ASTM E1225-04

(Test Method)Standard Test Method for Thermal Conductivity of Solids by Means of the Guarded-Comparative-Longitudinal Heat Flow Technique

Standard Test Method for Thermal Conductivity of Solids by Means of the Guarded-Comparative-Longitudinal Heat Flow Technique

SIGNIFICANCE AND USE

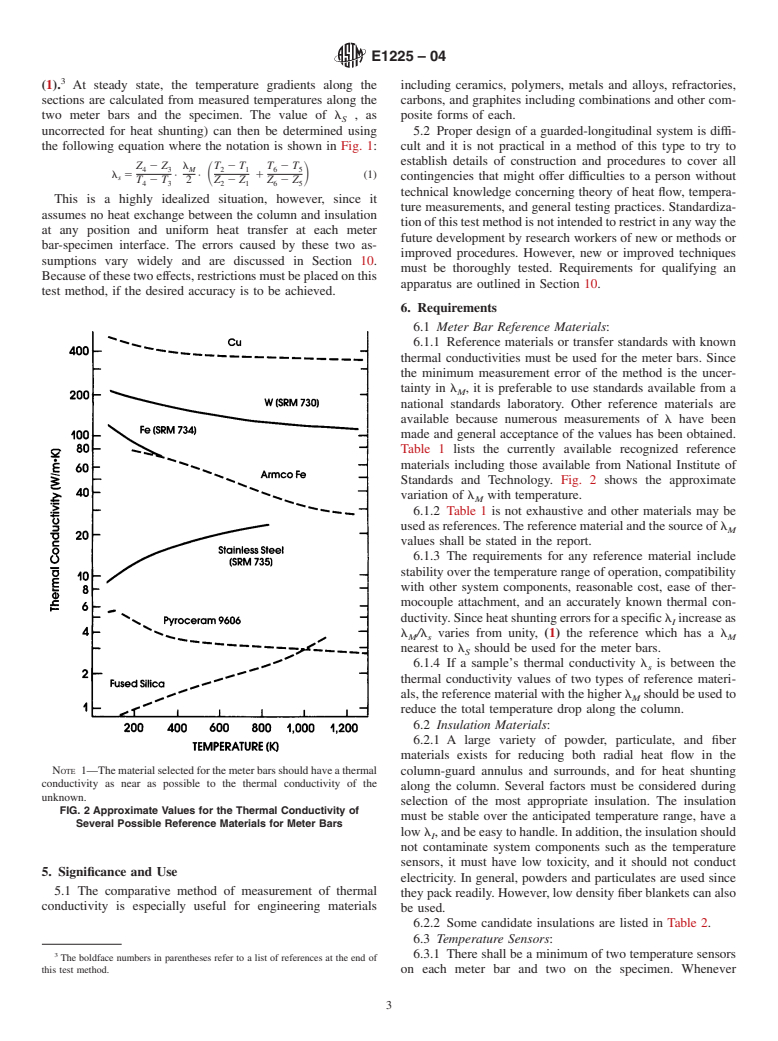

The comparative method of measurement of thermal conductivity is especially useful for engineering materials including ceramics, polymers, metals and alloys, refractories, carbons, and graphites including combinations and other composite forms of each.

Proper design of a guarded-longitudinal system is difficult and it is not practical in a method of this type to try to establish details of construction and procedures to cover all contingencies that might offer difficulties to a person without technical knowledge concerning theory of heat flow, temperature measurements, and general testing practices. Standardization of this test method is not intended to restrict in any way the future development by research workers of new or methods or improved procedures. However, new or improved techniques must be thoroughly tested. Requirements for qualifying an apparatus are outlined in Section 10.

SCOPE

1.1 This test method describes a steady state technique for the determination of the thermal conductivity, , of homogeneous-opaque solids (see Note 1 and Note 2). This test method is for materials with effective thermal conductivities in the approximate range 0.2 200 W/(mK) over the approximate temperature range between 90 and 1300 K. It can be used outside these ranges with decreased accuracy. Note 0For purposes of this technique, a system is homogeneous if the apparent thermal conductivity of the specimen, A, does not vary with changes of thickness or cross-sectional area by more than 5 %. For composites or heterogeneous systems consisting of slabs or plates bonded together, the specimen should be more than 20 units wide and 20 units thick, respectively, where a unit is the thickness of the thickest slab or plate, so that diameter or length changes of one-half unit will affect the apparent A by less than 5 %. For systems that are non-opaque or partially transparent in the infrared, the combined error due to inhomogeneity and photon transmission should be less than 5 %. Measurements on highly transparent solids must be accompanied with infrared absorption coefficient information, or the results must be reported as apparent thermal conductivity, A.Note 2

