ASTM G175-03

(Test Method)Standard Test Method for Evaluating the Ignition Sensitivity and Fault Tolerance of Oxygen Regulators Used for Medical and Emergency Applications

Standard Test Method for Evaluating the Ignition Sensitivity and Fault Tolerance of Oxygen Regulators Used for Medical and Emergency Applications

SIGNIFICANCE AND USE

This test method comprises two phases and is used to evaluate the ignition sensitivity and fault tolerance of oxygen regulators used for medical and emergency applications.

Phase 1: Oxygen Pressure Shock Test—The objective of this test phase is to determine whether the heat from oxygen pressure shocks will result in burnout or visible heat damage to the internal parts of the regulator. Phase 1 is performed according to ISO 10524, Section 11.8.1.

4.2.1 The criteria for an acceptable test are specified in ISO 10524, Section 11.8.1.

4.2.2 The pass/fail criteria for a regulator are specified in ISO 10524, Section 11.8.1.

Phase 2: Regulator Inlet Promoted Ignition Test—The objective of this test phase is to determine if an ignition event upstream of the regulator inlet filter will result in sustained combustion and burnout of the regulator.

4.3.1 The criterion for an acceptable test is either, (1) failure of the regulator, which is defined as the breach of the pressurized regulator component (burnout) and ejection of molten or burning metal or any internal parts from the regulator, or (2) if the regulator does not fail, consumption of at least 90 % of the ignition pill as determined by visual inspection or mass determination. Failure of the regulator at the seal ring does not constitute an acceptable test.

4.3.2 Momentary (less than 1 s) ejection of flame through normal vent paths, with sparks that look similar to those from metal applied to a grinding wheel, is acceptable.

SCOPE

1.1 This standard describes a test method for evaluating the ignition sensitivity and fault tolerance of oxygen regulators used for medical and emergency applications.

1.2 For the purpose of this standard, a pressure regulator is a device, also called a pressure-reducing valve, that is intended for medical or emergency purposes and that is used to convert a medical or emergency gas pressure from a high, variable pressure to a lower, more constant working pressure [21 CFR 868.2700 (a)].

1.3 This standard applies only to oxygen regulators used for medical and emergency applications that are designed and fitted with CGA 540 inlet connections or CGA 870 pin-index adapters (CGA V-1).

1.4 This standard provides an evaluation tool for determining the fault tolerance of oxygen regulators used for medical and emergency applications. A fault tolerant regulator is defined as (1) having a low probability of ignition as evaluated by rapid pressurization testing, and (2) having a low consequence of ignition as evaluated by forced ignition testing.

1.5 This standard is not a design standard; however, it can be used to aid designers in designing and evaluating the safe performance and fault tolerance capability of oxygen regulators used for medical and emergency applications (G 128).

Note 1—It is essential that a risk assessment be carried out on breathing gas systems, especially concerning oxygen compatibility (refer to ASTM G 63 and G 94) and toxic product formation due to ignition or decomposition of nonmetallic materials as weighed against the risk of flammability (refer to ISO 15001.2). See Appendix X1 and X2.1 for details.

1.6 This standard is also used to aid those responsible for purchasing or using oxygen regulators used for medical and emergency applications in ensuring that selected regulators are tolerant of the ignition mechanisms that are normally active in oxygen systems.

1.7 This standard does not purport to address the ignition sensitivity and fault tolerance of an oxygen regulator caused by contamination during field maintenance or use. Regulator designers and manufacturers should provide design safeguards to minimize the potential for contamination or its consequences (G 88).

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determin...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G175 – 03

Standard Test Method for

Evaluating the Ignition Sensitivity and Fault Tolerance of

Oxygen Regulators Used for Medical and Emergency

1

Applications

This standard is issued under the fixed designation G175; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6 This standard is also used to aid those responsible for

purchasing or using oxygen regulators used for medical and

1.1 This standard describes a test method for evaluating the

emergency applications in ensuring that selected regulators are

ignition sensitivity and fault tolerance of oxygen regulators

tolerant of the ignition mechanisms that are normally active in

used for medical and emergency applications.

oxygen systems.

1.2 For the purpose of this standard, a pressure regulator is

1.7 This standard does not purport to address the ignition

a device, also called a pressure-reducing valve, that is intended

sensitivityandfaulttoleranceofanoxygenregulatorcausedby

for medical or emergency purposes and that is used to convert

contamination during field maintenance or use. Regulator

a medical or emergency gas pressure from a high, variable

designers and manufacturers should provide design safeguards

pressure to a lower, more constant working pressure [21 CFR

tominimizethepotentialforcontaminationoritsconsequences

868.2700 (a)].

(Guide G88).

