ASTM B736-00(2006)

(Specification)Standard Specification for Aluminum, Aluminum Alloy and Aluminum-Clad Steel Cable Shielding Stock (Withdrawn 2015)

Standard Specification for Aluminum, Aluminum Alloy and Aluminum-Clad Steel Cable Shielding Stock (Withdrawn 2015)

ABSTRACT

This specification covers selected uncoated or coated aluminum, aluminum alloy, and aluminum clad steel cable shielding stocks used for electrostatic or electromagnetic shielding in insulated power, control, instrumentation, and communication cables including coaxial cables. Claddings may be bonded to the base metal by any method, provided it can produce a clad material that conforms to the requirements. Aluminum materials should be furnished in Temper 0 while aluminum clad steel materials should be in the annealed temper. When specified, cable shielding stock may be coated with a protective plastic coating on one or both sides.

SCOPE

1.1 This specification covers selected aluminum, aluminum-alloy and aluminum clad steel cable shielding stock, both uncoated and coated, for applications such as electrostatic or electromagnetic shielding for insulated power, control, instrumentation and communication cables (including coaxial cable). Note 1See B 694, Specification for Copper, Copper Alloy, and Copper-Clad Stainless Steel Sheet and Strip for Electrical Cable Shielding for related standards for copper-based shielding materials.

1.2 The materials covered are the following:Type of MaterialCoatingAluminum 1060noneAluminum 1100noneAluminum 1145noneAluminum 1235noneAlloy 3003noneAluminum 1060polyolefinAluminum 1100polyolefinAluminum 1145polyolefinAluminum 1235polyolefinAlloy 3003polyolefinAluminum 1060vinyl resinAluminum 1100vinyl resinAluminum 1145vinyl resinAluminum 1235vinyl resinAlloy 3003vinyl resinAluminum Clad SteelnoneAluminum Clad Steelpolyolefin Aluminum designations are in accordance with ANSI H35.1. The equivalent Unified Numbering System alloy designations are those shown preceded by A9, for example, A91100 for Aluminum 1100 in accordance with Practice E 527.

Cladding ratio must be specified (see 5.4).

1.3 For acceptance criteria for inclusion of new aluminum and aluminum alloys in this specification, see Annex A2.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

The following precautionary caveat pertains only to the test method portion, Section 12, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This specification covers selected aluminum, aluminum alloy, and aluminum clad steel cable shielding stock, both uncoated and coated, for applications such as electrostatic or electromagnetic shielding for insulated power, control, instrumentation and communication cables (including coaxial cable).

Formerly under the jurisdiction of Committee B07 on Light Metals and Alloys, this specification was withdrawn in January 2015 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B736 −00(Reapproved 2006)

Standard Specification for

Aluminum, Aluminum Alloy and Aluminum-Clad Steel Cable

Shielding Stock

This standard is issued under the fixed designation B736; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.4 The values stated in inch-pound units are to be regarded

as the standard. The values given in parentheses are for

1.1 Thisspecificationcoversselectedaluminum,aluminum-

information only.

alloy and aluminum clad steel cable shielding stock, both

1.5 The following precautionary caveat pertains only to the

uncoated and coated, for applications such as electrostatic or

test method portion, Section 12, of this specification. This

electromagnetic shielding for insulated power, control, instru-

standard does not purport to address all of the safety concerns,

mentationandcommunicationcables(includingcoaxialcable).

if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health

NOTE 1—See B694, Specification for Copper, Copper Alloy, and

Copper-Clad Stainless Steel Sheet and Strip for Electrical Cable Shielding

practices and determine the applicability of regulatory limita-

for related standards for copper-based shielding materials.

tions prior to use.

1.2 The materials covered are the following:

2. Referenced Documents

A

Type of Material Coating

2.1 The following documents of the issue in effect on date

Aluminum 1060 none

of material purchase form a part of this specification to the

Aluminum 1100 none

extent referenced herein:

