ASTM G74-13(2021)

(Test Method)Standard Test Method for Ignition Sensitivity of Nonmetallic Materials and Components by Gaseous Fluid Impact

Standard Test Method for Ignition Sensitivity of Nonmetallic Materials and Components by Gaseous Fluid Impact

SIGNIFICANCE AND USE

4.1 This test standard describes how to evaluate the relative sensitivity of materials and components to dynamic pressure impacts by various gaseous fluid media (can include gas mixtures).

4.2 Changes or variations in test specimen configurations, thickness, preparation, and cleanliness can cause a significant change in their impact ignition sensitivity/reaction. For material tests, the test specimen configuration shall be specified on the test report.

4.3 Changes or variation in the test system configuration from that specified herein may cause a significant change in the severity produced by a dynamic pressure surge of the gaseous media.

4.4 A reaction is indicated by an abrupt increase in test specimen temperature, by obvious changes in odor, color, or material appearance, or a combination thereof, as observed during post-test examinations. Odor alone is not considered positive evidence that a reaction has occurred. When an increase in test specimen temperature is observed, a test specimen reaction must be confirmed by visual inspection. To aid with visual inspection, magnification less than 10× can be used.

4.5 When testing components, the test article must be disassembled and the nonmetallic materials examined for evidence of ignition after completion of the specified pressure surge cycles.

4.6 Ignition or precursors to ignition for any test sample shall be considered a failure and are indicated by burning, material loss, scorching, or melting of a test material detected through direct visual means. Ignition is often indicated by consumption of the non-metallic material under test, whether as an individual material or within a component. Partial ignition can also occur, as shown in Fig. 3a, b, and c, and shall also be considered an ignition (failure) for the purpose of this test standard.

FIG. 3 a Untested PCTFE (10X Magnification) (Polychlorotrifluoroethylene) Sample.

FIG. 3 b Untested Nylon (PA, polyamide) Valve Seat (10X magnification) (c...

SCOPE

1.1 This test method describes a method to determine the relative sensitivity of nonmetallic materials (including plastics, elastomers, coatings, etc.) and components (including valves, regulators flexible hoses, etc.) to dynamic pressure impacts by gases such as oxygen, air, or blends of gases containing oxygen.

1.2 This test method describes the test apparatus and test procedures employed in the evaluation of materials and components for use in gases under dynamic pressure operating conditions up to gauge pressures of 69 MPa and at elevated temperatures.

1.3 This test method is primarily a test method for ranking of materials and qualifying components for use in gaseous oxygen. The material test method is not necessarily valid for determination of the sensitivity of the materials in an “as-used” configuration since the material sensitivity can be altered because of changes in material configuration, usage, and service conditions/interactions. However, the component testing method outlined herein can be valid for determination of the sensitivity of components under service conditions. The current provisions of this method were based on the testing of components having an inlet diameter (ID bore) less than or equal to 14 mm (see Note 1).

1.4 A 5 mm Gaseous Fluid Impact Sensitivity (GFIS) test system and a 14 mm GFIS test system are described in this standard. The 5 mm GFIS system is utilized for materials and components that are directly attached to a high-pressure source and have minimal volume between the material/component and the pressure source. The 14 mm GFIS system is utilized for materials and components that are attached to a high pressure source through a manifold or other higher volume or larger sized connection. Other sizes than these may be utilized but no attempt has been made to characterize the thermal profiles of other volumes and geometries (see Note 1).

Note 1: The energy delivered by this t...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: G74 − 13 (Reapproved 2021)

Standard Test Method for

Ignition Sensitivity of Nonmetallic Materials and

Components by Gaseous Fluid Impact

ThisstandardisissuedunderthefixeddesignationG74;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope attempt has been made to characterize the thermal profiles of

other volumes and geometries (see Note 1).

1.1 This test method describes a method to determine the

NOTE 1—The energy delivered by this test method is dependent on the

relativesensitivityofnonmetallicmaterials(includingplastics,

gas volume being rapidly compressed at the inlet to the test specimen or

elastomers, coatings, etc.) and components (including valves,

testarticle.Thereforethegeometryoftheupstreamvolume(diameterand

regulators flexible hoses, etc.) to dynamic pressure impacts by

length) is crucial to the test and crucial to the application of the results to

actual service conditions. It is therefore recommended that caution be

gases such as oxygen, air, or blends of gases containing

exercised in applying the results of this testing to rapid pressurization of

oxygen.

volumes larger than those standardized by this test method. This energy

1.2 This test method describes the test apparatus and test

deliveredbythisstandardisbasedontherapidcompressionofthevolume

in eithera5mmIDby 1000 mm long impact tube or a 14 mm ID by 750

procedures employed in the evaluation of materials and com-

mm long impact tube. These two upstream volumes are specified in this

ponents for use in gases under dynamic pressure operating

standard based on historic application within the industry.

