ASTM B928/B928M-09

(Specification)Standard Specification for High Magnesium Aluminum-Alloy Sheet and Plate for Marine Service and Similar Environments

Standard Specification for High Magnesium Aluminum-Alloy Sheet and Plate for Marine Service and Similar Environments

ABSTRACT

This specification covers high magnesium marine application aluminum-alloy in those alloy tempers for flat sheet, coiled sheet, and plate, in the mill finish that are intended for marine and similar environments. An inspection lot shall consist of an identifiable quantity of material of the same mill form, alloy, temper, cast or melt lot, and thickness, subjected to inspection at one time. The material shall be supplied in the mill finish and shall be uniform as defined by the requirements of this specification and shall be commercially sound. Each coil, sheet and plate shall be examined to determine conformance to this specification with respect to general quality and identification marking. One sample shall be taken from each end of each parent coil, or parent plate. Alloy-tempers are manufactured and corrosion tested for intended use in marine hull construction or in marine applications where frequent or constant direct contact with seawater is expected. The specimen shall be capable of exhibiting resistance to intergranular corrosion as indicated by an acceptable mass-loss when tested and shall also be capable of exhibiting no evidence of exfoliation or corrosion. Under metallographic examination, the microstructure of a sample from each production lot shall be compared to that of the producer-established reference photomicrograph of acceptable material, in the same thickness range. Each shipping container shall be marked with the purchase order number, material size, specification number, alloy and temper, gross and net weights, and the producer's name or trademark.

