ASTM D69-12

(Test Method)Standard Test Methods for Friction Tapes

Standard Test Methods for Friction Tapes

SIGNIFICANCE AND USE

In most applications, a friction tape must have adequate adhesion to remain in place and function properly.

SCOPE

1.1 These test methods cover the methods and procedures for testing friction tapes. Such tapes consist of a woven fabric sheeting that has been impregnated with an adhesive insulating compound and cut into rolls of narrow width. These tapes are commonly used for protecting and binding in place, insulation applied to joints of electrical wires and cables, and for other mechanical purposes.

Note 1—The material specifications formerly included in these test methods are now contained in Specification D4514.

1.2 The test methods included in this standard are as follows:

Sections Adhesion 6-11 Aged Adhesion 12-17 Breaking Strength 18-23 Dielectric Breakdown Voltage 24-29 Dimensions 30-35 Discoloration of Copper 36-40 Parallelism 41-45

1.3 The values stated in inch-pound units are the standard. The SI units in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 2—There is no equivalent IEC standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D69 − 12

Standard Test Methods for

1

Friction Tapes

This standard is issued under the fixed designation D69; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* at Commercial Power Frequencies

D412 Test Methods for Vulcanized Rubber and Thermoplas-

1.1 These test methods cover the methods and procedures

tic Elastomers—Tension

for testing friction tapes. Such tapes consist of a woven fabric

D1711 Terminology Relating to Electrical Insulation

sheeting that has been impregnated with an adhesive insulating

D4514 Specification for Friction Tape

compound and cut into rolls of narrow width. These tapes are

D5423 Specification for Forced-Convection Laboratory Ov-

commonly used for protecting and binding in place, insulation

ens for Evaluation of Electrical Insulation

applied to joints of electrical wires and cables, and for other

D6054 Practice for Conditioning Electrical Insulating Mate-

mechanical purposes.

3

rials for Testing (Withdrawn 2012)

NOTE 1—The material specifications formerly included in these test

methods are now contained in Specification D4514.

3. Terminology

1.2 The test methods included in this standard are as

3.1 Definitions:

follows:

3.1.1 For definitions of other terms used in this

Sections

specification, refer to Terminology D1711.

Adhesion 6–11

3.2 Definitions of Terms Specific to This Standard:

Aged Adhesion 12–17

3.2.1 adhesion, n—theresistanceofthetapetounwinditself

Breaking Strength 18–23

Dielectric Breakdown Voltage 24–29

after being wound up under pressure, in accordance with this

Dimensions 30–35

test method.

Discoloration of Copper 36–40

Parallelism 41–45

3.2.2 breaking strength, n—the force required, per unit

1.3 The values stated in inch-pound units are the standard. width, to break the tape when tested in accordance with this

test method.

The SI units in parentheses are for information only.

1.4 This standard does not purport to address all of the 3.2.3 conditioning, n—the exposure of the tape to the

influence of a prescribed atmosphere for a stipulated period of

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- time.

priate safety and health practices and determine the applica-

3.2.4 length of tape in a roll, n—the number of linear yards

bility of regulatory limitations prior to use.

or metres of tape wound into a roll as measured in accordance

with this test method.

NOTE 2—There is no equivalent IEC standard.

3.2.5 parallelism, n—the difference in width between two

2. Referenced Documents

mated ends of a tape that has been split in half, in accordance

2

with this test method.

2.1 ASTM Standards:

D149 Test Method for Dielectric Breakdown Voltage and

3.2.6 tackiness, n—the adherence of the friction tape sur-

Dielectric Strength of Solid Electrical Insulating Materials

faces to themselves after light contact has been made, in

accordance with this test method.

1

These test methods are under the jurisdiction of ASTM Committee D09 on

4. Sampling

Electrical and Electronic Insulating Materials and are the direct responsibility of

Subcommittee D09.07 on Flexible and Rigid Insulating Materials.

4.1 The producer and consumer shall agree upon the num-

Current edition approved April 1, 2012. Published April 2012. Originally

ber of rolls selected. Unless otherwise specified a minimum of

approved in 1920. Last previous edition approved in 2006 as D69 – 06. DOI:

three rolls per lot shall be tested.

