ASTM F3507-21

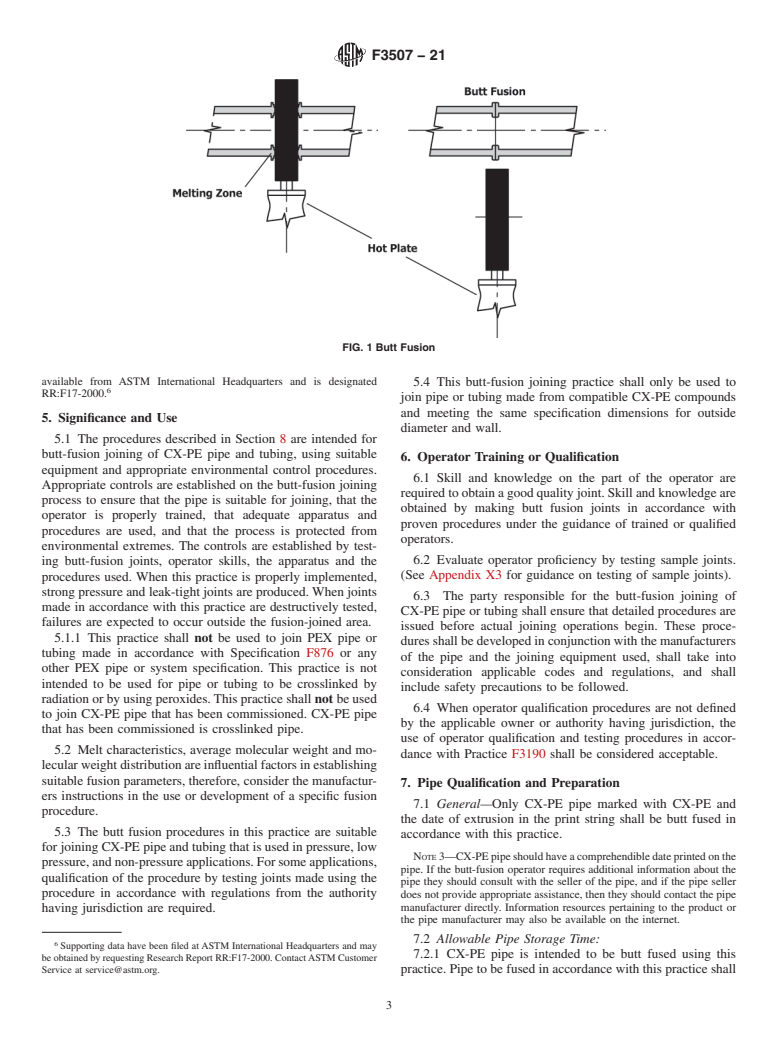

(Practice)Standard Practice for Butt-Fusion Joining of Crosslinkable Polyethylene (CX-PE) Pipe and Tubing

Standard Practice for Butt-Fusion Joining of Crosslinkable Polyethylene (CX-PE) Pipe and Tubing

SIGNIFICANCE AND USE

5.1 The procedures described in Section 8 are intended for butt-fusion joining of CX-PE pipe and tubing, using suitable equipment and appropriate environmental control procedures. Appropriate controls are established on the butt-fusion joining process to ensure that the pipe is suitable for joining, that the operator is properly trained, that adequate apparatus and procedures are used, and that the process is protected from environmental extremes. The controls are established by testing butt-fusion joints, operator skills, the apparatus and the procedures used. When this practice is properly implemented, strong pressure and leak-tight joints are produced. When joints made in accordance with this practice are destructively tested, failures are expected to occur outside the fusion-joined area.

5.1.1 This practice shall not be used to join PEX pipe or tubing made in accordance with Specification F876 or any other PEX pipe or system specification. This practice is not intended to be used for pipe or tubing to be crosslinked by radiation or by using peroxides. This practice shall not be used to join CX-PE pipe that has been commissioned. CX-PE pipe that has been commissioned is crosslinked pipe.

5.2 Melt characteristics, average molecular weight and molecular weight distribution are influential factors in establishing suitable fusion parameters, therefore, consider the manufacturers instructions in the use or development of a specific fusion procedure.

5.3 The butt fusion procedures in this practice are suitable for joining CX-PE pipe and tubing that is used in pressure, low pressure, and non-pressure applications. For some applications, qualification of the procedure by testing joints made using the procedure in accordance with regulations from the authority having jurisdiction are required.

5.4 This butt-fusion joining practice shall only be used to join pipe or tubing made from compatible CX-PE compounds and meeting the same specification dimensions for ou...

SCOPE

1.1 This practice describes procedures for making butt fusion joints with crosslinkable polyethylene (CX-PE) pipe and tubing2 which is less than 30 % crosslinked at the time of joining. This practice shall not be applied to crosslinked products, that is PEX pipe or tubing or to CX-PE after commissioning3 (commissioning transitions CX-PE pipe into crosslinked pipe).