conditions up to gauge pressures of 69 MPa and at elevated

1.5 This test method can be utilized to provide batch-to-

temperatures.

batch comparison screening of materials when the data is

1.3 This test method is primarily a test method for ranking

analyzed according to the methods described herein. Accept-

of materials and qualifying components for use in gaseous

ability of any material by this test method may be based on its

oxygen. The material test method is not necessarily valid for

50% reaction pressure or its probability of ignition based on a

determinationofthesensitivityofthematerialsinan“as-used”

logistic regression analysis of the data (described herein).

configuration since the material sensitivity can be altered

1.6 Many ASTM, CGA, and ISO test standards require

because of changes in material configuration, usage, and

ignition testing of materials and components by gaseous fluid

service conditions/interactions. However, the component test-

impact, also referred to as adiabatic compression testing. This

ing method outlined herein can be valid for determination of

test method provides the test system requirements consistent

the sensitivity of components under service conditions. The

with the requirements of these other various standards. The

current provisions of this method were based on the testing of

pass/fail acceptance criteria may be provided within other

components having an inlet diameter (ID bore) less than or

standards and users should refer to those standards. Pass/fail

equal to 14 mm (see Note 1).

guidance is provided in this standard such as that noted in

1.4 A 5 mm Gaseous Fluid Impact Sensitivity (GFIS) test

section 4.6. This test method is designed to ensure that

system and a 14 mm GFIS test system are described in this

consistent gaseous fluid impact tests are conducted in different

standard. The 5 mm GFIS system is utilized for materials and

laboratories.

componentsthataredirectlyattachedtoahigh-pressuresource

1.7 The criteria used for the acceptance, retest, and

andhaveminimalvolumebetweenthematerial/componentand

rejection, or any combination thereof of materials and compo-

the pressure source. The 14 mm GFIS system is utilized for

nentsforanygivenapplicationshallbedeterminedbytheuser

materials and components that are attached to a high pressure

and are not fixed by this method. However, it is recommended

source through a manifold or other higher volume or larger

that at a minimum the 95% confidence interval be established

sizedconnection.Othersizesthanthesemaybeutilizedbutno

for all test results since ignition by this method is inherently

probabilistic and should be treated by appropriate statistical

This test method is under the jurisdiction of ASTM Committee G04 on

methods.

Compatibility and Sensitivity of Materials in Oxygen EnrichedAtmospheres and is

the direct responsibility of Subcommittee G04.01 on Test Methods.

1.8 The values stated in SI units are to be regarded as

Current edition approved Oct. 15, 2021. Published November 2021. Originally

standard. No other units of measurement are included in this

approved in 1982. Last previous edition approved in 2013 as G74–13. DOI:

10.1520/G0074-13R21. standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G74 − 13 (2021)

1.9 This standard does not purport to address all of the Breathing, Liquid and Gas

safety concerns, if any, associated with its use. It is the

2.3 CGA Standards:

responsibility of the user of this standard to establish appro-

CGA V-9Compressed Gas Association Standard for Com-

priate safety, health, and environmental practices and deter-

pressed Gas Cylinder Valves

mine the applicability of regulatory limitations prior to use.

2.4 ISO Standards:

For specific precautions see Section 7.

ISO 291Plastics—Standard Atmospheres for Conditioning

1.10 This international standard was developed in accor-

and Testing

dance with internationally recognized principles on standard-

ISO 10297Transportable gas cylinders—Cylinder valves—

ization established in the Decision on Principles for the

Specification and type testing

Development of International Standards, Guides and Recom-

ISO 10524-1Pressure regulators for use with medical

mendations issued by the World Trade Organization Technical

gases—Part 1: Pressure regulators and pressure regulators

Barriers to Trade (TBT) Committee.

with flow-metering devices

ISO 10524-2Pressure regulators for use with medical

2. Referenced Documents

gases—Part 2: Manifold and line pressure regulators

2.1 ASTM Standards:

ISO 10524-3Pressure regulators for use with medical

D618Practice for Conditioning Plastics for Testing

gases—Part 3: Pressure regulators integrated with cylin-

D2463Test Method for Drop Impact Resistance of Blow-

der valves

Molded Thermoplastic Containers

ISO 14113Gas welding equipment—Rubber and plastics

D3182PracticeforRubber—Materials,Equipment,andPro-

hose and hose assemblies for use with industrial gases up

cedures for Mixing Standard Compounds and Preparing

to 450 bar (45 MPa)

