ASTM E2580-07

(Practice)Standard Practice for Ultrasonic Testing of Flat Panel Composites and Sandwich Core Materials Used in Aerospace Applications

Standard Practice for Ultrasonic Testing of Flat Panel Composites and Sandwich Core Materials Used in Aerospace Applications

SIGNIFICANCE AND USE

This practice is intended primarily for the testing of flat panel composites and sandwich core panels to an acceptance criteria most typically specified in a purchase order or other contractual document.

Basis of Application—There are areas in this practice that require agreement between the cognizant engineering organization and the supplier, or specific direction from the cognizant engineering organization.

SCOPE

1.1 This practice establishes two procedures for ultrasonic testing (UT) of flat panel composites and flat sandwich core panels (parallel surfaces). Typical as-fabricated lay-ups include uniaxial, cross ply and angle ply laminates; as well as honeycomb sandwich core materials. These procedures can be used throughout the life cycle of the materials; product and process design optimization, on line process control, after manufacture inspection, and in service inspection. Contact methods such as angle-beam techniques using shear waves, or surface-beam techniques using Lamb waves, are not discussed.

1.2 Ultrasonic testing is a common sub surface method for detection of laminar oriented discontinuities. Two techniques can be considered based on panel surface accessibility; pulse echo for one sided and through transmission (bubblers/squirters) for two sided. As used in this practice, both require the use of a pulsed straight-beam ultrasonic longitudinal wave followed by observing indications of either the reflected (pulse-echo) or received (through transmission) wave. The general types of anomalies detected by both techniques include foreign materials, delamination, disbond/un-bond, fiber de-bonding, inclusions, porosity, and voids.

1.3 This practice provides two ultrasonic test procedures. Each has its own merits and requirements for inspection and shall be selected as agreed upon in a contractual document.

1.3.1 Test Procedure A, Pulse Echo (non-contacting and contacting) is at a minimum a single transducer transmitting and receiving a longitudinal wave in the range of 0.5 to 20 MHz (see Fig. 1). This procedure requires access to only one side of the specimen. This procedure can be conducted by automated or manual means. Automated and manual test results may be imaged or recorded.

1.3.2 Test Procedure B, Through Transmission is a combination of two transducers. One transmits a longitudinal wave and the other receives the longitudinal wave in the range of 0.5 MHz to 20 MHz (see Fig. 2). This procedure requires access to both sides of the specimen. This procedure is automated and the examination results are recorded.

1.4 This practice does not specify accept-reject criteria.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E2580–07

Standard Practice for

Ultrasonic Testing of Flat Panel Composites and Sandwich

Core Materials Used in Aerospace Applications

This standard is issued under the fixed designation E2580; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope both sides of the specimen. This procedure is automated and

the examination results are recorded.

1.1 This practice establishes two procedures for ultrasonic

1.4 This practice does not specify accept-reject criteria.

testing (UT) of flat panel composites and flat sandwich core

1.5 This standard does not purport to address all of the

panels (parallel surfaces).Typical as-fabricated lay-ups include

safety concerns, if any, associated with its use. It is the

uniaxial, cross ply and angle ply laminates; as well as honey-

responsibility of the user of this standard to establish appro-

comb sandwich core materials. These procedures can be used

priate safety and health practices and determine the applica-

throughout the life cycle of the materials; product and process

bility of regulatory limitations prior to use.

design optimization, on line process control, after manufacture

inspection, and in service inspection. Contact methods such as

2. Referenced Documents

angle-beam techniques using shear waves, or surface-beam

2.1 ASTM Standards:

techniques using Lamb waves, are not discussed.

C274 Terminology of Structural Sandwich Constructions

1.2 Ultrasonic testing is a common sub surface method for

D3878 Terminology for Composite Materials

detection of laminar oriented discontinuities. Two techniques

D5687/D5687M Guide for Preparation of Flat Composite

can be considered based on panel surface accessibility; pulse

Panels with Processing Guidelines for Specimen Prepara-

echo for one sided and through transmission (bubblers/

tion

squirters) for two sided. As used in this practice, both require

E114 Practice for Ultrasonic Pulse-Echo Straight-Beam Ex-

the use of a pulsed straight-beam ultrasonic longitudinal wave

amination by the Contact Method

followed by observing indications of either the reflected

E543 Specification for Agencies Performing Nondestruc-

(pulse-echo) or received (through transmission) wave. The

tive Testing

general types of anomalies detected by both techniques include

E1309 Guide for Identification of Fiber-Reinforced

foreign materials, delamination, disbond/un-bond, fiber de-

Polymer-Matrix Composite Materials in Databases

bonding, inclusions, porosity, and voids.

