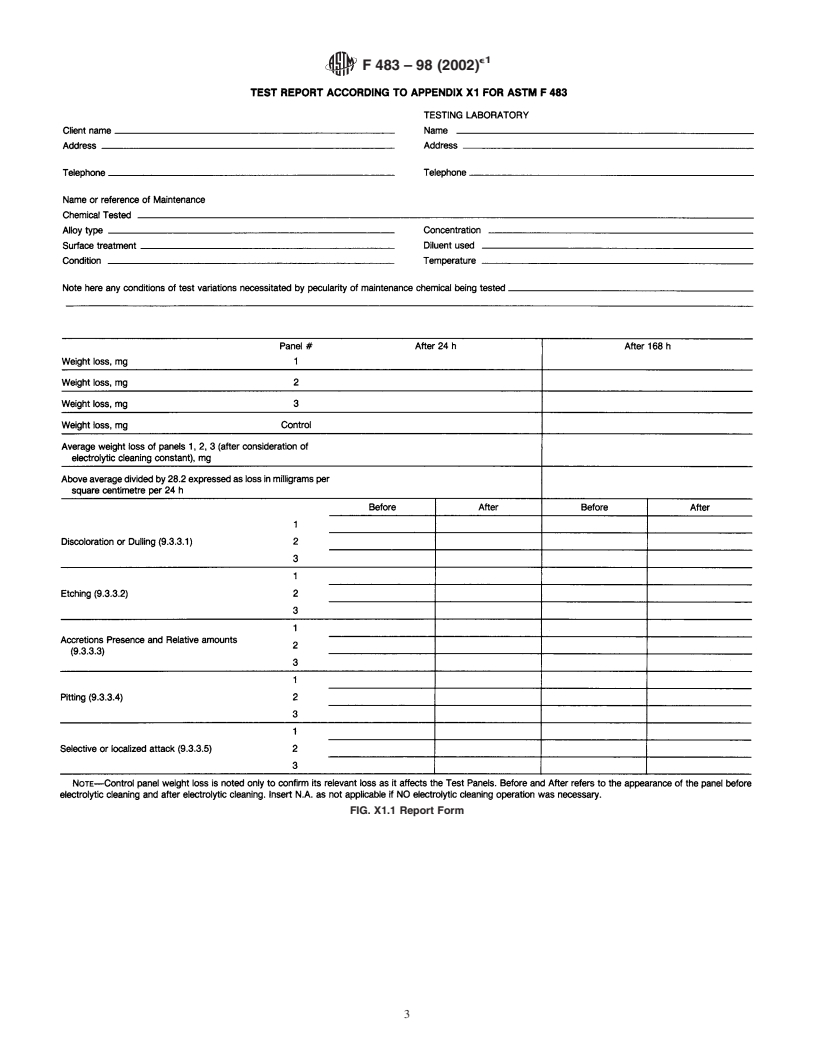

ASTM F483-98(2002)e1

(Test Method)Standard Test Method for Total Immersion Corrosion Test for Aircraft Maintenance Chemicals

Standard Test Method for Total Immersion Corrosion Test for Aircraft Maintenance Chemicals

SIGNIFICANCE AND USE

Many aircraft maintenance chemicals are used on components and structures which would be adversely affected by excessive dimensional change. This test method screens these chemicals to ensure compliance with specified weight change criteria.

SCOPE

1.1 This test method covers the determination of the corrosiveness of aircraft maintenance chemicals on aircraft metals with time under conditions of total immersion by a combination of weight change measurements and visual qualitative determination of change.

1.2 The values stated in SI units are to be regarded as standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation:F483–98 (Reapproved 2002)

Standard Test Method for

Total Immersion Corrosion Test for Aircraft Maintenance

Chemicals

This standard is issued under the fixed designation F483; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e NOTE—Editorial changes were made throughout in September 2002.

1. Scope 4. Apparatus

1.1 This test method covers the determination of the corro- 4.1 Wide-Mouth Sealable Glass Jar or Stoppered Flask of

siveness of aircraft maintenance chemicals on aircraft metals Suitable Size—The glass jar or flask should be so chosen so

with time under conditions of total immersion by a combina- that the specimens will remain fully immersed in a vertical

tion of weight change measurements and visual qualitative position during testing and the ratio of area of immersed metal

determination of change. to volume of solution will be in accordance with 8.1.

1.2 The values stated in SI units are to be regarded as 4.1.1 Warning—Some aircraft maintenance chemicals

standard. The values in parentheses are for information only. when heated have high vapor pressures or may produce gases

1.3 This standard does not purport to address all of the during testing. Suitable precautions should be taken to prevent

safety concerns, if any, associated with its use. It is the thecontainingvesselfromexplodingorthevesselshouldbeso

responsibility of the user of this standard to establish appro- chosen as to withstand the resulting pressure.

priate safety and health practices and determine the applica- 4.2 Specimen-Supporting Device—A glass of fluorocarbon

bility of regulatory limitations prior to use. plastic supporting system designed to keep the specimen fully

immersed while ensuring free contact with the solution, and

2. Referenced Documents

designed to isolate the specimens from each other physically.

2.1 ASTM Standards: 4.3 For materials containing low boiling point solvents, a

D235 Specification for Mineral Spirits (Petroleum Spirits) means of preventing evaporation losses shall be used.

(Hydrocarbon Dry Cleaning Solvent)

4.4 Constant-Temperature Device—Any suitable regulated

D329 Specification for Acetone heating device (mantle, hot plate, or bath) may be used to

D740 Specification for Methyl Ethyl Ketone

maintain the solution at the required temperature.

D1193 Specification for Reagent Water 4.5 Thermometer, having a range from −18 to 150°C (0 to

E1 Specification for ASTM Thermometers

302°F)andconformingtorequirementsforThermometer1Fin

accordance with Specification E1.

3. Significance and Use

4.6 Oven, low temperature explosion-proof, capable of

3.1 Many aircraft maintenance chemicals are used on com-

maintaining38 63°C(100 65°F)through120 65°C(248 6

ponents and structures which would be adversely affected by

5°F).

excessive dimensional change. This test method screens these

5. Reagents and Materials

chemicals to ensure compliance with specified weight change

criteria.

5.1 Acetone—conforming to Specification D329.

5.2 Methyl Ethyl Ketone—conforming to Specification

D740.

5.3 Mineral Spirits, Type II—conforming to Specification

This test method is under the jurisdiction of ASTM Committee F07 on

D235.

Aerospace andAircraft and is the direct responsibility of Subcommittee F07.07 on

Qualification Testing of Aircraft Cleaning Materials.

6. Test Specimens

Current edition approved Oct. 10, 1998. Published March 1999. Originally

e1

published as F483–77. Last previous edition F483–90 (Reapproved 1991) .

6.1 Taketestspecimensofagivenalloyfromthesamesheet

Annual Book of ASTM Standards, Vol 06.04.

stock, which shall be in new or like-new condition, and

Annual Book of ASTM Standards, Vol 11.01.

Annual Book of ASTM Standards, Vol 14.03. measure 50.8 by 25.4 by 1.6 mm (2 by 1 by 0.06 in.) with a

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

F483–98 (2002)

3.2-mm (0.125-in.) diameter mounting hole suitably located at 9.2 Immerse three weighed specimens of each alloy in the

oneendofthespecimen.Testthreereplicatespecimensineach test solution at the prescribed temperature. Place only speci-

concentration of maintenance chemical solution in accordance mensofthesameallo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.