SCOPE

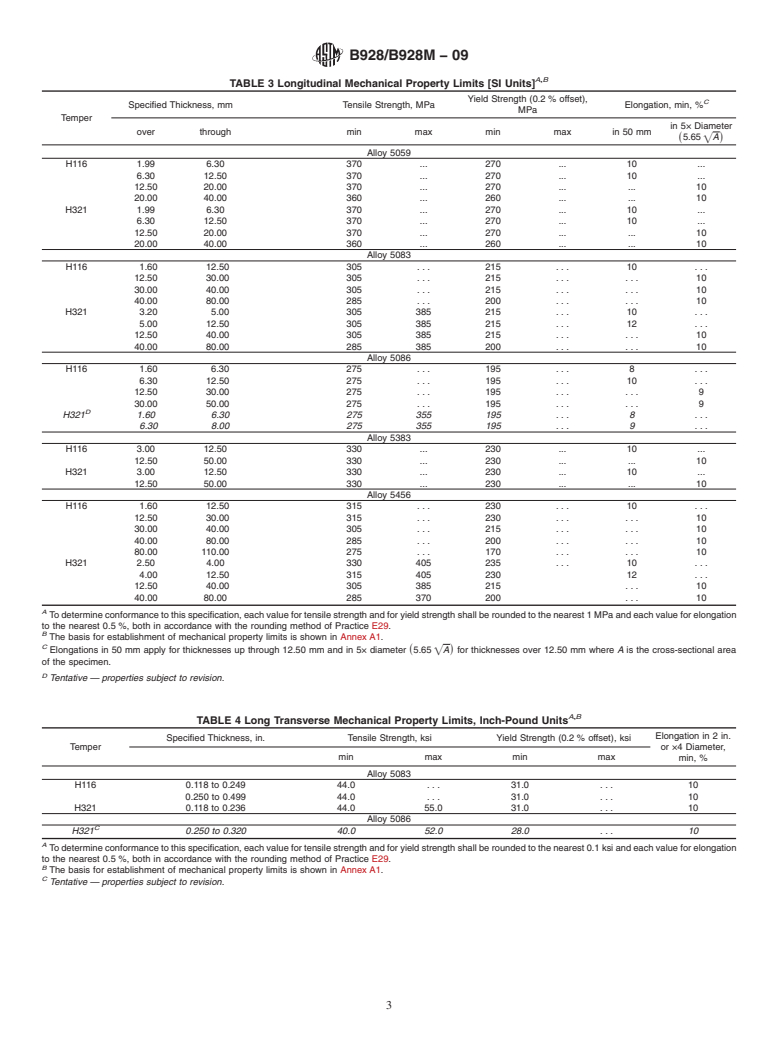

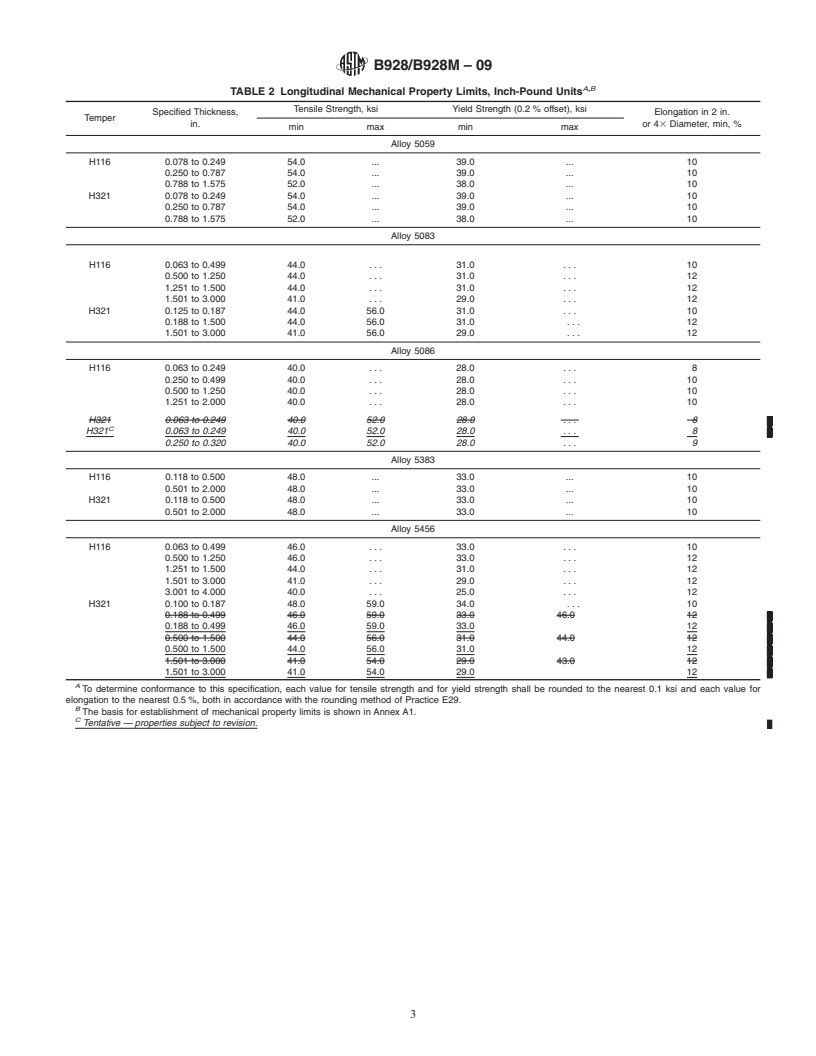

1.1 This specification covers high magnesium (Note 1) marine application aluminum-alloy (Note 2), in those alloy-tempers shown in Table 1 [Table 2] and Table 3 [Table 4], for flat sheet, coiled sheet, and plate, in the mill finish that are intended for marine and similar environments:

Note 1—The term high magnesium in the general sense includes those alloys containing 3 % or more nominal magnesium.

Note 2—Throughout this specification use of the term alloy in the general sense includes aluminum as well as aluminum alloy.

1.2 Alloy and temper designations are in accordance with ANSI H35.1/H35.1(M). The equivalent Unified Numbering System alloy designations are those of Table 5 preceded by A9, for example, A95083 for 5083 in accordance with Practice E527.