E1316 Terminology for Nondestructive Examinations

1.3 This practice provides two ultrasonic test procedures.

E1434 Guide for Recording Mechanical Test Data of Fiber-

Each has its own merits and requirements for inspection and

Reinforced Composite Materials in Databases

shall be selected as agreed upon in a contractual document.

E1471 Guide for Identification of Fibers, Fillers, and Core

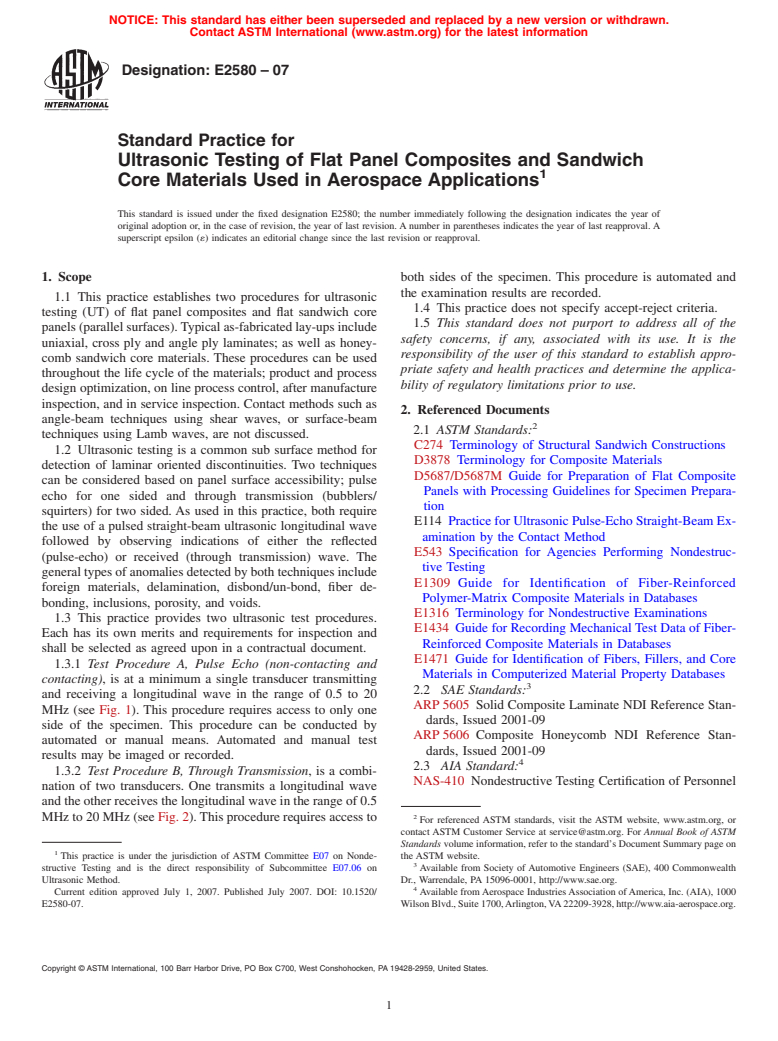

1.3.1 Test Procedure A, Pulse Echo (non-contacting and

Materials in Computerized Material Property Databases

contacting), is at a minimum a single transducer transmitting

2.2 SAE Standards:

and receiving a longitudinal wave in the range of 0.5 to 20

ARP 5605 Solid Composite Laminate NDI Reference Stan-

MHz (see Fig. 1). This procedure requires access to only one

dards, Issued 2001-09

side of the specimen. This procedure can be conducted by

ARP 5606 Composite Honeycomb NDI Reference Stan-

automated or manual means. Automated and manual test

dards, Issued 2001-09

results may be imaged or recorded.