Standard Vulcanized Sheets

ISO 15001 Anesthetic and Respiratory Equipment—

D3183Practice for Rubber—Preparation of Pieces for Test

Compatibility with Oxygen

Purposes from Products

ISO 23529Rubber—General procedures for preparing and

D4894 Specification for Polytetrafluoroethylene (PTFE)

conditioning test pieces for physical test methods refer-

Granular Molding and Ram Extrusion Materials

ence

G14TestMethodforImpactResistanceofPipelineCoatings

2.5 IEST Standards:

(Falling Weight Test)

IEST-STD-CC1246D“Product Cleanliness Levels and Con-

G63Guide for Evaluating Nonmetallic Materials for Oxy-

tamination Control Program,” Clean Rooms,August 2005

gen Service

G88Guide for Designing Systems for Oxygen Service

3. Summary of Method

G93GuideforCleanlinessLevelsandCleaningMethodsfor

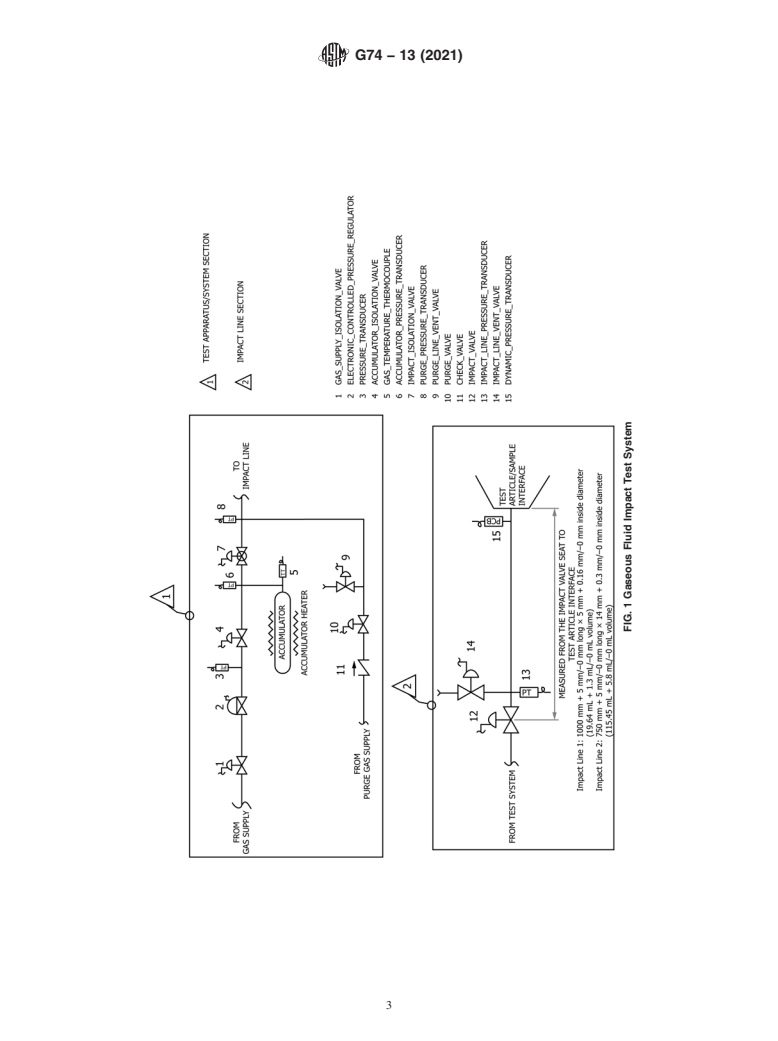

3.1 The gaseous impact test system exposes material speci-

Materials and Equipment Used in Oxygen-Enriched En-

mens or components/elements to high-velocity (dynamic) gas-

vironments

eous impact environments. The basic configuration consists of

G94Guide for Evaluating Metals for Oxygen Service

a high-pressure accumulator, a high-speed pressurization (im-

G128Guide for Control of Hazards and Risks in Oxygen

pact) valve, test system pressurization lines, test reaction

Enriched Systems

chamber/fixture (for materials tests), test chamber purge and

G175Test Method for Evaluating the Ignition Sensitivity

vent systems, and a valve sequencer/control device for auto-

and Fault Tolerance of Oxygen Pressure Regulators Used

maticcontrol.Fig.1depictsaschematicofatypical5mmand

for Medical and Emergency Applications

14mmGFIStestsystem.Fig.2aandbdepictschematicsofthe

MNL 36Safe Use of Oxygen and Oxygen Systems: Guide-

typical reaction chambers used for material screening for this

lines for Oxygen System Design, Materials Selection,

testing. Once a material test sample is installed in the reaction

Operations, Storage, and Transportation

chamber, the assembly is attached to the test article interface.