1.3 The values stated in either SI units (Table 2 and Table 4) or inch-pound units (Table 1 and Table 3) are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of each other. Combining values from the two systems may result in non-conformance with the standard.

1.4 For acceptance criteria for inclusion of new aluminum and aluminum alloys in this specification, see Annex A2.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B928/B928M −09

StandardSpecification for

High Magnesium Aluminum-Alloy Sheet and Plate for Marine

1

Service and Similar Environments

This standard is issued under the fixed designation B928/B928M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

2

1. Scope* 2.2 ASTM Standards:

B557Test Methods for Tension Testing Wrought and Cast

1.1 This specification covers high magnesium (Note 1)

Aluminum- and Magnesium-Alloy Products

marine application aluminum-alloy (Note 2), in those alloy-

B557MTest Methods forTensionTestingWrought and Cast

tempers shown in Table 2 [Table 3] and Table 4 [Table 5], for

Aluminum- and Magnesium-Alloy Products (Metric)

flat sheet, coiled sheet, and plate, in the mill finish that are

B660Practices for Packaging/Packing of Aluminum and

intended for marine and similar environments:

Magnesium Products

NOTE 1—The term high magnesium in the general sense includes those

B666/B666MPractice for Identification Marking of Alumi-

alloys containing 3% or more nominal magnesium.

num and Magnesium Products

NOTE 2—Throughout this specification use of the term alloy in the

B881Terminology Relating toAluminum- and Magnesium-

general sense includes aluminum as well as aluminum alloy.

Alloy Products

1.2 Alloy and temper designations are in accordance with

E3Guide for Preparation of Metallographic Specimens

ANSI H35.1/H35.1(M). The equivalent Unified Numbering

E29Practice for Using Significant Digits in Test Data to

SystemalloydesignationsarethoseofTable1precededbyA9,

Determine Conformance with Specifications

for example, A95083 for 5083 in accordance with Practice

E34Test Methods for Chemical Analysis of Aluminum and

E527.

Aluminum-Base Alloys

1.3 ThevaluesstatedineitherSIunits(Table3andTable5) E50Practices for Apparatus, Reagents, and Safety Consid-

or inch-pound units (Table 2 and Table 4) are to be regarded erations for Chemical Analysis of Metals, Ores, and

separately as standard. The values stated in each system may Related Materials

not be exact equivalents; therefore, each system shall be used E527Practice for Numbering Metals and Alloys in the

independently of each other. Combining values from the two Unified Numbering System (UNS)

systems may result in non-conformance with the standard. E607Test Method for Atomic Emission Spectrometric

Analysis Aluminum Alloys by the Point to Plane Tech-

1.4 For acceptance criteria for inclusion of new aluminum

3

nique Nitrogen Atmosphere (Withdrawn 2011)

and aluminum alloys in this specification, see Annex A2.

E716Practices for Sampling and Sample Preparation of

Aluminum and Aluminum Alloys for Determination of

1.5 This standard does not purport to address all of the

Chemical Composition by Spectrochemical Analysis

safety concerns, if any, associated with its use. It is the

E1251Test Method for Analysis of Aluminum and Alumi-

responsibility of the user of this standard to establish appro-

num Alloys by Spark Atomic Emission Spectrometry

priate safety and health practices and determine the applica-

G66Test Method for Visual Assessment of Exfoliation

bility of regulatory limitations prior to use.

Corrosion Susceptibility of 5XXX Series Aluminum Al-

loys (ASSET Test)

2. Referenced Documents

G67Test Method for Determining the Susceptibility to

2.1 The following documents of the issue in effect on the

Intergranular Corrosion of 5XXX Series Aluminum Al-

date of material purchase, unless otherwise noted, form a part

loysbyMassLossAfterExposuretoNitricAcid(NAMLT

of this specification to the extent referenced herein:

Test)

1 2

This specification is under the jurisdiction ofASTM Committee B07 on Light For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Metals and Alloys and is the direct responsibility of Subcommittee B07.03 on contactASTM Customer Service at service@astm.org. ForAnnual Book ofASTM

Aluminum Alloy Wrought Products. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Nov. 1, 2009. Published December 2009. Originally the ASTM website.

