ASTM E799-03(2020)e1

(Practice)Standard Practice for Determining Data Criteria and Processing for Liquid Drop Size Analysis

Standard Practice for Determining Data Criteria and Processing for Liquid Drop Size Analysis

SIGNIFICANCE AND USE

4.1 These criteria6 and procedures provide a uniform base for analysis of liquid drop data.

SCOPE

1.1 This practice gives procedures for determining appropriate sample size, size class widths, characteristic drop sizes, and dispersion measure of drop size distribution. The accuracy of and correction procedures for measurements of drops using particular equipment are not part of this practice. Attention is drawn to the types of sampling (spatial, flux-sensitive, or neither) with a note on conversion required (methods not specified). The data are assumed to be counts by drop size. The drop size is assumed to be the diameter of a sphere of equivalent volume.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 The analysis applies to all liquid drop distributions except where specific restrictions are stated.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

ϵ1

Designation: E799 − 03 (Reapproved 2020)

Standard Practice for Determining

Data Criteria and Processing for Liquid Drop Size Analysis

This standard is issued under the fixed designation E799; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Keywords were added editorially in April 2020.

1. Scope 2.2 ISO Standards:

ISO13320–1ParticleSizeAnalysis-LaserDiffractionMeth-

1.1 This practice gives procedures for determining appro-

ods

priate sample size, size class widths, characteristic drop sizes,

ISO 9276–1Representation of Results of Particle Size

and dispersion measure of drop size distribution.The accuracy

Analysis-Graphical Representation

of and correction procedures for measurements of drops using

ISO9272–2CalculationofAverageParticleSizes/Diameters

particular equipment are not part of this practice. Attention is

and Moments from Particle Size Distribution

drawn to the types of sampling (spatial, flux-sensitive, or

neither) with a note on conversion required (methods not

3. Terminology

specified).Thedataareassumedtobecountsbydropsize.The

3.1 Definitions of Terms Specific to This Standard:

drop size is assumed to be the diameter of a sphere of

3.1.1 flux-sensitive, adj—describes the observation of mea-

equivalent volume.

surement of the traffic of drops through a fixed area during

1.2 The values stated in SI units are to be regarded as

intervals of time. Examples of flux-sensitive sampling are the

standard. No other units of measurement are included in this

collection for a period of time on a stationary slide or in a

standard.

sampling cell, or the measurement of drops passing through a

1.3 The analysis applies to all liquid drop distributions

plane (gate) with a shadowing on photodiodes or by using

except where specific restrictions are stated.

capacitance changes.An example that may be characterized as

neither flux-sensitive nor spatial is a collection on a slide

1.4 This international standard was developed in accor-

movingsothatthereismeasurablesettlingofdropsontheslide

dance with internationally recognized principles on standard-

in addition to the collection by the motion of the slide through

ization established in the Decision on Principles for the

the swept volume. Optical scattering devices sensing continu-

Development of International Standards, Guides and Recom-

ously may be difficult to identify as flux-sensitive, spatial, or

mendations issued by the World Trade Organization Technical

neither due to instantaneous sampling of the sensors and the

Barriers to Trade (TBT) Committee.

measurable accumulation and relaxation time of the sensors.

For widely spaced particles sampling may resemble temporal

2. Referenced Documents

2 and for closely spaced particles it may resemble spatial. A

2.1 ASTM Standards:

flux-sensitivesetofdataisproportionaltofluxdensity:number

E1296Terminology for Liquid Particle Statistics (With-

3 per (unit area×unit time).

drawn 1997)

3.1.2 local, adj—indicates observations of a very small part

(volume or area) of a larger region of concern.

ThispracticeisunderthejurisdictionofASTMCommitteeE29onParticleand

3.1.3 representative, adj—indicates that sufficient data have

Spray Characterization and is the direct responsibility of Subcommittee E29.02 on

been obtained to make the effect of random fluctuations

Non-Sieving Methods.

acceptably small. For temporal observations this requires

Current edition approved April 1, 2020. Published April 2020. Originally

sufficienttimedurationorsufficienttotaloftimedurations.For

approved in 1981. Last previous edition approved in 2015 as E799–03 (2015).