2.3 AIA Standard:

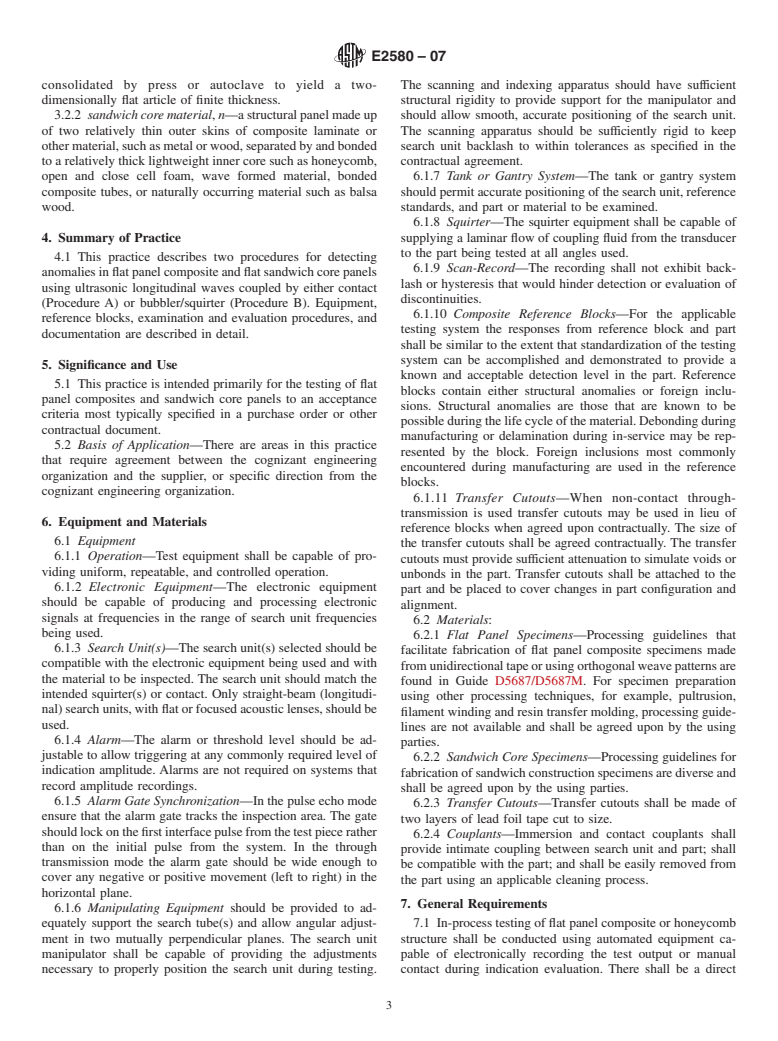

1.3.2 Test Procedure B, Through Transmission, is a combi-

NAS-410 Nondestructive Testing Certification of Personnel

nation of two transducers. One transmits a longitudinal wave

and the other receives the longitudinal wave in the range of 0.5

MHz to 20 MHz (see Fig. 2).This procedure requires access to

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

This practice is under the jurisdiction of ASTM Committee E07 on Nonde- the ASTM website.

structive Testing and is the direct responsibility of Subcommittee E07.06 on Available from Society of Automotive Engineers (SAE), 400 Commonwealth

Ultrasonic Method. Dr., Warrendale, PA 15096-0001, http://www.sae.org.

Current edition approved July 1, 2007. Published July 2007. DOI: 10.1520/ Available fromAerospace IndustriesAssociation ofAmerica, Inc. (AIA), 1000

E2580-07. WilsonBlvd.,Suite1700,Arlington,VA22209-3928,http://www.aia-aerospace.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E2580–07

FIG. 1 Test Procedure A, Pulse Echo Apparatus Set-up

FIG. 2 Test Procedure B, Through Transmission Apparatus Set-up

2.4 ASNT Standards: 3. Terminology

SNT-TC-1A Recommended Practice for Personnel Qualifi-

3.1 Definitions—Terminology in accordance with Termi-

cation and Certification in Nondestructive Testing

nologies C274, E1316, and D3878 shall be used where

ANSI/ASNT CP-189 Standard for Qualification and Certi-

applicable.