1.3 This standard applies only to oxygen regulators used for

1.8 This standard does not purport to address all of the

medical and emergency applications that are designed and

safety concerns, if any, associated with its use. It is the

fitted with CGA 540 inlet connections or CGA 870 pin-index

responsibility of the user of this standard to establish appro-

adapters (CGA V-1).

priate safety and health practices and determine the applica-

1.4 This standard provides an evaluation tool for determin-

bility of regulatory limitations prior to use.

ing the fault tolerance of oxygen regulators used for medical

and emergency applications. A fault tolerant regulator is

2. Referenced Documents

defined as (1) having a low probability of ignition as evaluated

2

2.1 ASTM Standards:

by rapid pressurization testing, and (2) having a low conse-

G63 Guide for Evaluating Nonmetallic Materials for Oxy-

quence of ignition as evaluated by forced ignition testing.

gen Service

1.5 This standard is not a design standard; however, it can

G88 Guide for Designing Systems for Oxygen Service

be used to aid designers in designing and evaluating the safe

G93 Practice for Cleaning Methods and Cleanliness Levels

performance and fault tolerance capability of oxygen regula-

for Material and Equipment Used in Oxygen-Enriched

tors used for medical and emergency applications (Guide

Environments

G128).

G94 Guide for Evaluating Metals for Oxygen Service

NOTE 1—It is essential that a risk assessment be carried out on

G128 Guide for Control of Hazards and Risks in Oxygen

breathing gas systems, especially concerning oxygen compatibility (refer

Enriched Systems

to Guides G63 and G94) and toxic product formation due to ignition or

2.2 ASTM Manual:

decomposition of nonmetallic materials as weighed against the risk of

2

Manual 36 Safe Use of Oxygen and Oxygen Systems

flammability (refer to ISO 15001.2). See Appendix X1 and X2.1 for

2.3 Compressed Gas Association (CGA) Standards:

details.

1

This test method is under the jurisdiction of ASTM Committee G04 on

Compatibility and Sensitivity of Materials in Oxygen EnrichedAtmospheres and is

2

the direct responsibility of Subcommittee G04.01 on Test Methods. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 10, 2003. Published May 2003. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

published as PS 127 – 00. Last previous edition PS 127 – 00. DOI: 10.1520/G0175- Standards volume information, refer to the standard’s Document Summary page on

03. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

G175 – 03

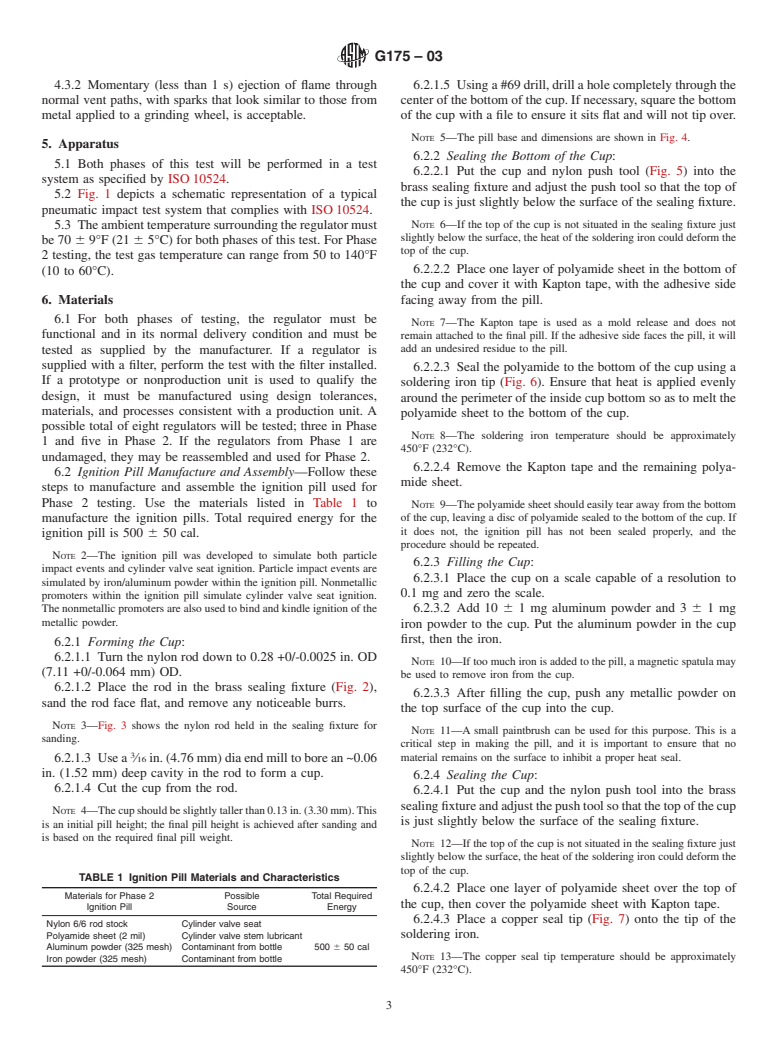

FIG. 1 Typical Test System Configuration

3

CGA E-4 Standard for Gas Pressure Regulators 3.3 Phase 2: Regulator Inlet Promoted Ignition Test—In

3

CGA G-4 Oxygen this test phase, fault tolerance is evaluated by subjecting the

3

CGA G-4.1 Cleaning Equipment for Oxygen Service regulator to the forced application of a positive ignition source

CGA V-1 American National/Compressed Gas Association

at the regulator inlet to simulate cylinder valve seat ignition

Standard

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.