ASTM E877-08

(Practice)Standard Practice for Sampling and Sample Preparation of Iron Ores and Related Materials for Determination of Chemical Composition

Standard Practice for Sampling and Sample Preparation of Iron Ores and Related Materials for Determination of Chemical Composition

SIGNIFICANCE AND USE

This practice is to be used for sampling and sample preparation of iron ores and related materials, prior to use of a referee method for testing for compliance with compositional specifications for metal content or physical properties. It is assumed that all who use this procedure will be trained analysts capable of performing common laboratory practices skillfully and safely. It is expected that work will be performed in a properly equipped laboratory and that proper waste disposal procedures will be followed. Appropriate quality control practices must be followed, such as those described in Guide E 882.

Adequate methods for obtaining representative samples for testing the chemical and physical properties of a consignment of iron ore are essential. The sale and use are dependent on the chemical or physical properties, or both, of an ore.

The criteria to prevent bias may be used for both design of a sampling system and in checking the design of an existing system.

SCOPE

1.1 This practice covers procedures for mechanical sampling of iron ores and related materials in a falling stream or stopped-belt sampling and preparing the gross sample to the various test samples required for each characteristic to be measured. Included as Annexes are (1) design criteria to prevent bias, (2) statistical methods to determine quality variation and precisions of sampling and division, and (3) a method for comparing two sampling procedures for possible systematic differences.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 8.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E877 − 08

StandardPractice for

Sampling and Sample Preparation of Iron Ores and Related

1

Materials for Determination of Chemical Composition

This standard is issued under the fixed designation E877; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

3

1. Scope Iron Ores (Withdrawn 1995)

1.1 This practice covers procedures for mechanical sam-

3. Terminology

pling of iron ores and related materials in a falling stream or

3.1 Definitions—For definitions of terms used in this test

stopped-belt sampling and preparing the gross sample to the

method, refer to Terminology E135.

various test samples required for each characteristic to be

3.1.1 nominal size—in sampling, the opening of the screen

measured. Included as Annexes are (1) design criteria to

of the standard series that would pass 95 % of a representative

prevent bias, (2) statistical methods to determine quality

sample.

variation and precisions of sampling and division, and (3)a

3.1.2 precision—a measure of reproducibility of test results,

method for comparing two sampling procedures for possible

using the same equipment and method, statistically derived

systematic differences.

from multiple data expressed at 95 % confidence level.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Summary of Practice

responsibility of the user of this standard to establish appro-

4.1 The precision required for the sampling and sample

priate safety and health practices and determine the applica-

preparation steps is calculated based on the objectives of the

bility of regulatory limitations prior to use. Specific precau-

testing, resulting in a sampling plan specifying the minimum

tionary statements are given in Section 8.

weights and number of increments required for each step in the

procedure. Samples are then collected, dried, blended, divided,

2. Referenced Documents

crushed, pulverized, and ground as required by the test

2

2.1 ASTM Standards:

methods to be utilized.

E135 Terminology Relating to Analytical Chemistry for

Metals, Ores, and Related Materials

5. Significance and Use

E276 TestMethodforParticleSizeorScreenAnalysisatNo.

5.1 This practice is to be used for sampling and sample

4 (4.75-mm) Sieve and Finer for Metal-Bearing Ores and

preparation of iron ores and related materials, prior to use of a

Related Materials

referee method for testing for compliance with compositional

E279 Test Method for Determination ofAbrasion Resistance

specifications for metal content or physical properties. It is

of Iron Ore Pellets and Sinter by the Tumbler Test

assumedthatallwhousethisprocedurewillbetrainedanalysts

E389 TestMethodforParticleSizeorScreenAnalysisatNo.

capable of performing common laboratory practices skillfully

4 (4.75-mm) Sieve and Coarser for Metal-Bearing Ores

and safely. It is expected that work will be performed in a

and Related Materials

properly equipped laboratory and that proper waste disposal

E882 Guide for Accountability and Quality Control in the

procedures will be followed. Appropriate quality control prac-

Chemical Analysis Laboratory

tices must be followed, such as those described in Guide E882.

E1072 Test Method for Low Temperature Breakdown of

5.2 Adequate methods for obtaining representative samples

for testing the chemical and physical properties of a consign-

ment of iron ore are essential. The sale and use are dependent

1

This practice is under the jurisdiction of ASTM Committee E01 on Analytical

on the chemical or physical properties, or both, of an ore.

Chemistry for Metals, Ores, and Related Materials and is the direct responsibility of

Subcommittee E01.02 on Ores, Concentrates, and Related Metallurgical Materials.

5.3 The criteria to prevent bias may be used for both design

Current edition approved Nov. 1, 2008. Published December 2008. Originally

of a sampling system and in checking the design of an existing

approved in 1982. Last previous edition approved in 2003 as E877 – 03. DOI:

10.1520/E0877-08.

