ASTM A874/A874M-98(2018)e1

(Specification)Standard Specification for Ferritic Ductile Iron Castings Suitable for Low-Temperature Service

Standard Specification for Ferritic Ductile Iron Castings Suitable for Low-Temperature Service

ABSTRACT

This specification covers ductile iron castings suitable low temperature service. Castings shall be produced by casting or heat treatment and shall have essentially a ferritic structure that contains no massive carbides. The iron shall conform to the required chemical composition for carbon, silicon, phosphorus, magnesium, manganese, copper, nickel and chromium. The iron shall conform to the required tensile properties such as tensile strength, yield strength and elongation. Graphite contained in the microstructure shall be evaluated and the percentage of each graphite type shall be estimated. The surface of the casting shall be examined visually and shall be free from adhering sand, scale cracks, and hot tears.

SCOPE

1.1 This specification covers ductile iron castings suitable for service at temperatures of −40 °F [–40 °C] and above.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3 The following precautionary statement pertains only to the test methods portion, Section 11, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: A874/A874M −98 (Reapproved 2018)

Standard Specification for

Ferritic Ductile Iron Castings Suitable for Low-Temperature

Service

This standard is issued under the fixed designationA874/A874M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Paragraph 11.3 was corrected editorially in November 2018.

1. Scope Open-Hearth Iron, and Wrought Iron (Withdrawn 1995)

E59Practice for Sampling Steel and Iron for Determination

1.1 This specification covers ductile iron castings suitable

of Chemical Composition (Withdrawn 1996)

for service at temperatures of −40°F [–40°C] and above.

E94/E94MGuide for Radiographic Examination Using In-

1.2 The values stated in either SI units or inch-pound units

dustrial Radiographic Film

are to be regarded separately as standard. The values stated in

E165/E165MPractice for Liquid Penetrant Examination for

each system may not be exact equivalents; therefore, each

General Industry

system shall be used independently of the other. Combining

E351TestMethodsforChemicalAnalysisofCastIron—All

values from the two systems may result in nonconformance

Types

with the standard.

E562Test Method for Determining Volume Fraction by

1.3 The following precautionary statement pertains only to

Systematic Manual Point Count

the test methods portion, Section 11, of this specification: This E689Reference Radiographs for Ductile Iron Castings

standarddoesnotpurporttoaddressallofthesafetyconcerns,

E709Guide for Magnetic Particle Testing

ifany,associatedwithitsuse.Itistheresponsibilityoftheuser

3. Ordering Information

of this standard to establish appropriate safety, health, and

environmental practices and determine the applicability of 3.1 Ordersformaterialunderthisspecificationshallinclude

regulatory limitations prior to use. the following applicable information:

1.4 This international standard was developed in accor- 3.1.1 Drawing, catalog number, or part identification,

dance with internationally recognized principles on standard- 3.1.2 Quantity (weight or number of pieces),

ization established in the Decision on Principles for the

3.1.3 ASTM designation and year of issue,

Development of International Standards, Guides and Recom- 3.1.4 Marking instructions (see Section 15),

mendations issued by the World Trade Organization Technical

3.1.5 Place of inspection (see 13.1),

Barriers to Trade (TBT) Committee. 3.1.6 Limits on residual elements (see 5.2),

3.1.7 Visual and dimensional acceptance standard (see 7.1),

2. Referenced Documents

3.1.8 Sampling plan (see Section 9), and

3.1.9 Supplementary requirements.

2.1 ASTM Standards:

A247Test Method for Evaluating the Microstructure of

4. Materials and Manufacture

Graphite in Iron Castings

4.1 Castings may be supplied either as cast or heat treated

E8/E8MTest Methods for Tension Testing of Metallic Ma-

and shall have essentially a ferritic structure that contains no

terials

massive carbides.

E30TestMethodsforChemicalAnalysisofSteel,CastIron,

5. Chemical Composition

5.1 The iron shall conform to the requirements for chemical

This specification is under the jurisdiction of ASTM Committee A04 on Iron

Castings and is the direct responsibility of Subcommittee A04.02 on Malleable and composition shown in Table 1.

Ductile Iron Castings.

5.2 By agreement between the manufacturer and purchaser,

Current edition approved Nov. 1, 2018. Published November 2018. Originally

approved in 1989. Last previous edition approved in 2014 as A874/A874M–98 analysis may be required and limits established for elements

(2014). DOI: 10.1520/A0874_A0874M-98R18E01.

not specified in Table 1.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

A874/A874M − 98 (2018)

TABLE 1 Chemical Composition

10. Number of Tests and Retests

Element Minimum, % Maximum, %

10.1 The number of tension tests and the number of micro-

Total carbon 3.0 3.7

structural examinations shall be agreed upon between the

Carbon equivalent (carbon + ⁄3 silicon) . . . 4.5

manufacturer and purchaser.