10.1520/D0069-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D69−12

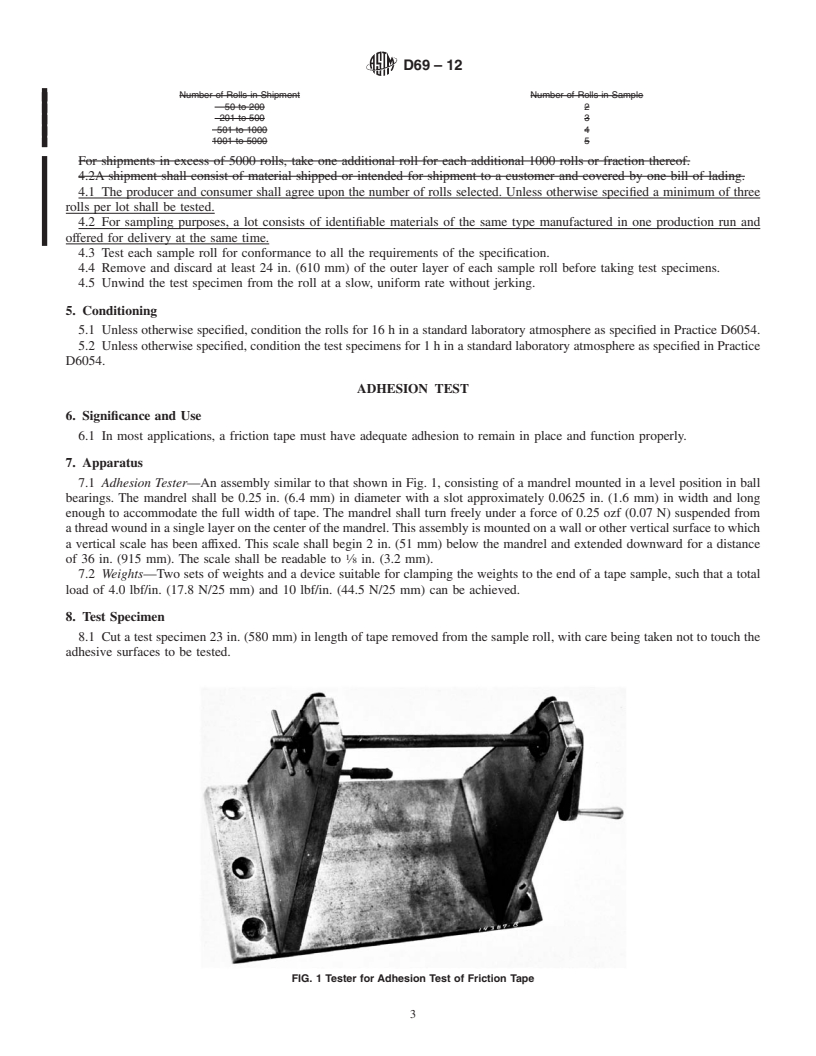

4.2 For sampling purposes, a lot consists of identifiable extended downward for a distance of 36 in. (915 mm). The

1

materials of the same type manufactured in one production run scale shall be readable to ⁄8 in. (3.2 mm).

and offered for delivery at the same time.

7.2 Weights—Two sets of weights and a device suitable for

4.3 Test each sample roll for conformance to all the require- clamping the weights to the end of a tape sample, such that a

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:D69–06 Designation: D69 – 12

Standard Test Methods for

1

Friction Tapes

This standard is issued under the fixed designation D69; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 These test methods cover the methods and procedures for testing friction tapes. Such tapes consist of a woven fabric

sheeting that has been impregnated with an adhesive insulating compound and cut into rolls of narrow width. These tapes are

commonly used for protecting and binding in place, insulation applied to joints of electrical wires and cables, and for other

mechanical purposes.

NOTE 1—The material specifications formerly included in these test methods are now contained in Specification D4514.

1.2 The test methods included in this standard are as follows:

Sections

Adhesion 6-11

Aged Adhesion 12-17

Breaking Strength 18-23

Dielectric Breakdown Voltage 24-29

Dimensions 30-35

Discoloration of Copper 36-40

Parallelism 41-45 Tackiness

1.3 The values stated in inch-pound units are the standard. The SI units in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

NOTE 2—There is no equivalent IEC standard.

2. Referenced Documents

2

2.1 ASTM Standards:

D149 Test Method for Dielectric Breakdown Voltage and Dielectric Strength of Solid Electrical Insulating Materials at

Commercial Power Frequencies

D412 Test Methods for Vulcanized Rubber and Thermoplastic ElastomersTension

D1711 Terminology Relating to Electrical Insulation

D4514 Specification for Friction Tape

D5423 Specification for Forced-Convection Laboratory Ovens for Evaluation of Electrical Insulation

D6054 Practice for Conditioning Electrical Insulating Materials for Testing

3. Terminology

3.1 Definitions:

3.1.1 For definitions of other terms used in this specification, refer to Terminology D1711.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 adhesion, n—the resistance of the tape to unwind itself after being wound up under pressure, in accordance with this test

method.

3.2.2 breaking strength, n—the force required, per unit width, to break the tape when tested in accordance with this test method.

1

ThesetestmethodsareunderthejurisdictionofASTMCommitteeD09onElectricalandElectronicInsulatingMaterialsandarethedirectresponsibilityofSubcommittee

D09.07 on Flexible and Rigid Insulating Materials.

Current edition approved Oct.April 1, 2006.2012. Published October 2006.April 2012. Originally approved in 1920. Last previous edition approved in 20012006 as

D69–01.D69 – 06. DOI: 10.1520/D0069-06.10.1520/D0069-12.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D69–12

3.2.3 conditioning, n—the exposure of the tape to the influence of a prescribed atmosphere for a stipulated period of time.

3.2.4 length of tape in a roll, n—the number of linear yards or metres of tape wound into a roll as measured in accordance with

this test method.

3.2.5 parallelism, n—the difference in width between two mated ends of a tape that has been split in half, in accordance with

this test method.

3.2.6 tackiness, n—the adherence of the friction tape surfaces to themselves after light contact has been made, in accordance

with this test method.

4. Sampling

4.1Select sample rolls at random from each shipment in accordance with the following table:

2

---------------------- Page: 2 ----------------------

D69–12

Number of Rolls in Shipment Number of Rolls in Sample

50 to 200 2

201 to 500 3

501 to 1000 4

1001 to 5000 5

For shipments in excess of 5000 rolls, take one additional roll for each additional 100

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.