fication or Nondestructive Testing Personnel

3.2 Definitions of Terms Specific to This Standard:

3.2.1 flat panel composite, n—any fiber reinforced compos-

5 ite lay-up consisting of laminate (plies) with one or more

AvailablefromAmericanSocietyforNondestructiveTesting(ASNT),P.O.Box

28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org. orientations with respect to some reference direction that are

E2580–07

consolidated by press or autoclave to yield a two- The scanning and indexing apparatus should have sufficient

dimensionally flat article of finite thickness. structural rigidity to provide support for the manipulator and

3.2.2 sandwichcorematerial,n—astructuralpanelmadeup should allow smooth, accurate positioning of the search unit.

of two relatively thin outer skins of composite laminate or The scanning apparatus should be sufficiently rigid to keep

othermaterial,suchasmetalorwood,separatedbyandbonded search unit backlash to within tolerances as specified in the

to a relatively thick lightweight inner core such as honeycomb, contractual agreement.

open and close cell foam, wave formed material, bonded 6.1.7 Tank or Gantry System—The tank or gantry system

composite tubes, or naturally occurring material such as balsa should permit accurate positioning of the search unit, reference

wood. standards, and part or material to be examined.

6.1.8 Squirter—The squirter equipment shall be capable of

4. Summary of Practice supplying a laminar flow of coupling fluid from the transducer

to the part being tested at all angles used.

4.1 This practice describes two procedures for detecting

6.1.9 Scan-Record—The recording shall not exhibit back-

anomaliesinflatpanelcompositeandflatsandwichcorepanels

lash or hysteresis that would hinder detection or evaluation of

using ultrasonic longitudinal waves coupled by either contact

discontinuities.

(Procedure A) or bubbler/squirter (Procedure B). Equipment,

6.1.10 Composite Reference Blocks—For the applicable

reference blocks, examination and evaluation procedures, and

testing system the responses from reference block and part

documentation are described in detail.

shall be similar to the extent that standardization of the testing

system can be accomplished and demonstrated to provide a

5. Significance and Use

known and acceptable detection level in the part. Reference

5.1 This practice is intended primarily for the testing of flat

blocks contain either structural anomalies or foreign inclu-

panel composites and sandwich core panels to an acceptance

sions. Structural anomalies are those that are known to be

criteria most typically specified in a purchase order or other

possibleduringthelifecycleofthematerial.Debondingduring

contractual document.

manufacturing or delamination during in-service may be rep-

5.2 Basis of Application—There are areas in this practice

resented by the block. Foreign inclusions most commonly

that require agreement between the cognizant engineering

encountered during manufacturing are used in the reference

organization and the supplier, or specific direction from the

blocks.

cognizant engineering organization.

6.1.11 Transfer Cutouts—When non-contact through-

transmission is used transfer cutouts may be used in lieu of

6. Equipment and Materials

reference blocks when agreed upon contractually. The size of

6.1 Equipment

the transfer cutouts shall be agreed contractually. The transfer

6.1.1 Operation—Test equipment shall be capable of pro-

cutouts must provide sufficient attenuation to simulate voids or

viding uniform, repeatable, and controlled operation.

unbonds in the part. Transfer cutouts shall be attached to the

6.1.2 Electronic Equipment—The electronic equipment

part and be placed to cover changes in part configuration and

should be capable of producing and processing electronic

alignment.

signals at frequencies in the range of search unit frequencies

6.2 Materials:

being used.

6.2.1 Flat Panel Specimens—Processing guidelines that

6.1.3 Search Unit(s)—The search unit(s) selected should be

facilitate fabrication of flat panel composite specimens made

compatible with the electronic equipment being used and with

fromunidirectionaltapeorusingorthogonalweavepatternsare

the material to be inspected. The search unit should match the

found in Guide D5687/D5687M. For specimen preparation

intended squirter(s) or contact. Only straight-beam (longitudi-

using other processing techniques, for example, pultrusion,

nal)searchunits,withflatorfocusedacousticlenses,shouldbe

filament winding and resin transfer molding, processing guide-

used.

lines are not available and shall be agreed upon by the using

6.1.4 Alarm—The alarm or threshold level should be ad-

parties.

justable to allow triggering at any commonly required level of

6.2.2 Sandwich Core Specimens—Processing guidelines for

indication amplitude. Alarms are not required on systems that

fabricationofsandwichconstructionspecimensarediverseand

record amplitude recordings.

shall be agreed upon by the using parties.

