ASTM E659-78(2005)

(Test Method)Standard Test Method for Autoignition Temperature of Liquid Chemicals

Standard Test Method for Autoignition Temperature of Liquid Chemicals

SIGNIFICANCE AND USE

Autoignition, by its very nature, is dependent on the chemical and physical properties of the material and the method and apparatus employed for its determination. The autoignition temperature by a given method does not necessarily represent the minimum temperature at which a given material will self-ignite in air. The volume of the vessel used is particularly important since lower autoignition temperatures will be achieved in larger vessels. (See Appendix X2.) Vessel material can also be an important factor.

The temperatures determined by this test method are those at which air oxidation leads to ignition. These temperatures can be expected to vary with the test pressure and oxygen concentration.

This test method is not designed for evaluating materials which are capable of exothermic decomposition. For such materials, ignition is dependent upon the thermal and kinetic properties of the decomposition, the mass of the sample, and the heat transfer characteristics of the system.

This test method can be employed for solid chemicals which melt and vaporize or which readily sublime at the test temperature. No condensed phase, liquid or solid, should be present when ignition occurs.

This test method is not designed to measure the autoignition temperature of materials which are solids or liquids at the test temperature (for example, wood, paper, cotton, plastics, and high-boiling point chemicals). Such materials will thermally degrade in the flask and the accumulated degradation products may ignite.

This test method was developed primarily for liquid chemicals but has been employed to test readily vaporized solids. Responsibility for extension of this method to solids of unknown thermal stability, boiling point, or degradation characteristics rests with the operator.

SCOPE

1.1 This test method covers the determination of hot- and cool-flame autoignition temperatures of a liquid chemical in air at atmospheric pressure in a uniformly heated vessel.

Note 1—Within certain limitations, this test method can also be used to determine the autoignition temperature of solid chemicals which readily melt and vaporize at temperatures below the test temperature.

1.2 This standard should be used to measure and describe the properties of materials, products, or assemblies in response to heat and flame under controlled laboratory conditions and should not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, results of this test may be used as elements of a fire risk assessment which takes into account all of the factors which are pertinent to an assessment of the fire hazard of a particular end use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E659 − 78 (Reapproved2005)

Standard Test Method for

Autoignition Temperature of Liquid Chemicals

This standard is issued under the fixed designation E659; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This test method is one of several methods developed by ASTM Committee E27 for determining

the hazards of chemicals. It is designed to be used in conjunction with other tests to characterize the

hazard potential of the chemical under test.

1. Scope made in total darkness because some flames, such as cool-

flames, are observed with difficulty.

1.1 This test method covers the determination of hot- and

cool-flameautoignitiontemperaturesofaliquidchemicalinair

3.2 autoignition, n—the ignition of a material commonly in

at atmospheric pressure in a uniformly heated vessel.

air as the result of heat liberation due to an exothermic

oxidation reaction in the absence of an external ignition source

NOTE1—Withincertainlimitations,thistestmethodcanalsobeusedto

such as a spark or flame.

determine the autoignition temperature of solid chemicals which readily

melt and vaporize at temperatures below the test temperature.

3.3 autoignition temperature, n—the minimum temperature

1.2 This standard should be used to measure and describe

at which autoignition occurs under the specified conditions of

the properties of materials, products, or assemblies in response

test.

to heat and flame under controlled laboratory conditions and

3.3.1 Autoignition temperature is also referred to as spon-

should not be used to describe or appraise the fire hazard or

taneous ignition temperature, self-ignition temperature, autog-

fire risk of materials, products, or assemblies under actual fire

enous ignition temperature, and by the acronymsAIT and SIT.

conditions. However, results of this test may be used as

Asdeterminedbythismethod,AITisthelowesttemperatureat

elements of a fire risk assessment which takes into account all

which the substance will produce hot-flame ignition in air at

of the factors which are pertinent to an assessment of the fire

atmospheric pressure without the aid of an external energy

hazard of a particular end use.

source such as spark or flame. It is the lowest temperature to

which a combustible mixture must be raised, so that the rate of

2. Referenced Documents

heat evolved by the exothermic oxidation reaction will over-

2.1 ASTM Standards:

balance the rate at which heat is lost to the surroundings and

D2883 Test Method for Reaction Threshold Temperature of

cause ignition.

Liquid and Solid Materials

3.4 cool-flame, n—a faint, pale blue luminescence or flame

occurring below the autoignition temperature (AIT).

