ASTM D2149-97

(Test Method)Standard Test Method for Permittivity (Dielectric Constant) And Dissipation Factor Of Solid Ceramic Dielectrics At Frequencies To 10 MHz And Temperatures To 500°C

Standard Test Method for Permittivity (Dielectric Constant) And Dissipation Factor Of Solid Ceramic Dielectrics At Frequencies To 10 MHz And Temperatures To 500°C

SCOPE

1.1 This test method covers the determination of the relative permittivity (dielectric constant) and dissipation factor of solid ceramic dielectrics from 50 Hz to 10 MHz over a range of temperatures from -80 to 500°C. Two procedures are included as follows:

1.1.1 Procedure A -Using Micrometer Electrode.

1.1.2 Procedure B -Using Precision Capacitor.

Note 1-In common usage the word "relative" is frequently dropped.

1.2 This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 2149 – 97

Standard Test Method for

Permittivity (Dielectric Constant) And Dissipation Factor Of

Solid Dielectrics At Frequencies To 10 MHz And

Temperatures To 500°C

This standard is issued under the fixed designation D 2149; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope material is the ratio of the capacitance between two conductors

when embedded in the material to the capacitance between the

1.1 This test method covers the determination of the relative

same configuration of conductors in a vacuum (or air). The

permittivity (dielectric constant) and dissipation factor of solid

dissipation factor is the ratio of the resistive to capacitive

dielectrics from 50 Hz to 10 MHz over a range of temperatures

2,3

currents in the dielectric. The product of the permittivity and

from −80 to 500°C. Two procedures are included as follows:

dissipation factor is the loss index.

1.1.1 Procedure A—Using Micrometer Electrode.

1.1.2 Procedure B—Using Precision Capacitor.

4. Significance and Use

NOTE 1—In common usage the word “relative” is frequently dropped.

4.1 Permittivity and dissipation factor are sensitive to

1.2 This standard does not purport to address the safety changes in chemical composition, impurities, and homogene-

ity. Measurement of these properties is, therefore, useful for

concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and quality control and for determining the effect of environments

such as moisture, heat, or radiation.

health practices and determine the applicability of regulatory

limitations prior to use.

5. Apparatus

2. Referenced Documents

5.1 Measuring Circuits—Suitable measuring circuits are

2.1 ASTM Standards: described in Test Methods D 150. For measurements from 50

Hz to 100 kHz a substitution method using a low-voltage

D 150 Test Methods for AC Loss Characteristics and Per-

capacitance bridge is recommended. For measurements at 1

mittivity (Dielectric Constant) of Solid Electrical Insulat-

ing Materials MHz and above, a resonant-circuit susceptance variation

method is recommended. The Q of the circuit should be at least

D 1711 Terminology Relating to Electrical Insulation

E 197 Specification for Enclosures and Servicing Units for 200 except for very low loss materials, for which a Q of 500 or

higher is desirable.

Tests Above and Below Room Temperature

5.2 Test Enclosure—Unless testing only at room tempera-

3. Terminology

ture, it is necessary to adapt a Hartshorn-Ward type specimen

3.1 Definitions: holder to a temperature-controlled test enclosure. Where ap-

3.1.1 Permittivity and dissipation factor are fully defined in plicable, use the requirements for a grade A enclosure as in

