ASTM C1404/C1404M-98(2003)

(Test Method)Standard Test Method for Bond Strength of Adhesive Systems Used with Concrete as Measured by Direct Tension (Withdrawn 2010)

Standard Test Method for Bond Strength of Adhesive Systems Used with Concrete as Measured by Direct Tension (Withdrawn 2010)

SIGNIFICANCE AND USE

The bonding properties of adhesives are important for concrete repair applications. This test method provides a means to measure the adhesive characteristics of materials used to bond freshly mixed mortar to hardened concrete.

In addition to providing information on bond strength, the location of failure is determined visually and is thus instructive regarding the weakest element in the composite tested.

The bond strength that is measured is limited by the tensile strength of the base concrete and mortar. While an attempt has been made to choose materials that are strong enough to force a bond failure, there may be cases where failure occurs in concrete or mortar. In these situations, the actual bond strength exceeds the measured result.

SCOPE

1.1 This test method covers the laboratory determination of the bond strength of adhesive systems used to adhere freshly mixed mortar to hardened portland-cement concrete.

1.2 The values stated, in either SI units or other units shall be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore each system must be used independently of the other, without combining values in any way.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers the laboratory determination of the bond strength of adhesive systems used to adhere freshly mixed mortar to hardened portland-cement concrete.

Formerly under the jurisdiction of Committee C09 on Concrete and Concrete Aggregates, this test method was withdrawn without replacement in December 2010 because of limited use by the industry.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1404/C1404M–98 (Reapproved 2003)

Standard Test Method for

Bond Strength of Adhesive Systems Used With Concrete as

Measured by Direct Tension

This standard is issued under the fixed designation C1404/C1404M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C192/C192M Practice for Making and Curing Concrete

Test Specimens in the Laboratory

1.1 This test method covers the laboratory determination of

C305 Practice for Mechanical Mixing of Hydraulic Cement

the bond strength of adhesive systems used to adhere freshly

Pastes and Mortars of Plastic Consistency

mixed mortar to hardened portland-cement concrete.

C494/C494M Specification for Chemical Admixtures for

1.2 The values stated, in either SI units or other units shall

Concrete

be regarded separately as standard. The values stated in each

C881/C881M Specification for Epoxy-Resin-Base Bonding

system may not be exact equivalents; therefore each system

Systems for Concrete

must be used independently of the other, without combining

C670 Practice for Preparing Precision and Bias Statements

values in any way.

for Test Methods for Construction Materials

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3. Summary of Test Method

responsibility of the user of this standard to establish appro-

3.1 Each specimen consists of a base and overlay, bonded

priate safety and health practices and determine the applica-

together with the adhesive being tested. The base is half of a

bility of regulatory limitations prior to use.

3-in. [75-mm] by 6-in. [150-mm] hardened-concrete cylinder

2. Referenced Documents mounted inside of a steel-pipe nipple. The overlay consists of

freshly mixed mortar placed in a steel-pipe nipple positioned

2.1 ASTM Standards:

on top of the base.

A333/A333M Specification for Seamless and Welded Steel

3.2 The prepared surface of the base is coated with the

Pipe for Low-Temperature Service

adhesive, onto which freshly mixed mortar is applied. After

C33 Specification for Concrete Aggregates

curing, the assembly is pulled in tension to measure the bond

C39/C39M Test Method for Compressive Strength of Cy-

strength of the adhesive. The tensile strength is calculated, and

lindrical Concrete Specimens

the location of failure is determined visually.

C42/C42M Test Method for Obtaining and Testing Drilled

Cores and Sawed Beams of Concrete

4. Significance and Use

C109/C109M Test Method for Compressive Strength of

4.1 The bonding properties of adhesives are important for

Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube

concreterepairapplications.Thistestmethodprovidesameans

Specimens)

to measure the adhesive characteristics of materials used to

C150 Specification for Portland Cement

bond freshly mixed mortar to hardened concrete.

C171 Specification for Sheet Materials for Curing Concrete

4.2 In addition to providing information on bond strength,

the location of failure is determined visually and is thus

This test method is under the jurisdiction of ASTM Committee C09 on

instructive regarding the weakest element in the composite

ConcreteandConcreteAggregates,andisthedirectresponsibilityofSubcommittee

tested.

C09.25 on Organic Materials for Bonding.

4.3 The bond strength that is measured is limited by the

Current edition approved Sept. 10, 1998. Published April 1999. Originally

tensile strength of the base concrete and mortar. While an

approved in 1998. Last previous edition approved in 1998 as C1404/C1404M – 98.

