ASTM F1861-08(2012)

(Specification)Standard Specification for Resilient Wall Base

Standard Specification for Resilient Wall Base

ABSTRACT

This specification covers resilient wall base. These products are manufactured from rubber or thermoplastic materials, or a combination thereof. Wall base is used to provide a functional, as well as decorative border, between walls and floors. This specification does not include rigid products. Wall base shall be of the following types, as specified: type TS - rubber, vulcanized thermoset, type TP - rubber, thermoplastic, and type TV - vinyl, thermoplastic. Wall base shall be one of the following groups, as specified: group 1 - solid, and group 2 - layered. Wall base shall be of the following styles as specified: style A - straight, style B - cove, style C - butt-to, style D - sculptured. The wear layer thickness, flexibility, adjacent surface straining induced by wall base, light resistance, chemical resistance, dimensional stability, height, thickness, and length shall be tested to meet the requirements prescribed.

SCOPE

1.1 This specification covers resilient wall base. These products are manufactured from rubber or thermoplastic materials, or a combination thereof. Wall base is used to provide a functional, as well as decorative border, between walls and floors. This specification does not include rigid products.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following safety caveat pertains to the test methods portion, Section 12, of this specification: This standard does not purport to address all the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1861 −08(Reapproved 2012)

Standard Specification for

Resilient Wall Base

This standard is issued under the fixed designation F1861; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope F925 Test Method for Resistance to Chemicals of Resilient

Flooring

1.1 This specification covers resilient wall base. These

F1515 Test Method for Measuring Light Stability of Resil-

products are manufactured from rubber or thermoplastic

ient Flooring by Color Change

materials, or a combination thereof. Wall base is used to

2.3 Other Standards:

provide a functional, as well as decorative border, between

ANSI/ASQC Z1.4–2003 Sampling Procedures and Tables

walls and floors. This specification does not include rigid

for Inspection by Attributes

products.

1.2 The values stated in inch-pound units are to be regarded

3. Terminology

as the standard. The values given in parentheses are for

3.1 Definitions—For definitions of other terms used in this

information only.

standard, see Terminology F141.

1.3 The following safety caveat pertains to the test methods

portion, Section 12, of this specification: This standard does

4. Classification

not purport to address all the safety concerns, if any, associ-

4.1 Types—Wall base shall be of the following types, as

ated with its use. It is the responsibility of the user of this

specified (see 5.1.2, 6.1, and 7.1).

standard to establish appropriate safety and health practices

4.1.1 Type TS—rubber, vulcanized thermoset.

and determine the applicability of regulatory limitations prior

4.1.2 Type TP—rubber, thermoplastic.

to use.

4.1.3 Type TV—vinyl, thermoplastic.

2. Referenced Documents

4.2 Groups—Wallbaseshallbeoneofthefollowinggroups,

as specified (see 5.1.2, 6.2.1, and 6.2.2):

2.1 The following documents of the issue in effect on the

4.2.1 Group 1—solid (homogeneous).

dateofthematerialpurchaseformapartofthisspecificationto

4.2.2 Group 2—layered (multiple layers).

the extent referenced herein:

4.2.3 Either group may be specified with any of the types

2.2 ASTM Standards:

above. It is not necessary to specify group when either is

D883 Terminology Relating to Plastics

acceptable.