3

approved in 2003. Last previous edition approved in 2007 as B928/B928M–07. The last approved version of this historical standard is referenced on

DOI: 10.1520/B0928_B0928M-09. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B928/B928M−09

A,B,C

TABLE 1 Chemical Composition Limits

D

Other Elements

Alloy Silicon Iron Copper Manganese Magnesium Chromiu

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B928/B928M–07 Designation: B928/B928M – 09

Standard Specification for

High Magnesium Aluminum-Alloy Sheet and Plate for Marine

1

Service and Similar Environments

This standard is issued under the fixed designation B928/B928M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers high magnesium (Note 1) marine application aluminum-alloy (Note 2), in those alloy-tempers

showninTable2[Table3]andTable4[Table5],forflatsheet,coiledsheet,andplate,inthemillfinishthatareintendedformarine

and similar environments:

NOTE 1—The term high magnesium in the general sense includes those alloys containing 3 % or more nominal magnesium.

NOTE 2—Throughout this specification use of the term alloy in the general sense includes aluminum as well as aluminum alloy.

1.2 Alloy and temper designations are in accordance with ANSI H35.1/H35.1(M). The equivalent Unified Numbering System

alloy designations are those of Table 1 preceded by A9, for example, A95083 for 5083 in accordance with Practice E527.

1.3 The values stated in either SI units (Table 3 and Table 5) or inch-pound units (Table 2 and Table 4) are to be regarded

separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used

independently of each other. Combining values from the two systems may result in non-conformance with the standard.

1.4 For acceptance criteria for inclusion of new aluminum and aluminum alloys in this specification, see Annex A2.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 The following documents of the issue in effect on the date of material purchase, unless otherwise noted, form a part of this

specification to the extent referenced herein:

2

2.2 ASTM Standards:

B557 Test Methods for Tension Testing Wrought and Cast Aluminum- and Magnesium-Alloy Products

B557M Test Methods for Tension Testing Wrought and Cast Aluminum- and Magnesium-Alloy Products (Metric)

B660 Practices for Packaging/Packing of Aluminum and Magnesium Products

B666/B666M Practice for Identification Marking of Aluminum and Magnesium Products

B881 Terminology Relating to Aluminum- and Magnesium-Alloy Products E3

E3 Guide for Preparation of Metallographic Specimens

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E34 Test Methods for Chemical Analysis of Aluminum and Aluminum-Base Alloys

E55Practice for SamplingWrought Nonferrous Metals andAlloys for Determination of Chemical Composition 50 Practices for

Apparatus, Reagents, and Safety Considerations for Chemical Analysis of Metals, Ores, and Related Materials

E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

E607 Test Method for Atomic Emission Spectrometric Analysis Aluminum Alloys by the Point to Plane Technique Nitrogen

Atmosphere

E716 Practices for Sampling Aluminum and Aluminum Alloys for Spectrochemical Analysis

E1251 Test Method for Analysis of Aluminum and Aluminum Alloys by Atomic Emission Spectrometry

1

This specification is under the jurisdiction ofASTM Committee B07 on Light Metals andAlloys and is the direct responsibility of Subcommittee B07.03 onAluminum

Alloy Wrought Products.

Current edition approved May 15, 2007. Published June 2007. Originally approved in 2003. Last previous edition approved in 2004 as B928/B928M–04a. DOI:

10.1520/B0928_B0928M-07.

Current edition approved Nov. 1, 2009. Published December 2009. Originally approved in 2003. Last previous edition approved in 2007 as B928/B928M – 07. DOI:

10.1520/B0928_B0928M-09.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B928/B928M –

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.