ASTM B275-13

(Practice)Standard Practice for Codification of Certain Nonferrous Metals and Alloys, Cast and Wrought

Standard Practice for Codification of Certain Nonferrous Metals and Alloys, Cast and Wrought

ABSTRACT

This practice covers a system for designating cast and wrought nonferrous metals and alloys. It was originally adopted for light metals and alloys that are cast and wrought and later extended to heavier base-metal die-casting alloys. Chemical composition limits serve as the basis for the Unified Numbering System (UNS) designations. The temper designations used for all metal forms, except for ingots, follow the alloy designation.

SCOPE

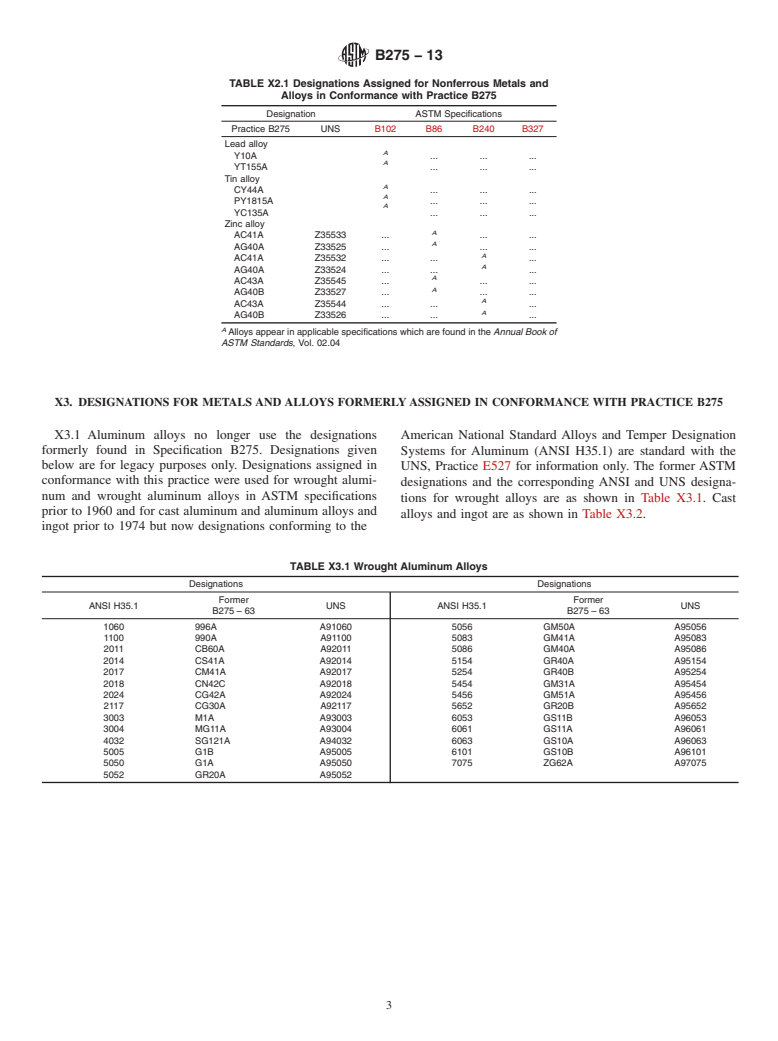

1.1 This practice covers a system for designating die-casting alloys of zinc, tin and lead. Those designations currently being used in specifications under the jurisdiction of Committees B02 on Nonferrous Metals and are listed in Appendix Table X2.1.

1.1.1 The alloy designations now being used in Committee B07 specifications for aluminum and aluminum-alloy wrought and cast products conform to ANSI H35.1. Alloys formerly codified by this practice and the corresponding ANSI designations are shown in Tables X3.1 and X3.2 of the Appendix for legacy purposes.

1.1.2 The alloy designations now being used in Committee B07 specifications for magnesium and magnesium-alloy wrought and cast products conform to Practice B951, as indicated in Appendix X4. Alloy designations formerly codified by this practice are no longer relevant.

1.2 The equivalent Unified Numbering System (UNS) alloy designations shown in the appendixes are in accordance with Practice E527.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B275 −13

StandardPractice for

Codification of Certain Nonferrous Metals and Alloys, Cast

1

and Wrought

This standard is issued under the fixed designation B275; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* loys in Ingot Form for Foundry and Die Castings

B327 Specification for Master Alloys Used in Making Zinc

1.1 Thispracticecoversasystemfordesignatingdie-casting

Die Casting Alloys

alloys of zinc, tin and lead. Those designations currently being

B951 PracticeforCodificationofUnalloyedMagnesiumand

usedinspecificationsunderthejurisdictionofCommitteesB02

Magnesium-Alloys, Cast and Wrought

on Nonferrous Metals and are listed in Appendix Table X2.1.