D1566 Terminology Relating to Rubber

4.3 Styles—Wall base shall be of the following styles as

D1755 Specification for Poly(Vinyl Chloride) Resins

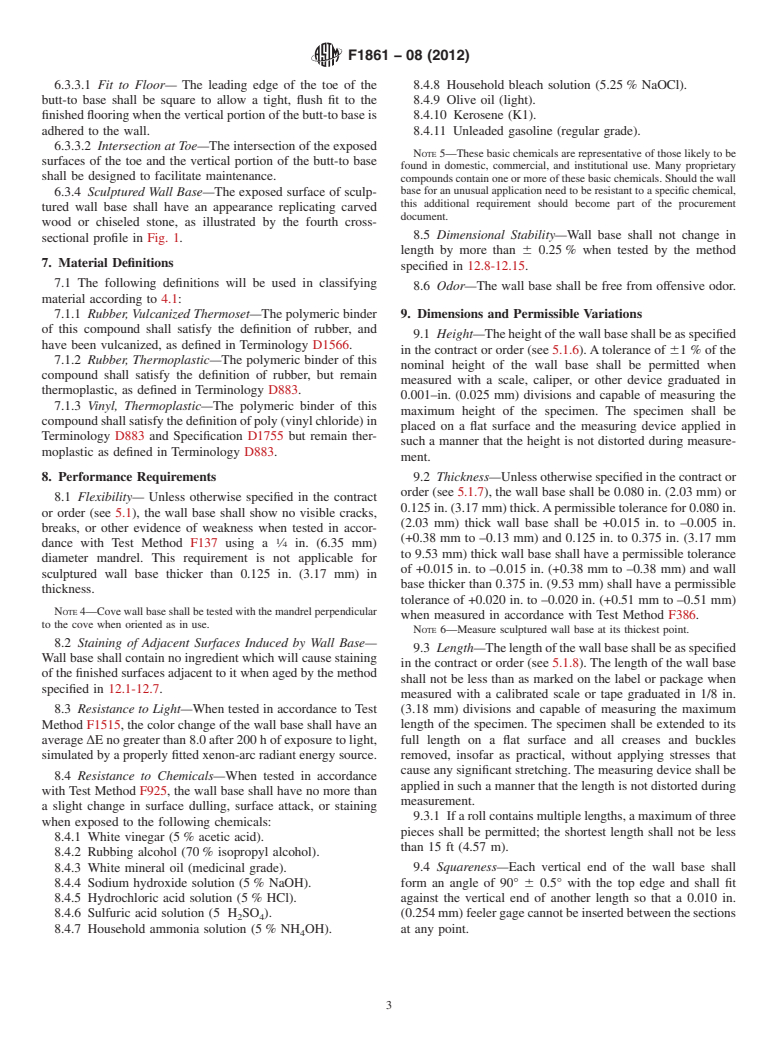

specified (see 5.1.2, 6.3, and Fig. 1):

F137 Test Method for Flexibility of Resilient Flooring Ma-

4.3.1 Style A—straight.

terials with Cylindrical Mandrel Apparatus

4.3.2 Style B—cove.

F141 Terminology Relating to Resilient Floor Coverings

4.3.3 Style C—butt-to.

F386 Test Method for Thickness of Resilient Flooring Ma-

4.3.4 Style D—sculptured.

terials Having Flat Surfaces

F410 Test Method for Wear Layer Thickness of Resilient

4.4 Corners—Where specified, both inside and outside 90°

Floor Coverings by Optical Measurement

factory-made corners should be specified by style. Corners

must meet the same height and thickness requirements as wall

base (see Section 9).

This specification is under the jurisdiction of ASTM Committee F06 on

Resilient Floor Coverings and is the direct responsibility of Subcommittee F06.80

NOTE 1—Factory-made corners and wall base may have visual color

on Specifications.

differences due to process and material variations. Consult the manufac-

Current edition approved Nov. 15, 2012. Published November 2012. Originally

turer to ensure color acceptability between factory-made corners and wall

approved in 1998. Last previous edition approved in 2008 as F1861–08. DOI:

base prior to ordering.

10.1520/F1861-08R12.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1861−08 (2012)

FIG. 1Typical Profiles of Wall Base

5. Ordering Information 6.2 Color—The color shall be as specified in the contract or

order (see 5.1.4).

5.1 Purchasers shall state whether this specification is to be

used, select the preferred options permitted herein, and include

NOTE 2—The colors and styles that are available are indicated in

the following information in the invitation to bid or purchase individual manufacturer’s current catalogs. As manufactured, colors may

vary somewhat in hue or shade from the catalog.

order:

NOTE 3—Where color match is a concern, obtain current samples from

5.1.1 Title, number, and date of this specification,

the manufacturer to verify color acceptability.

5.1.2 Type, group, and style, (see Sections 4, 6, and 7),

5.1.3 Factory-made corners, if required (see 4.4), 6.2.1 Solid Wall Base—The color shall be uniform through-

5.1.4 Color (see 6.2), out the entire thickness of the wall base.

5.1.5 Quantity: in pieces, linear feet, or cartons,

6.2.2 LayeredWallBase—Thesurfacecolorneednotextend

5.1.6 Height required (see 9.1),

through the entire thickness of the wall base, but must extend

5.1.7 Thickness required (see 9.2),

throughout the entire wear layer. Layered wall base shall have

5.1.8 Length required (see 9.3, 9.3.1, and Section 15),

a minimum wear layer thickness of 0.002 in. (0.05 mm) when

5.1.9 Lot information, if other than as specified in ANSI/

measured in accordance with Test Method F410 and shall not

ASQC Z1.4–2003, (see 11.1 and 13.1),

delaminate under normal use.