DOI: 10.1520/C1404_C1404M-98R03.

attempt has been made to choose materials that are strong

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

enough to force a bond failure, there may be cases where

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

failure occurs in concrete or mortar. In these situations, the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. actual bond strength exceeds the measured result.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1404/C1404M–98 (2003)

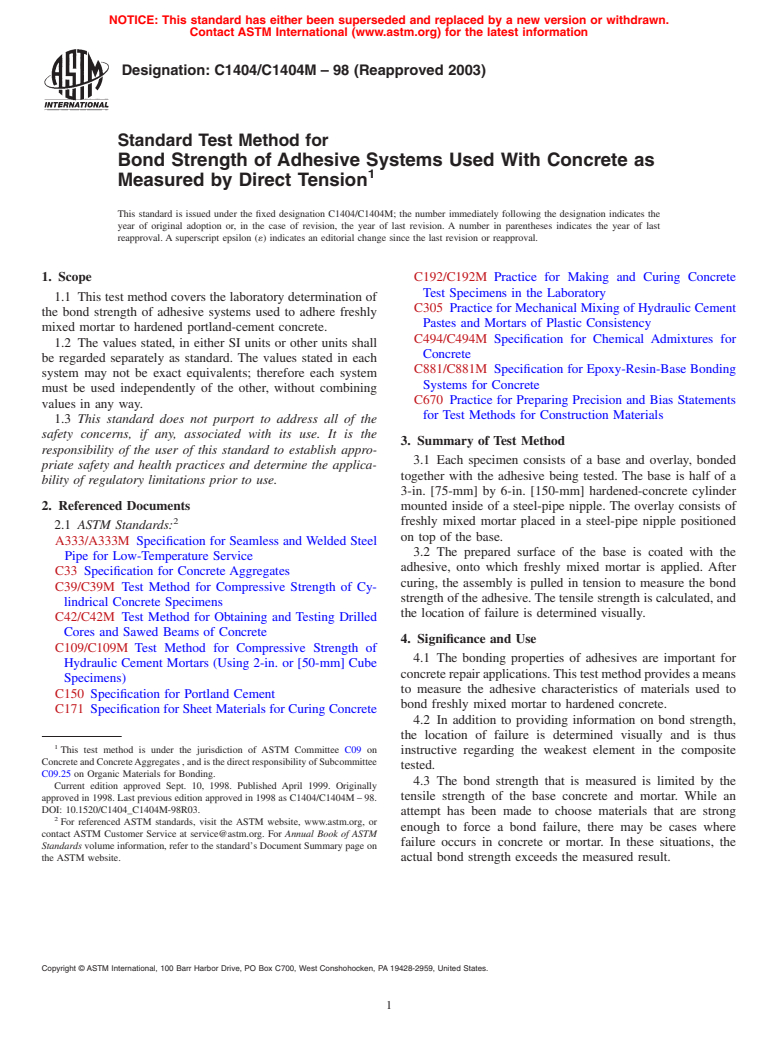

5. Apparatus machine. The assembly shall have a tensile capacity of at least

5000 lbf [22 kN]. See Fig. 1 for details of preparation.

5.1 Testing Machine—The testing machine shall be of the

5.4 Base Assembly—Concrete cylinder and steel pipe

hydraulic or screw-type and capable of measuring tensile loads

nipple,preparedaccordingtoSection7;oneforeachspecimen.

up to 5000 lbf [22 kN] in increments of 45 lbf [200 N] at rates

5.5 O-rings—Rubber, 2- ⁄8 in. [73 mm] inside diameter3

described in 9.3.

1 3

3- ⁄4in.[83mm]outsidediameter; ⁄16in.[5mm]thick;onefor

5.2 Steel-Pipe Nipples—The steel-pipe nipples shall con-

each specimen.

form to Specification A333/A333M, be nominally 3 in. [75

5.6 Concrete Mixer—As described in Practice C192/

mm] in diameter by 3 in. [75 mm] long Schedule 40, threaded;

C192M.

two per specimen. The inside surface of the steel-pipe nipples

5.7 Mixer, Bowl, and Paddle—A mechanical mortar mixer,

shall be clean and free of oil or other contaminants that could

as described in Practice C305.

inhibit bond. The inside surface shall be sandblasted to gray

5.8 Small Tools—Tools and items such as a straightedge,

metal condition.

