ASTM F901-97

(Specification)Standard Specification for Aluminum Transmission Tower Bolts and Nuts

Standard Specification for Aluminum Transmission Tower Bolts and Nuts

SCOPE

1.1 This specification covers aluminum structural bolts and nuts for use in the construction of aluminum transmission towers, substations, and similar aluminum structures.

1.2 Diameters of bolts and nuts furnished to this specification are 5/8, 3/4, and 7/8 in.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 901 – 97

Standard Specification for

1

Aluminum Transmission Tower Bolts and Nuts

This standard is issued under the fixed designation F 901; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope B1.1 Unified Inch Screw Threads (UN and UNR Thread

Form)

1.1 This specification covers aluminum structural bolts and

B18.2.1 Square and Hex Bolts and Screws, Including Hex

nuts for use in the construction of aluminum transmission

Cap Screws and Lag Screws

towers, substations, and similar aluminum structures.

B18.2.2 Square and Hex Nuts

1.2 Diameters of bolts and nuts furnished to this specifica-

5 3 7 2.3 Military Standard:

tion are ⁄8, ⁄4, and ⁄8in.

MIL-STD-A-8625 Anodic Coatings for Aluminum and Alu-

1.3 The values stated in inch-pound units are to be regarded

9

minum Alloys

as the standard. The values given in parentheses are for

information only.

3. Ordering Information

2. Referenced Documents 3.1 Orders for bolts and nuts under this specification shall

include the following:

2.1 ASTM Standards:

3.1.1 Quantity (number of pieces of each item and size),

B 565 Test Method for Shear Testing of Aluminum and

3.1.2 Name of item,

Aluminum-Alloy Rivets and Cold-Heading Wire and

2 3.1.3 Size (diameter, threads per inch, length),

Rods

3

3.1.4 Alloy number,

D 3951 Practice for Commerical Packaging

3.1.5 Shipment lot testing, as required (see Supplementary

E 29 Practice for Using Significant Digits in Test Data to

4

Requirements S1),

Determine Conformance with Specifications

3.1.6 Source inspection, if required (see Section 14),

E 34 Test Methods for Chemical Analysis of Aluminum and

5

3.1.7 Certificate of compliance or test report, if required

Aluminum Base Alloys

(see Section 16),

E 55 Practice for Sampling Wrought Nonferrous Metals and

5

3.1.8 Additional requirements, if any, to be specified on the

Alloys for Determination of Chemical Composition

purchase order (see 4.2.1, 4.2.3, 8.2.1, 8.2.2, 9.2, 12.1, and

E 101 Test Method for Spectrographic Analysis of Alumi-

13.1),

num and Aluminum Alloys by the Point-to-Plane Tech-

6

3.1.9 Supplementary requirements, if any, and

nique

3.1.10 ASTM specification and year of issue.

E 227 Test Method for Optical Emission Spectrometric

Analysis of Aluminum and Aluminum Alloys by the

NOTE 1—Example: 10 000 pieces Aluminum Transmission Tower Bolt,

6

Point-to-Plane Technique 0.750-10 by 2.00 in., Alloy 2024-T4, Furnish Certificate of Compliance,

Supplementary Requirement S2, ASTM F 901–XX.

F 606 Test Methods for Determining the Mechanical Prop-

erties of Externally and Internally Threaded Fasteners,

4. Materials and Manufacture

7

Washers, and Rivets

4.1 Materials—Bolts shall be manufactured from Alloy

F 1470 Guide for Fastener Sampling for Specified Me-

7

2024 and nuts from Alloy 6061 or 6262. The materials

chanical Properties and Performance Inspection

8

chemical composition shall be capable of developing the

2.2 ANSI Standards:

mechanical properties required by Table 1, when in the finished

condition.

1

This specification is under the jurisdiction of ASTM Committee F-16 on

4.2 Manufacture:

Fasteners and is the direct responsibility of Subcommittee F16.04 on Nonferrous

4.2.1 Forming—Unless otherwise specified, the bolts and

Fasteners.

Current edition approved July 10, 1997. Published September 1997. Originally

nuts shall be cold formed, hot formed, or machined from

published as F 901 – 84. Last previous edition F 901 – 90a.

suitable material at the option of the manufacturer.