system.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E877 − 08

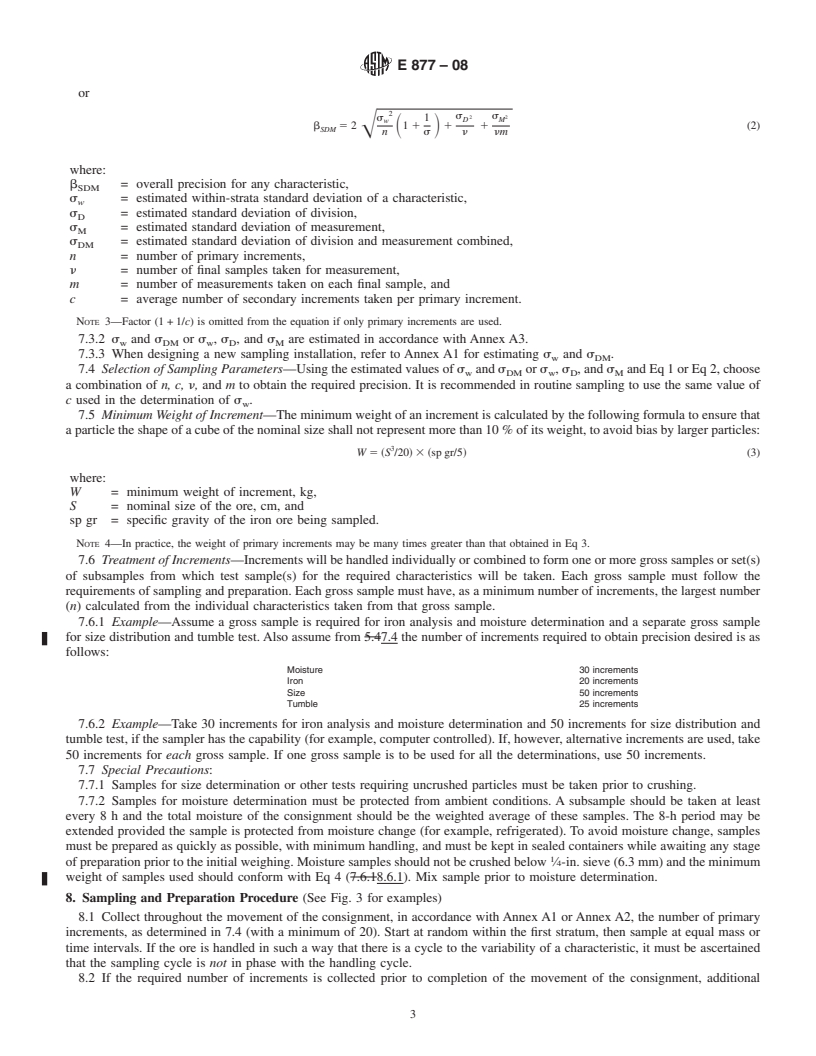

6. Apparatus 7.2.2 Overall precisions for oth

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E877–03 Designation: E 877 – 08

Standard Practice for

Sampling and Sample Preparation of Iron Ores and Related

MaterialsSampling and Sample Preparation of Iron Ores and

Related Materials for Determination of Chemical

1

Composition

This standard is issued under the fixed designation E 877; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 Thispracticecoversproceduresformechanicalsamplingofironoresandrelatedmaterialsinafallingstreamorstopped-belt

sampling and preparing the gross sample to the various test samples required for each characteristic to be measured. Included as

Annexes are (1) design criteria to prevent bias, (2) statistical methods to determine quality variation and precisions of sampling

and division, and (3) a method for comparing two sampling procedures for possible systematic differences.

1.2 This standard does not purport to address all of the safety problems,concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of

regulatory limitations prior to use. Specific precautionary statements are given in Section 8.

2. Referenced Documents

2

2.1 ASTM Standards:E135Terminology Relating to Analytical Chemistry for Metals, Ores and Related Materials

E276Test Method for Particle Size or ScreenAnalysis at No. 4 (4.75-mm) Sieve and Finer for Metal-Bearing Ores and Related

2

Materials 135 Terminology Relating to Analytical Chemistry for Metals, Ores, and Related Materials

2

E279Test Method for Determination of Abrasion Resistance of Iron Ore Pellets and Sinter (Tumbler Test) 276 Test Method

for Particle Size or Screen Analysis at No. 4 (4.75-mm) Sieve and Finer for Metal-Bearing Ores and Related Materials

E389TestMethodforParticleSizeorScreenAnalysisatNo.4(4.75-mm)SieveandCoarserforMetalBearingOresandRelated

Materials 279 Test Method for Determination of Abrasion Resistance of Iron Ore Pellets and Sinter by the Tumbler Test

3

E882Guide forAccountability and Quality Control in the ChemicalAnalysis Laboratory 389 Test Method for Particle Size or

Screen Analysis at No. 4 (4.75-mm) Sieve and Coarser for Metal-Bearing Ores and Related Materials

E 882 Guide for Accountability and Quality Control in the Chemical Analysis Laboratory

3

E 1072 Test Method for Low Temperature Breakdown of Iron Ores

3. Terminology

3.1 Definitions—For definitions of terms used in this test method, refer to Terminology E 135.

3.1.1 nominal size—in sampling, the opening of the screen of the standard series that would pass 95 % of a representative

sample.

3.1.2 precision—a measure of reproducibility of test results, using the same equipment and method, statistically derived from

multiple data expressed at 95 % confidence level.

4. Summary of Practice

4.1 The precision required for the sampling and sample preparation steps areis calculated based on the objectives of the testing,

resulting in a sampling plan specifying the minimum weights and number of increments required for each step in the procedure.

Samples are then collected, dried, blended, divided, crushed, pulverized, and ground as required by the test methods to be utilized.

1

This practice is under the jurisdiction of ASTM Committee E01 on Analytical Chemistry for Metals, Ores, and Related Materials and is the direct responsibility of

Subcommittee E01.02 on Ores, Concentrates, and Related Metallurgical Materials.

Current edition approved June 10, 2003. Published September 2003. Originally approved in 1982. Last previous edition approved in 1998 as E877–93 (1998).

Current edition approved Nov. 1, 2008. Published December 2008. Originally approved in 1982. Last previous edition approved in 2003 as E 877 – 03.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 03.05.volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Withdrawn. The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E877–08

5. Significance and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.