This test method may also be used to evaluate the contact thermal conductance/resistance of materials.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:E1225–04

Standard Test Method for

Thermal Conductivity of Solids by Means of the Guarded-

1

Comparative-Longitudinal Heat Flow Technique

This standard is issued under the fixed designation E1225; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope C177 Test Method for Steady-State Heat Flux Measure-

ments and Thermal Transmission Properties by Means of

1.1 This test method describes a steady state technique for

the Guarded-Hot-Plate Apparatus

the determination of the thermal conductivity, l,of

C408 Test Method for Thermal Conductivity of Whiteware

homogeneous-opaque solids (see Notes 1 and 2). This test

Ceramics

methodisformaterialswitheffectivethermalconductivitiesin

C1045 PracticeforCalculatingThermalTransmissionProp-

the approximate range 0.2 < l < 200 W/(m·K) over the

erties Under Steady-State Conditions

approximate temperature range between 90 and 1300 K. It can

D4351 Test Method for Measuring the Thermal Conductiv-

be used outside these ranges with decreased accuracy.

ity of Plastics by the Evaporation-Calorimetric Method

NOTE 1—For purposes of this technique, a system is homogeneous if

E220 Test Method for Calibration of Thermocouples By

the apparent thermal conductivity of the specimen, l , does not vary with

A

Comparison Techniques

changes of thickness or cross-sectional area by more than 65%. For

E230 Specification and Temperature-Electromotive Force

composites or heterogeneous systems consisting of slabs or plates bonded

(EMF) Tables for Standardized Thermocouples

together, the specimen should be more than 20 units wide and 20 units

F433 Practice for EvaluatingThermal Conductivity of Gas-

thick, respectively, where a unit is the thickness of the thickest slab or

plate, so that diameter or length changes of one-half unit will affect the

ket Materials

apparent l by less than 65%. For systems that are non-opaque or

A

partially transparent in the infrared, the combined error due to inhomo- 3. Terminology

geneityandphotontransmissionshouldbelessthan 65%.Measurements

3.1 Descriptions of Terms and Symbols Specific to This

onhighlytransparentsolidsmustbeaccompaniedwithinfraredabsorption

Standard:

coefficientinformation,ortheresultsmustbereportedasapparentthermal

3.1.1 Terms:

conductivity, l .

A

3.1.1.1 thermal conductivity, l—the time rate of heat flow,

NOTE 2—This test method may also be used to evaluate the contact

understeadyconditions,throughunitarea,perunittemperature

thermal conductance/resistance of materials.

gradient in the direction perpendicular to the area;

3.1.1.2 apparent thermal conductivity—when other modes

1.2 This standard does not purport to address all of the

of heat transfer through a material are present in addition to

safety concerns, if any, associated with its use. It is the

conduction,theresultsofthemeasurementsperformedaccord-

responsibility of the user of this standard to establish appro-

ing to this test method will represent the apparent or effective

priate safety and health practices and determine the applica-

thermal conductivity for the material tested.

bility of regulatory limitations prior to use.

3.1.2 Symbols:

2. Referenced Documents

2

2.1 ASTM Standards:

l (T) = thermalconductivityofmeterbars(reference

M

materials) as a function of temperature, (W/

1

ThistestmethodisunderthejurisdictionofASTMCommitteeE37onThermal

(m·K)),

1

Measurements and is the direct responsibility of Subcommittee E37.05 onThermo-

l = thermal conductivity of top meter bar (W/

M

physical Properties.

(m·K)),

Current edition approved May 1, 2004. Published June 2004. Originally

2

l = thermal conductivity of bottom meter bar

approved in 1987. Last previous edition approved in 1999 as E1225–99. DOI: M

10.1520/E1225-04. (W/(m·K)),

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E1225–04

l (T) = thermal conductivity of specimen corrected

S

for heat exchange where necessary, (W/(

m·K)),

l8 (T) = thermal conductivity of specimen calculated

S

by ignoring heat exchange correction, (W/

(m·K)),

l (T) = thermal conductivity of insulation as a func-

I

tion of temperature, (W/(m·K)),

T = absolute temperature (K),

Z = position as measured from t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.