ASTM D2719-89(2001)

(Test Method)Standard Test Methods for Structural Panels in Shear Through-the-Thickness

Standard Test Methods for Structural Panels in Shear Through-the-Thickness

SCOPE

1.1 These test methods determine the shear through-the-thickness properties of structural panels associated with shear distortion of the major axis. Structural panels in use include plywood, wafer board, oriented strand board, and composites of veneer and of wood based layers. Three test methods are included which differ somewhat in their application: Test MethodSectionA.Small Panel Shear Test5B.Large Panel Shear Test6C.Two Rail Shear Test7

The choice of test method will be determined in part by the purpose of the tests, characteristics of test material, and equipment availability. In general, Test Method B or C for large specimens is preferred when equipment, amount of test material, and experimental plan permit.

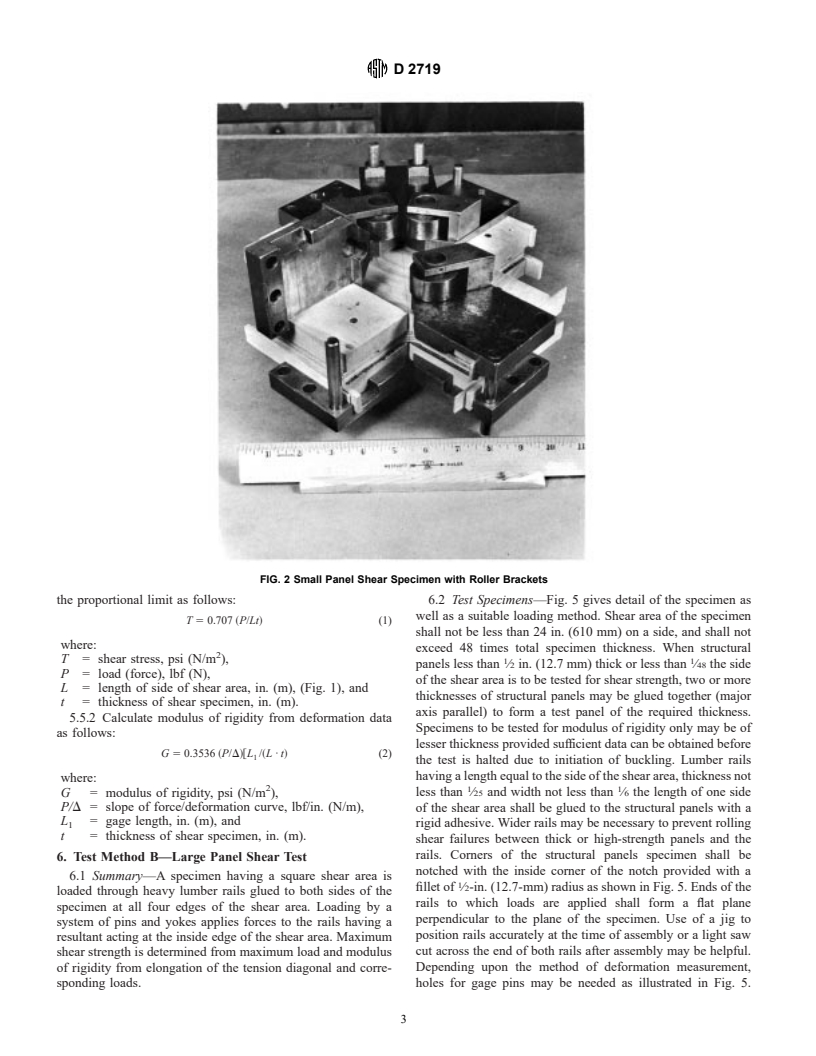

1.1.1 Test Method A: Small Panel Shear Test—This test method is suitable for testing small samples of uniform material including investigations of the effects of grain direction or orientation and of many raw materials and manufacturing process variables which influence shear properties uniformly throughout the specimen. The test method is unsuited for determining effects of grade and manufacturing features such as density variations, knots, and core gaps within the specimen.

1.1.2 Test Method B: Large Panel Shear Test—This test method is regarded as giving the most accurate modulus of rigidity and is therefore recommended for elastic tests of materials to be used in stress analysis studies of test structures. This test method also yields excellent shear strength values for clear material. However, in spite of the large size of the specimen, failures generally occur only in narrow zones at the perimeter of the test area. This characteristic, a result of the heavy perimeter framing, causes this test method to be generally unsuited for determining grade and manufacturing effects such as density variations, core gaps, and knots that are not uniformly distributed throughout the panel. Generally, only in cases where effects of these factors under conditions of heavy perimeter framing are desired, should the test method be applied.