Silicon 1.2 2.3

Phosphorous . . . 0.03

10.2 If any tension test specimen shows obvious defects, it

Magnesium . . . 0.07

Manganese . . . 0.25 may be discarded and another from the same coupon may be

Copper . . . 0.1

tested.

Nickel . . . 1.0

Chromium . . . 0.07

11. Test Methods

11.1 Conduct the tension test in accordance with Test

Methods E8/E8M.

6. Mechanical and Microstructural Properties

11.2 Determinetheyieldstrengthusingoneofthefollowing

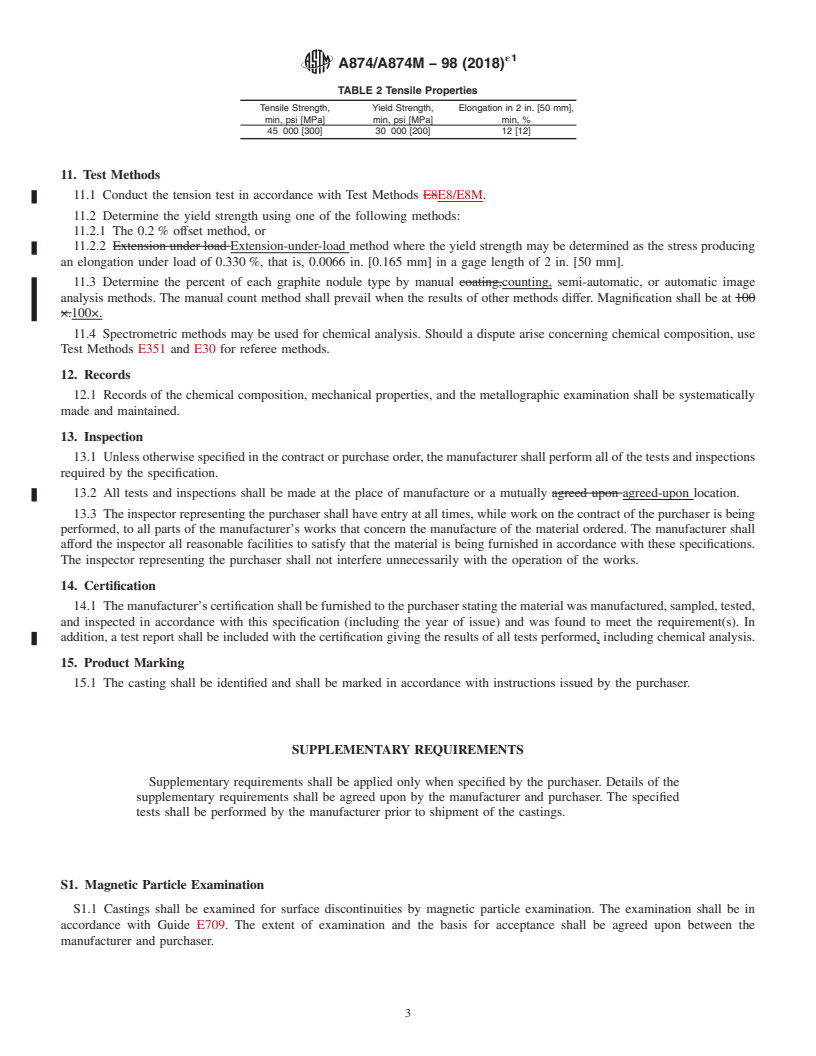

6.1 Tensile Properties—The iron shall conform to the re- methods:

quirements for tensile properties shown in Table 2. 11.2.1 The 0.2% offset method, or

11.2.2 Extension-under-load method where the yield

6.2 Microstructure—Graphite contained in the microstruc-

strength may be determined as the stress producing an elonga-

ture shall be evaluated in accordance with Test Method A247.

tion under load of 0.330%, that is, 0.0066 in. [0.165 mm] in a

The percent of each graphite type shall be estimated, and the

gage length of 2 in. [50 mm].

total of all estimates shall equal 100%. The total percent of

Types 1 and 2 graphite shall be a minimum of 90%. 11.3 Determine the percent of each graphite nodule type by

manual counting, semi-automatic, or automatic image analysis

7. Workmanship, Finish, and Appearance

methods. The manual count method shall prevail when the

results of other methods differ. Magnification shall be at 100×.

7.1 The surface of the casting shall be examined visually

and shall be free from adhering sand, scale, cracks, and hot

11.4 Spectrometric methods may be used for chemical

tears. Other surface discontinuities shall meet visual and

analysis. Should a dispute arise concerning chemical

dimensional acceptance standards specified in the order.

composition, use Test Methods E351 and E30 for referee

methods.