5.3 Steel-Pipe Cap—Two steel-pipe caps nominally 3 in. scoops, rubber gloves, and metal mixing bowls.

5.9 Tamping Rod—The tamping rod shall be a round steel

[75 mm] in diameter, and threaded to fit the steel-pipe nipple

molds. Each cap shall be fitted with a steel rod or eye bolt with rod, ⁄8 in. [10 mm] in diameter, conforming to Practice

at least one universal joint for connection to the testing C192/C192M.

FIG. 1 Pipe Cap Detail

C1404/C1404M–98 (2003)

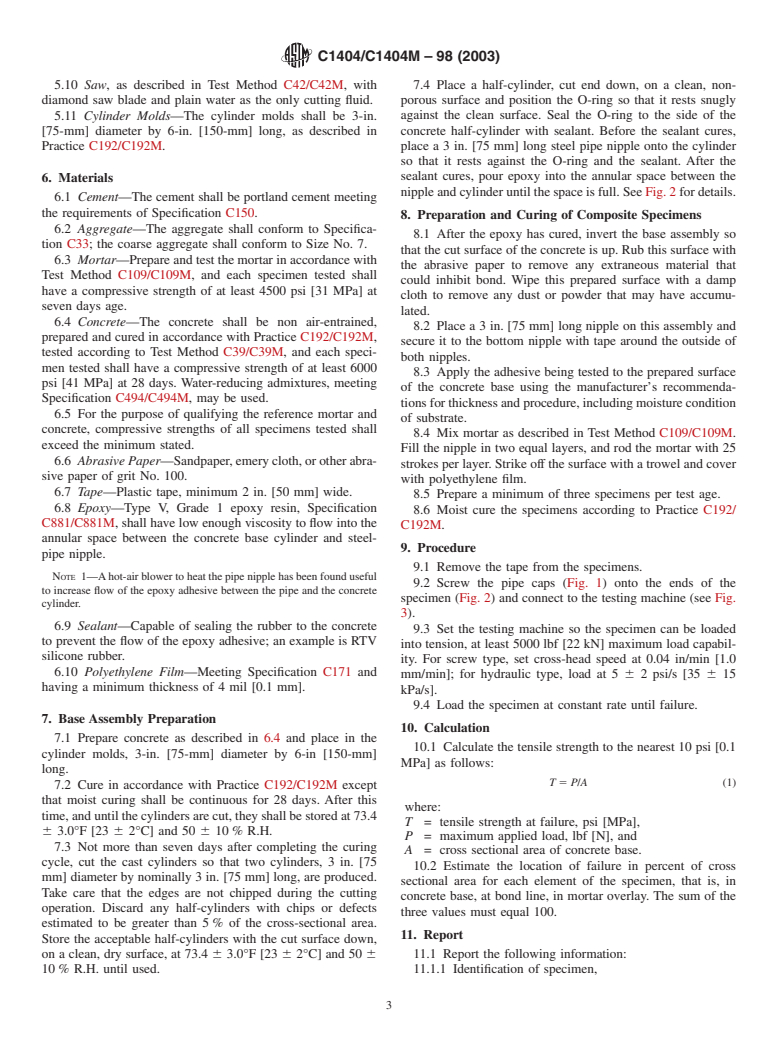

5.10 Saw, as described in Test Method C42/C42M, with 7.4 Place a half-cylinder, cut end down, on a clean, non-

diamond saw blade and plain water as the only cutting fluid. porous surface and position the O-ring so that it rests snugly

against the clean surface. Seal the O-ring to the side of the

5.11 Cylinder Molds—The cylinder molds shall be 3-in.

[75-mm] diameter by 6-in. [150-mm] long, as described in concrete half-cylinder with sealant. Before the sealant cures,

place a 3 in. [75 mm] long steel pipe nipple onto the cylinder

Practice C192/C192M.

so that it rests against the O-ring and the sealant. After the

sealant cures, pour epoxy into the annular space between the

6. Materials

nipple and cylinder until the space is full. See Fig. 2 for details.

6.1 Cement—The cement shall be portland cement meeting

the requirements of Specification C150.

8. Preparation and Curing of Composite Specimens

6.2 Aggregate—The aggregate shall conform to Specifica-

8.1 After the epoxy has cured, invert the base assembly so

tion C33; the coarse aggregate shall conform to Size No. 7.

that the cut surface of the concrete is up. Rub this surface with

6.3 Mortar—Prepare and test the mortar in accordance with

the abrasive paper to remove any extraneous ma

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.