Aluminum 1145 none

Aluminum 1235 none

2.2 ASTM Standards:

Alloy 3003 none

A568/A568M Specification for Steel, Sheet, Carbon,

Aluminum 1060 polyolefin

Structural,andHigh-Strength,Low-Alloy,Hot-Rolledand

Aluminum 1100 polyolefin

Cold-Rolled, General Requirements for

Aluminum 1145 polyolefin

B193 Test Method for Resistivity of Electrical Conductor

Aluminum 1235 polyolefin

Alloy 3003 polyolefin

Materials

B557 Test Methods for Tension Testing Wrought and Cast

Aluminum 1060 vinyl resin

Aluminum 1100 vinyl resin Aluminum- and Magnesium-Alloy Products

Aluminum 1145 vinyl resin

B694 Specification for Copper, Copper-Alloy, Copper-Clad

Aluminum 1235 vinyl resin

Bronze (CCB), Copper-Clad Stainless Steel (CCS), and

Alloy 3003 vinyl resin

Copper-Clad Alloy Steel (CAS) Sheet and Strip for

B

Aluminum Clad Steel none

Electrical Cable Shielding

B D903 Test Method for Peel or Stripping Strength of Adhe-

Aluminum Clad Steel polyolefin

sive Bonds

A

E29 Practice for Using Significant Digits in Test Data to

Aluminum designations are in accordance with ANSI H35.1. The equivalent

Unified Numbering System alloy designations are those shown preceded by A9,

Determine Conformance with Specifications

for example, A91100 for Aluminum 1100 in accordance with Practice E527.

E34 Test Methods for Chemical Analysis of Aluminum and

B

Cladding ratio must be specified (see 5.4).

Aluminum-Base Alloys

1.3 For acceptance criteria for inclusion of new aluminum

E55 Practice for Sampling Wrought Nonferrous Metals and

and aluminum alloys in this specification, see Annex A2.

Alloys for Determination of Chemical Composition

E227 Test Method for Optical Emission Spectrometric

Analysis of Aluminum and Aluminum Alloys by the

This specification is under the jurisdiction of ASTM Committee B07 on Light

Metals and Alloys and is the direct responsibility of Subcommittee B07.03 on

Aluminum Alloy Wrought Products. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2006. Published May 2006. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1984. Last previous edition approved in 2000 as B736–00. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/B0736-00R06. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B736−00 (2006)

Point-to-Plane Technique (Withdrawn 2002) 4.2.1 Whether the resistivity test is required for any item

E527 Practice for Numbering Metals and Alloys in the (Section 13),

Unified Numbering System (UNS)

4.2.2 Core requirements (core material, inner core diameter,

E607 Test Method for Atomic Emission Spectrometric

if required; see 17.2),

Analysis Aluminum Alloys by the Point to Plane Tech-

4.2.3 Coil dimension (outer coil diameter limitation, if

nique Nitrogen Atmosphere (Withdrawn 2011)

required; see 17.2),

E716 Practices for Sampling and Sample Preparation of

4.2.4 Weight of coils and packages (coil weights and pack-

Aluminum and Aluminum Alloys for Determination of

age size limitations, if required; see 17.3),

Chemical Composition by Spectrochemical Analysis

4.2.5 Certification, if required (see Section 18),

E1251 Test Method for Analysis of Aluminum and Alumi-

4.2.6 Special tests or exceptions, if any.

num Alloys by Spark Atomic Emission Spectrometry

2.3 American National Standards:

5. General Requirements, Materials and Manufacture

H35.1 Alloy and Temper Designation Systems for Wrought

Aluminum

5.1 The material and manufacturing methods used shall be

H35.2 Dimensional Tolerances forAluminum Mill Products

such that the resulting products will conform to the properties

B46.1 Surface Texture

and characteristics prescribed in this specification.

3. Terminology

5.2 Cladding may be bonded to the base metal by any

method that will produce a clad material that will conform to

3.1 Definitions:

this specification.

3.1.1 cable shielding stock—a rolled product, rectangular in

cross section and form, of nominal thickness 0.004 in. (0.10

5.3 For bare or coated aluminum, Aluminum 1100, 1145

mm) through 0.019 in. (0.48 mm) in coils (rolls) or traverse

and 1235 shall be understood to be interchangeable, unless

wound on reels or spools, with sheared or slit edges for

otherwise agreed upon between the producer and purchaser.

electrical cable shielding applications.

5.4 Unless otherwise stated (4.1.6), the cladding ratio shall

3.1.2 cladding ratio—ratio by percent thickness of the

be the standard ratio listed in Table 2 and shall be expressed as

aluminum/steel/aluminum component layers; for example, 20/

xx/xx/xx, aluminum/steel/aluminum.

60/20.

3.1.3 producer—the primary manufacturer of the material.