3. Terminology

3.1 Definitions:

NOTE 2—Cool-flames occur in rich vapor-air mixtures of most hydro-

carbons and oxygenated hydrocarbons. They are the first part of the

3.1.1 ignition, n—the initiation of combustion.

multistage ignition process.

3.1.2 Ignition, which is subjective, is defined for this

method as the appearance of a flame accompanied by a sharp

3.5 ignition delay time, n—the time lapse between applica-

rise in the temperature of the gas mixture.The determination is tion of heat to a material and its ignition. It is the time in

seconds between insertion of the sample into the flask and

ignition. It is maximum at the minimum autoignition tempera-

This test method is under the jurisdiction ofASTM Committee E27 on Hazard

ture and also referred to as ignition lag.

Potential of Chemicals and is the direct responsibility of Subcommittee E27.04 on

Flammability and Ignitability of Chemicals.

Current edition approved Sept. 15, 2005. Published December 2005. Originally

4. Summary of Test Method

approved in 1978. Last previous edition approved in 2000 as E659 – 78 (2000).

DOI: 10.1520/E0659-78R05.

4.1 A small, metered sample of the product to be tested is

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

inserted into a uniformly heated 500-ml glass flask containing

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

air at a predetermined temperature. The contents of the flask

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. are observed in a dark room for 10 min following insertion of

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E659 − 78 (2005)

the sample, or until autoignition occurs. Autoignition is evi- unknown thermal stability, boiling point, or degradation char-

denced by the sudden appearance of a flame inside the flask acteristics rests with the operator.

and by a sharp rise in the temperature of the gas mixture. The

lowest internal flask temperature (T) at which hot-flame 6. Apparatus

ignition occurs for a series of prescribed sample volumes is

6.1 Furnace—An electrically heated crucible furnace or

taken to be the hot-flame autoignition temperature (AIT) of the

fluidized sand bath of appropriate internal geometry and

chemical in air at atmospheric pressure. Ignition delay times

dimensions to contain the test flask and which will maintain a

(ignition time lags) are measured in order to determine the

uniform temperature within the flask shall be used. A furnace

ignition delay-ignition temperature relationship.

with a cylindrically shaped interior, 5 in. (12.7 cm) in inside

4.2 The temperatures at which cool-flame ignitions are diameter, and 7 in. (17.8 cm) deep is minimal for this purpose.

observed or evidenced by small sharp rises of the gas mixture

It should be capable of attaining a temperature of 600°C or

temperature are also recorded along with the corresponding higher.

ignition delay times. The lowest flask temperature at which

6.2 Temperature Controller—Atemperature control system,

cool-flame ignition occurs is taken to be the cool-flame

capable of controlling the temperature in the furnace to

autoignition temperature (CFT). Similarly, observations are

within6 1°C at temperatures up to 350°C, and to within 62°C

made of any nonluminous preflame reactions, as evidenced by

above 350°C, is required. Temperatures are monitored at the

a relatively gradual temperature rise which then falls off to the

bottom, side, and neck of the flask by means of three external

base temperature. The lowest flask temperature at which these

thermocouples. Heating adjustments are made when necessary

reactions are observed is the reaction threshold temperature

in order to maintain uniform temperature within the flask. If a

(RTT).

controller is not available, temperature control may be

NOTE 3—The hot-flame autoignition, cool-flame autoignition, and achieved by the use of suitable autotransformers or rheostats,

reaction threshold temperatures obtained by this test method approximate

thermocouples, and a suitable potentiometer.

thosetemperaturesobtainedbyTestMethodD2883forhot-flamereaction,

6.3 Test Flask—The test flask shall be a commercial 500-ml

cool-flame reaction, and reaction threshold, respectively.

borosilicate round-bottom, short-necked boiling flask.