2.2 Military Standards:

Components to be qualified are attached directly to the test

MIL-STD-1330DStandard Practice for precision Cleaning

article interface.

and Testing of Shipboard Oxygen, Helium, Helium-

3.2 Thegeneraltestprocedureistopreparethetestmaterial

Oxygen, Nitrogen, and Hydrogen Systems

or component, record significant pretest data, pressurize the

MIL-STD-1622Cleaning Shipboard Compressed Air Sys-

system accumulators to the test pressure, calibrate the pressure

tems

risetime,andplacethetestmaterialinthereactionchamberor

MIL-D-16791GDetergents, General Purpose (Liquid, Non-

installthecomponentonthesysteminterface.Thetestmaterial

ionic) (26 Jan 1990)

or component is then subjected to sequential gaseous impacts

MIL-O-27210E Amendment 1—Oxygen, Aviator’s

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from Compressed Gas Association (CGA), 4221 Walney Rd., 5th

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Floor, Chantilly, VA 20151-2923, http://www.cganet.com.

Standards volume information, refer to the standard’s Document Summary page on Available from International Organization for Standardization (ISO), 1, ch. de

the ASTM website. la Voie-Creuse, CP 56, CH-1211 Geneva 20, Switzerland, http://www.iso.org.

3 6

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Available from Institute of Environmental Sciences and Technology (IEST),

Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http:// Arlington Place One, 2340 S.Arlington Heights Rd., Suite 100,Arlington Heights,

dodssp.daps.dla.mil. IL 60005-4516, http://www.iest.org.

G74 − 13 (2021)

FIG. 1 Gaseous Fluid Impact Test System

G74 − 13 (2021)

FIG. 2 a Material Test Sample Reaction Chamber Assembly for 5 mm Impact Tube.

by alternately opening and closing the test chamber pressur- 4.4 A reaction is indicated by an abrupt increase in test

ization (impact) and vent valves. The test data obtained shall specimen temperature, by obvious changes in odor, color, or

include test chamber pressures and temperatures, test chamber material appearance, or a combination thereof, as observed

pressure rise times, pressurization and vent valve actuation during post-test examinations. Odor alone is not considered

times, test gas temperature and pressure, and cycle-to-cycle positive evidence that a reaction has occurred. When an

sequence times. The test material or component is then increase in test specimen temperature is observed, a test

removedandexaminedforanysignificantchangesorevidence specimen reaction must be confirmed by visual inspection. To

of reactions. Pertinent documentation is recorded. aid with visual inspection, magnification less than 10× can be

used.

4. Significance and Use

4.5 When testing components, the test article must be

4.1 This test standard describes how to evaluate the relative

disassembled and the nonmetallic materials examined for

sensitivity of materials and components to dynamic pressure

evidence of ignition after completion of the specified pressure

impacts by various gaseous fluid media (can include gas

surge cycles.

mixtures).

4.6 Ignition or precursors to ignition for any test sample

4.2 Changes or variations in test specimen configurations,

shall be considered a failure and are indicated by burning,

thickness, preparation, and cleanliness can cause a significant

material loss, scorching, or melting of a test material detected

change in their impact ignition sensitivity/reaction. For mate-

through direct visual means. Ignition is often indicated by

rial tests, the test specimen configuration shall be specified on

consumption of the non-metallic material under test, whether

the test report.

as an individual material or within a component. Partial

4.3 Changes or variation in the test system configuration ignition can also occur, as shown in Fig. 3a, b, and c, and shall

fromthatspecifiedhereinmaycauseasignificantchangeinthe also be considered an ignition (failure) for the purpose of this

severity produced by a dynamic pressure surge of the gaseous test standard.

media. NOTE 2—A representative (exemplar) material or component may be

G74 − 13 (2021)

NOTE 1—Detailed drawings for Fig. 2 can be found in Appendix X1.

FIG. 2 b Material Test Sample Reaction Chamber Assembly for 14 mm Impact Tube. (continued)

requested by the test laboratory personnel for visual comparison with the

4.8 For component testing, a specified number of pressure

post-test condition of the test samples.

surge cycles are conducted at a defined test pressure, usually

4.7 For material testing, the prescribed procedure is con- specified by a particular industry test standard. Usually, this

ducted on multiple samples until a statistically significant pressureis1.2timesthemaximumallowableworkingpressure

number of ignitions or no-ignitions, or both, are achieved at of the component. The initial test gas temperature may be

varioustestpressures.Thedataisthenanalyzedbyaprocedure varied depending on the requirements of the test; however,

that calculates the median failure pressure (i.e., the 50% most commonly the initial test gas temperature is 60 6 3 °C.

reaction pressure) or the functional form of the ignition

5. Apparatus

probability versus pressure by logistic regression analysis.

Materials tested in a similar configuration can be ranked 5.1 Atypical gaseous impact test system used for determin-

againsteachotherbyeitherofthesetwocriteria.Theinitialtest ing the sensitivity of materials to gaseous fluid impact is

gas temperature may be varied as

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.