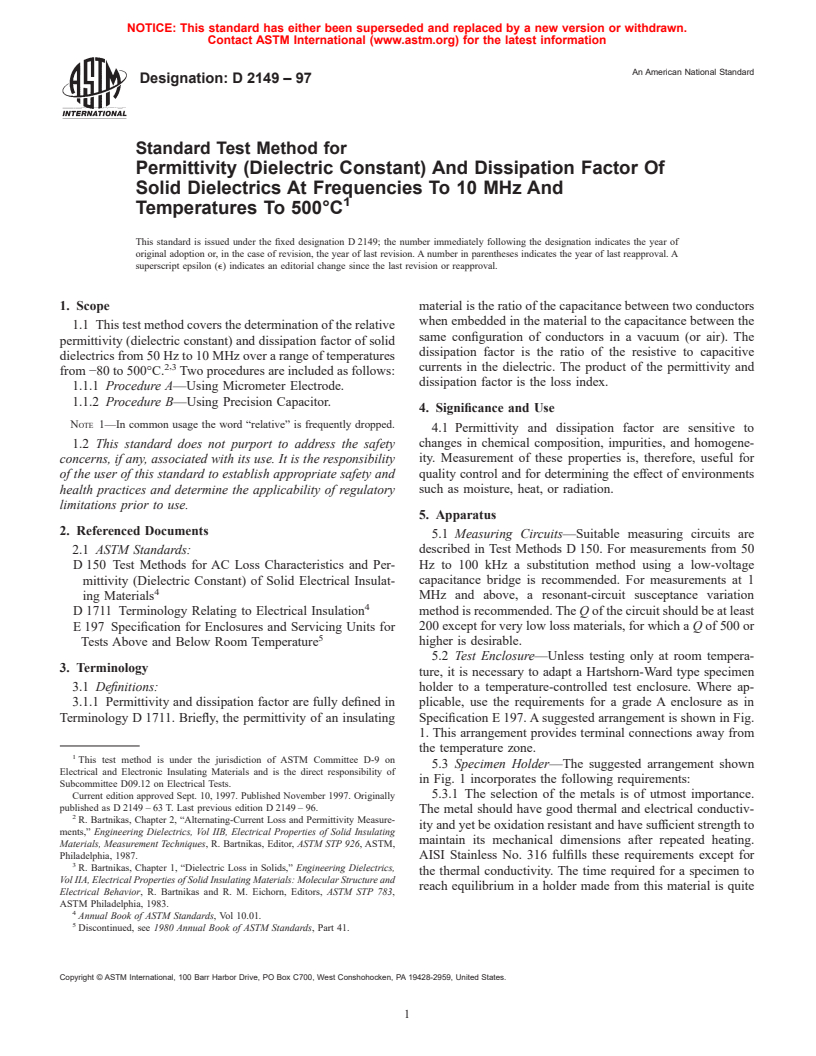

Terminology D 1711. Briefly, the permittivity of an insulating Specification E 197. A suggested arrangement is shown in Fig.

1. This arrangement provides terminal connections away from

the temperature zone.

This test method is under the jurisdiction of ASTM Committee D-9 on

5.3 Specimen Holder—The suggested arrangement shown

Electrical and Electronic Insulating Materials and is the direct responsibility of

in Fig. 1 incorporates the following requirements:

Subcommittee D09.12 on Electrical Tests.

5.3.1 The selection of the metals is of utmost importance.

Current edition approved Sept. 10, 1997. Published November 1997. Originally

published as D 2149 – 63 T. Last previous edition D 2149 – 96.

The metal should have good thermal and electrical conductiv-

R. Bartnikas, Chapter 2, “Alternating-Current Loss and Permittivity Measure-

ity and yet be oxidation resistant and have sufficient strength to

ments,” Engineering Dielectrics, Vol IIB, Electrical Properties of Solid Insulating

maintain its mechanical dimensions after repeated heating.

Materials, Measurement Techniques, R. Bartnikas, Editor, ASTM STP 926, ASTM,

Philadelphia, 1987. AISI Stainless No. 316 fulfills these requirements except for

R. Bartnikas, Chapter 1, “Dielectric Loss in Solids,” Engineering Dielectrics,

the thermal conductivity. The time required for a specimen to

Vol IIA, Electrical Properties of Solid Insulating Materials: Molecular Structure and

reach equilibrium in a holder made from this material is quite

Electrical Behavior, R. Bartnikas and R. M. Eichorn, Editors, ASTM STP 783,

ASTM Philadelphia, 1983.

Annual Book of ASTM Standards, Vol 10.01.

Discontinued, see 1980 Annual Book of ASTM Standards, Part 41.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 2149

FIG. 1 Suggested Specimen Holder

long. Precious metal alloys such as type B silver-magnesium- electrodes may be useful. Additional information on the

nickel have better overall properties but require special heat suitability of various electrode systems may be found in Test

treating. Methods D 150.

5.3.2 The insulators may be aluminum oxide, beryllium

7. Sampling

oxide, or polytetrafluoroethylene.

5.3.3 Use electrodes 50 mm in diameter and at least 5 mm 7.1 See ASTM standards for specific materials.

thick, with sharp corners. Maintain electrode parallellism to

8. Test Specimen

within 0.01 mm.

5.3.4 Select a length and cross-section for the lower tube so

8.1 Use a disk test specimen with a diameter of 40.006 0.01

that the temperature of each insulator does not exceed 100°C

mm and a thickness of 2 to 3 mm. Finish the surfaces to 1.8 μm

when the oven is at 500°C. Select a length and crosssection for

or better and maintain parallel surfaces to within 0.01 mm. The

the upper tube so that the drive nut can be touched with the

samples should be free of bubbles and other defects.

operator’s fingers (keep the drive nut less than 60°C) when the

oven is at 500°C. 9. Standard Test Frequencies

5.3.5 Use a micrometer or dial gage with a precision of

9.1 Unless otherwise specified, make measurements at one

0.005 mm to determine electrode separation and to monitor

or more of the following frequencies:

specimen expansion.

60 Hz 100 000 Hz

100 Hz 1 MHz

6. Electrodes

400 Hz 10 MHz

1000 Hz

6.1 Prior to measurement, apply conducting film or foil

Common test frequencies are 60 Hz, 1000 Hz, and 1 MHz.

electrodes to both flat surfaces of the specimen. (The specimen

thickness should be determined before applying electrodes.)

10. Temperature Control

Silver paint, tin or tin-lead foil, or evaporated metal electrodes

have ranges of usefulness. Evaporated metal electrodes are the 10.1 Take measurements at frequent temperature intervals

most suitable. When the specimen is porous sprayed-on metal (not to exceed 20°C), until the required temperature range has

D 2149

been traversed. Reduce the temperature to the lowest required D 5 C /C ~D 2 D ! (3)

s t s i v

test temperature and leave until equilibrium has been achieved.

where:

Determine equilibrium by clamping a specimen betwee

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.