5.1.10 Sampling, if other than as specified in ANSI/ASQC

6.3 Styles—The style shall be as specified in the contract or

Z1.4–2003, (see 11.1),

order (see 5.1.2).

5.1.11 Statement requesting certification, if certification of

6.3.1 Straight Wall Base—The exposed surface of straight

compliance is required (see Section 14),

(toeless) wall base is vertical, as illustrated by the first

5.1.12 Packing requirements, if other than as specified (see

cross-sectional profile in Fig. 1.

Section 16),

6.3.2 Cove Wall Base— The exposed surface of cove wall

5.1.13 Palletization, if required,

base shall be distinguished by a “toe” at its bottom edge as

5.1.14 Marking required, if other than specified (see Section

illustrated by the second cross-sectional profile in Fig. 1.

15), and

5.1.15 Other requirements. 6.3.2.1 Fit to Floor— The toe shall be curved, or angled, or

both, to allow it to fit snugly against the floor when the vertical

6. Materials and Manufacture

portion of the cove base is adhered to the wall.

6.3.2.2 Intersection at Toe—The intersection of the exposed

6.1 Materials—Any polymeric material or combination of

surfaces of the toe and the vertical portion of the cove base

polymeric materials is acceptable if, in combination with

shall be rounded and smooth to facilitate maintenance.

processing chemicals, fillers, and colorants, the material can be

formed into wall base, which satisfies all the requirements of 6.3.3 Butt-to Wall Base—The exposed surface of butt-to

this specification (see 5.1 and 7.1). Other suitable recycled wall base shall be distinguished by a “toe,” which butts against

polymeric material may be incorporated as a part of the total the flooring as illustrated by the third cross-sectional profile in

polymeric content. Fig. 1.

F1861−08 (2012)

6.3.3.1 Fit to Floor— The leading edge of the toe of the 8.4.8 Household bleach solution (5.25 % NaOCl).

butt-to base shall be square to allow a tight, flush fit to the 8.4.9 Olive oil (light).

finished flooring when the vertical portion of the butt-to base is 8.4.10 Kerosene (K1).

adhered to the wall. 8.4.11 Unleaded gasoline (regular grade).

6.3.3.2 Intersection at Toe—The intersection of the exposed

NOTE 5—These basic chemicals are representative of those likely to be

surfaces of the toe and the vertical portion of the butt-to base

found in domestic, commercial, and institutional use. Many proprietary

shall be designed to facilitate maintenance.

compounds contain one or more of these basic chemicals. Should the wall

base for an unusual application need to be resistant to a specific chemical,

6.3.4 Sculptured Wall Base—The exposed surface of sculp-

this additional requirement should become part of the procurement

tured wall base shall have an appearance replicating carved

document.

wood or chiseled stone, as illustrated by the fourth cross-

8.5 Dimensional Stability—Wall base shall not change in

sectional profile in Fig. 1.

length by more than 6 0.25 % when tested by the method

7. Material Definitions

specified in 12.8-12.15.

7.1 The following definitions will be used in classifying

8.6 Odor—The wall base shall be free from offensive odor.

material according to 4.1:

7.1.1 Rubber, Vulcanized Thermoset—The polymeric binder 9. Dimensions and Permissible Variations

of this compound shall satisfy the definition of rubber, and

9.1 Height—Theheightofthewallbaseshallbeasspecified

have been vulcanized, as defined in Terminology D1566.

in the contract or order (see 5.1.6).Atolerance of 61%ofthe

7.1.2 Rubber, Thermoplastic—The polymeric binder of this

nominal height of the wall base shall be permitted when

compound shall satisfy the definition of rubber, but remain

measured with a scale, caliper, or other device graduated in

thermoplastic, as defined in Terminology D883.

0.001–in. (0.025 mm) divisions and capable of measuring the

7.1.3 Vinyl, Thermoplastic—The polymeric binder of this

maximum height of the specimen. The specimen shall be

compoundshallsatisfythedefinitionofpoly(vinylchloride)in

placed on a flat surface and the measuring device applied in

Terminology D883 and Specification D1755 but remain ther-

such a manner that the height is not distorted during measure-

moplastic as defined in Terminology D883.

ment.

