ASTM C944/C944M-99(2005)e1

(Test Method)Standard Test Method for Abrasion Resistance of Concrete or Mortar Surfaces by the Rotating-Cutter Method

Standard Test Method for Abrasion Resistance of Concrete or Mortar Surfaces by the Rotating-Cutter Method

ABSTRACT

This test method covers the procedure for determining the abrasion resistance of either concrete or mortar surfaces using the rotating-cutter method. The method involves an abrasion device, a rotating cutter, a balance and a leveling plate. The surface description, size, and finish type of the specimen, as well as the concrete compaction, age, and strength; applied surface treatment; abrasion time; load used; depth of wear; mass loss; and abrasion time are reported. This test method has been successfully used in the quality control of highway and bridge concrete subject to traffic.

SIGNIFICANCE AND USE

This test method gives an indication of the relative wear resistance of mortar and concrete based on testing of cored or fabricated specimens. This test method has been successfully used in the quality control of highway and bridge concrete subject to traffic. Primarily intended for use on the top ends of 152-mm [6-in.] diameter concrete cores, mortar specimens, or other samples of concrete of insufficient test area to permit the conduct of tests by Test Method C 418 or C 779/C 779M, this test method is also applicable on concrete surfaces in place by measuring the abrasion loss as described in Section 9, Procedure B, of Test Method C 779/C 779M.

SCOPE

1.1 This test method covers a procedure for determining the resistance of either concrete or mortar to abrasion. This test method is similar to Procedure B of Test Method C 779/C 779M.

1.2 The values stated in SI units or inch–pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non–conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: C944/C944M − 99(Reapproved 2005)

Standard Test Method for

Abrasion Resistance of Concrete or Mortar Surfaces by the

Rotating-Cutter Method

This standard is issued under the fixed designation C944/C944M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—The designation was changed editorially to agree with the existing values statement in the Scope in March

2008.

1. Scope fabricated specimens. This test method has been successfully

used in the quality control of highway and bridge concrete

1.1 This test method covers a procedure for determining the

subject to traffic. Primarily intended for use on the top ends of

resistance of either concrete or mortar to abrasion. This test

152-mm [6-in.] diameter concrete cores, mortar specimens, or

method is similar to Procedure B of Test Method C779/

other samples of concrete of insufficient test area to permit the

C779M.

conduct of tests by Test Method C418 or C779/C779M, this

1.2 The values stated in SI units or inch–pound units are to

test method is also applicable on concrete surfaces in place by

be regarded separately as standard. The values stated in each

measuring the abrasion loss as described in Section 9, Proce-

system may not be exact equivalents; therefore, each system

dure B, of Test Method C779/C779M.

shall be used independently of the other. Combining values

from the two systems may result in non–conformance with the 4. Apparatus

standard.

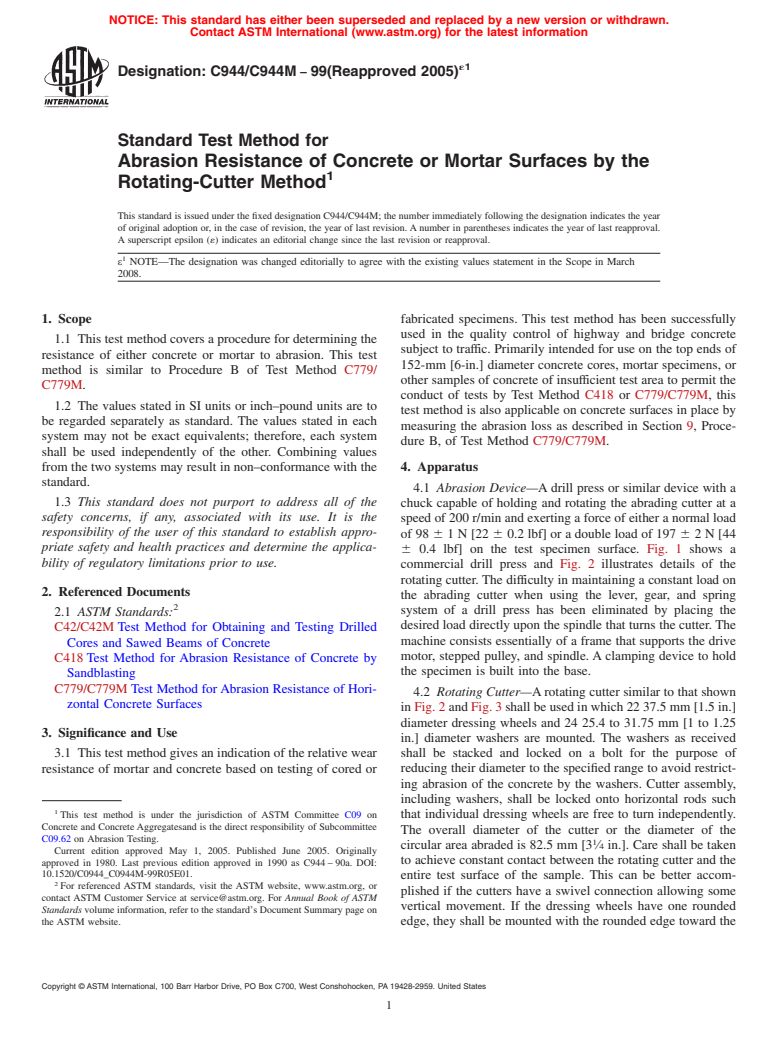

4.1 Abrasion Device—A drill press or similar device with a

1.3 This standard does not purport to address all of the

chuck capable of holding and rotating the abrading cutter at a

safety concerns, if any, associated with its use. It is the

speed of 200 r/min and exerting a force of either a normal load

responsibility of the user of this standard to establish appro-

of 98 6 1 N [22 6 0.2 lbf] or a double load of 197 6 2 N [44

priate safety and health practices and determine the applica-

6 0.4 lbf] on the test specimen surface. Fig. 1 shows a

bility of regulatory limitations prior to use.