6. Responsibility for Quality Assurance

3.1.4 supplier—includes only the category of jobbers and

6.1 Responsibility for Inspection and Tests—Unless other-

distributors as distinct from producers.

wise specified in the contract or purchase order, the producer is

responsible for the performance of all inspection and test

4. Ordering Information

requirements specified herein. The producer may use his own

4.1 Orders for material to this specification shall include the

or any other suitable facilities for the performance of the

following information:

inspection and test requirements specified herein, unless dis-

4.1.1 This specification designation (which includes the

approvedbythepurchaserintheorderoratthetimeofcontract

number, the year, and the revision letter, if applicable),

signing. The purchaser shall have the right to perform any of

4.1.2 Quantity for each item, in pounds (kilograms),

the inspections and tests set forth in this specification where

4.1.3 Name of material (cable shielding),

such inspections are deemed necessary to assure that material

4.1.4 Type of material (bare aluminum, coated aluminum,

conforms to prescribed requirements.

aluminum clad steel, or coated aluminum clad steel) (see 1.2),

6.2 Lot Definition—An inspection lot shall consist of an

4.1.5 Aluminum designation, when appropriate (see 1.2 and

5.3), identifiable quantity of the same material, temper, and nominal

dimensions subjected to inspection at one time.

4.1.6 Cladding ratio, when appropriate (see 5.4),

4.1.7 Type of coating, class of coating and number of sides

to be coated (see 1.2, 11.1 and Table 1), 7. General Quality

4.1.8 Color of coated aluminum (see 11.3),

7.1 All cable shielding stock shall be commercially flat and

4.1.9 Temperwhennon-standardisrequired(seeSection9),

free of buckles; they shall be free of injurious surface defects

4.1.10 Dimensions (thickness and width),

and shall have an 80 µin. (2.0 µm) maximum roughness

4.1.11 How furnished: coils (rolls), traverse wound on reels

measurement (AA) per ANSI B46.1, unless otherwise agreed

or spools, etc.,

upon by the producer and purchaser. Unless otherwise

4.2 Additionally, orders for material to this specification

specified, discoloration due to proper annealing shall not be a

shall include the following information when required by the

cause for rejection.

purchaser:

7.2 Each ordered item shall be examined to determine

conformance to this specification with respect to general

The last approved version of this historical standard is referenced on

quality and package marking. On approval of the purchaser,

www.astm.org.

however, the producer may use a system of statistical quality

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036. control for such examinations.

B736−00 (2006)