DOI: 10.1520/E0799-03R20E01.

spatial observations this requires a sufficient number of obser-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

vations.Aspatialsampleofoneflashphotographisusuallynot

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

The last approved version of this historical standard is referenced on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

www.astm.org. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

ϵ1

E799 − 03 (2020)

representative since the drop population distribution fluctuates where:

with time. 1000 such photographs exhibiting no correlation ¯ ¯

D = the overbar in D designates an averaging

withthefluctuationswouldmostprobablyberepresentative.A

process,

¯

temporal sample observed over a total of periods of time that

(p−q)p>q = the algebraic power of D ,

pq

is long compared to the time lapse between extreme fluctua- p and q = the integers 1, 2, 3 or 4,

D = the diameter of the ith drop, and

tions would most probably be representative.

i

p q

∑ = the summation of D or D , representing

i i i

3.1.4 spatial, adj—describes the observation or measure-

all drops in the sample.

mentofdropscontainedinavolumeofspaceduringsuchshort

0=p and q = values 0, 1, 2, 3, or 4.

intervals of time that the contents of the volume observed do

∑D is the total number of drops in the sample, and some

i i

not change during any single observation. Examples of spatial

of the more common representative diameters are:

samplingaresingleflashphotographyorlaserholography.Any

sum of such photographs would also constitute spatial sam-

¯

D = linear (arithmetic) mean diameter,

pling. A spatial set of data is proportional to concentration:

¯

D = surface area mean diameter,

number per unit volume. ¯

D = volume mean diameter,

¯

D = volume/surface mean diameter (Sauter), and

3.2 Symbols—Representative Diameters:

¯

D = meandiameterovervolume(DeBroukereorHerdan).

¯

3.2.1 (D ) is defined to be such that:

pq

See Table 1 for numerical examples.

p

D

(i i

3.2.2 D ,D ,D , and D are diameters such that the

¯ ~p2q!

Nf Lf Af Vf

D 5 (1)

pq

q

D

fraction, f, of the total number, length of diameters, surface

(i i

area,andvolumeofdrops,respectively,containpreciselyallof

the drops of smaller diameter. Some examples are:

D = number median diameter,

N0.5

D = length median diameter,

L0.5

This notation follows: Mugele, R.A., and Evans, H.D., “Droplet Size Distri-

bution in Sprays,” Industrial and Engineering Chemistry, Vol 43, No. 6, 1951, pp.

1317–1324.

TABLE 1 Sample Data Calculation Table

r A

Size Class Bounds No. of Sum of D in Each Size Class

i

Class Vol. % Cum. %

(Diameter Drops in

B

Width 2 3 4 in Class by Vol.

D D D D

in Micrometres) Class i i i i

3 6 9 12

240–360 120 65 19.5 × 10 5.9×10 1.8×10 1. × 10 0.005 0.005

360–450 90 119 48.2 19.6 8.0 3 0.021 0.026

450–562.5 112.5 232 117.4 59.7 30.5 16 0.081 0.107

562.5–703 140.5 410 259.4 164.8 105.2 67 0.280 0.387

703–878 175 629 497.2 394.7 314.5 252 0.837 1.224

878–1097 219 849 838.4 831.3 827.6 827 2.202 3.426

1097–1371 274 990 1221.7 1513.7 1883.2 2352 5.010 8.436

1371–1713 342 981 1512.7 2342.1 3641.1 5683 9.687 18.123

1713–2141 428 825 1589.8 3076.1 5976.2 11657 15.900 34.023

2141–2676 535 579 1394.5 3372.5 8189.2 19965 21.788 55.811

2676–3345 669 297 894.1 2702.8 8203.5 24999 21.826 77.637

3345–4181 836 111 417.7 1578.2 5987.6 22807 15.930 93.567

4181–5226 1045 21 98.8 466.5 2212.1 10532 5.885 99.453

5226–6532 1306 1 5.9 34.7 348.5 1534 0.547 100.000

r 3 6 9 12

Totals of D in ^κ = 6109 8915.3 × 10 16562.6 × 10 37729.0 × 10 100695 × 10

i

¯ ¯ ¯ ¯

entire sample D = 1300 D =1460 D =1860 D =2280 D =2670

N0.5 10 21 32 43

¯ ¯

D =1650 D =2060

20 31

¯

D = 1830

D = 2540 Worst case class width

V0.5

348.5 669

5 0.009 Relative Span 5 sD 2 D d/D 5 s3900 2 14200d/2530 5 0.98 3 0.21826 5 0.024

V0.9 V0.5 V0.5

37729 267613345

Less than 1 %, adequate sample size Adequate class sizes

A

The individual entries are the values for each κ as used in 5.2.1 (Eq 1) for summing by size class.