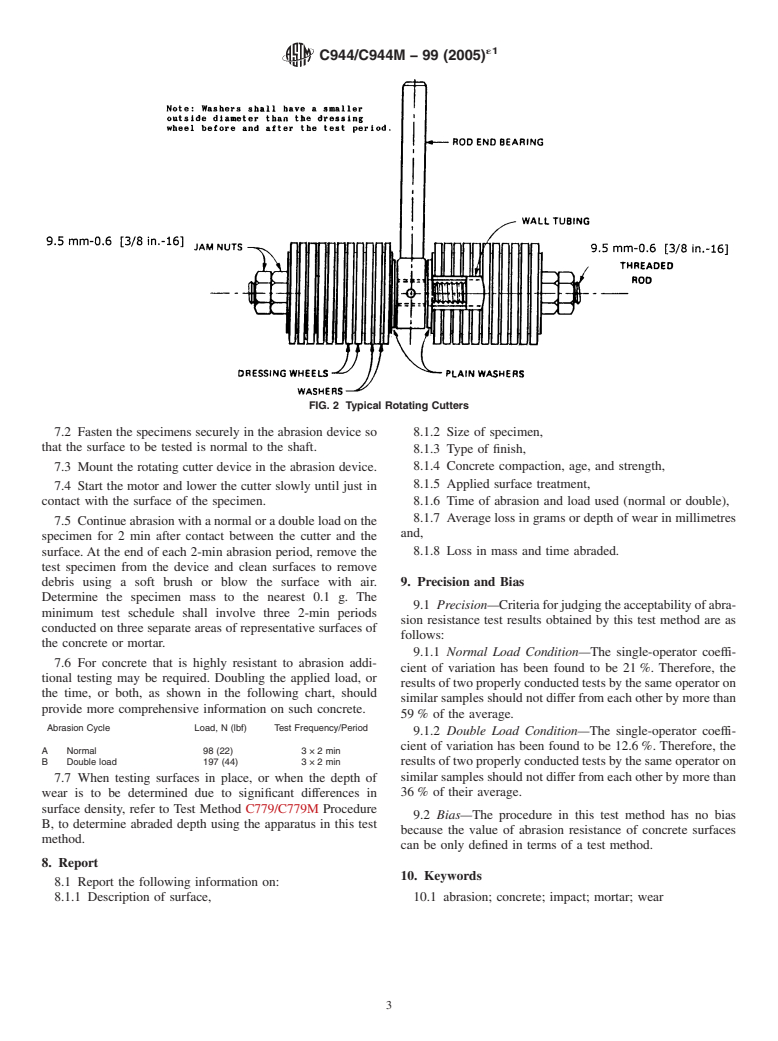

commercial drill press and Fig. 2 illustrates details of the

rotating cutter. The difficulty in maintaining a constant load on

2. Referenced Documents

the abrading cutter when using the lever, gear, and spring

system of a drill press has been eliminated by placing the

2.1 ASTM Standards:

desired load directly upon the spindle that turns the cutter. The

C42/C42M Test Method for Obtaining and Testing Drilled

machine consists essentially of a frame that supports the drive

Cores and Sawed Beams of Concrete

motor, stepped pulley, and spindle. A clamping device to hold

C418 Test Method for Abrasion Resistance of Concrete by

the specimen is built into the base.

Sandblasting

C779/C779M Test Method forAbrasion Resistance of Hori-

4.2 Rotating Cutter—Arotating cutter similar to that shown

zontal Concrete Surfaces

in Fig. 2 and Fig. 3 shall be used in which 22 37.5 mm [1.5 in.]

diameter dressing wheels and 24 25.4 to 31.75 mm [1 to 1.25

3. Significance and Use

in.] diameter washers are mounted. The washers as received

3.1 This test method gives an indication of the relative wear shall be stacked and locked on a bolt for the purpose of

reducing their diameter to the specified range to avoid restrict-

resistance of mortar and concrete based on testing of cored or

ing abrasion of the concrete by the washers. Cutter assembly,

including washers, shall be locked onto horizontal rods such

This test method is under the jurisdiction of ASTM Committee C09 on

that individual dressing wheels are free to turn independently.

Concrete and Concrete Aggregatesand is the direct responsibility of Subcommittee

The overall diameter of the cutter or the diameter of the

C09.62 on Abrasion Testing.

circular area abraded is 82.5 mm [3 ⁄4 in.]. Care shall be taken

Current edition approved May 1, 2005. Published June 2005. Originally

to achieve constant contact between the rotating cutter and the

approved in 1980. Last previous edition approved in 1990 as C944 – 90a. DOI:

10.1520/C0944_C0944M-99R05E01.

entire test surface of the sample. This can be better accom-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

plished if the cutters have a swivel connection allowing some

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

vertical movement. If the dressing wheels have one rounded

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. edge, they shall be mounted with the rounded edge toward the

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

C944/C944M − 99 (2005)

FIG. 1 Rotating-Cutter Drill Press

vertical shaft. The individual grinding wheel dressers on the that the specimens when placed thereon can be positioned to

horizontal shaft of the cutter shall be repositioned whenever a secure maximum contact with the rotating cutter throughout

change in the diameter of the outer cutters becomes apparent. the full test area.

This is accomplished by reversing each set of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.