2

Annual Book of ASTM Standards, Vol 02.02.

3

4.2.2 Condition—The fasteners shall be furnished in the

Annual Book of ASTM Standards, Vol 15.09.

4

Annual Book of ASTM Standards, Vol 14.02. following conditions:

5

Annual Book of ASTM Standards, Vol 03.05.

6

Annual Book of ASTM Standards, Vol 03.06.

7

Annual Book of ASTM Standards, Vol 01.08.

8 9

Available from American National Standards Institute, 11 West 42nd St., 13th Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Floor, New York, NY 10036. Robbins Ave., Philadelphia, PA 19111-5094 Attn: NPODS.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

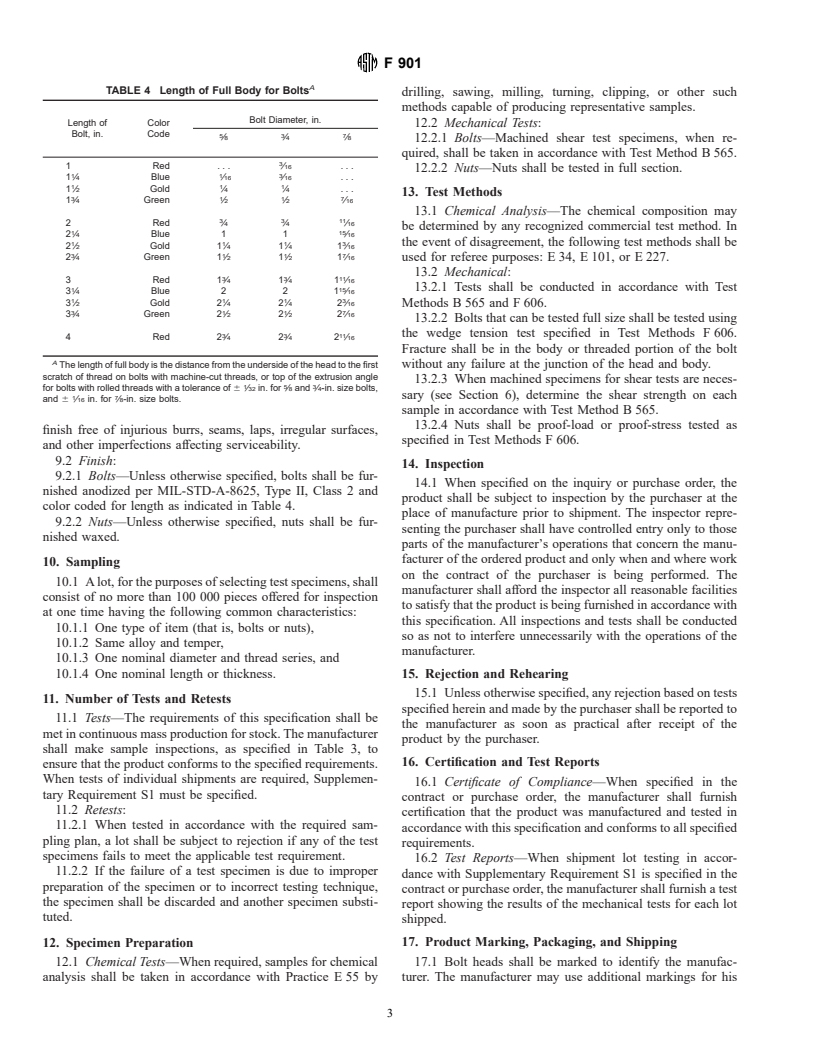

F 901

TABLE 1 Tensile Strength of 2024-T4 Bolts and Proof Loads for TABLE 3 Sample Size and Acceptance for Mechanical Property

A

6061-T6 and 6262-T9 Nuts Tests

Bolt Size, in. Tensile Strength, min, lbf (kN) Acceptance Criteria

5 Number of Pieces in Lot

⁄8 12 400 (55)

Number of Acceptance Rejection

3

⁄4 18 400 (82)

Tests Number Number

7

⁄8 25 400 (113)

50 and under 2 0 1

A

Based on a ten

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.