7.2 Conditioning of castings is permitted to the extent that

the removal of me

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: A874/A874M − 98 (Reapproved 2014) A874/A874M − 98 (Reapproved 2018)

Standard Specification for

Ferritic Ductile Iron Castings Suitable for Low-Temperature

Service

This standard is issued under the fixed designation A874/A874M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Paragraph 11.3 was corrected editorially in November 2018.

1. Scope

1.1 This specification covers ductile iron castings suitable for service at temperatures of −40°F [–40°C]−40 °F [–40 °C] and

above.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformancenonconformance with the standard.

1.3 The following precautionary statement pertains only to the test methods portion, Section 11, of this specification: This

standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the applicability

of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

A247 Test Method for Evaluating the Microstructure of Graphite in Iron Castings

E8E8/E8M Test Methods for Tension Testing of Metallic Materials [Metric] E0008_E0008M

E30 Test Methods for Chemical Analysis of Steel, Cast Iron, Open-Hearth Iron, and Wrought Iron (Withdrawn 1995)

E59 Practice for Sampling Steel and Iron for Determination of Chemical Composition (Withdrawn 1996)

E94E94/E94M Guide for Radiographic Examination Using Industrial Radiographic Film

E165E165/E165M Practice for Liquid Penetrant Examination for General Industry

E351 Test Methods for Chemical Analysis of Cast Iron—All Types

E562 Test Method for Determining Volume Fraction by Systematic Manual Point Count

E689 Reference Radiographs for Ductile Iron Castings

E709 Guide for Magnetic Particle Testing

3. Ordering Information

3.1 Orders for material under this specification shall include the following applicable information:

3.1.1 Drawing, catalog number, or part identification,

3.1.2 Quantity (weight or number of pieces),

3.1.3 ASTM designation and year of issue,

3.1.4 Marking instructions (see Section 15),

3.1.5 Place of inspection (see 13.1),

This specification is under the jurisdiction of ASTM Committee A04 on Iron Castings and is the direct responsibility of Subcommittee A04.02 on Malleable and Ductile

Iron Castings.

Current edition approved April 1, 2014Nov. 1, 2018. Published April 2014November 2018. Originally approved in 1989. Last previous edition approved in 20092014 as

A874/A874M - 98A874/A874M – 98 (2014). (2009). DOI: 10.1520/A0874_A0874M-98R14.10.1520/A0874_A0874M-98R18E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

A874/A874M − 98 (2018)

3.1.6 Limits on residual elements (see 5.2),

3.1.7 Visual and dimensional acceptance standard (see 7.1),

3.1.8 Sampling plan (see Section 9), and

3.1.9 Supplementary requirements.

4. Materials and Manufacture

4.1 Castings may be supplied either as cast or heat treated and shall have essentially a ferritic structure that contains no massive

carbides.

5. Chemical Composition

5.1 The iron shall conform to the requirements for chemical composition shown in Table 1.

5.2 By agreement between the manufacturer and purchaser, analysis may be required and limits established for elements not

specified in Table 1.

6. Mechanical and Microstructural Properties

6.1 Tensile Properties—The iron shall conform to the requirements for tensile properties shown in Table 2.

6.2 Microstructure—Graphite contained in the microstructure shall be evaluated in accordance with Test Method A247. The

percent of each graphite type shall be estimated, and the total of all estimates shall equal 100 %. The total percent of Types 1 and

2 graphite shall be a minimum of 90 %.

7. Workmanship, Finish, and Appearance

7.1 The surface of the casting shall be examined visually and shall be free from adhering sand, scale, cracks, and hot tears. Other

surface discontinuities shall meet visual and dimensional acceptance standards specified in the order.

7.2 Conditioning of castings is permitted to the extent that the removal of metal does not extend into the envelope of the finished

container and does not alter the properties of the metal remaining in the finished container.

8. Repair

8.1 Castings shall not be repaired by plugging, welding, brazing, impregnation, or any other means.

9. Sampling

9.1 Test coupons will be obtained from the casting. The location in the casting from which the test coupons are obtained and

the number obtained from each location shall be agreed upon between the manufacturer and purchaser.

9.2 Metallographic samples shall be obtained from the same location as the mechanical test coupons.

9.3 Nondestructive examination methods for estimating microstructure may be used to supplement the destructive examination

sampling plan.

9.4 Sampling for chemical analysis shall be in accordance with Practice E59.

9.4.1 The chemical analysis for total carbon shall be made on either chilled cast pencil-type specimens or thin wafers

approximately ⁄32 in. [0.8 mm] thick cut from test coupons.

10. Number of Tests and Retests

10.1 The number of tension tests and the number of microstructural examinations shall be agreed upon between the

manufacturer and purchaser.

10.2 If any tension test specimen shows obvious defects, it m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.