5. Significance and Use

6.3.1 The flask is closely wrapped in reflective metal foil,

5.1 Autoignition, by its very nature, is dependent on the

such as aluminum, to promote temperature uniformity, and is

chemical and physical properties of the material and the

suspended in the furnace so as to be completely enclosed with

method and apparatus employed for its determination. The

the top of the neck being inset below the top of the insulated

autoignition temperature by a given method does not necessar-

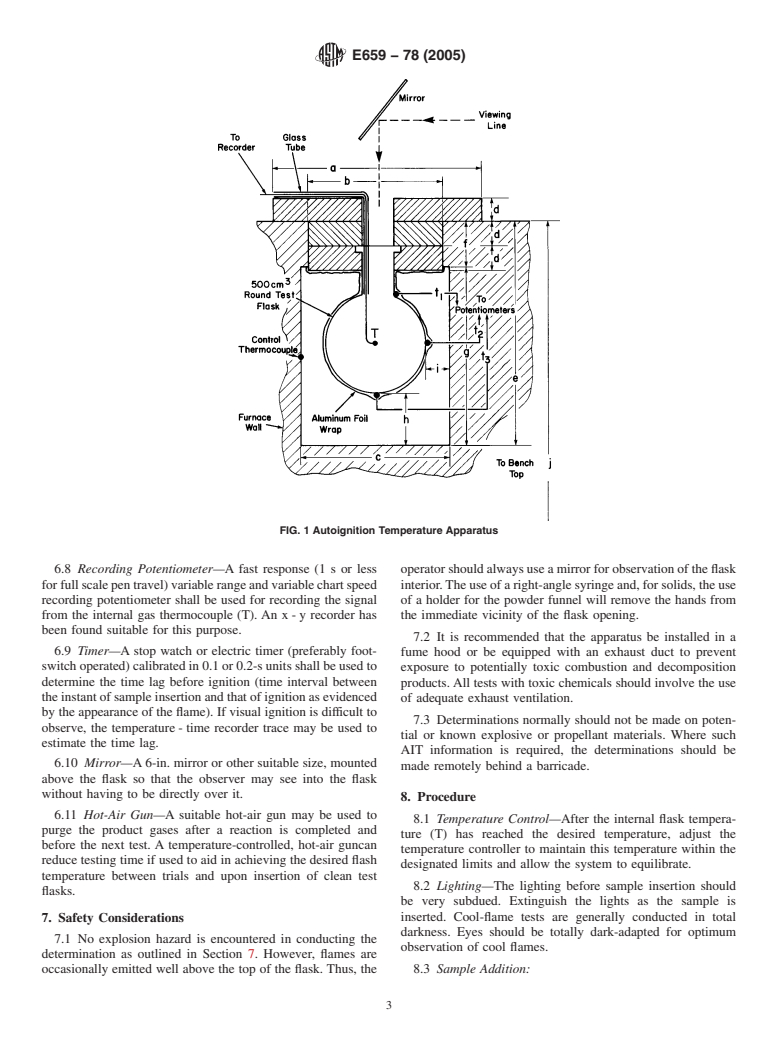

cover (see Fig. 1).

ily represent the minimum temperature at which a given

6.3.2 The flask is suspended in the furnace or sand bath by

material will self-ignite in air.The volume of the vessel used is

means of a thick insulating holder, the bottom of which is also

particularly important since lower autoignition temperatures

covered with reflective metal foil.

will be achieved in larger vessels. (See Appendix X2.) Vessel

6.4 Hypodermic Syringe—A 500 or 1000-µl hypodermic

material can also be an important factor.

syringe equipped with a 6-in., No. 26 or finer stainless steel

5.2 The temperatures determined by this test method are

needle, and calibrated in units of 10 µl should be used to inject

those at which air oxidation leads to ignition. These tempera-

liquid samples into the heated flask. It is suggested that a

tures can be expected to vary with the test pressure and oxygen

needle with a right-angle bend be used so that the operator’s

concentration.

fingers can be kept away from the flask opening.

5.3 Thistestmethodisnotdesignedforevaluatingmaterials

6.5 Balance—A laboratory balance capable of weighing to

which are capable of exothermic decomposition. For such

the nearest 10 mg shall be used for preparing samples that are

materials, ignition is dependent upon the thermal and kinetic

solid at room temperature. Sample weights will range from 10

properties of the decomposition, the mass of the sample, and

to 1000 mg.

the heat transfer characteristics of the system.

6.6 Powder Funnel—A 60-mm filling funnel is used to aid

5.4 This test method can be employed for solid chemicals

the insertion of solid samples into the flask. It is suggested that

which melt and vaporize or which readily sublime at the test

a holder such as a small buret clamp be used so that the

temperature. No condensed phase, liquid or solid, should be

operator’s fingers can be kept away from the flask opening.

present when ignition occurs.