B 3 3

SUM D in size class divided by SUM D in entire sample.

i i

ϵ1

E799 − 03 (2020)

where:

D = surface area median diameter,

A0.5

D = volume median diameter, and

f = 1−1⁄e ≈ 0.6321, and

V0.5

D = drop diameter such that 90% of the total liquid

D = Rosin-Rammler Diameter fitting the Rosin-Rammler

V0.9

RR

volume is in drops of smaller diameter.

distribution factor (see Terminology E1296).

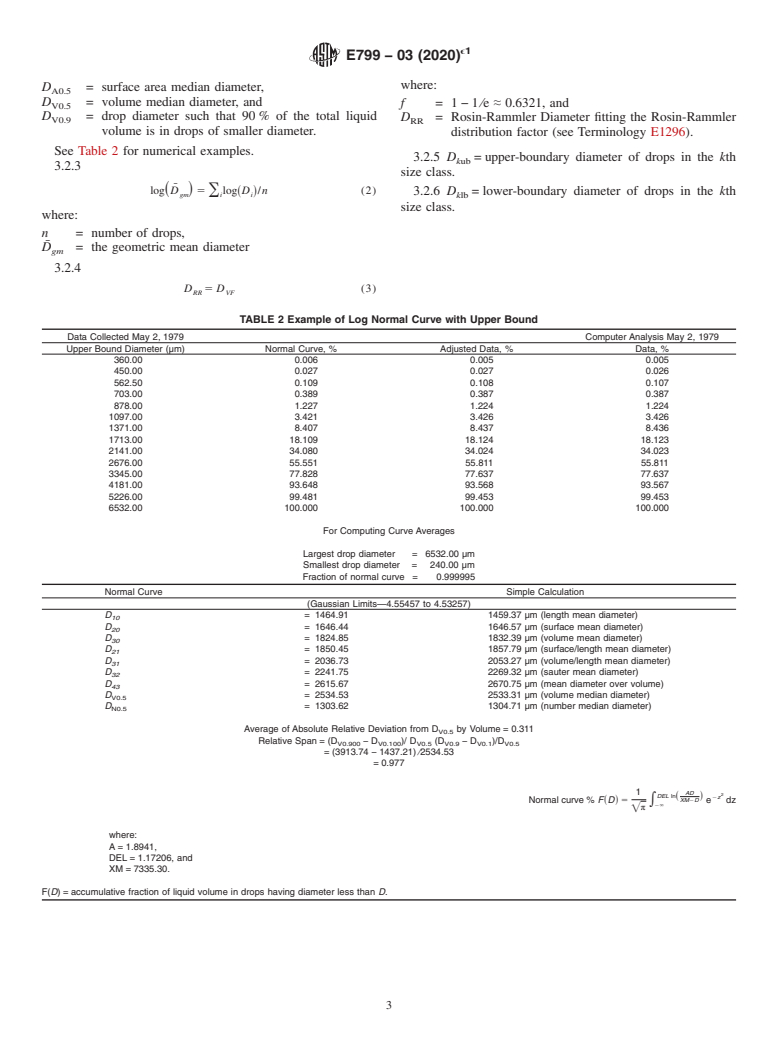

See Table 2 for numerical examples.

3.2.5 D =upper-boundary diameter of drops in the kth

kub

3.2.3

size class.

¯

log~D ! 5 log D /n (2)

~ ! 3.2.6 D =lower-boundary diameter of drops in the kth

gm (i i klb

size class.

where:

n = number of drops,

¯

D = the geometric mean diameter

gm

3.2.4

D 5 D (3)

RR VF

TABLE 2 Example of Log Normal Curve with Upper Bound

Data Collected May 2, 1979 Computer Analysis May 2, 1979

Upper Bound Diameter (µm) Normal Curve, % Adjusted Data, % Data, %

360.00 0.006 0.005 0.005

450.00 0.027 0.027 0.026

562.50 0.109 0.108 0.107

703.00 0.389 0.387 0.387

878.00 1.227 1.224 1.224

1097.00 3.421 3.426 3.426

1371.00 8.407 8.437 8.436

1713.00 18.109 18.124 18.123

2141.00 34.080 34.024 34.023

2676.00 55.551 55.811 55.811

3345.00 77.828 77.637 77.637

4181.00 93.648 93.568 93.567

5226.00 99.481 99.453 99.453

6532.00 100.000 100.000 100.000

For Computing Curve Averages

Largest drop diameter = 6532.00 µm

Small

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.