ASTM C704/C704M-12

(Test Method)Standard Test Method for Abrasion Resistance of Refractory Materials at Room Temperature

Standard Test Method for Abrasion Resistance of Refractory Materials at Room Temperature

SIGNIFICANCE AND USE

This test method measures the relative abrasion resistance of various refractory samples under standard conditions at room temperature.

The abrasion resistance of a refractory material provides an indication of its suitability for service in abrasive environments.

The results obtained by this test method could be different than those obtained in service because of the different conditions encountered.

SCOPE

1.1 This test method covers the determination of relative abrasion resistance of refractory brick at room temperature. This test method can also be applied to castable refractories (see Metric Dimensions, Practice C861 and Practice C865) and plastic refractories (see Practice C1054).

1.2 Units—When values are stated in both SI and inch-pound units, the units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, use each system independently of the other. Combining values from the two systems may result in non-conformance with the standard. Several values are stated only in SI units as a matter of convention and to permit comparison of results. Included are the abrading media weight (grams), specimen weight (grams), specimen weight loss due to abrasion (grams), and the resultant volume loss (cubic centimeters).

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C704/C704M − 12

StandardTest Method for

Abrasion Resistance of Refractory Materials at Room

1

Temperature

This standard is issued under the fixed designation C704/C704M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C862Practice for Preparing Refractory Concrete Specimens

by Casting

1.1 This test method covers the determination of relative

C865Practice for Firing Refractory Concrete Specimens

abrasion resistance of refractory brick at room temperature.

C1036Specification for Flat Glass

This test method can also be applied to castable refractories

C1054Practice for Pressing and Drying Refractory Plastic

(seeMetricDimensions,PracticeC861andPracticeC865)and

and Ramming Mix Specimens

plastic refractories (see Practice C1054).

D4285Test Method for Indicating Oil or Water in Com-

1.2 Units—When values are stated in both SI and inch-

pressed Air

poundunits,theunitsaretoberegardedseparatelyasstandard.

2.2 American Society of Mechanical Engineers (ASME)

Thevaluesstatedineachsystemmaynotbeexactequivalents;

Standard:

therefore, use each system independently of the other. Com-

B40.100Pressure Gauges and Gauge Attachments

bining values from the two systems may result in non-

2.3 ASTM Adjuncts:

conformance with the standard. Several values are stated only

3

Abrasion Tester (1 dwg)

in SI units as a matter of convention and to permit comparison

of results. Included are the abrading media weight (grams),

3. Summary of Test Method

specimen weight (grams), specimen weight loss due to abra-

3.1 This test method measures the volume of material in

sion(grams),andtheresultantvolumeloss(cubiccentimeters).

cubiccentimetersabradedfromaflatsurfaceatarightangleto

1.3 This standard does not purport to address all of the

a nozzle through which 1000 g of size-graded silicon carbide

safety concerns, if any, associated with its use. It is the

grain is blasted by air at a prescribed air pressure.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 4. Significance and Use

bility of regulatory limitations prior to use.

4.1 This test method measures the relative abrasion resis-

tance of various refractory samples under standard conditions

2. Referenced Documents

at room temperature.

2

2.1 ASTM Standards:

4.2 Theabrasionresistanceofarefractorymaterialprovides

A681Specification for Tool Steels Alloy

an indication of its suitability for service in abrasive environ-

C134Test Methods for Size, Dimensional Measurements,

ments.

and Bulk Density of Refractory Brick and Insulating

4.3 The results obtained by this test method could be

Firebrick

different than those obtained in service because of the different

C179Test Method for Drying and Firing Linear Change of

conditions encountered.

Refractory Plastic and Ramming Mix Specimens

C861Practice for Determining Metric Dimensions of Stan-

5. Interferences (Factors known to Affect Results)

dard Series Refractory Brick and Shapes

5.1 During development, a ruggedness test was performed

1 1 1

using 114 by 114 by 12.7 mm [4 ⁄2 by 4 ⁄2 by ⁄2 in.] float glass

1

This test method is under the jurisdiction of ASTM Committee C08 on

platesconformingtoSpecificationC1036.Severalfactorswere

Refractories and is the direct responsibility of Subcommittee C08.03 on Physical

found to cause statistically significant effects on measured

Properties.

results (see Section 10).

Current edition approved March 1, 2012. Published April 2012. Originally

ϵ

approved in 1972. Last previous edition approved in 2009 as C704–09 . DOI:

10.1520/C0704_C0704M-12.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Detailed prints for the construction of the test chamber are available at a

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM nominal cost from ASTM International Headquarters. Order Adjunct No.