1.1.3 Test Method C: Two-Rail Shear Test— This test method is applicable to a wide variety of materials and problems. The specimen fabrication and test procedures are somewhat simpler than in Test Methods A and B. The specimen is free to shear parallel to its 24-in.(610-mm) length dimension anywhere within the 8-in. (203-mm) width between rails. Thus, the test method is well suited for determining grade and manufacturing effects such as core gaps and knots occupying and affecting small areas. The test method is not so ideally suited for determination of modulus of rigidity, but when adjusted for strain distribution effects, values approximating those obtained by Test Method B result. The test method simulates effects of heavy framing when expected planes of weakness are oriented perpendicular to rails and no framing at all when parallel to rails.

1.2 Significant differences, moderate to small in magnitude, among the three test methods have been found to exist when these test methods are applied to plywood of clear straight-grained veneers. Therefore, when comparisons are made among test results, it is recommended that the same test method be used throughout.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 2719 – 89 (Reapproved 2001)

Standard Test Methods for

1

Structural Panels in Shear Through-the-Thickness

This standard is issued under the fixed designation D 2719; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope method is applicable to a wide variety of materials and

problems. The specimen fabrication and test procedures are

1.1 These test methods determine the shear through-the-

somewhat simpler than in Test Methods A and B. The specimen

thickness properties of structural panels associated with shear

is free to shear parallel to its 24-in.(610-mm) length dimension

distortion of the major axis. Structural panels in use include

anywhere within the 8-in. (203-mm) width between rails. Thus,

plywood, wafer board, oriented strand board, and composites

the test method is well suited for determining grade and

of veneer and of wood based layers. Three test methods are

manufacturing effects such as core gaps and knots occupying

included which differ somewhat in their application:

and affecting small areas. The test method is not so ideally

Test Method Section

suited for determination of modulus of rigidity, but when

A. Small Panel Shear Test 5

B. Large Panel Shear Test 6

adjusted for strain distribution effects, values approximating

C. Two Rail Shear Test 7

those obtained by Test Method B result. The test method

The choice of test method will be determined in part by the

simulates effects of heavy framing when expected planes of

purpose of the tests, characteristics of test material, and weakness are oriented perpendicular to rails and no framing at

equipment availability. In general, Test Method B or C for large

all when parallel to rails.

specimens is preferred when equipment, amount of test mate- 1.2 Significant differences, moderate to small in magnitude,

rial, and experimental plan permit.

among the three test methods have been found to exist when

1.1.1 Test Method A: Small Panel Shear Test—This test these test methods are applied to plywood of clear straight-

method is suitable for testing small samples of uniform

grained veneers. Therefore, when comparisons are made

material including investigations of the effects of grain direc- among test results, it is recommended that the same test

tion or orientation and of many raw materials and manufactur-

method be used throughout.

ing process variables which influence shear properties uni- 1.3 This standard does not purport to address all of the

formly throughout the specimen. The test method is unsuited

safety concerns, if any, associated with its use. It is the

for determining effects of grade and manufacturing features responsibility of the user of this standard to establish appro-

such as density variations, knots, and core gaps within the

priate safety and health practices and determine the applica-

specimen. bility of regulatory limitations prior to use.

1.1.2 Test Method B: Large Panel Shear Test—This test

2. Referenced Documents

method is regarded as giving the most accurate modulus of

rigidity and is therefore recommended for elastic tests of 2.1 ASTM Standards:

materials to be used in stress analysis studies of test structures.

D 2395 Test Methods for Specific Gravity of Wood and

2

This test method also yields excellent shear strength values for Wood-Base Materials

clear material. However, in spite of the large size of the D 4442 Test Methods for Direct Moisture Content Measure-

2

specimen, failures generally occur only in narrow zones at the ment of Wood and Wood–Base Materials

perimeter of the test area. This characteristic, a result of the

3. Significance and Use

heavy perimeter framing, causes this test method to be gener-

ally unsuited for determining grade and manufacturing effects 3.1 The strength and modulus of rigidity of structural panels

in shear through-the-thickness obtained by these test methods

such as density variations, core gaps, and knots that are not

uniformly distributed throughout the panel. Generally, only in are required for the rigorous design of many lumber-panel

structural components such as trusses with panel gussets, box

cases where effects of these factors under conditions of heavy

perimeter framing are desired, should the test method be beams, folded plate roofs, and space plane structures, as well as

floor and roof diaphragms, and shear walls. These properties

applied.

1.1.3 Test Method C: Two-Rail Shear Test—This test are of secondary importance in typical roof deck and sheathing

applications, and in crates and shipping containers.

3.2 Veneer produced by slicing or rotary peeling may

1

These

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.