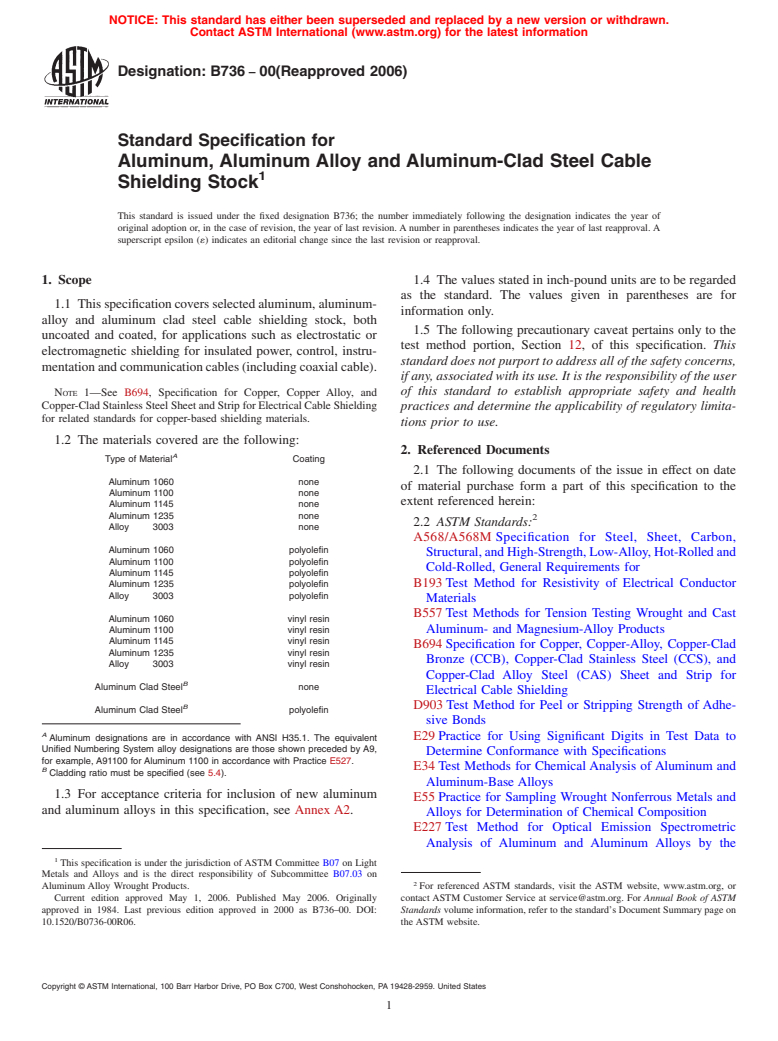

TABLE 1 Property Requirements for Coated Metals

Coating Performance Requirements, lbf/in. (N/m), min

Type Sides Bonding to Heat Sealability Moisture Resist-

Description Class Lap-Shear (12.4)

No. Coated Metal (12.2) (12.3) ance (12.5)

1 1.5 (260)

1 1.5 (260) 5.0 (875) The coated metal tape

I Polyolefin fails in tension

1 3.5 (610) 10.0 (1750) 3.5 (610)

2 before the bond

between coatings

II Vinyl Resin 1 N/A 5.0 (875) fails in shear. N/A

A,B

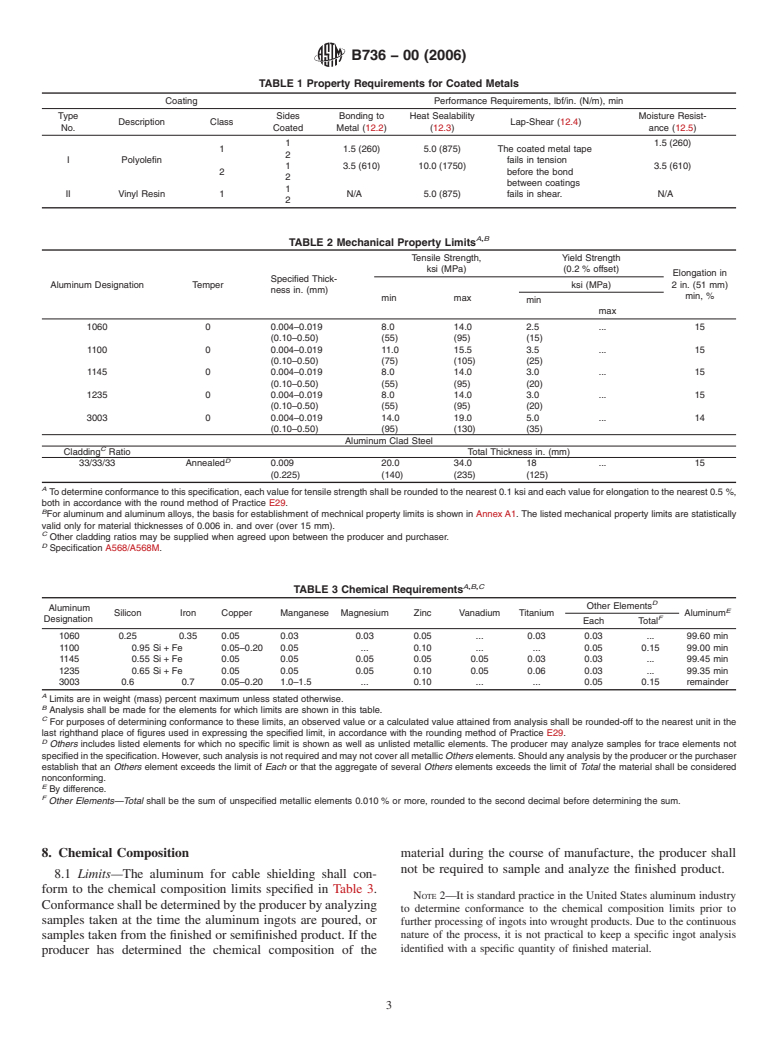

TABLE 2 Mechanical Property Limits

Tensile Strength, Yield Strength

ksi (MPa) (0.2 % offset)

Elongation in

Specified Thick-

Aluminum Designation Temper ksi (MPa) 2 in. (51 mm)

ness in. (mm)

min, %

min max

min

max

1060 0 0.004–0.019 8.0 14.0 2.5 . 15

(0.10–0.50) (55) (95) (15)

1100 0 0.004–0.019 11.0 15.5 3.5 . 15

(0.10–0.50) (75) (105) (25)

1145 0 0.004–0.019 8.0 14.0 3.0 . 15

(0.10–0.50) (55) (95) (20)

1235 0 0.004–0.019 8.0 14.0 3.0 . 15

(0.10–0.50) (55) (95) (20)

3003 0 0.004–0.019 14.0 19.0 5.0 . 14

(0.10–0.50) (95) (130) (35)

Aluminum Clad Steel

C

Cladding Ratio Total Thickness in. (mm)

D

33/33/33 Annealed 0.009 20.0 34.0 18 . 15

(0.225) (140) (235) (125)

A

Todetermineconformancetothisspecification,eachvaluefortensilestrengthshallberoundedtothenearest0.1ksiandeachvalueforelongationtothenearest0.5 %,

both in accordance with the round method of Practice E29.

