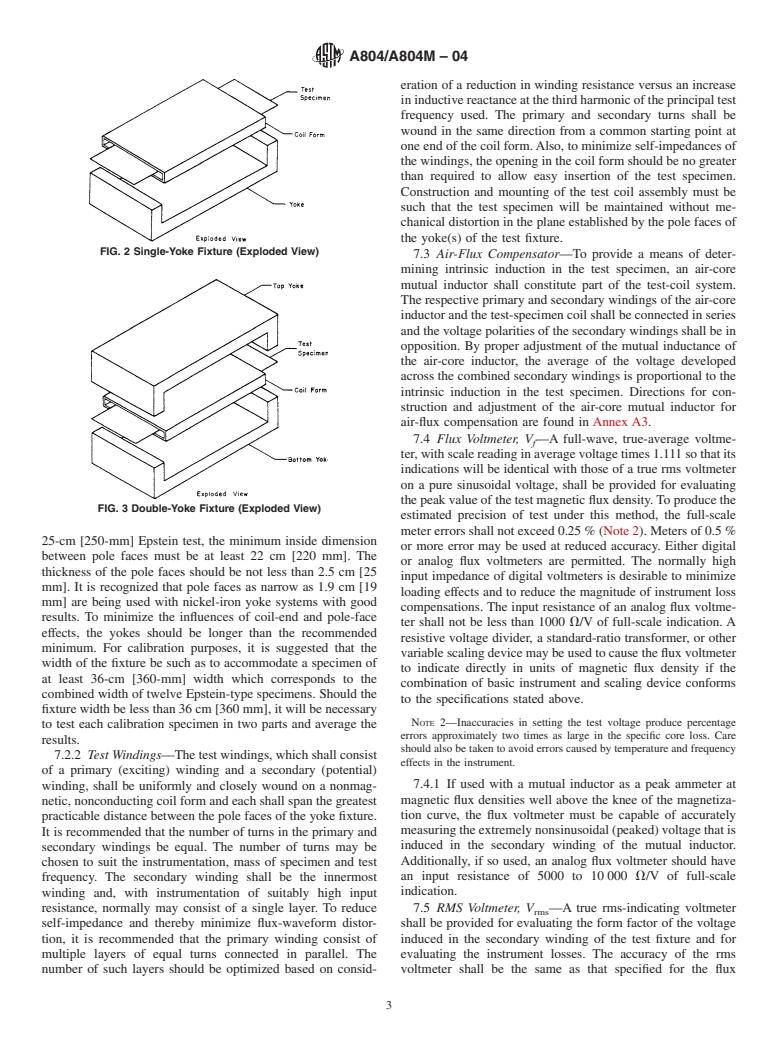

1.4.2 Test Method 2 uses a test fixture having (1) two windings that encircle the test specimen, (2) a third winding located inside the other two windings and immediately adjacent to one surface of the test specimen, and (3) a ferromagnetic yoke structure which serves as the flux-return path and has low magnetic reluctance.

1.5 The values and equations stated in customary (cgs-emu and inch-pound) units or SI units are to be regarded separately as standard. Within this standard, SI units are shown in brackets except for the sections concerning calculations where there are separate sections for the respective unit systems. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:A804/A804M–04

Standard Test Methods for

Alternating-Current Magnetic Properties of Materials at

1

Power Frequencies Using Sheet-Type Test Specimens

This standard is issued under the fixed designationA804/A804M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.5 The values and equations stated in customary (cgs-emu

and inch-pound) units or SI units are to be regarded separately

1.1 These test methods cover the determination of specific

as standard. Within this standard, SI units are shown in

core loss and peak permeability of single layers of sheet-type

brackets except for the sections concerning calculations where

specimenstestedwithnormalexcitationatafrequencyof50or

there are separate sections for the respective unit systems. The

60 Hz.

values stated in each system may not be exact equivalents;

NOTE 1—These test methods have been applied only at the commercial

therefore,eachsystemshallbeusedindependentlyoftheother.

power frequencies, 50 and 60 Hz, but with proper instrumentation and

Combiningvaluesfromthetwosystemsmayresultinnoncon-

applicationoftheprinciplesoftestingandcalibrationembodiedinthetest

formance with this standard.

methods, they are believed to be adaptable to testing at frequencies

1.6 This standard does not purport to address all of the

ranging from 25 to 400 Hz.

safety concerns, if any, associated with its use. It is the

1.2 These test methods use calibration procedures that

responsibility of the user of this standard to establish appro-

provide correlation with the 25-cm [250-mm] Epstein test.

priate safety and health practices and determine the applica-

1.3 The range of test magnetic flux densities is governed by

bility of regulatory limitations prior to use.

the properties of the test specimen and by the available

instruments and other equipment components. Normally, non-

2. Referenced Documents

orientedelectricalsteelscanbetestedoverarangefrom8to16

2

2.1 ASTM Standards:

kG[0.8to1.6T]forcoreloss.Fororientedelectricalsteels,the

A34/A34M Practice for Sampling and Procurement Testing

normal range extends to 18 kG [1.8 T]. Maximum magnetic

of Magnetic Materials

flux densities in peak permeability testing are limited princi-

A340 Terminology of Symbols and Definitions Relating to

pally by heating of the magnetizing winding and tests are

Magnetic Testing

limited normally to a maximum ac magnetic field strength of

A343/A343M Test Method for Alternating-Current Mag-

about 150 Oe [12000 A/m].

netic Properties of Materials at Power Frequencies Using

1.4 These test methods cover two alternative procedures as

Wattmeter-Ammeter-VoltmeterMethodand25-cmEpstein

follows:

Test Frame

Test Method 1—Sections 6-12

A677 Specification for Nonoriented Electrical Steel Fully

Test Method 2—Sections 13-19

Processed Types

1.4.1 Test Method 1 uses a test fixture having (1) two

A683/A683M Specification for Nonoriented Electrical

windings that encircle the test specimen, and (2) a ferromag-

Steel, Semiprocessed Types

netic yoke structure that serves as the flux return path and has

A876 Specification for Flat-Rolled, Grain-Oriented,

low core loss and low magnetic reluctance.

Silicon-Iron, Electrical Steel, Fully Processed Types

1.4.2 Test Method 2 uses a test fixture having (1) two

windings that encircle the test specimen, (2) a third winding

3. Terminology

located inside the other two windings and immediately adja-

3.1 Definitions:

cent to one surface of the test specimen, and (3) a ferromag-

3.1.1 General—The definitions of terms, symbols, and con-

netic yoke structure which serves as the flux-return path and

versionfactorsrelatingtomagnetictestingfoundinDefinitions

has low magnetic reluctance.

A340 are used in these methods.

3.2 Definitions of Terms Specific to This Standard:

1

These methods are under the jurisdiction of ASTM Committee A06 on

Magnetic Properties and are the direct responsibility of Subcommittee A06.01 on

2

Test Methods. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2004. Published May 2004. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1982. Last previous edition approved in 1999 as A804/A804M–99. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/A0804_A0804M-04. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A804/A804M–04

3.2.1 sheet specimen—arectangularspecimencomprisedof flattened, grain-ori

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.