E527 Practice for Numbering Metals and Alloys in the

1.1.1 The alloy designations now being used in Committee

Unified Numbering System (UNS)

B07 specifications for aluminum and aluminum-alloy wrought

4

2.3 ANSI Standard:

and cast products conform to ANSI H35.1. Alloys formerly

H35.1 Alloy and Temper Designation Systems for Alumi-

codified by this practice and the correspondingANSI designa-

num

tions are shown in Tables X3.1 and X3.2 of the Appendix for

legacy purposes.

3. Basis of Codification

1.1.2 The alloy designations now being used in Committee

B07 specifications for magnesium and magnesium-alloy

3.1 The designations for alloys and unalloyed metals are

wrought and cast products conform to Practice B951,as

based on their chemical composition limits.

indicated in Appendix X4. Alloy designations formerly codi-

3.2 Designations shall be assigned, revised, and cancelled

fied by this practice are no longer relevant.

by Subcommittee B02.04 of ASTM Committee B02 on Non-

1.2 The equivalent Unified Numbering System (UNS) alloy

ferrous Metals and Alloys on written requests to its chairman.

designations shown in the appendixes are in accordance with

Complete chemical composition limits shall be submitted with

Practice E527.

request for assignment or revision of designations. Arbitrary

assignments by other subcommittees or committees will not be

2. Referenced Documents

recognized.

2.1 The following documents form a part of this practice to

the extent referenced herein: 4. Alloys

2

4.1 Designationforalloysshallconsistofnotmorethantwo

2.2 ASTM Standards:

B86 Specification for Zinc and Zinc-Aluminum (ZA) Alloy letters representing the alloying elements (Note 1) specified in

the greatest amount, arranged in order of decreasing

Foundry and Die Castings

B102 Specification for Lead- and Tin-Alloy Die Castings percentages, or in alphabetical order if of equal percentages,

3

followed by the respective percentages rounded off to whole

(Withdrawn 2011)

B240 Specification for Zinc and Zinc-Aluminum (ZA) Al- numbers and a serial letter (Notes 2 and 3). The full name of

the base metal precedes the designation, but it is omitted for

brevity when the base metal being referred to is obvious.

1

This practice is under the jurisdiction ofASTM Committee B02 on Nonferrous

NOTE 1—For codification, an alloying element is defined as an element

Metals andAlloys and is the direct responsibility of Subcommittee B02.04 on Zinc

(other than the base metal) having a minimum content greater than zero

and Cadmium.

either directly specified or computed in accordance with the percentages

Current edition approved Dec. 1, 2013. Published January 2014. Originally

approved in 1962. Last previous edition approved in 2013 as B275 – 05 (2013). specified.

DOI: 10.1520/B0275-13. NOTE 2—The serial letter is arbitrarily assigned in alphabetical se-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

quencestartingwith“A”(omitting“I”and“O”)andservestodifferentiate

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

The last approved version of this historical standard is referenced on Available in the Related Materials section (gray pages) of the Annual Book of

www.astm.org. ASTM Standards, Vol 02.02.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B275−13

otherwise identical designations. A serial letter is necessary to complete

4.3 Inroundingpercentages,thenearestwholenumbershall

each designation.

be used. If two choices are possible as when the decimal is

NOTE 3—The designation of a ca

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B275 − 05 (Reapproved 2013) B275 − 13

Standard Practice for

Codification of Certain Nonferrous Metals and Alloys, Cast

1

and Wrought

This standard is issued under the fixed designation B275; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