B

For aluminum and aluminum alloys, the basis for establishment of mechnical property limits is shown in AnnexA1. The listed mechanical property limits are statistically

valid only for material thicknesses of 0.006 in. and over (over 15 mm).

C

Other cladding ratios may be supplied when agreed upon between the producer and purchaser.

D

Specification A568/A568M.

A,B,C

TABLE 3 Chemical Requirements

D

Other Elements

Aluminum

E

Silicon Iron Copper Manganese Magnesium Zinc Vanadium Titanium Aluminum

F

Designation

Each Total

1060 0.25 0.35 0.05 0.03 0.03 0.05 . 0.03 0.03 . 99.60 min

1100 0.95 Si + Fe 0.05–0.20 0.05 . 0.10 . . 0.05 0.15 99.00 min

1145 0.55 Si + Fe 0.05 0.05 0.05 0.05 0.05 0.03 0.03 . 99.45 min

1235 0.65 Si + Fe 0.05 0.05 0.05 0.10 0.05 0.06 0.03 . 99.35 min

3003 0.6 0.7 0.05–0.20 1.0–1.5 . 0.10 . . 0.05 0.15 remainder

A

Limits are in weight (mass) percent maximum unless stated otherwise.

B

Analysis shall be made for the elements for which limits are shown in this table.

C

For purposes of determining conformance to these limits, an observed value or a calculated value attained from analysis shall be rounded-off to the nearest unit in the

last righthand place of figures used in expressing the specified limit, in accordance with the rounding method of Practice E29.

D

Others includes listed elements for which no specific limit is shown as well as unlisted metallic elements. The producer may analyze samples for trace elements not

specifiedinthespecification.However,suchanalysisisnotrequiredandmaynotcoverallmetallic Otherselements.Shouldanyanalysisbytheproducerorthepurchaser

establish that an Others element exceeds the limit of Each or that the aggregate of several Others elements exceeds the limit of Total the material shall be considered

nonconforming.

E

By difference.

F

Other Elements—Total shall be the sum of unspecified metallic elements 0.010 % or more, rounded to the second decimal before determining the sum.

8. Chemical Composition material during the course of manufacture, the producer shall

not be required to sample and analyze the finished product.

8.1 Limits—The aluminum for cable shielding shall con-

form to the chemical composition limits specified in Table 3.

NOTE 2—It is standard practice in the United States aluminum industry

Conformanceshallbedeterminedbytheproducerbyanalyzing

to determine conformance to the chemical composition limits prior to

samples taken at the time the aluminum ingots are poured, or

further processing of ingots into wrought products. Due to the continuous

nature of the process, it is not practical to keep a specific ingot analysis

samples taken from the finished or semifinished product. If the

identified with a specific quantity of finished material.

producer has determined the chemical composition of the

B736−00 (2006)

8.2 Aluminum cladding shall be, unless otherwise specified, 10.3 Test Specimens—Geometry of test specimens and the

an aluminum conforming in chemical composition to Alumi- location in the product from which they are taken shall be as

num 1100, 1145 or 1235 (Table 3). These aluminums shall be specified in Test Methods B557.

understood to be interchangeable for cladding purposes, unless

10.4 Test Methods—The tension test shall be made in

otherwise agreed upon between the producer and purchaser.

accordance with Test Methods B557.

8.3 Number of Samples—The number of samples taken for

determination of chemical composition shall be as follows: 11. Coated Metals

8.3.1 When samples are taken at the time the aluminum

11.1 When ordered, the cable shielding stock may be coated

ingots are poured, at least one sample shall be taken for each

on one or both sides with a protective plastic coating of the

groupofingotspouredsimultaneouslyfromthesamesourceof

specified type and class, as agreed upon by the producer and

molten metal.

the purchaser.

8.3.2 When samples are taken from the finished or semifin-

11.1.1 Type I: Polyolefin Coating—The c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.