6.1.5 Alarm Gate Synchronization—In the pulse echo mode

6.2.3 Transfer Cutouts—Transfer cutouts shall be made of

ensure that the alarm gate tracks the inspection area. The gate

two layers of lead foil tape cut to size.

shouldlockonthefirstinterfacepulsefromthetestpiecerather

6.2.4 Couplants—Immersion and contact couplants shall

than on the initial pulse from the system. In the through

provide intimate coupling between search unit and part; shall

transmission mode the alarm gate should be wide enough to

be compatible with the part; and shall be easily removed from

cover any negative or positive movement (left to right) in the

the part using an applicable cleaning process.

horizontal plane.

7. General Requirements

6.1.6 Manipulating Equipment should be provided to ad-

equately support the search tube(s) and allow angular adjust- 7.1 In-process testing of flat panel composite or honeycomb

ment in two mutually perpendicular planes. The search unit structure shall be conducted using automated equipment ca-

manipulator shall be capable of providing the adjustments pable of electronically recording the test output or manual

necessary to properly position the search unit during testing. contact during indication evaluation. There shall be a direct

E2580–07

correlation of the electronic recording and the tested specimen. 7.5 Material Condition—Perform ultrasonic testing of parts

Transducer frequency shall be determined by the material’s or materials that possess a clean and smooth surface.

7.6 Coverage—In all examinations, perform scanning to

apparent attenuation and the required acceptance criteria. Scan

locate discontinuities that are oriented parallel with the entry

increment shall be set to provide three ultrasonic signal

surface. The index increment shall be such that the target

violations from the standard at the specified threshold level.

simulated anomaly registers three times at a contractually

7.2 If required by contract, evaluation of the agency per-

agreed upon threshold.

forming testing shall be in accordance with Practice E543.

7.7 Ultrasonic Frequency—For a particular test select the

7.3 In-service testing shall be conducted using manual

frequency based on the material being inspected and of the

contact techniques, these tests are for the determination of

anticipated type of discontinuities.

suspected areas of damage. Testing shall be conducted using a

7.8 Evaluation—Evaluate each discontinuity to determine

referencestandard.Thisreferencestandardshallbeofthesame

its type, size, location and conformance to the applicable

configuration as the test specimen or as agreed upon contrac-

accept/reject criteria. Specific discontinuity evaluation proce-

tually. This reference standard shall be acoustically similar and

dures shall be agreed upon contractually.

contain simulated or actual discontinuities.

7.9 Technique Record—For each part inspected, a technique

7.4 In-process testing of flat panel composites shall be for

record shall be completed for each discontinuity detection scan

the detection of foreign materials, delaminations, voids and

and indication evaluation set-up used. The technique record

porosity. In-process testing of honeycomb structures shall be

shall identify the part, the area or zone, or bond-line of the part

for the detection of non-bonds between the face sheets and

being inspected, the inspector, the inspection procedure, and

core. In-service testing of flat panel composites shall be for the the equipment used. The record shall include cross-sectional

detection of damage such as delaminations. In-service testing

sketches as necessary to show part coverage. The technique

of honeycomb structure shall be for unbond between the face record shall note instrument control settings such that the test

sheet and core. can be repeated.

TEST PROCEDURES

8. Procedure A 8.2.2.1 Clean surface of part and apply the contact couplant

that provides the most consistent signal. Select a probe that

8.1 Test procedure A (Pulse-Echo) is a single transducer

provides at least a 3:1 signal to noise response from reference

transmitting and receiving a longitudinal wave in the range of

standard and provides proper indication sizing capabilities.

0.5 MHz to 20 MHz (see Fig. 1). This procedure can be

8.3 Standardize the System

auto

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.