Standards volume information, refer to the standard’s Document Summary page on ADJC0704.Anacceptabletestchambercanbemadefromaweatherproofelectrical

the ASTM website. switch box.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C704/C704M − 12

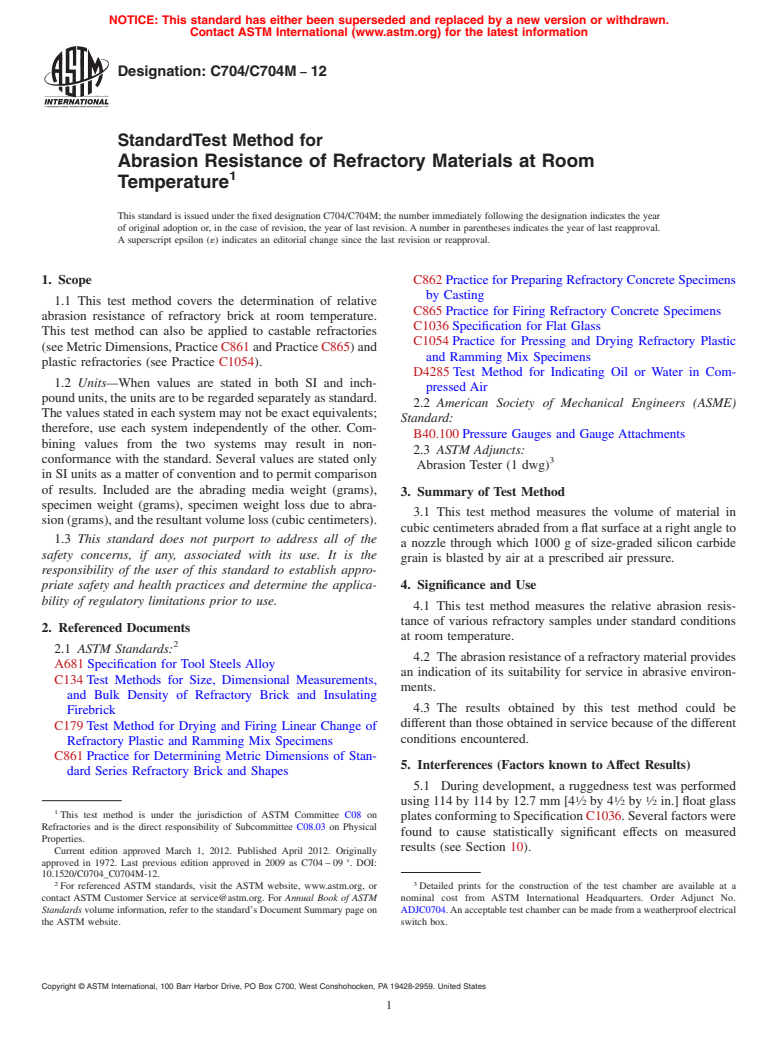

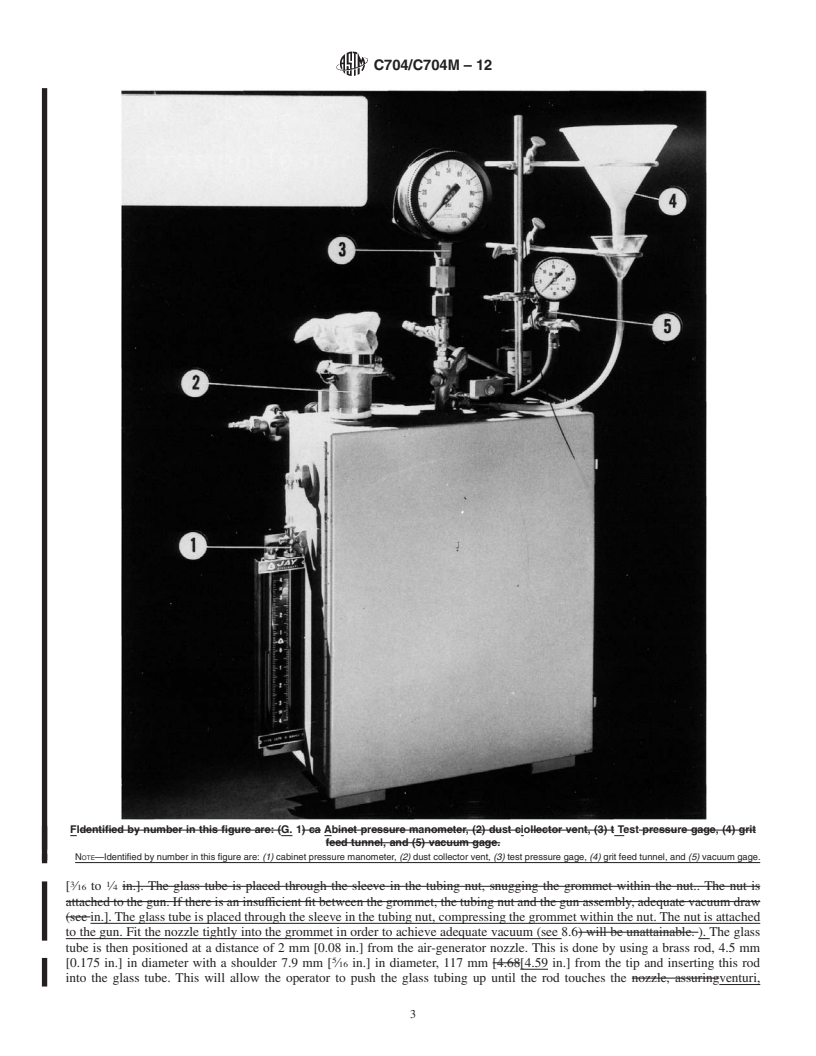

5.1.1 Nozzle Tube Inside Diameter—Variation in the inside nut. This sleeve is glued or soldered in place inside the 9.53

3

diameter of the flint glass nozzle tube statistically affected the mm [ ⁄8 in.] tubing nut, and is used primarily to hold the glass

abrasion values obtained on the glass plate. Ideal glass tube tubing perpendicular to

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:C704/C704M–09 Designation: C704/C704M – 12

Standard Test Method for

Abrasion Resistance of Refractory Materials at Room

1

Temperature

This standard is issued under the fixed designation C704/C704M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Section 2 was corrected editorially in August 2009.

1. Scope

1.1 This test method covers the determination of relative abrasion resistance of refractory brick at room temperature. This test

method can also be applied to castable refractories (see Metric Dimensions, Practice C861 and Practice C865) and plastic

refractories (see Practice C1054).

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated

in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values

fromthetwosystemsmayresultinnon-conformancewiththestandard.—WhenvaluesarestatedinbothSIandinch-poundunits,

the units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, use

eachsystemindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnon-conformancewiththestandard.

Several values are stated only in SI units as a matter of convention and to permit comparison of results. Included are the abrading

media weight (grams), specimen weight (grams), specimen weight loss due to abrasion (grams), and the resultant volume loss

(cubic centimeters).

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards: ASTM Standards:

A681 Specification for Tool Steels Alloy