8. Performance Requirements

9.2 Thickness—Unless otherwise specified in the contract or

order (see 5.1.7), the wall base shall be 0.080 in. (2.03 mm) or

8.1 Flexibility— Unless otherwise specified in the contract

0.125in.(3.17mm)thick.Apermissibletolerancefor0.080in.

or order (see 5.1), the wall base shall show no visible cracks,

(2.03 mm) thick wall base shall be +0.015 in. to –0.005 in.

breaks, or other evidence of weakness when tested in accor-

(+0.38 mm to –0.13 mm) and 0.125 in. to 0.375 in. (3.17 mm

dance with Test Method F137 using a ⁄4 in. (6.35 mm)

to 9.53 mm) thick wall base shall have a permissible tolerance

diameter mandrel. This requirement is not applicable for

of +0.015 in. to –0.015 in. (+0.38 mm to –0.38 mm) and wall

sculptured wall base thicker than 0.125 in. (3.17 mm) in

base thicker than 0.375 in. (9.53 mm) shall have a permissible

thickness.

tolerance of +0.020 in. to –0.020 in. (+0.51 mm to –0.51 mm)

NOTE 4—Cove wall base shall be tested with the mandrel perpendicular

when measured in accordance with Test Method F386.

to the cove when oriented as in use.

NOTE 6—Measure sculptured wall base at its thickest point.

8.2 Staining of Adjacent Surfaces Induced by Wall Base—

9.3 Length—Thelengthofthewallbaseshallbeasspecified

Wall base shall contain no ingredient which will cause staining

in the contract or order (see 5.1.8). The length of the wall base

of the finished surfaces adjacent to it when aged by the method

shall not be less than as marked on the label or package when

specified in 12.1-12.7.

measured with a calibrated scale or tape graduated in 1/8 in.

8.3 Resistance to Light—When tested in accordance to Test (3.18 mm) divisions and capable of measuring the maximum

length of the specimen. The specimen shall be extended to its

Method F1515, the color change of the wall base shall have an

average∆E no greater than 8.0 after 200 h of exposure to light, full length on a flat surface and all creases and buckles

removed, insofar as practical, without applying stresses that

simulated by a properly fitted xenon-arc radiant energy source.

cause any significant stretching.The measuring device shall be

8.4 Resistance to Chemicals—When tested in accordance

applied in such a manner that the length is not distorted during

with Test Method F925, the wall base shall have no more than

measurement.

a slight change in surface dulling, surface attack, or staining

9.3.1 Ifarollcontainsmultiplelengths,amaximumofthree

when exposed to the following chemicals:

pieces shall be permitted; the shortest length shall not be less

8.4.1 White vinegar (5 % acetic acid).

than 15 ft (4.57 m).

8.4.2 Rubbing alcohol (70 % isopropyl alcohol).

8.4.3 White mineral oil (medicinal grade). 9.4 Squareness—Each vertical end of the wall base shall

8.4.4 Sodium hydroxide solution (5 % NaOH). form an angle of 90° 6 0.5° with the top edge and shall fit

8.4.5 Hydrochloric acid solution (5 % HCl). against the vertical end of another length so that a 0.010 in.

8.4.6 Sulfuric acid solution (5 H SO ). (0.254mm)feelergagecannotbeinsertedbetweenthesections

2 4

8.4.7 Household ammonia solution (5 % NH OH). at any point.

F1861−08 (2012)

10. Workmanship, Finish, and Appearance 11.2 Sampling for testing physical characteristics listed in

Table I ofANSI/ASQC Z1.4–2003 shall be agreed upon by the

10.1 The wall base furnished in accordance with this speci-

purchaser and manufacturer as part of the procurement docu-

fication shall be free of defects, which adversely affect perfor-

ment.

mance or appearance. Such defects include blemishes, spots,

lines, indentations, blisters, and delamination.

12. Test Methods

10.2 Unless otherwise specified in the contract or order (see

5.1), the back or bonding surface of the wall base shall be

Wall Base—Staining of Adjacent Surfaces Induced by

buffed, roughened, ribbed, grooved, or otherwise modified to Wall Base

improvetheapplicationtoandadhesiontothewallsurface,but

12.1 Scope—This test method describes a technique for

in no case shall the thickness of the wall base be decreased to

producing a stain or discoloration that wall base may cause

theextentthatanydepressionorgrooveonthebondingsurface

when in contact with a light-colored surface, when exposed to

be perceptible, under any circumstances, on the exposed

elevated temperature aging under controlled conditions.

surface.

12.2 Significance and Use—Wall base often is required to

11. Sampling for Test be in contact with light-colored surfaces. In such applications,

the discoloration or stain of the light-colored surfaces is

11.1 Sampling for testing physical characteristics listed in

objectionable.Thistestmethodprovidesawaytoeva

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.