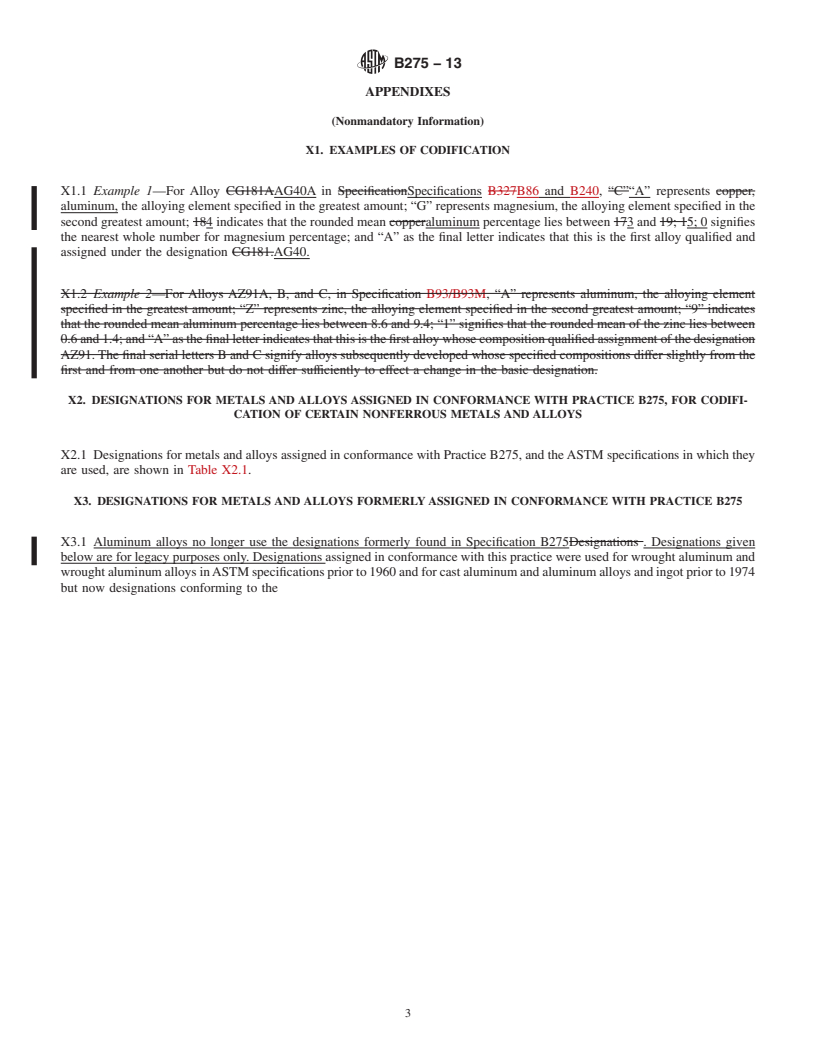

1.1 This practice covers a system originally adopted for designating light metals and alloys, cast and wrought, and later extended

to certain heavier, base-metal die-casting alloys. Those designations, which are for designating die-casting alloys of zinc, tin and

lead. Those designations currently being used in specifications under the jurisdiction of Committees B02 on Nonferrous Metals

and Alloys and B07 on Light Metals and Alloys, are listed in Appendix Table X2.1.

1.1.1 The alloy designations now being used in Committee B07 specifications for aluminum and aluminum-alloy wrought and

cast products conform to ANSI H35.1. Alloys formerly codified by this practice and the corresponding ANSI designations are

shown in Tables X3.1 and X3.2. of the Appendix for legacy purposes.

1.1.2 The alloy designations now being used in Committee B07 specifications for magnesium and magnesium-alloy wrought

and cast products conform to Practice B951, as indicated in Appendix X4. Alloy designations formerly codified by this practice

are no longer relevant.

1.2 This practice also provides a system for designating magnesium alloys that have been used commercially since 1952, and

thus is intended to be the registration source for new magnesium alloys. A record of designations along with the established

compositions is given in Table X4.1.

1.2 The equivalent Unified Numbering System (UNS) alloy designations shown in the appendixes are in accordance with

Practice E527.

2. Referenced Documents

2.1 The following documents form a part of this practice to the extent referenced herein:

2

2.2 ASTM Standards:

B37 Specification for Aluminum for Use in Iron and Steel Manufacture

B80 Specification for Magnesium-Alloy Sand Castings

B86 Specification for Zinc and Zinc-Aluminum (ZA) Alloy Foundry and Die Castings

B93/B93M Specification for Magnesium Alloys in Ingot Form for Sand Castings, Permanent Mold Castings, and Die Castings

B94 Specification for Magnesium-Alloy Die Castings

3

B102 Specification for Lead- and Tin-Alloy Die Castings (Withdrawn 2011)

B240 Specification for Zinc and Zinc-Aluminum (ZA) Alloys in Ingot Form for Foundry and Die Castings

B327 Specification for Master Alloys Used in Making Zinc Die Casting Alloys

B951 Practice for Codification of Unalloyed Magnesium and Magnesium-Alloys, Cast and Wrought

E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

4

2.3 ANSI Standard:

H35.1 Alloy and Temper Designation Systems for Aluminum

1

This practice is under the jurisdiction of ASTM Committee B02 on Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee B02.04 on Zinc and

Cadmium.

Current edition approved Aug. 1, 2013Dec. 1, 2013. Published August 2013January 2014. Originally approved in 1962. Last previous edition approved in 20052013 as

B275 – 05.B275 – 05 (2013). DOI: 10.1520/B0275-05R13.10.1520/B0275-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

4

Available in the Related Materials section (gray pages) of the Annual Book of ASTM Standards, Vol 02.02.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B275 − 13

3. Basis of Codification

3.1 The designations for alloys and unalloyed metals are based on their chemical composition limits.

NOTE 1—For aluminum and magnesium alloys, cast and wrought, standard limits for alloying elements and impurities are expressed to the following

places:

Less than 0.0001 % (used only for magnesium alloys) 0.0000X

0.0001 to 0.001 % 0.000X

0.001 to 0.01 % 0.00X

0.01 to 0

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.