C134 Test Methods for Size, Dimensional Measurements, and Bulk Density of Refractory Brick and Insulating Firebrick

C179 Test Method for Drying and Firing Linear Change of Refractory Plastic and Ramming Mix Specimens

C861 Practice for Determining Metric Dimensions of Standard Series Refractory Brick and Shapes

C862 Practice for Preparing Refractory Concrete Specimens by Casting

C865 Practice for Firing Refractory Concrete Specimens

C1036 Specification for Flat Glass

C1054 Practice for Pressing and Drying Refractory Plastic and Ramming Mix Specimens Practice for Pressing and Drying

Refractory Plastic and Ramming Mix Specimens

D4285 Test Method for Indicating Oil or Water in Compressed Air

2.2 American Society of Mechanical Engineers (ASME) Standard:

B40.100 Pressure Gauges and Gauge Attachments

2.3 ASTM Adjuncts:

3

Abrasion Tester (1 dwg)

1

This test method is under the jurisdiction of ASTM Committee C08 on Refractories and is the direct responsibility of Subcommittee C08.03 on Physical Properties.

Current edition approved March 1, 2009. Published March 2009. Originally approved in 1972. Last previous edition approved in 2007 as C704–07. DOI:

10.1520/C0704_C0704M-09E01.

´

Current edition approved March 1, 2012. Published April 2012. Originally approved in 1972. Last previous edition approved in 2009 as C704–09 . DOI:

10.1520/C0704_C0704M-12.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from ASTM International Headquarters. Order Adjunct No. ADJC0704. Original adjunct produced in 1970.

3

Detailed prints for the construction of the test chamber are available at a nominal cost from ASTM International Headquarters. Order Adjunct No. ADJC0704. An

acceptable test chamber can be made from a weatherproof electrical switch box.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C704/C704M – 12

3. Summary of Test Method

3.1 This test method measures the volume of material in cubic centimetrers abraded from a flat surface at a right angle to a

nozzle through which 1000 g of size-graded silicon carbide grain is blasted by air at 448 kPa [65 psi]. a prescribed air pressure.

4. Signi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.