6.7 Thermocouple—A fine Chromel-Alumel thermocouple

5.5 This test method is not designed to measure the autoi-

(36 B and S gage) is used for measuring the gas temperature

gnition temperature of materials which are solids or liquids at

(T) inside the flask. Position the tip of the thermocouple at the

thetesttemperature(forexample,wood,paper,cotton,plastics,

center of the flask.Thermocouples should be calibrated against

and high-boiling point chemicals). Such materials will ther-

standard temperatures or a standard thermocouple, and should

mally degrade in the flask and the accumulated degradation

be rechecked frequently. Iron-constantan thermocouples are to

products may ignite.

be avoided because they may promote catalytic oxidation on

5.6 This test method was developed primarily for liquid the iron-oxide surface. External flask temperatures are mea-

chemicals but has been employed to test readily vaporized sured with a No. 20 B and S gage or finer thermocouple

solids. Responsibility for extension of this method to solids of mountedatthetop(t ),middle(t ),andbottom(t )oftheflask.

1 2 3

E659 − 78 (2005)

FIG. 1 Autoignition Temperature Apparatus

6.8 Recording Potentiometer—A fast response (1 s or less operatorshouldalwaysuseamirrorforobservationoftheflask

forfullscalepentravel)variablerangeandvariablechartspeed interior.Theuseofaright-anglesyringeand,forsolids,theuse

recording potentiometer shall be used for recording the signal of a holder for the powder funnel will remove the hands from

from the internal gas thermocouple (T). An x - y recorder has the immediate vicinity of the flask opening.

been found suitable for this purpose.

7.2 It is recommended that the apparatus be installed in a

6.9 Timer—A stop watch or electric timer (preferably foot-

fume hood or be equipped with an exhaust duct to prevent

switchoperated)calibratedin0.1or0.2-sunitsshallbeusedto

exposure to potentially toxic combustion and decomposition

determine the time lag before ignition (time interval between

products.All tests with toxic chemicals should involve the use

theinstantofsampleinsertionandthatofignitionasevidenced

of adequate exhaust ventilation.

by the appearance of the flame). If visual ignition is difficult to

7.3 Determinations normally should not be made on poten-

observe, the temperature - time recorder trace may be used to

tial or known explosive or propellant materials. Where such

estimate the time lag.

AIT information is required, the determinations should be

6.10 Mirror—A6-in. mirror or other suitable size, mounted

made remotely behind a barricade.

above the flask so that the observer may see into the flask

without having to be directly over it.

8. Procedure

6.11 Hot-Air Gun—A suitable hot-air gun may be used to

8.1 Temperature Control—After the internal flask tempera-

purge the product gases after a reaction is completed and

ture (T) has reached the desired temperature, adjust the

before the next test. A temperature-controlled, hot-air guncan

temperature controller to maintain this temperature within the

reduce testing time if used to aid in achieving the desired flash

designated limits and allow the system to equilibrate.

temperature between trials and upon insertion of clean test

8.2 Lighting—The lighting before sample insertion should

flasks.

be very subdued. Extinguish the lights as the sample is

inserted. Cool-flame tests are generally conducted in total

7. Safety Considerations

darkness. Eyes should be totally dark-adapted for optimum

7.1 No explosion hazard is encountered in conducting the

observation of cool flames.

determination as outlined in Section 7. However, flames are

occasionally emitted well above the top of the flask. Thus, the 8.3 Sample Addition:

E659 − 78 (2005)

8.3.1 Liquids—Inject 100 µl of the sample to be tested into 8.5.4 Use a new flask for tests on each product. Should the

the flask with the hypodermic syringe and quickly withdraw flaskbecomevisiblycoatedwithresiduebeforethecompletion

of tests for a given product, conduct the final series of tests

the syringe. Extinguish the lights as the sample is injected.

with a new flask.

8.3.2 Solids—Inserta100-mgsamplebypouringitfromthe

8.6 Autoignition—Autoignition is usually evidenced in

weighingvesselthroughthepowderfunnelwhichisinsertedin

these tests by hot flames of various colors, usually yellow, red,

the neck of the flask. Quickly withdraw the powder funnel and

or blue, but sometimes by cool flames that appear as faint

extinguish the lights.

bluish glows which are visible only in total darkness. Nor-

8.4 Time Measurement—Start the timer as the sample is

mally,thehotflamesproducesharptemperaturerisesofatleast

inserted into the flask, and also mark this on the recorder trace.

a few hundred degrees or more, whereas, the cool flames are

In most cases, the recorder trace of the interior thermocouple

accompanied by rises of less than 100°C. Cool flames gener-

will indicate the time of sample injection as a cooling spike.

ally occur at lower

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.