Note 1: For avoidance of doubt, CX-PE is a completely different product than PEX, especially for the purposes of butt-fusion joining and the fabrication of fittings. The two must not be confused by the reader of this standard.

1.2 The main difference between this practice and Practice F2620 is that the production date of pipe must be checked prior to butt fusion. Field experiments have indicated that it is best to make heat fused joints before the pipe has aged six months to ensure it has not crosslinked more than 30 % at ambient conditions. (See 7.2.)

1.3 Joints are made by means of butt-fusion joining in, but not limited to, a field environment. Other suitable butt-fusion joining procedures may be available from various sources including pipe and fitting manufacturers. This practice does not claim to address all possible butt-fusion joining procedures and does not prevent the use of qualified procedures developed by other parties that have been proven to produce reliable butt fusion joints.

1.4 The parameters and procedures set forth in this practice are applicable to the butt-fusion joining of CX-PE pipe and tubing. Consult with the manufacturers of CX-PE pipe or tubing to ensure that they approve of the use of this practice for butt-fusion joining of their products. This practice applies to butt fusion of both CX-PE pipe and tubing even when tubing is not explicitly referred to.

1.5 CX-PE pipe or tubing is required to produce sound joints when using the joining procedures described in this practice. Component ends joined in accordance with th...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F3507 − 21 An American National Standard

Standard Practice for

Butt-Fusion Joining of Crosslinkable Polyethylene (CX-PE)

1

Pipe and Tubing

This standard is issued under the fixed designation F3507; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope butt fusion of both CX-PE pipe and tubing even when tubing

is not explicitly referred to.

1.1 This practice describes procedures for making butt

fusionjointswithcrosslinkablepolyethylene(CX-PE)pipeand

1.5 CX-PE pipe or tubing is required to produce sound

2

tubing which is less than 30 % crosslinked at the time of

joints when using the joining procedures described in this

joining. This practice shall not be applied to crosslinked

practice. Component ends joined in accordance with this

products, that is PEX pipe or tubing or to CX-PE after

practice shall be of the same nominal diameter and wall

3

commissioning (commissioning transitions CX-PE pipe into

thickness.

crosslinked pipe).

1.6 The ability to join pipe using this practice does not

NOTE 1—For avoidance of doubt, CX-PE is a completely different

imply that the pipe joined is suitable for any intended use.

product than PEX, especially for the purposes of butt-fusion joining and

1.7 This practice does not purport to address any issues

the fabrication of fittings. The two must not be confused by the reader of

this standard.

related to the commissioning of a CX-PE system prior to its

use. The intention of this standard practice is to set forth

1.2 The main difference between this practice and Practice

requirements for the butt fusion of CX-PE pipe and tubing

F2620isthattheproductiondateofpipemustbecheckedprior

whichwhenfollowedareexpectedtoyielddurablejointsinthe

to butt fusion. Field experiments have indicated that it is best

said pipe and tubing.

to make heat fused joints before the pipe has aged six months

to ensure it has not crosslinked more than 30 % at ambient

1.8 Only procedures related to butt-fusion joining are cov-

conditions. (See 7.2.)

ered in this practice. Saddle fusion and socket fusion are not

included in this practice.

1.3 Joints are made by means of butt-fusion joining in, but

not limited to, a field environment. Other suitable butt-fusion

1.9 The values stated in inch-pound units are to be regarded

joining procedures may be available from various sources

as standard. The values given in parentheses are mathematical

includingpipeandfittingmanufacturers.Thispracticedoesnot

conversions to SI units that are provided for information only

claimtoaddressallpossiblebutt-fusionjoiningproceduresand

and are not considered standard.

does not prevent the use of qualified procedures developed by

1.10 The text of this practice references notes, footnotes,

other parties that have been proven to produce reliable butt

and appendixes which provide explanatory material. These

fusion joints.

notesandfootnotes(excludingthoseintablesandfigures)shall

1.4 The parameters and procedures set forth in this practice

not be considered as requirements of the practice.

are applicable to the butt-fusion joining of CX-PE pipe and

1.11 This standard does not purport to address all of the

tubing. Consult with the manufacturers of CX-PE pipe or

safety concerns, if any, associated with its use. It is the

tubingtoensurethattheyapproveoftheuseofthispracticefor

responsibility of the user of this standard to establish appro-

butt-fusion joining of their products. This practice applies to

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

1

This practice is under the jurisdiction of ASTM Committee F17 on Plastic

1.12 This international standard was developed in accor-

Piping Systems and is the direct responsibility of Subcommittee F17.20 on Joining.

dance with internationally recognized principles on standard-

Current edition approved April 1, 2021. Published August 2021. DOI: 10.1520/

F3507–21

ization established in the Decision on Principles for the

2

A standard specification for CX-PE pipe is being developed by Subcommittee

Development of International Standards, Guides and Recom-

F17.68.

3 mendations issued by the World Trade Organization Technical

Apractice for commissioning of CX-PE piping systems is being developed by

Subcommittee F17.68. Barriers to Trade (TBT) Committee.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United St

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.